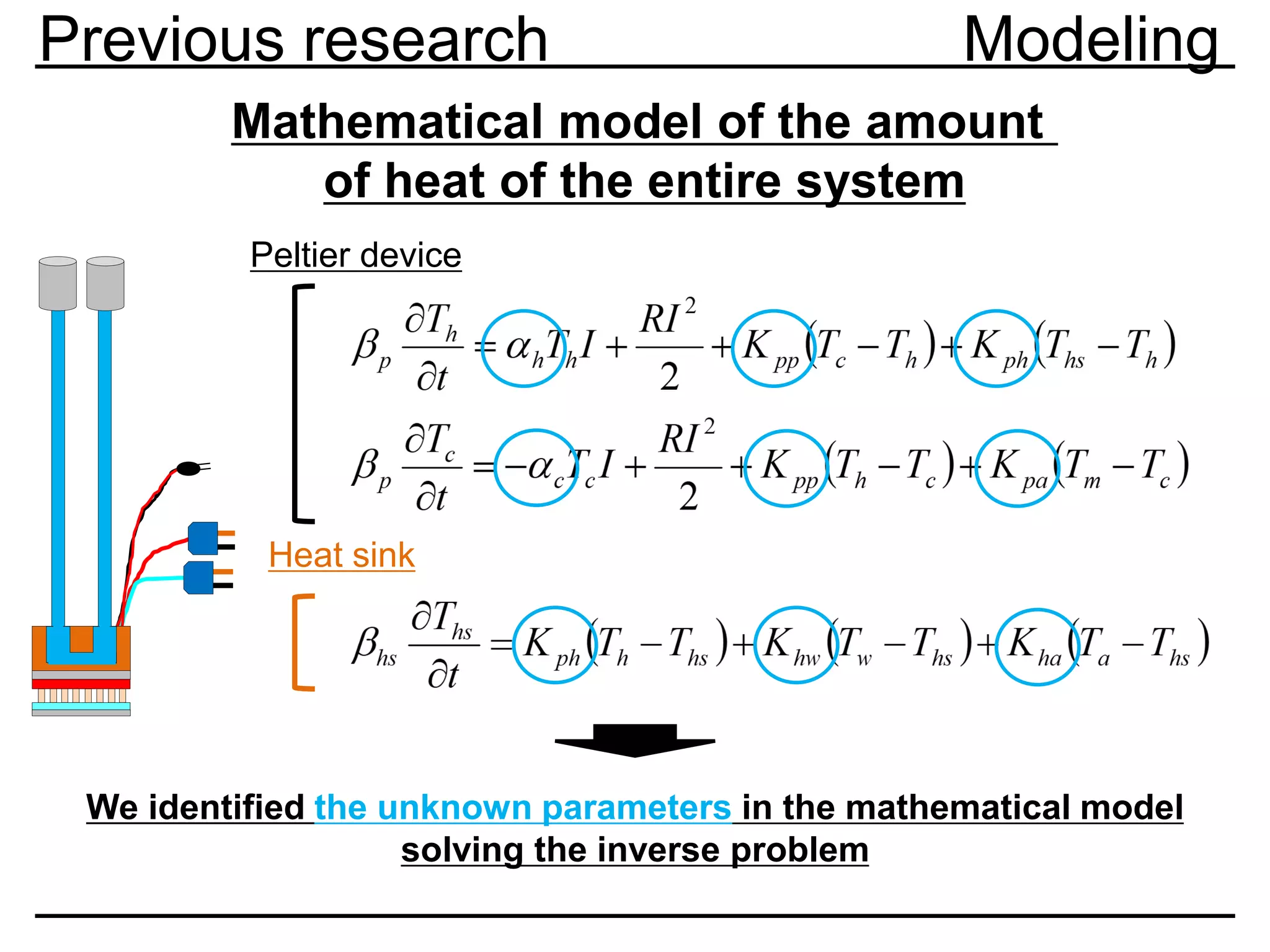

This study developed a mathematical model to simulate temperature control of a focal cooling device using a Peltier module on human skin. Experiments using a phantom validated the model, with errors within 1.16% compared to proportional control simulations. Adding integral control improved stability and reduced steady-state error to within 0.45-1.92% of experimental temperatures. Future work will refine model parameters and test new devices to enable precise temperature regulation for medical applications.

