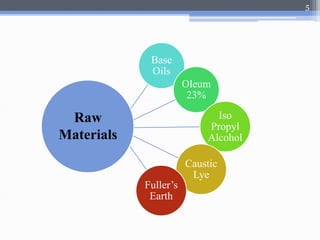

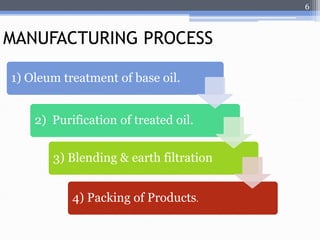

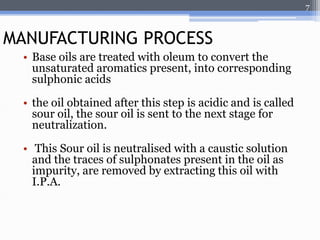

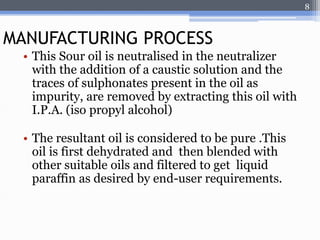

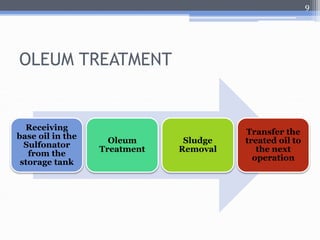

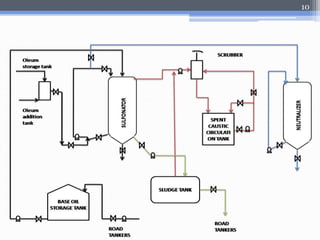

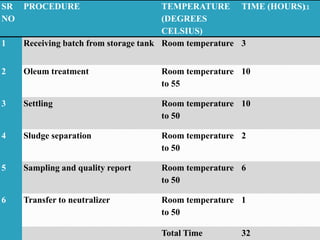

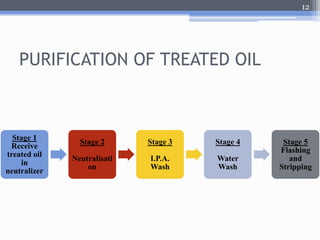

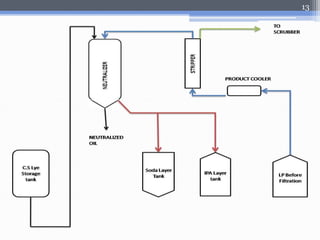

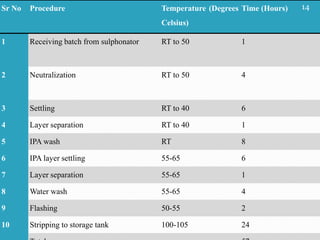

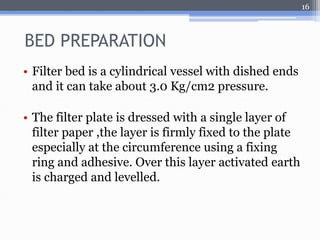

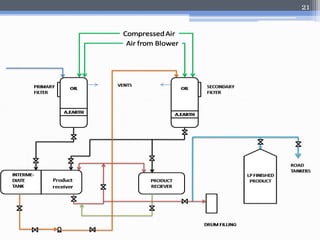

The document describes the process for manufacturing heavy liquid paraffins. It involves treating base oils with oleum to convert unsaturated compounds. The treated oil is then neutralized, purified through steps like IPA washing and water washing. It is blended and filtered through a bed of activated earth to remove any remaining impurities. Finally, it is blended to the required viscosity and packed in drums or tankers.