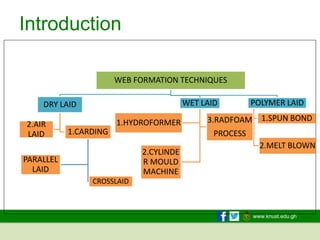

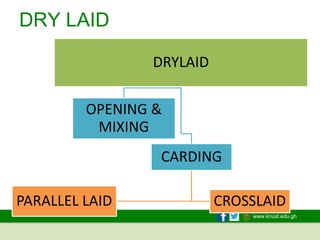

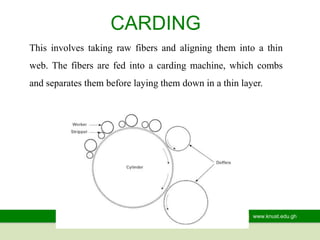

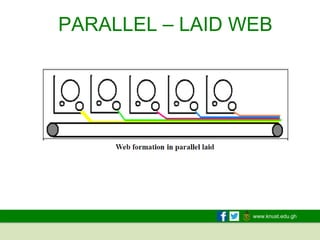

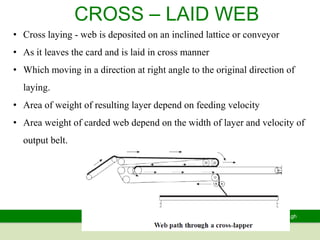

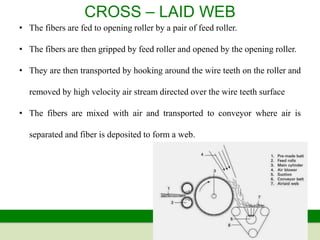

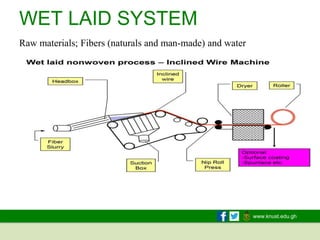

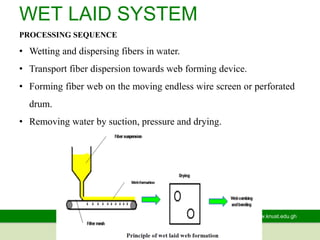

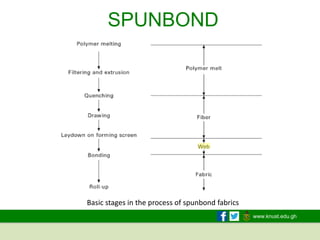

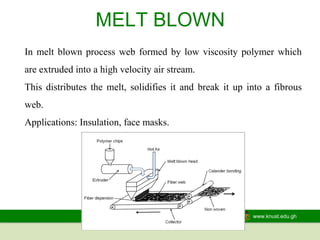

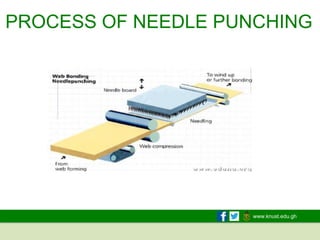

The document discusses various techniques for nonwoven web preparation, including dry laid (carding, parallel laid, crosslaid), wet laid, and polymer laid (spunbond, melt blown) methods. It provides details on the key steps for each method, such as opening, cleaning and mixing fibers for dry laid processes and dispersing fibers in water and forming the web for wet laid. Needle punching is also summarized as a process to mechanically interlock fibers through repeated penetration with barbed needles.