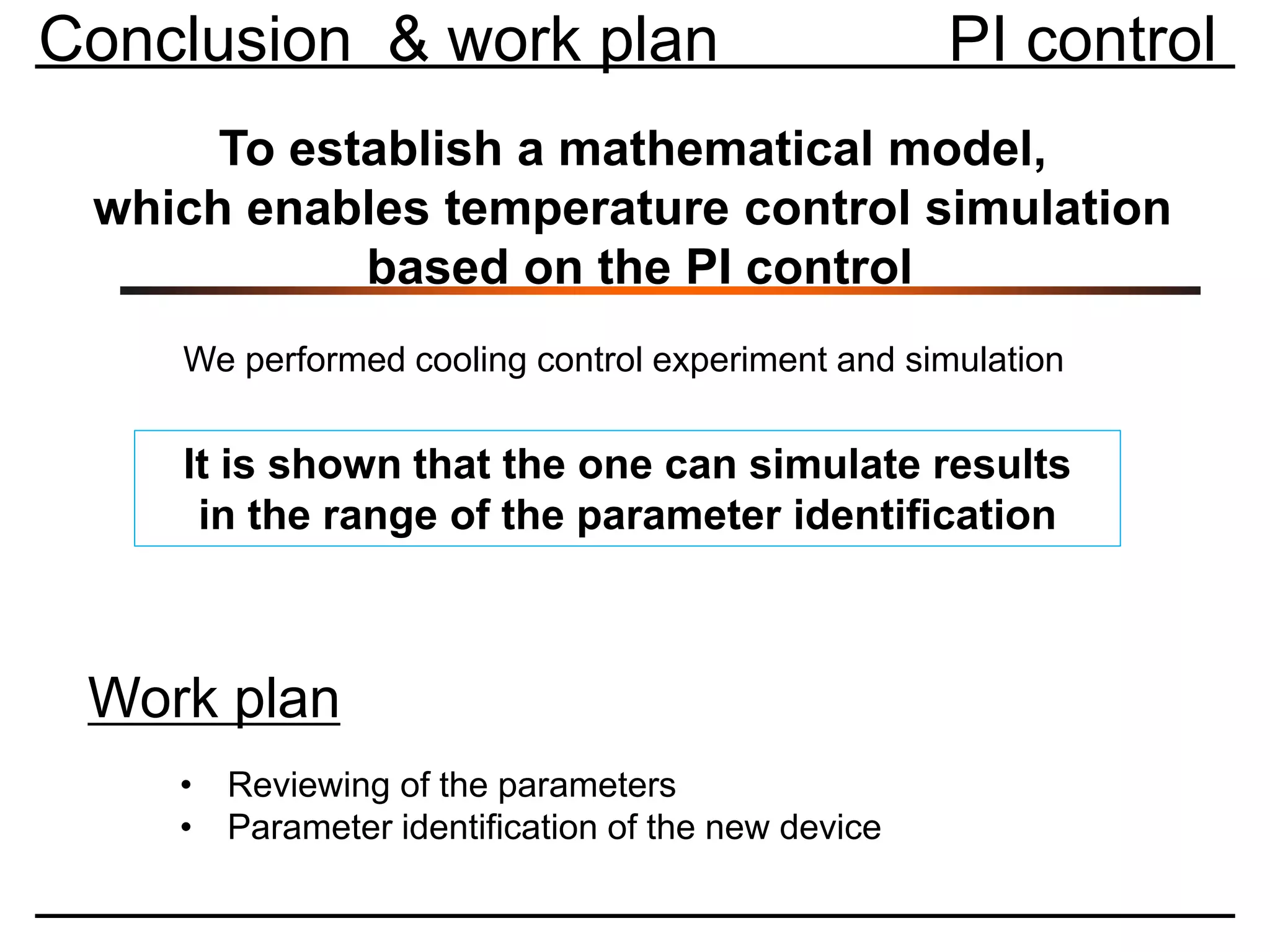

![In order to minimize the difference

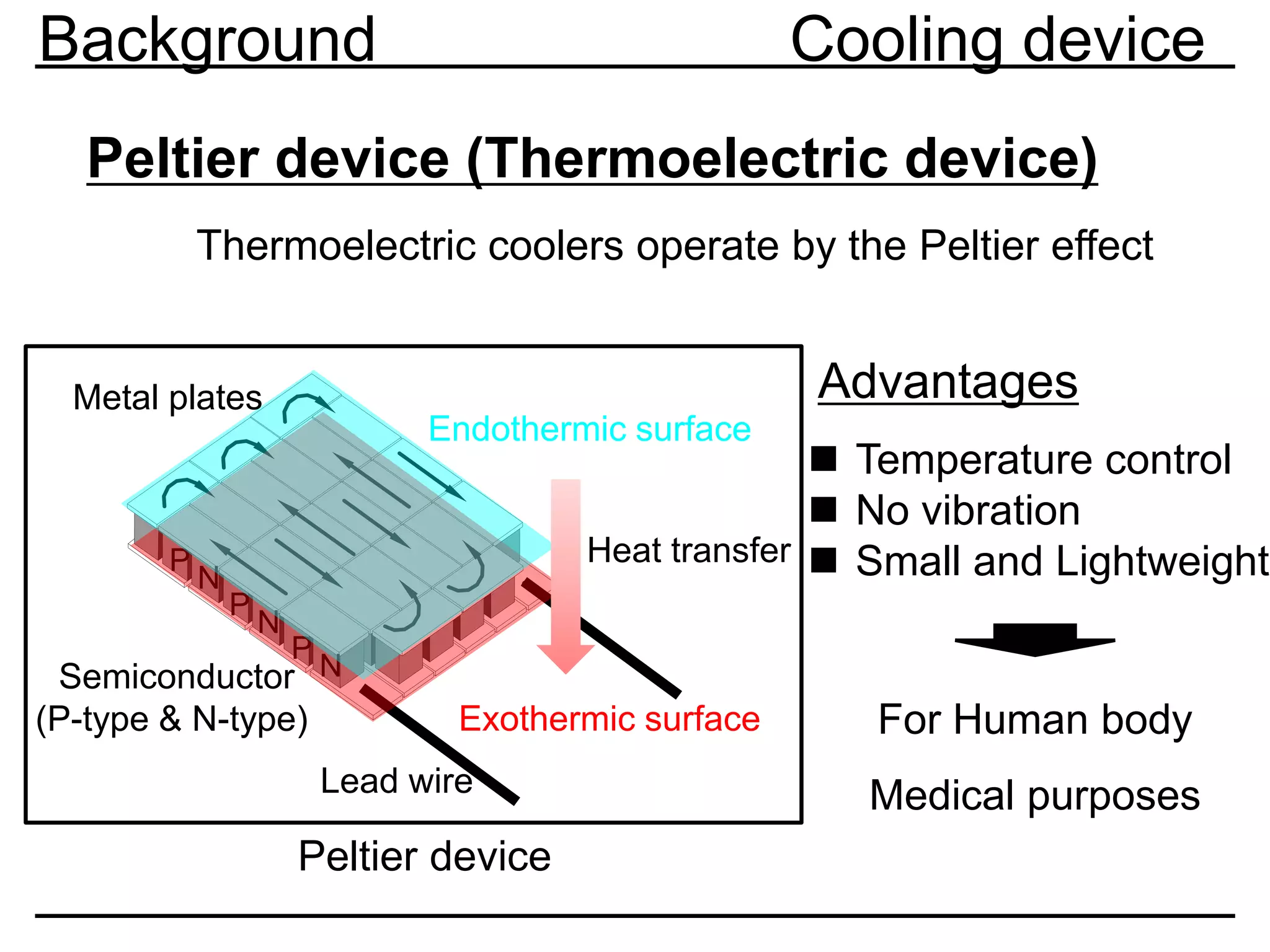

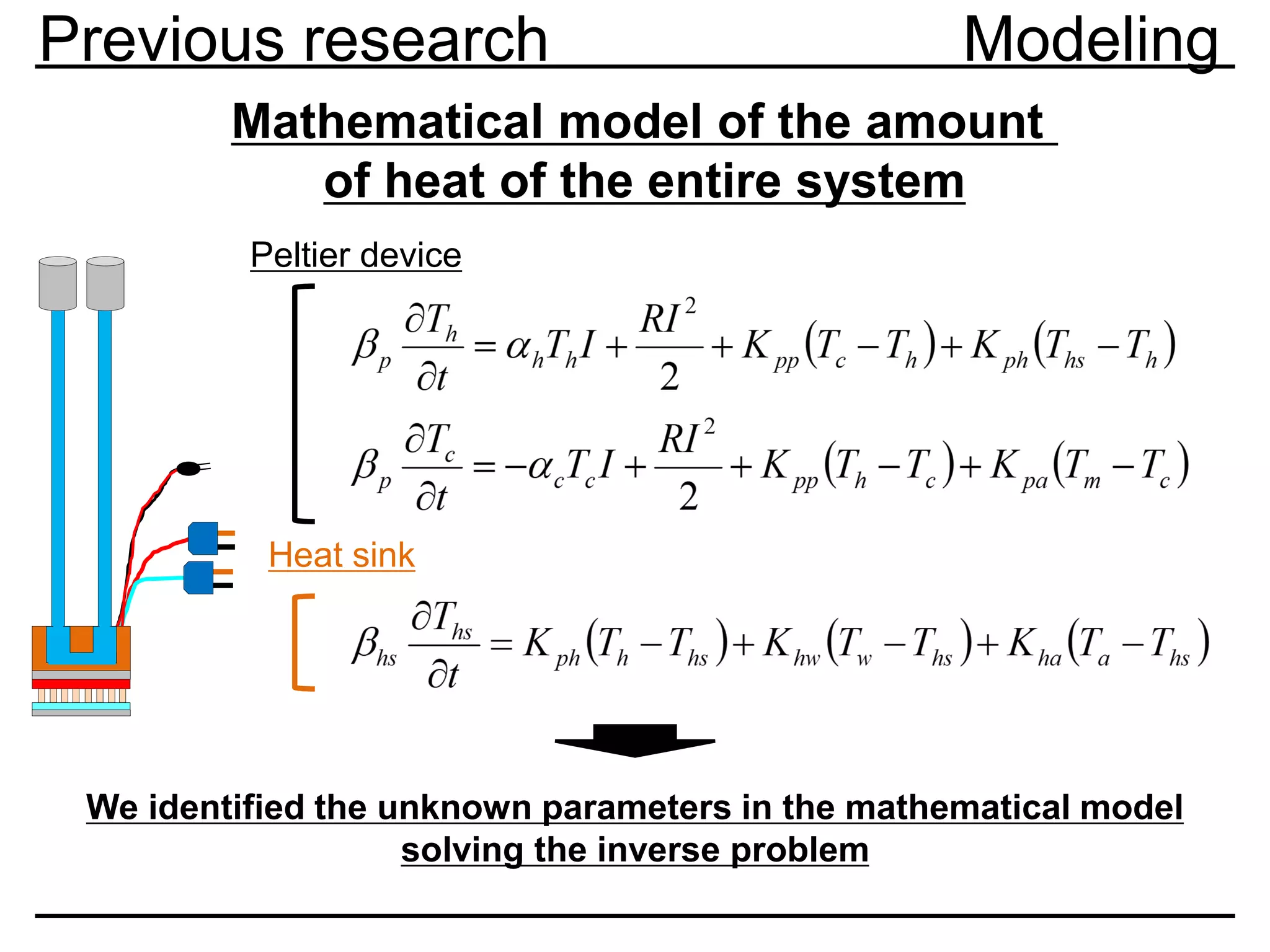

Previous research Modeling

0.0 0.2 0.4 0.6 0.8 1.0 1.2

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

MeanError[%/point]

Input voltage [V]

The relative difference per-point error of the

experimental and simulation value vs. input voltage

1.16 % / point

Average error

Error function

℃

s

Texp.

Tsim.](https://image.slidesharecdn.com/midtermreportm1-181103045002/75/Study-on-temperature-control-model-of-a-focal-cooling-human-physiological-system-10-2048.jpg)

