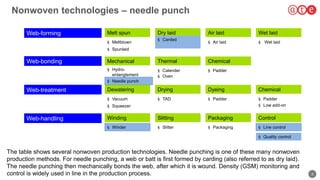

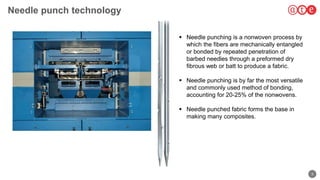

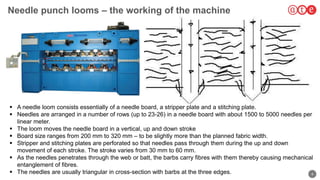

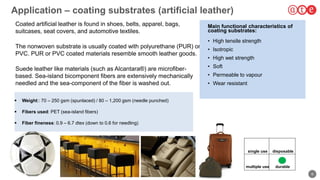

The document provides an overview of needle punch nonwoven technologies, detailing the production process, applications, and characteristics of needle punched fabrics. Needle punching is a versatile method that accounts for 20-25% of nonwovens and serves various markets including automotive, filtration, and personal care wipes. Key characteristics of needle punched products include high tensile strength, durability, and resistance to wear, making them suitable for a wide range of applications.