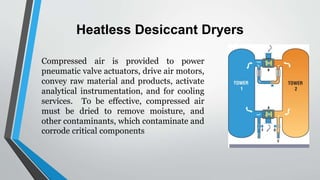

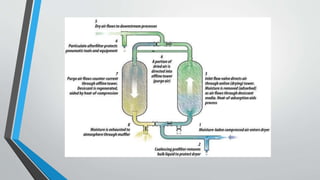

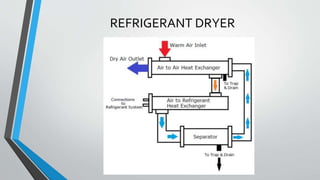

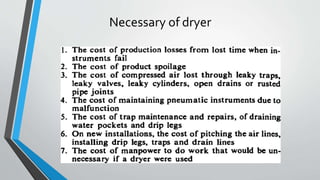

Industrial dryers are used to efficiently reduce the moisture levels of bulk materials as part of manufacturing processes. Drying is commonly the last stage and is done through heating or desiccant methods to improve properties or allow for easier transportation and handling. There are different dryer types for various materials and quantities, including heatless desiccant dryers which use regenerating towers to continuously supply dry air, and refrigerant dryers which use cooling to condense moisture for removal. Selection of dryers depends on factors like flow capacity and drying needs.