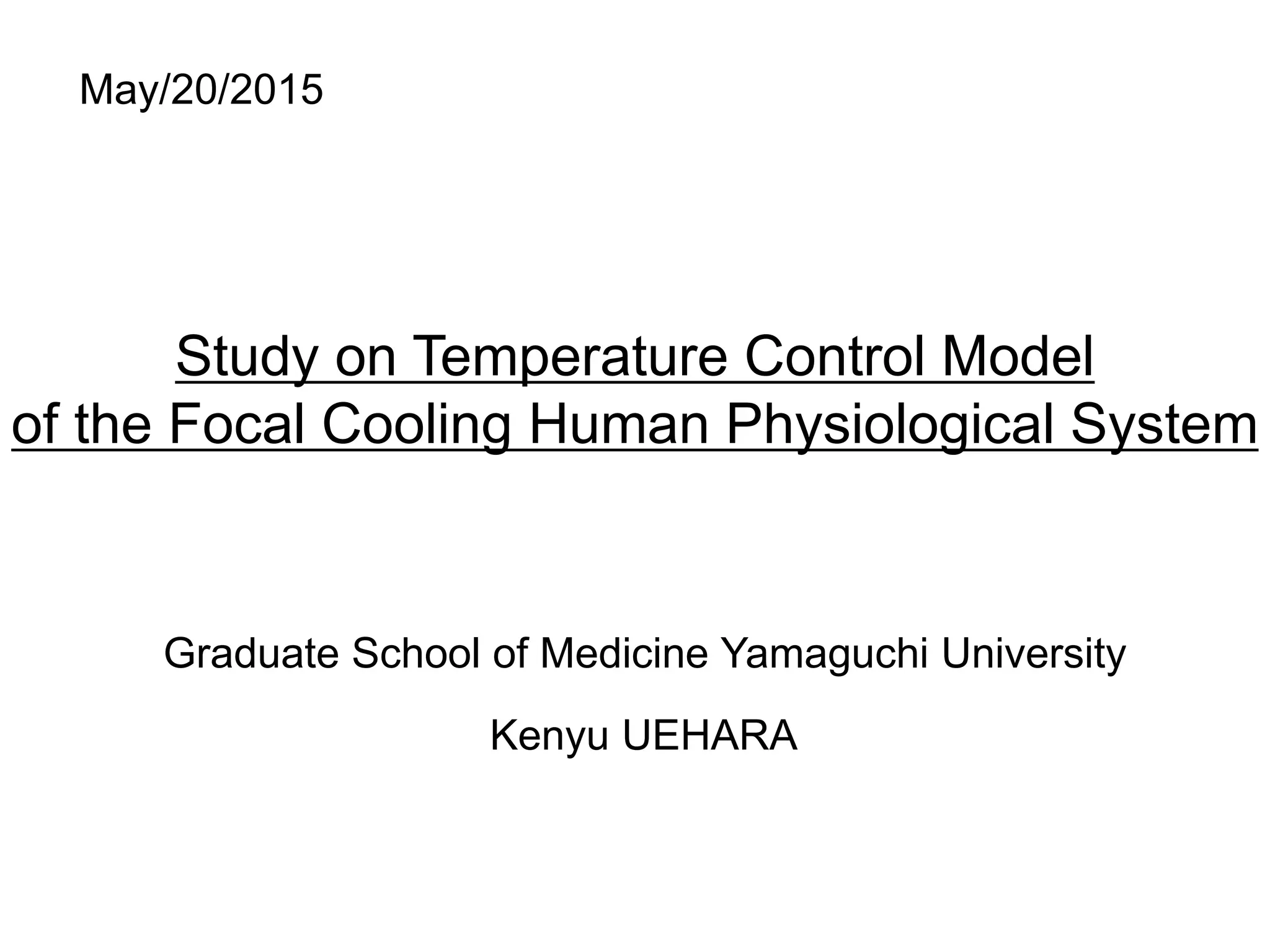

![0 10 20 30 40 50

15

20

25

30

35

40

45

Exp.

Sim.

Temperature[

o

C]

Time [s]

