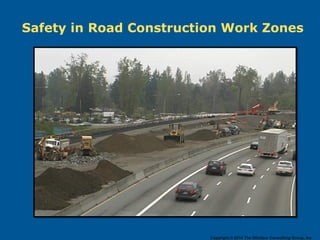

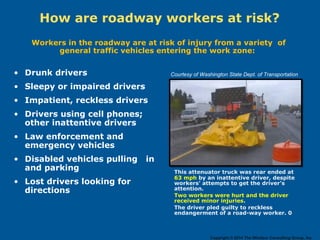

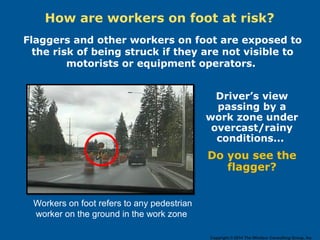

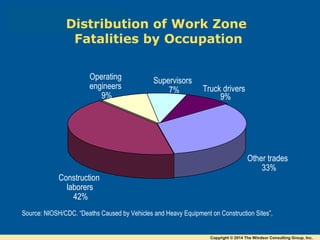

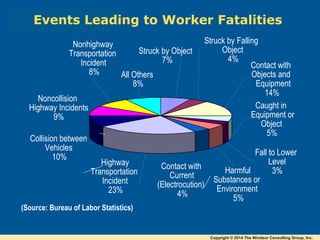

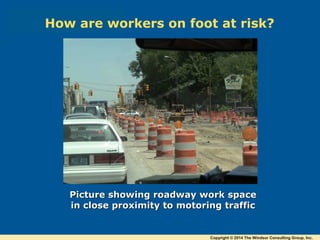

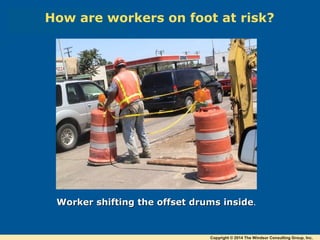

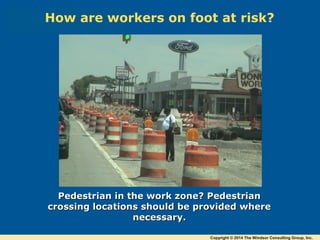

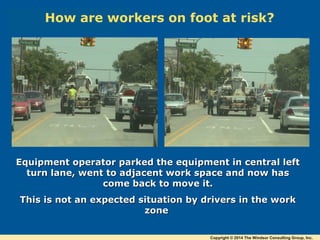

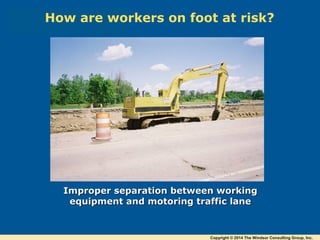

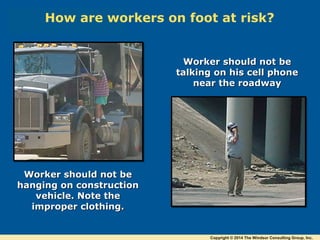

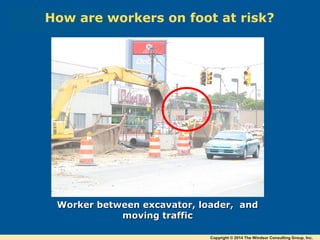

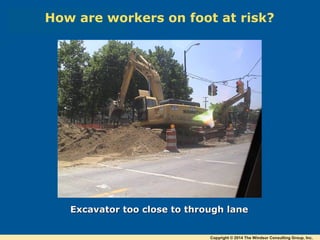

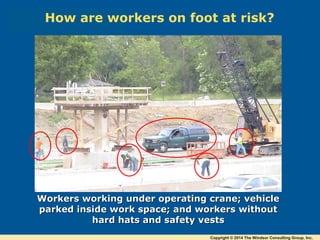

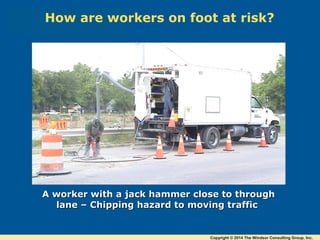

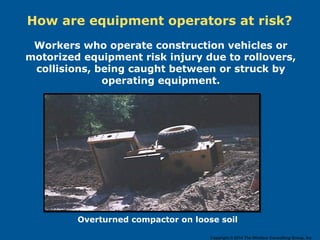

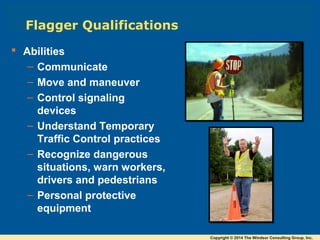

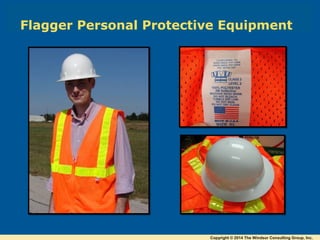

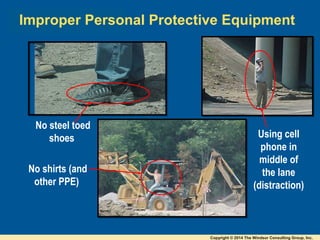

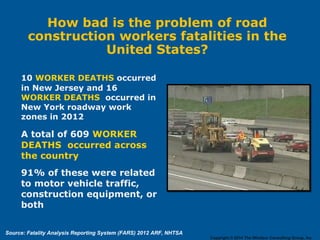

