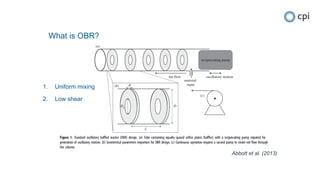

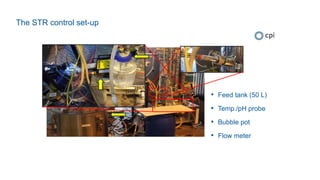

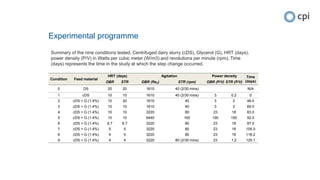

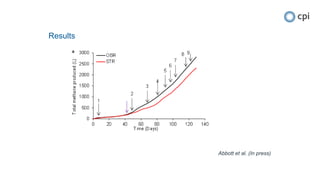

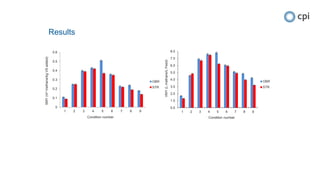

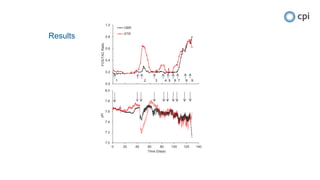

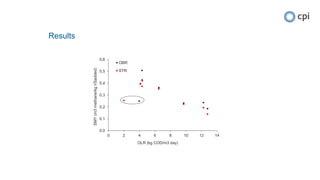

Michelle Morrison presented on a study comparing a novel tubular anaerobic digestion technology called OBR to a conventional STR design. The study co-digested dairy slurry and glycerol. The OBR was able to successfully digest this mixture and achieved a 28% higher methane yield than the STR under optimal conditions. Continuous agitation improved yields in both systems up to a point, while decreasing retention time had a negative effect. The OBR was more stable but required more energy for temperature control and pumping than the STR. Overall, the OBR performed well and has potential for small-scale anaerobic digestion applications.