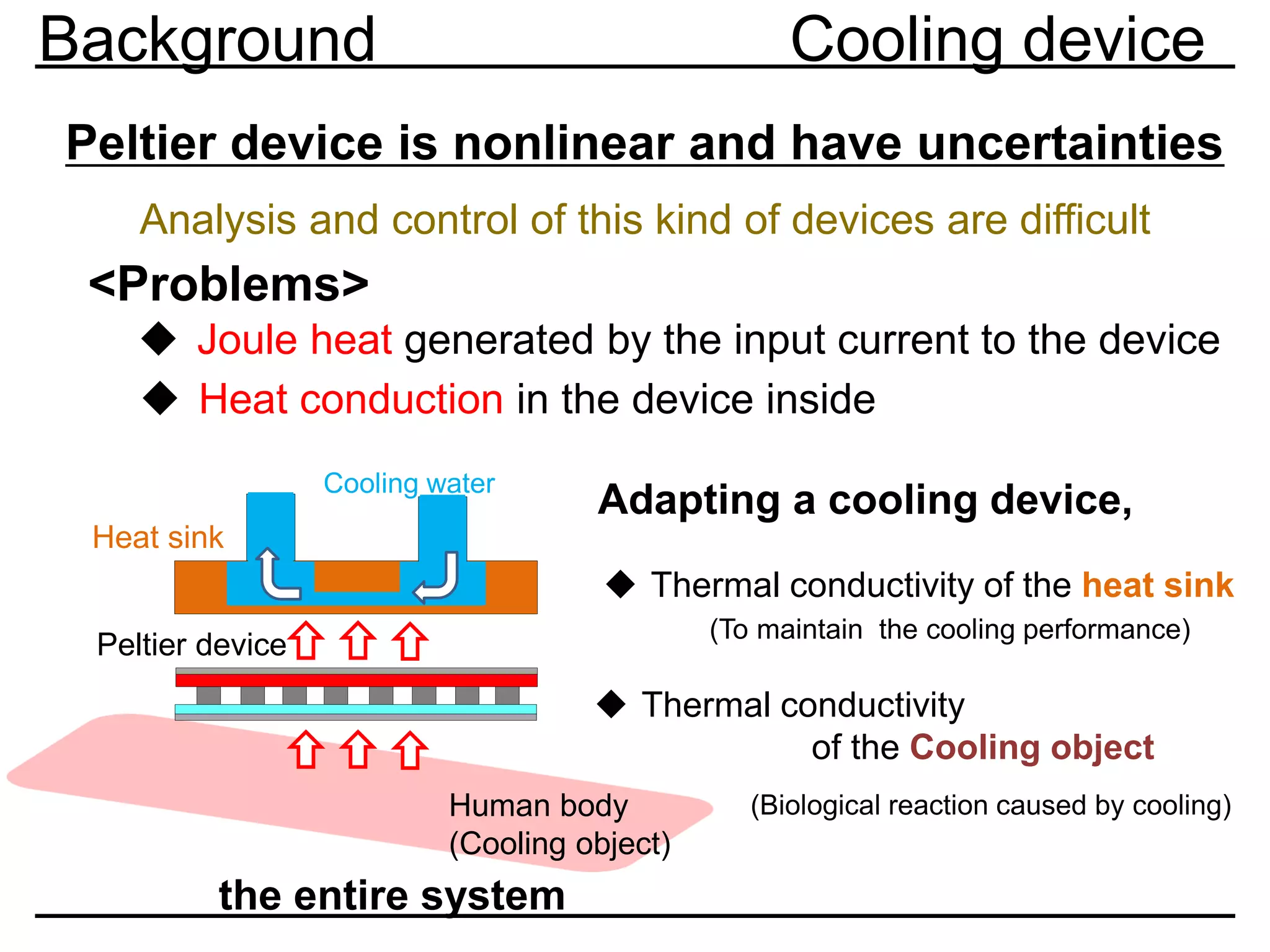

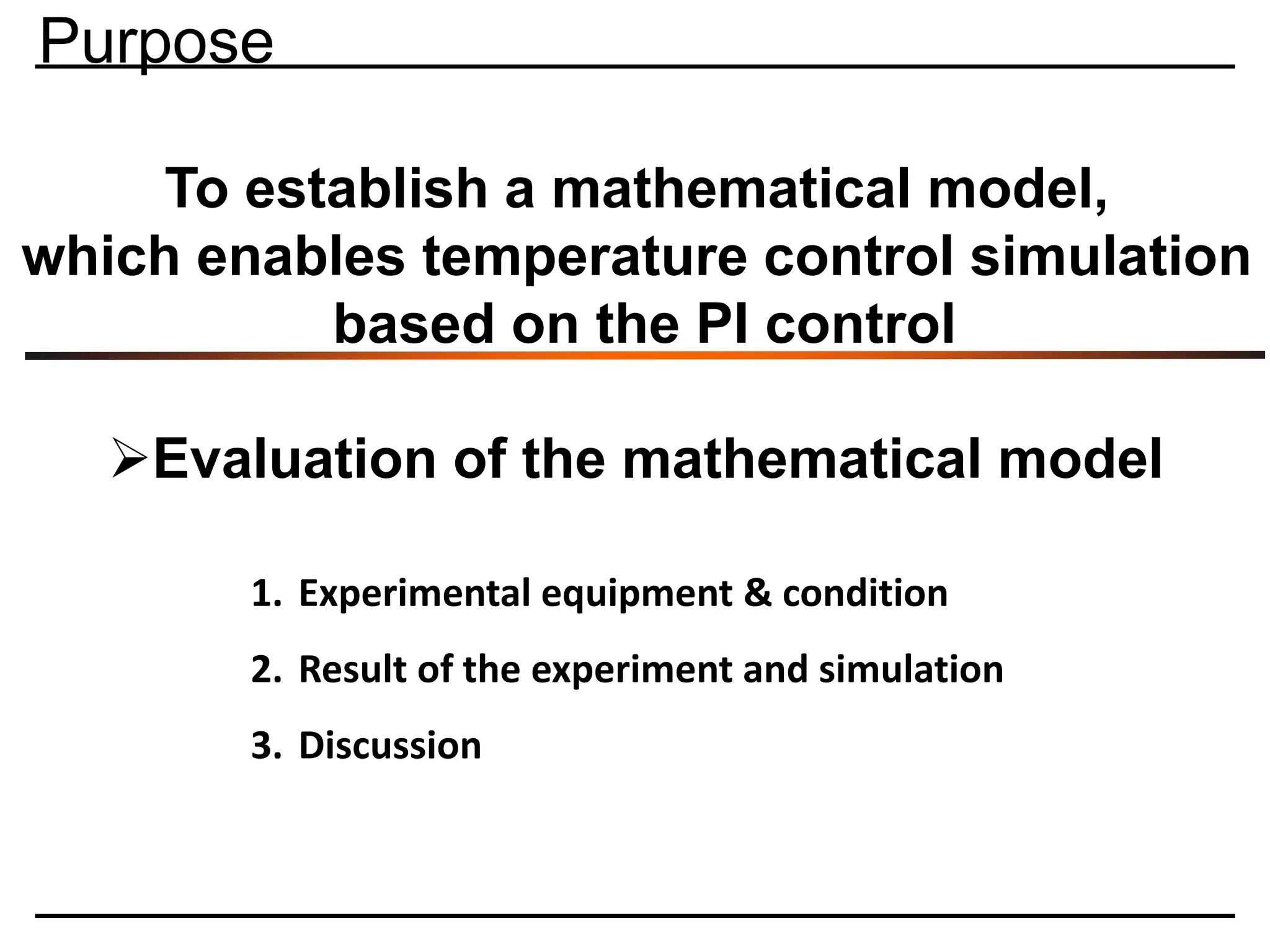

Previous research Modeling

Comparison of the experimental and simulation

results in case of proportional gain Kp is 0.5

Result of the validation of the mathematical model

Proportional control [V]

The relative Error

of the controlled side

1 %/point (0.2~0.3 ℃)

Mathematical model can simulate

Experimental result in the error range

of the parameter identification](https://image.slidesharecdn.com/midtermreportm1-181103045002/75/Study-on-temperature-control-model-of-a-focal-cooling-human-physiological-system-11-2048.jpg)