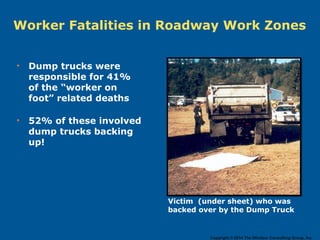

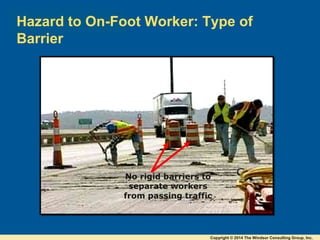

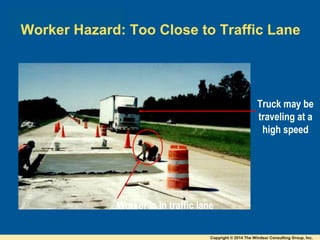

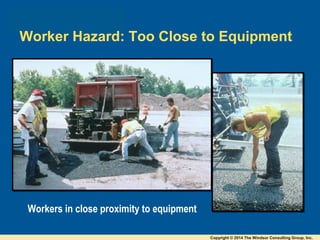

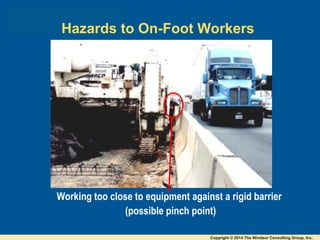

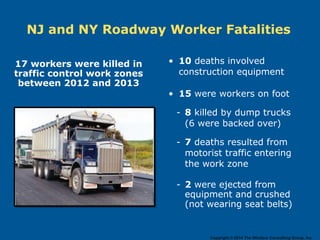

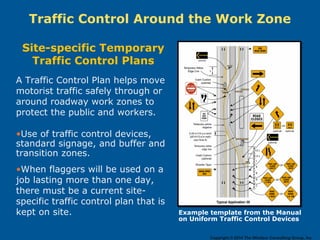

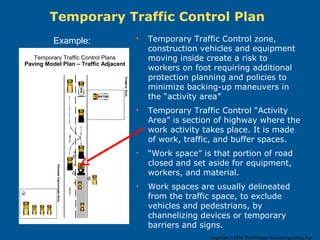

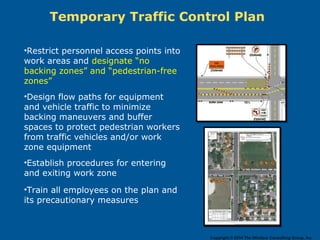

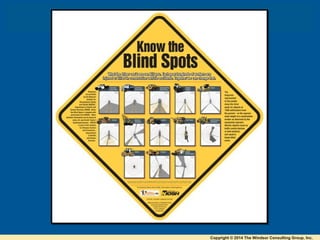

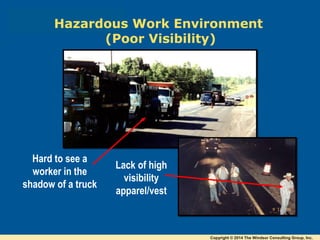

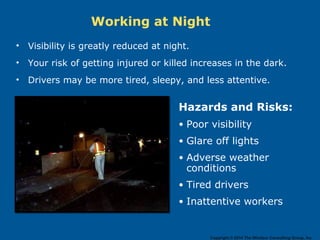

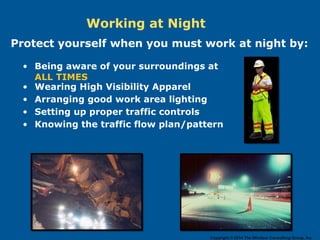

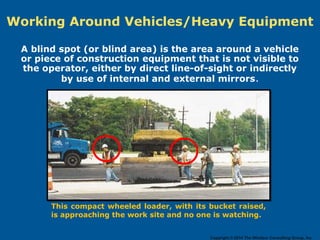

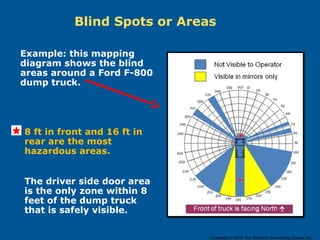

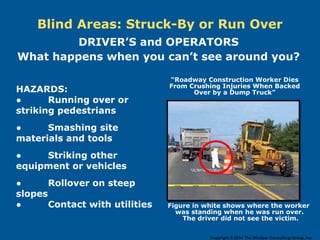

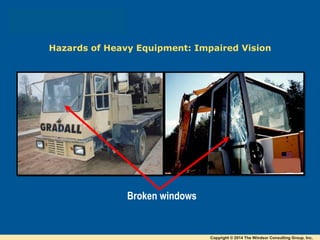

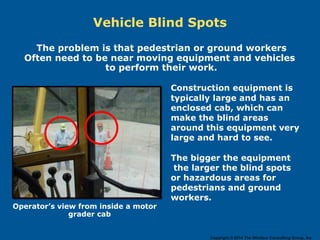

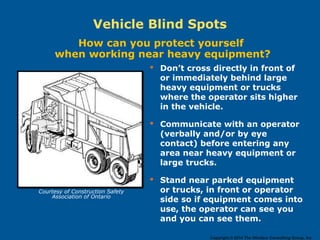

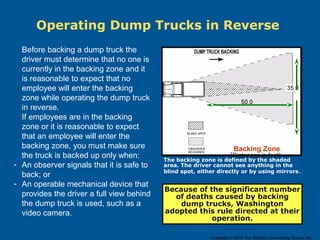

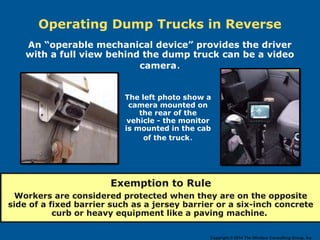

