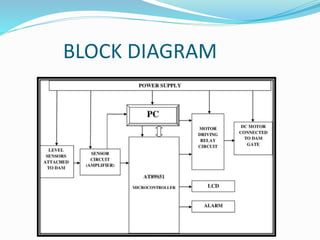

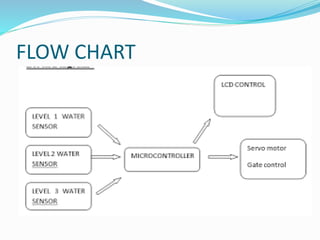

The document outlines an automated dam shutter opening system designed to enhance the management of water levels and prevent dam failures. The system utilizes sensors, microcontrollers, and a motor driving relay circuit to control the opening and closing of dam gates based on real-time water level readings. By automating this process, the project aims to reduce manpower, maintenance costs, and the risk of disasters caused by manual operations.