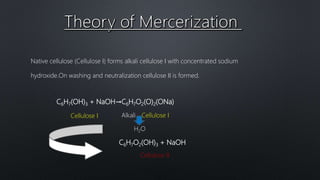

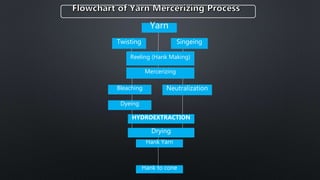

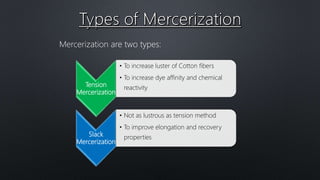

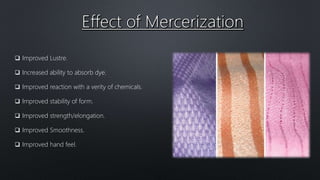

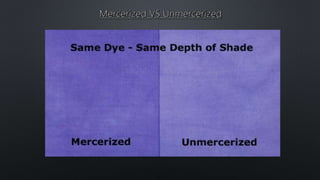

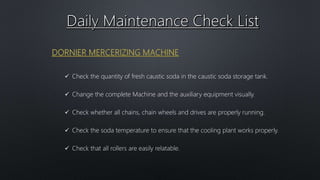

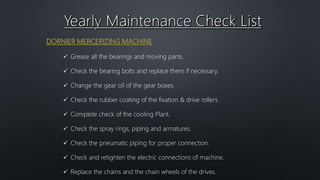

Mercerization is a treatment for cotton that enhances its luster, strength, and dye absorption by treating it with a caustic alkaline solution, first developed by John Mercer. The process involves converting native cellulose into alkali cellulose and is performed using either tension or slack methods to achieve different properties. Important factors in mercerization include temperature, tension, and time, with specific maintenance checks necessary to ensure optimal operation.