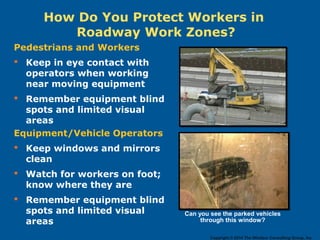

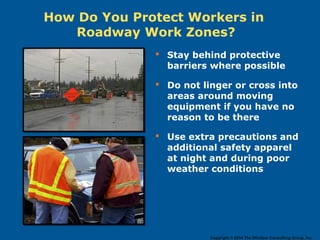

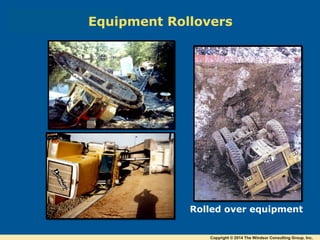

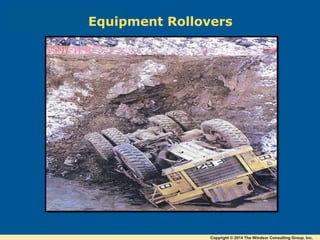

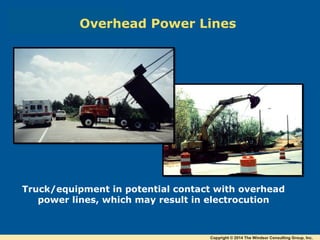

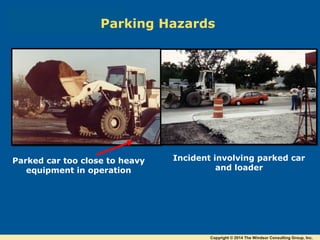

This presentation discusses hazards faced by workers in road construction zones and measures to improve their safety. It notes that over 600 road construction workers are killed annually in the US, mostly from vehicles or equipment. Common causes of death include workers being struck while on foot, especially by backing vehicles. The presentation covers traffic control plans, high visibility clothing, blind spots of vehicles and equipment, and risks of low light conditions. It emphasizes keeping workers separated from traffic and developing zone plans to minimize backing.