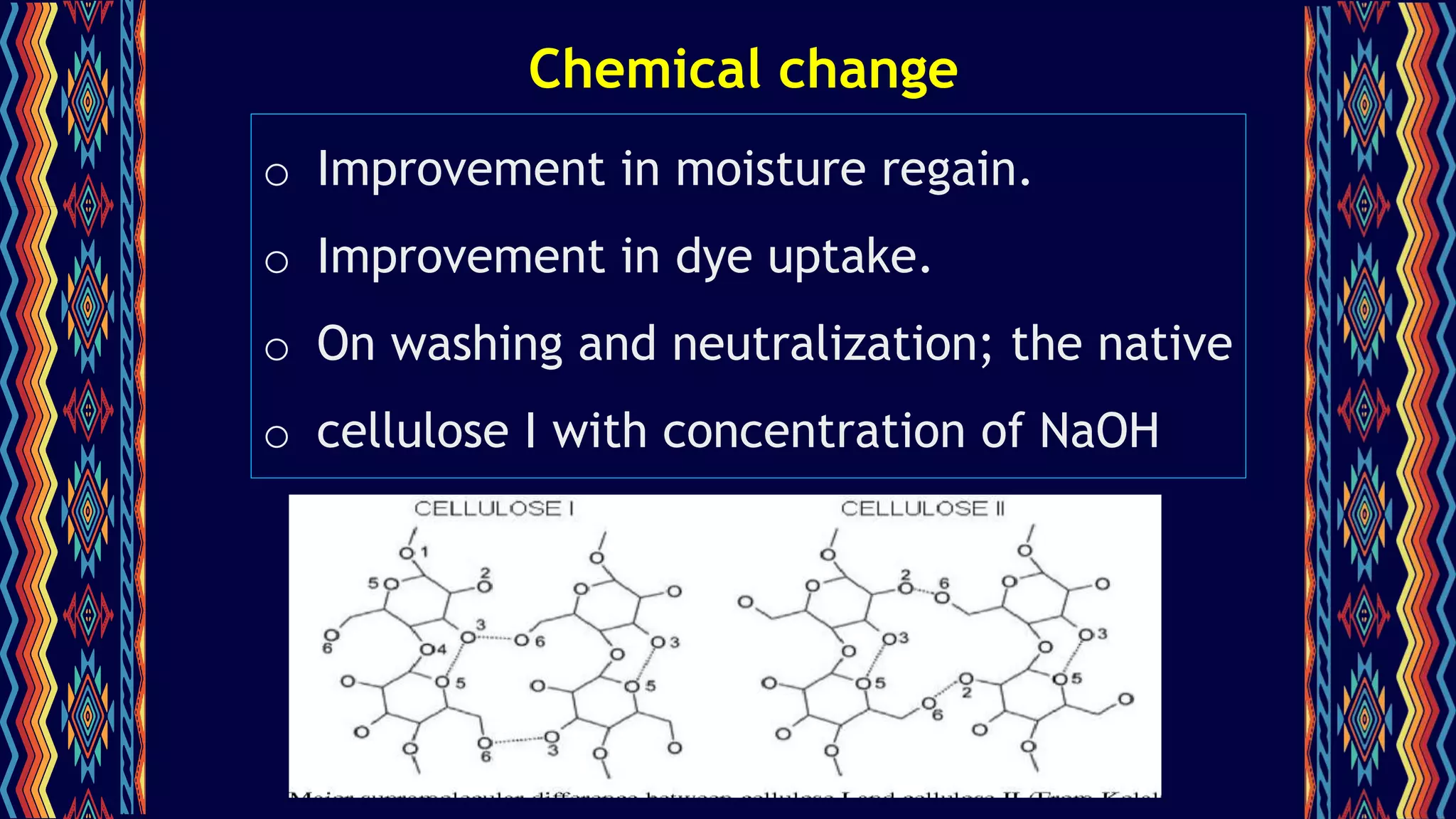

1) Mercerization is a finishing process that treats cotton fabric with a strong alkaline solution to improve luster, strength, and other properties.

