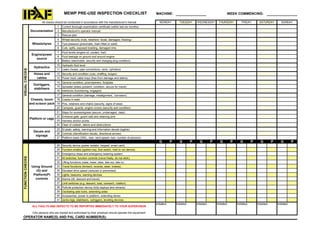

This document provides a pre-use inspection checklist for a mobile elevating work platform (MEWP). The checklist includes over 40 visual and functional checks of the machine's documentation, wheels/tyres, engine, hydraulics, hoses/cables, outriggers/stabilizers, chassis/boom/scissors, platform, decals/signage, and operating controls. Any faults or defects found during inspection must be reported immediately to the operator's supervisor. The checklist also requires the operator's name and training certification number to be recorded.