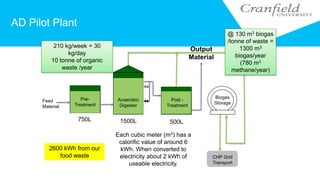

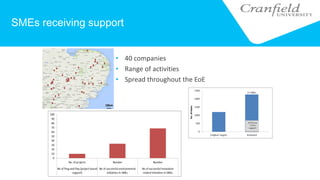

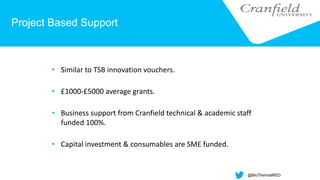

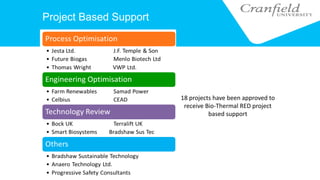

Dr. Raffaella Villa discusses the Bio-Thermal RED project at Cranfield University, which provides support to SMEs in anaerobic digestion. The project includes an AD pilot plant facility available to SMEs, as well as workshops and project-based grants of £1000-5000. So far the project has supported 40 companies through workshops and approved funding for 18 projects involving areas like small-scale biogas plants, silage management best practices, and modular farm-scale digesters. The overall goal is to help SMEs develop renewable energy technologies and applications.

![Low Carbon KEEP

Farm Renewables Ltd.

• Development of a cost effective farm scale anaerobic digester system

• Modular components to allow technical adaptation to locally available

waste quantities

• Emphasis of development on easy maintenance and operation of the AD

plant

• Flexible system to allow the digestion of carious waste streams (e.g. food

waste, manure, energy crops)

• Spatial efficiency [LCH4 / m-3] needs to be

determined

• For this comparably small AD system,

special attention has to be directed

towards energy efficiency (pumping,

mixing, heating…)](https://image.slidesharecdn.com/raffaellavilla-150422062622-conversion-gate01/85/Raffaella-Villa-15-320.jpg)