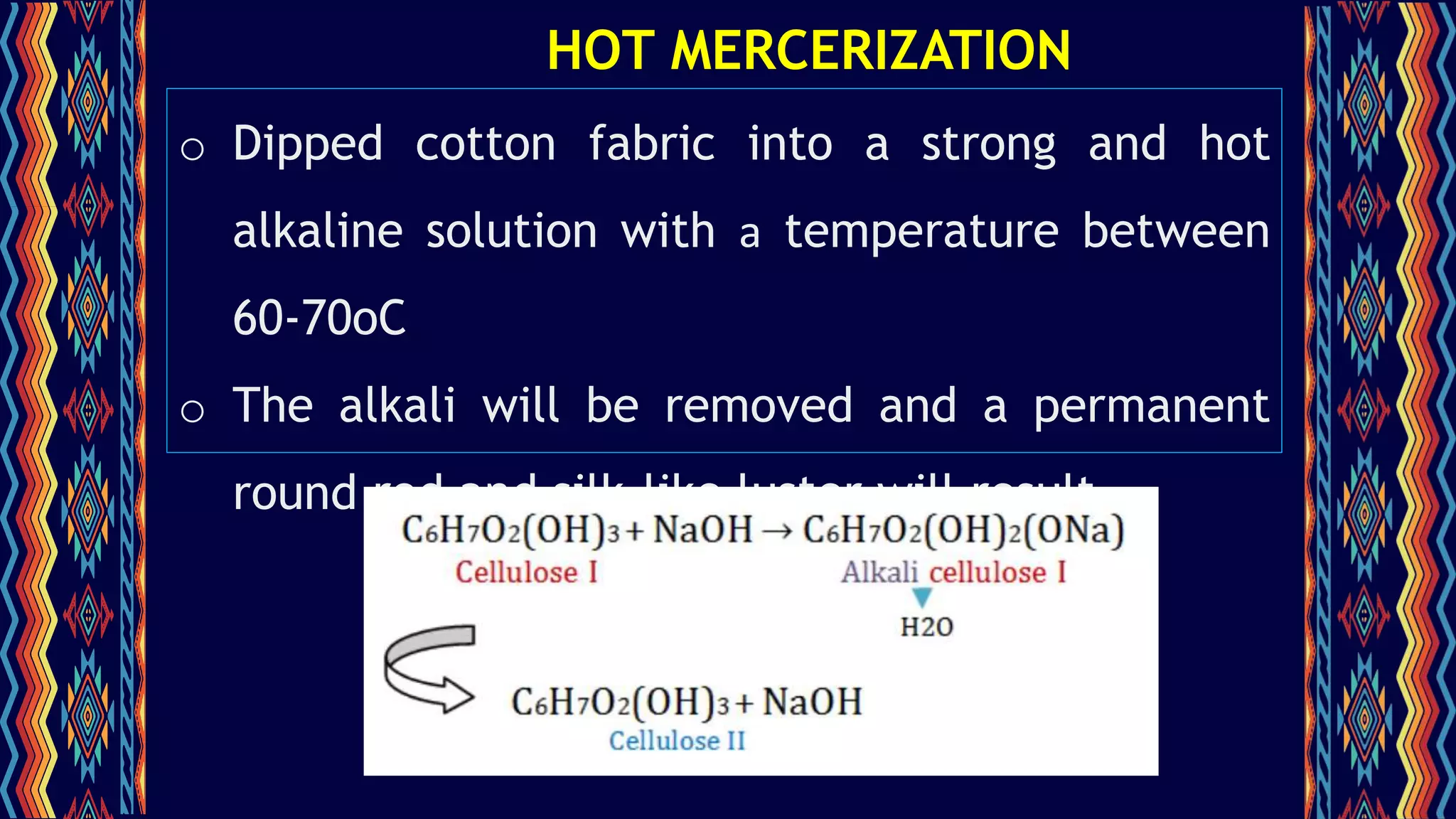

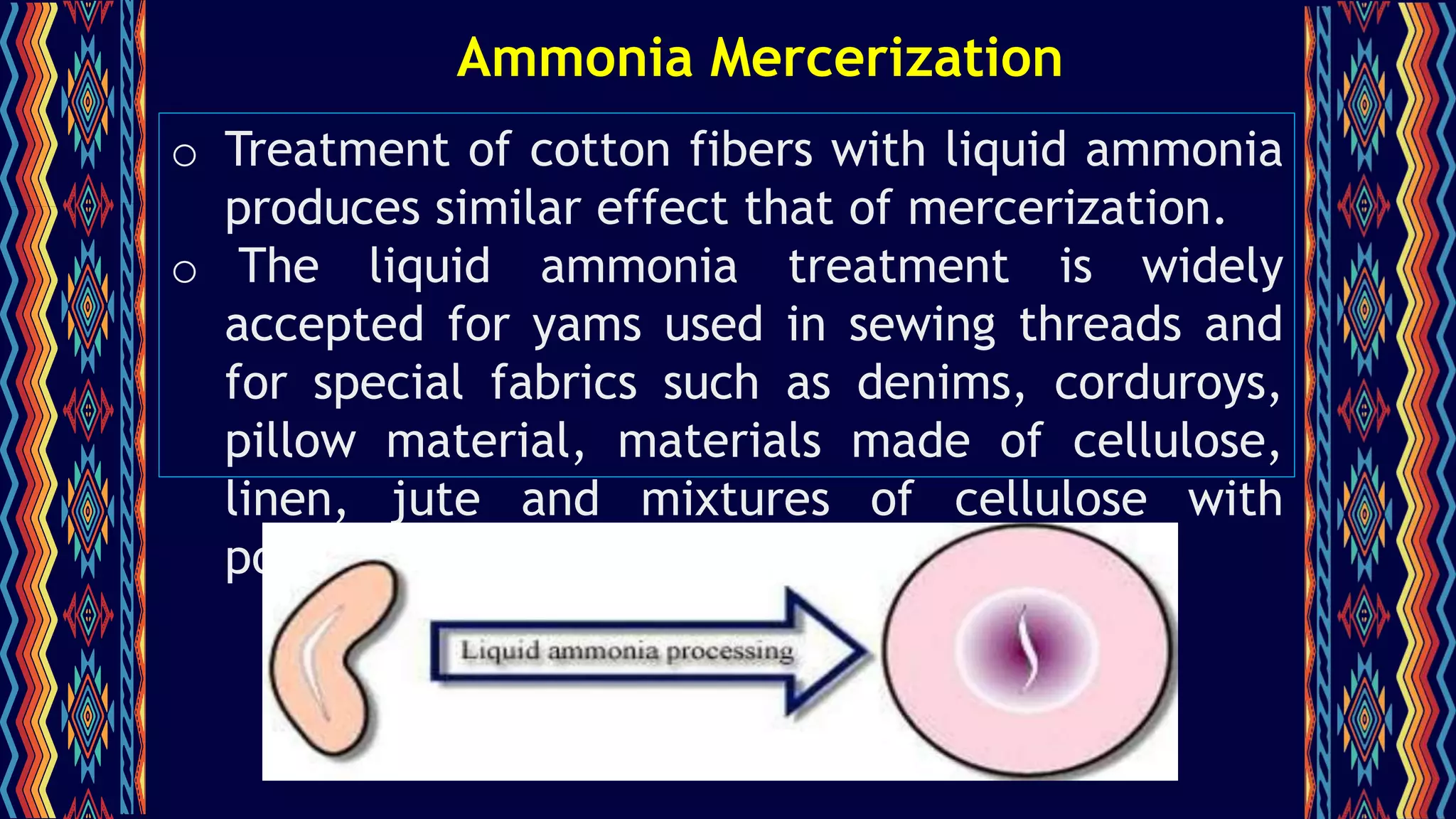

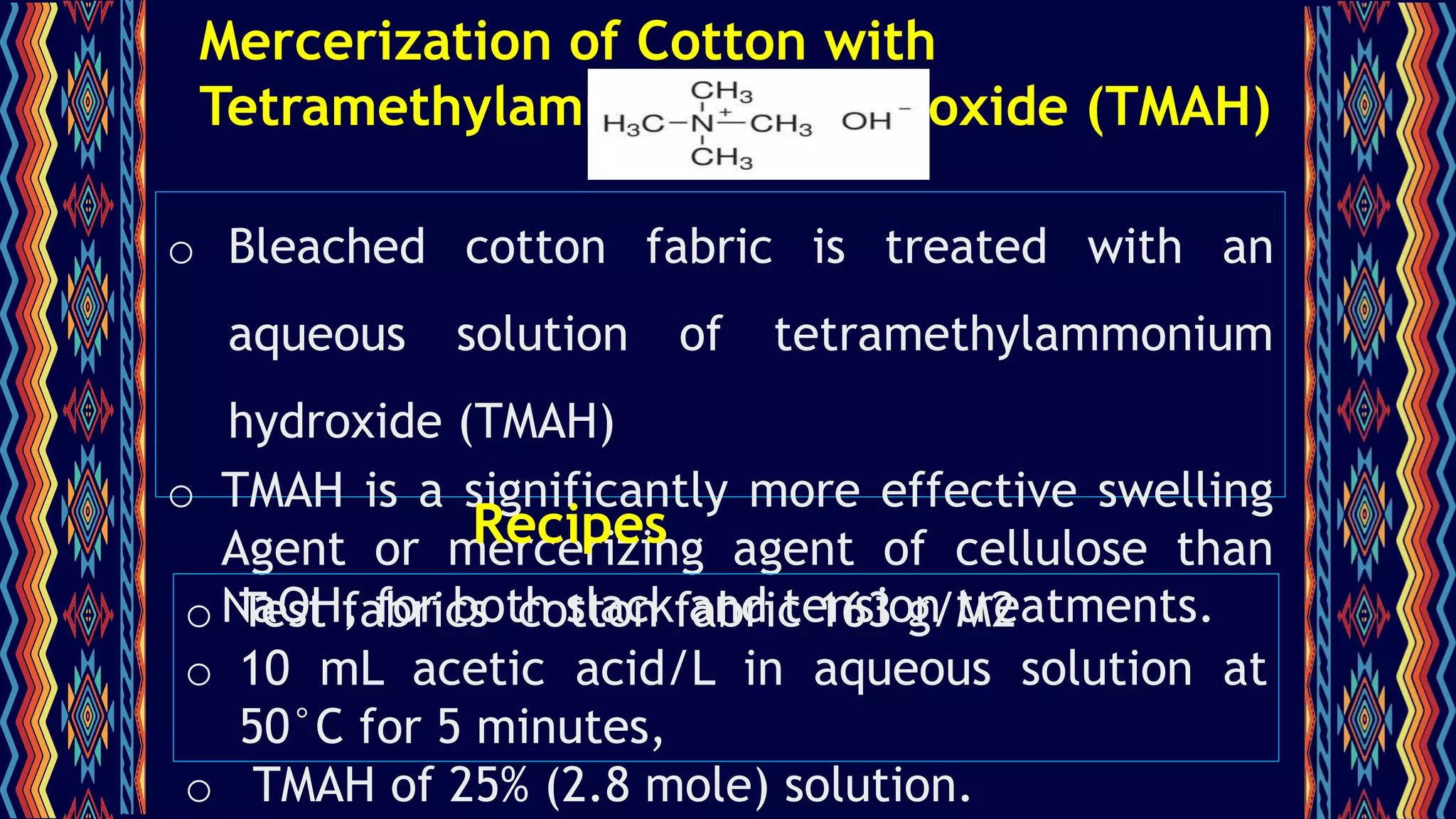

