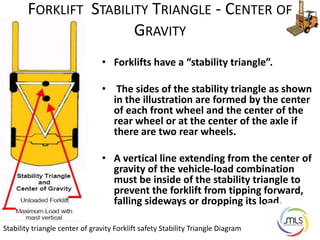

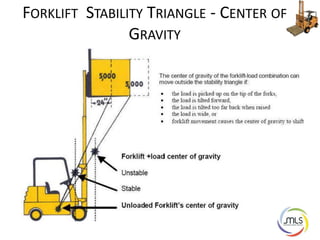

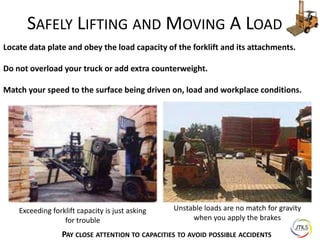

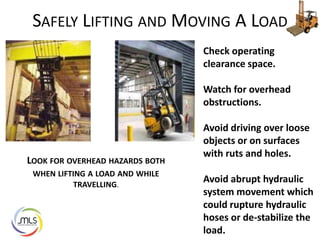

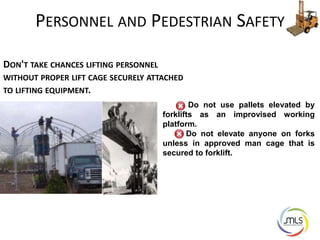

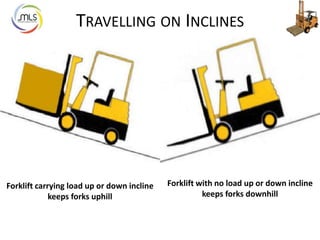

The document discusses forklift safety and provides guidance on proper forklift operation. It covers the forklift stability triangle and center of gravity, load capacities, safely lifting and moving loads, personnel safety, travelling on inclines, loading trucks, factors contributing to accidents, and performing a forklift circle check. Maintaining forklift stability and paying attention to load capacities and weights are emphasized as important safety practices.