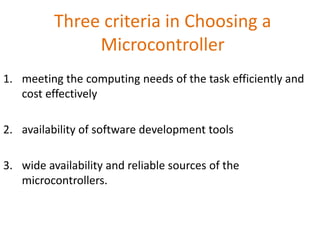

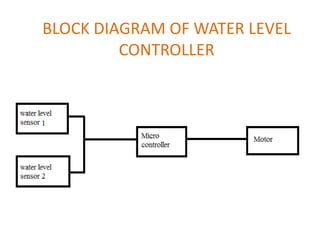

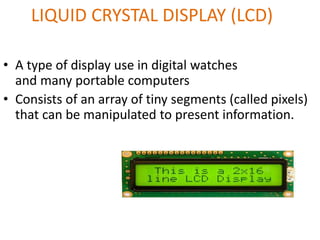

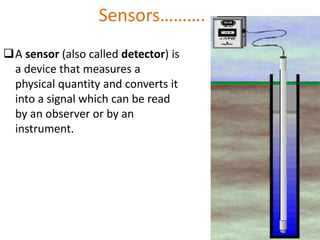

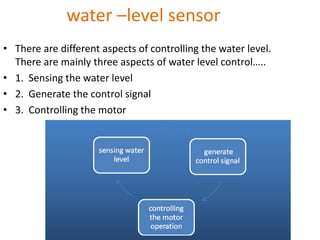

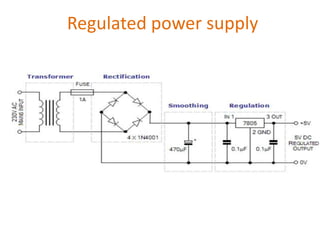

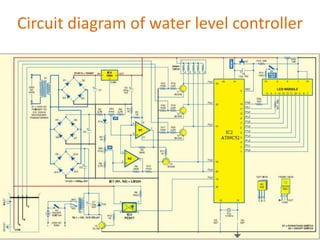

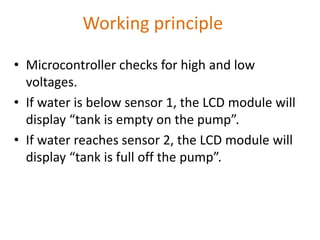

This document describes a microcontroller-based water level controller project. The controller uses an AT89C52 microcontroller, LCD display, water level sensors, and a DC motor. It monitors the water level and controls the motor to automatically fill or drain the tank based on signals from two sensors. This automatic control saves electricity, water, and reduces human effort compared to a manual system. Potential applications include use in homes, industries, and municipal water systems.