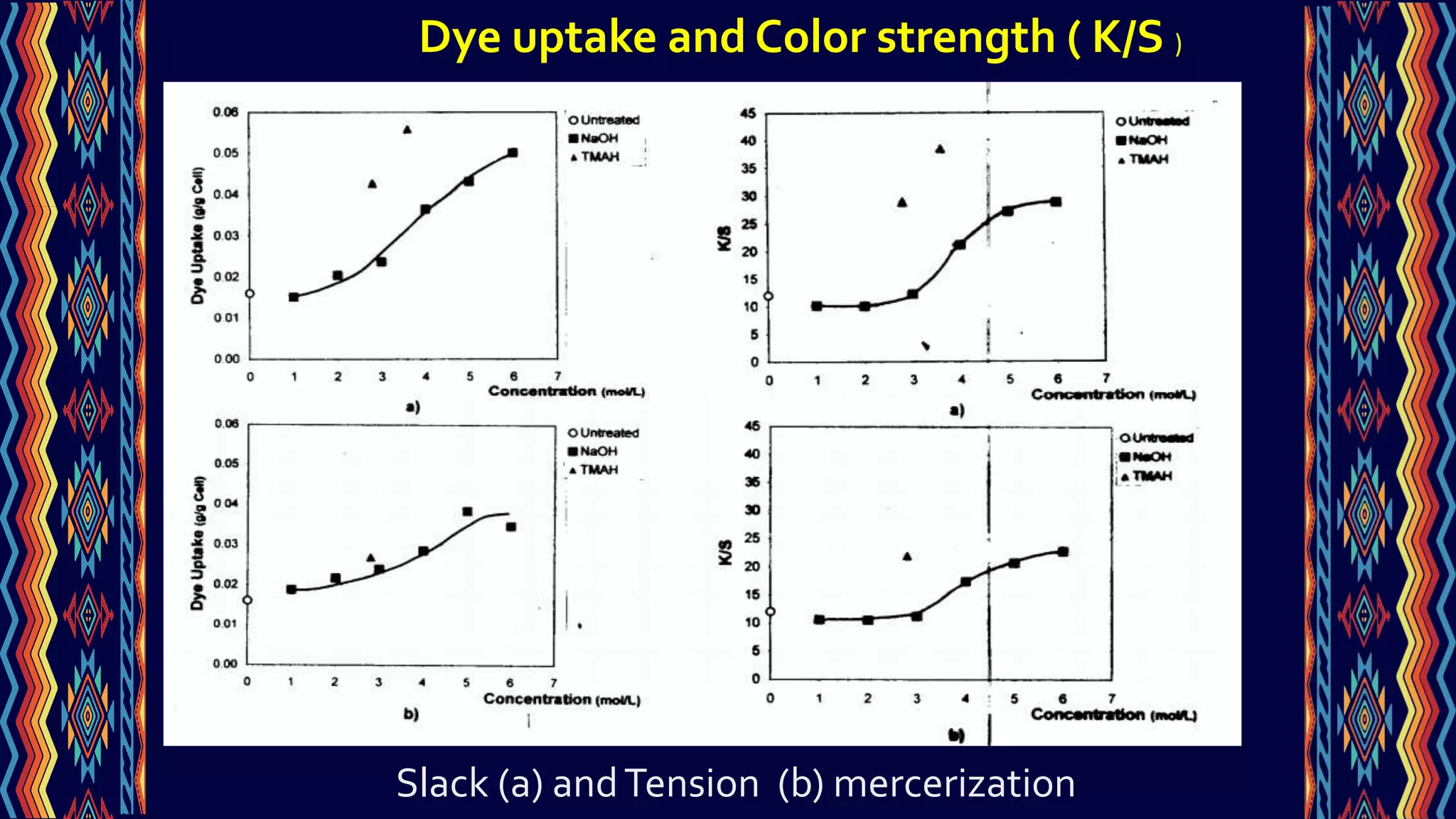

2) Recent developments in mercerization include using hot alkaline solutions, ammonia, and tetramethylammonium hydroxide which can provide better dye uptake, strength, and luster compared to conventional mercerization.

3) Ultrasound assisted mercerization is also being studied as a more efficient and eco-friendly method that uses ultrasonic energy to accelerate the chemical reactions during mercerization.