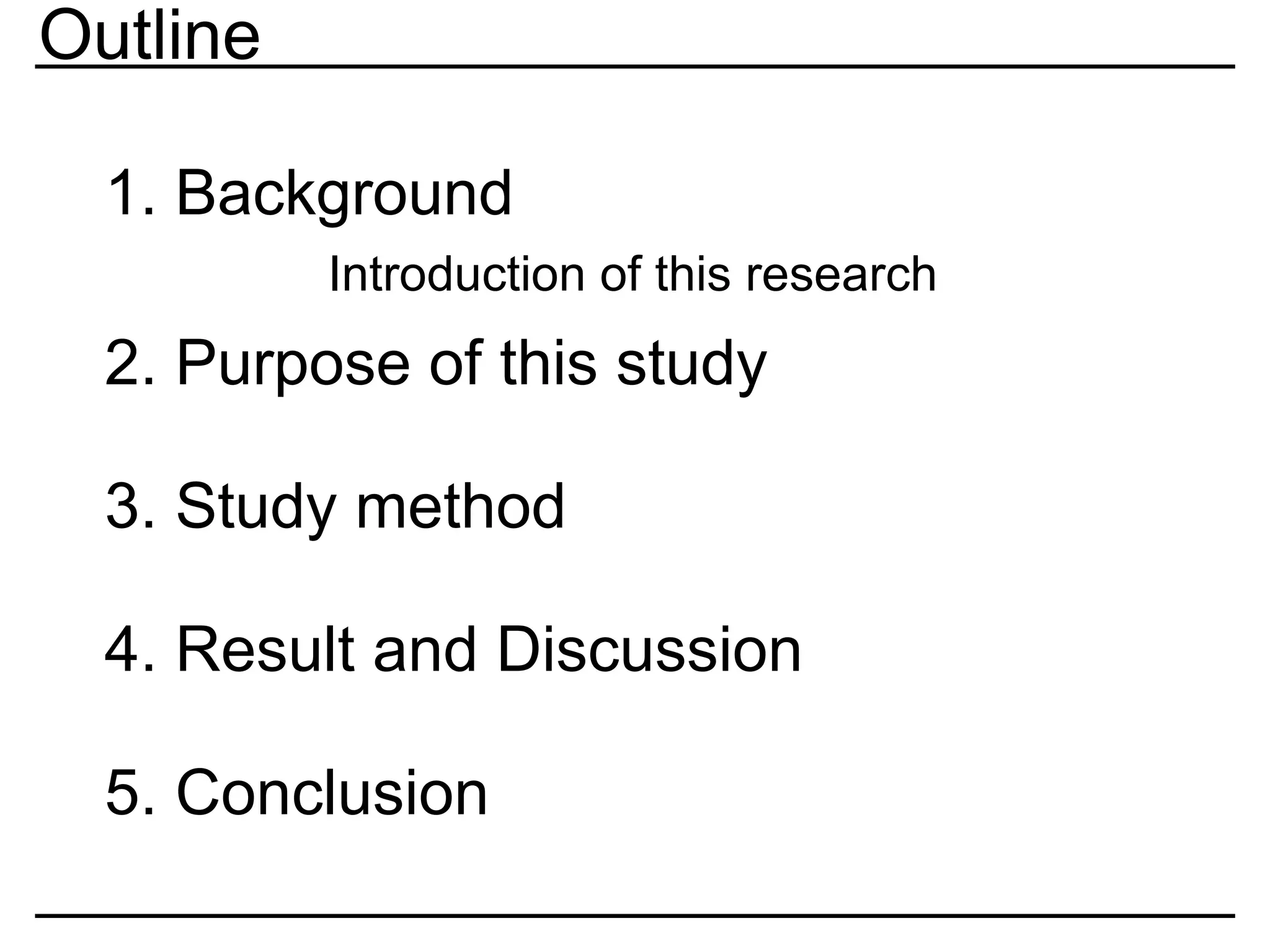

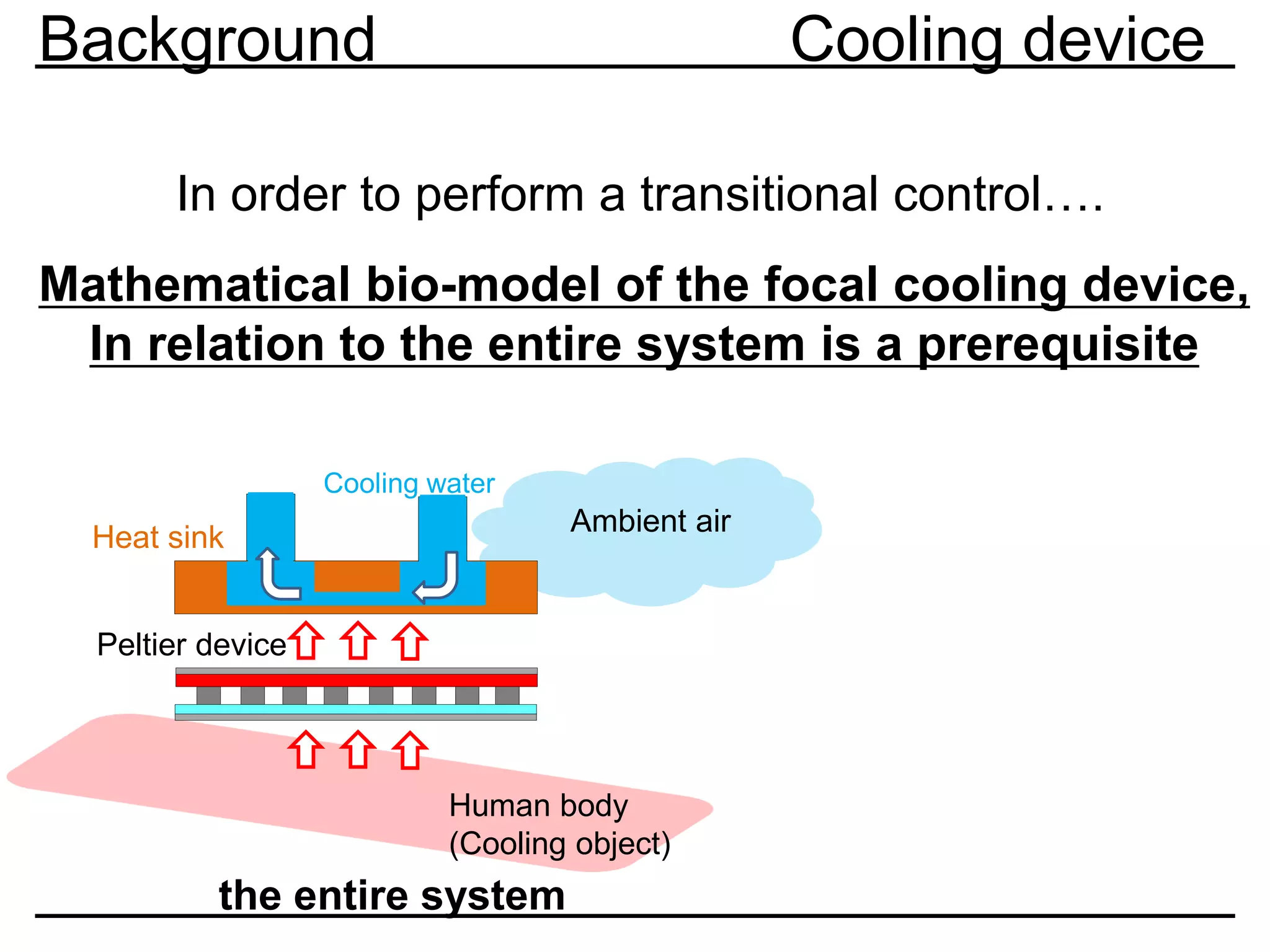

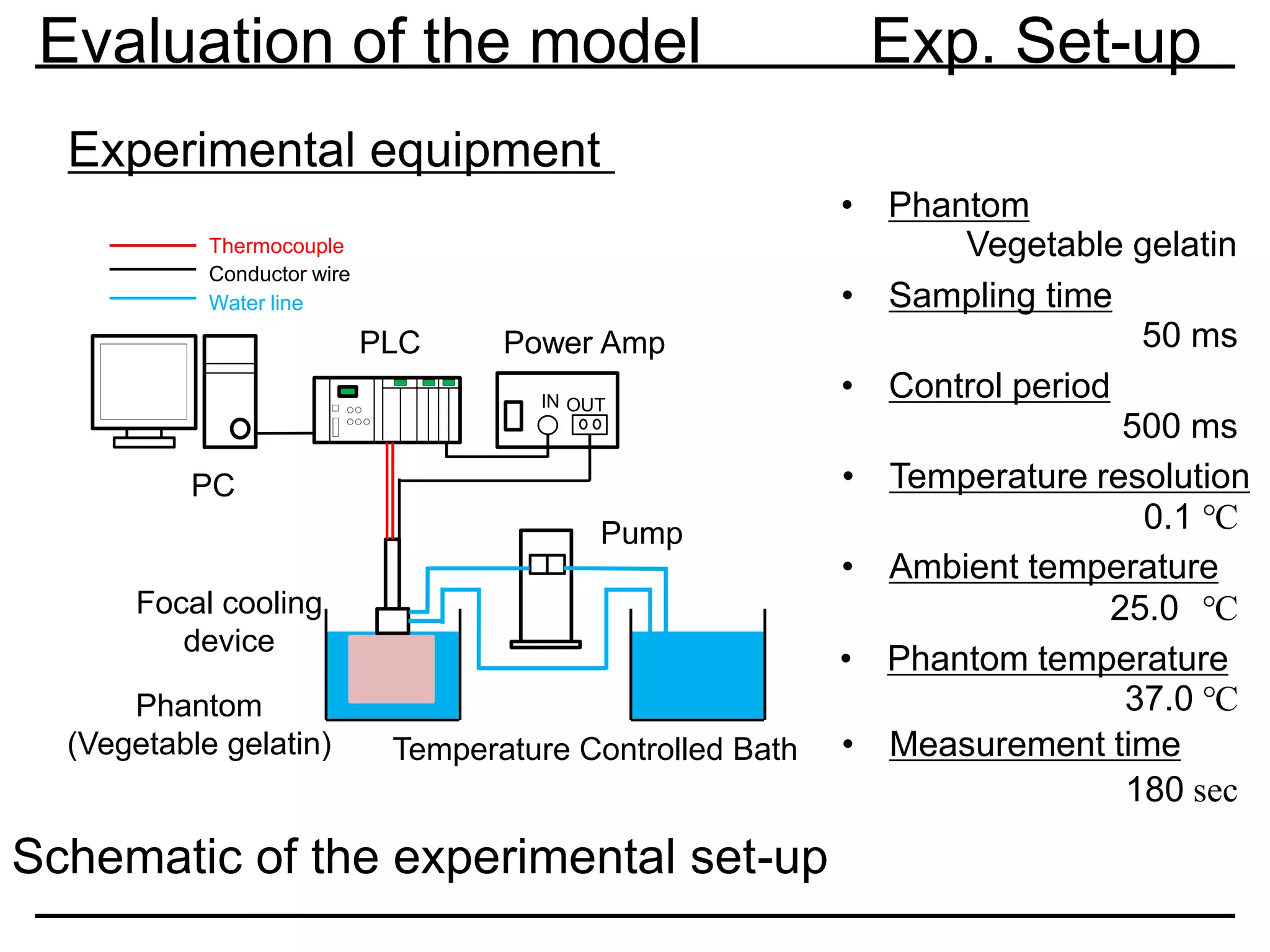

![Previous research Modeling

Comparison of the experimental and simulation

results in case of proportional gain Kp is 0.5

Result of the validation of the mathematical model

Using a temperature control based on ONLY Proportional action

Error in the temperature

of the controlled side

0.2~0.3 ℃

Mathematical model can simulate

Experimental based on the P-control

0 10 20 30 40 50

15

20

25

30

35

40

45

Exp.

Sim.

Temperature[

o

C]

Time [s]

Controlled temperature reaches

a balance away from the target](https://image.slidesharecdn.com/midtermreportm1-181103045002/75/Study-on-temperature-control-model-of-a-focal-cooling-human-physiological-system-12-2048.jpg)

