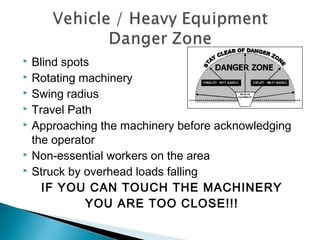

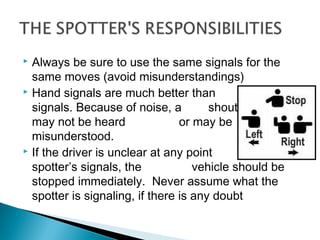

The document discusses the importance of using spotters when operating heavy machinery to direct movement when the operator's view is obstructed. A spotter stands to the side of the vehicle and uses clear hand signals to communicate with the operator to ensure safe movement and avoid injuries or property damage from collisions that blind spots could cause. Proper communication between the spotter and operator is essential for safety.