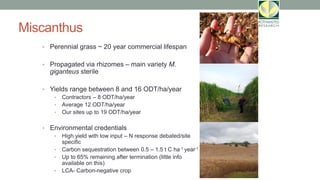

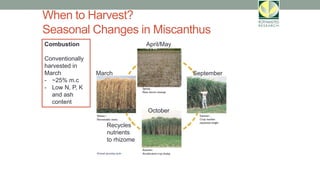

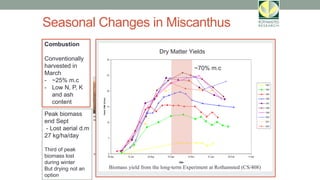

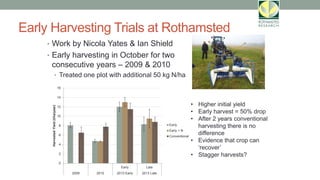

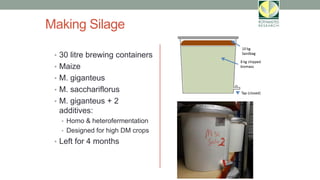

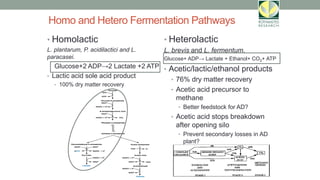

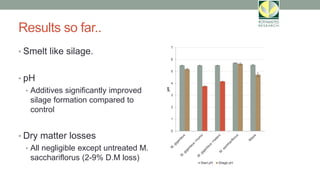

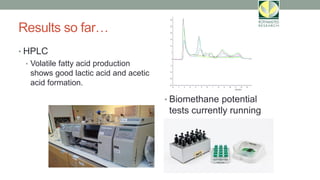

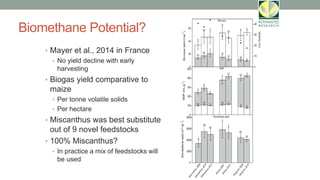

This document summarizes research testing the biomethane potential of Miscanthus harvested green and stored as silage. The study compares Miscanthus to maize, the control. Preliminary results found that Miscanthus can be stored as silage, especially with additive application, with negligible dry matter losses. Biomethane potential tests are ongoing. The research aims to determine if early harvested and ensiled Miscanthus is a viable substitute for maize in anaerobic digestion plants.