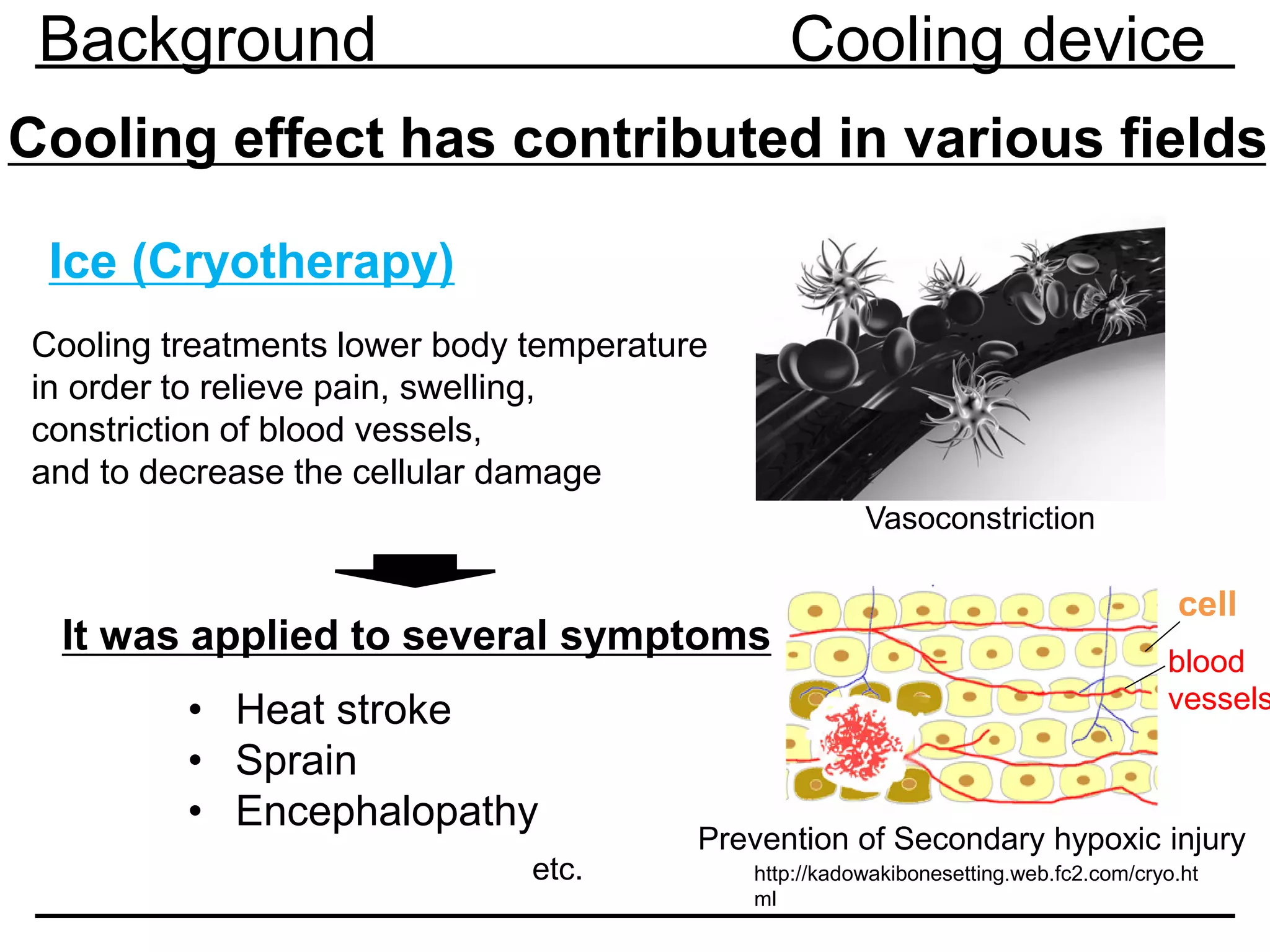

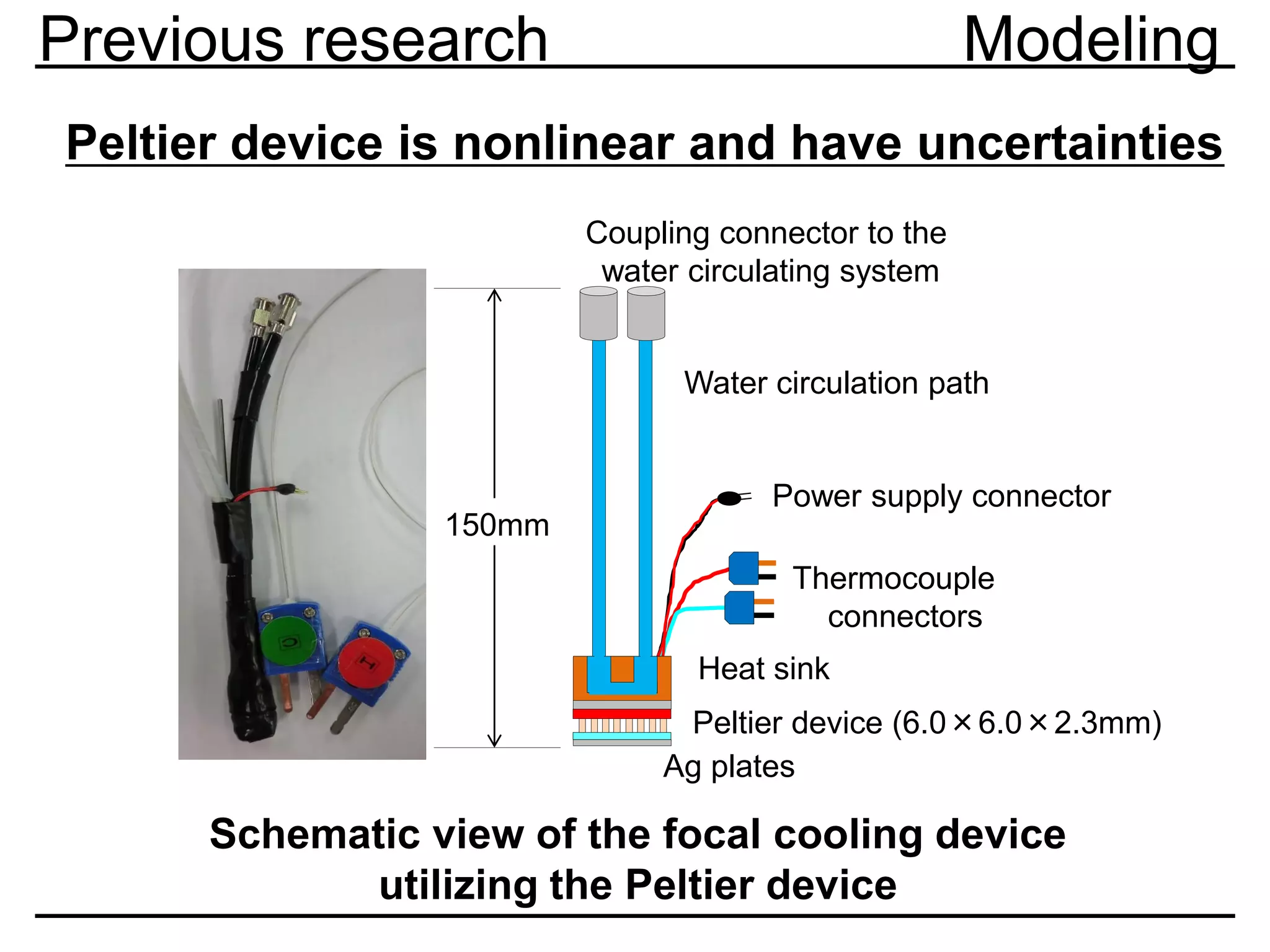

![Previous research Modeling

Comparison of the experimental and simulation

results in case of proportional gain Kp is 0.5

Using a temperature control based on ONLY Proportional action

Error in the temperature

of the controlled side

0.2~0.3 ℃

Mathematical model can simulate

Experimental based on the P-control

0 10 20 30 40 50

15

20

25

30

35

40

45

Exp.

Sim.

Temperature[

o

C]

Time [s]

Controlled temperature reaches

a balance away from the target

General temperature control.

⚫ To eliminate the steady-state error

⚫ To improve the stability of the system

In order to adapt to a living body,

accuracy of the cooling temperature is an important factor

PI,PD, or PID control

P : Proportional action

I : Integral action

D : Derivative action

Is used as needed in the temperature control](https://image.slidesharecdn.com/midtermreportm1-181103045002/75/Study-on-temperature-control-model-of-a-focal-cooling-human-physiological-system-13-2048.jpg)

![PI control

[V]

Input voltage

25

32 ~ 33

Time [s]

Temperature [℃]

Cooling start Cooling end

10 50

Heat side

Cool side

controlled

Evaluation of the model Exp.& Sim.

Proportional gain Integral gainControl error

(0.5) 15.0

30.0

50.0

Condition of the experiment and simulation](https://image.slidesharecdn.com/midtermreportm1-181103045002/75/Study-on-temperature-control-model-of-a-focal-cooling-human-physiological-system-16-2048.jpg)

![0 10 20 30 40 50

15

20

25

30

35

40

45

Exp.

Sim.

Temperature[

o

C]

Time [s]

An example of result in case of proportional

gain is 0.5 and integral gain is 15.0

Ki Controlled side Both sides

15.0 0.66 1.92

30.0 0.24 1.23

50.0 0.45 1.48

Relative error per-point of the results [%/point]

The average error in the parameter

identification is 1.16%/point

The relative error in the both sides is nearly equal

to the time of the parameter identification

It is to be sufficiently possible simulated in the error

range at the time of the parameter identification

Evaluation Result & discussion](https://image.slidesharecdn.com/midtermreportm1-181103045002/75/Study-on-temperature-control-model-of-a-focal-cooling-human-physiological-system-17-2048.jpg)