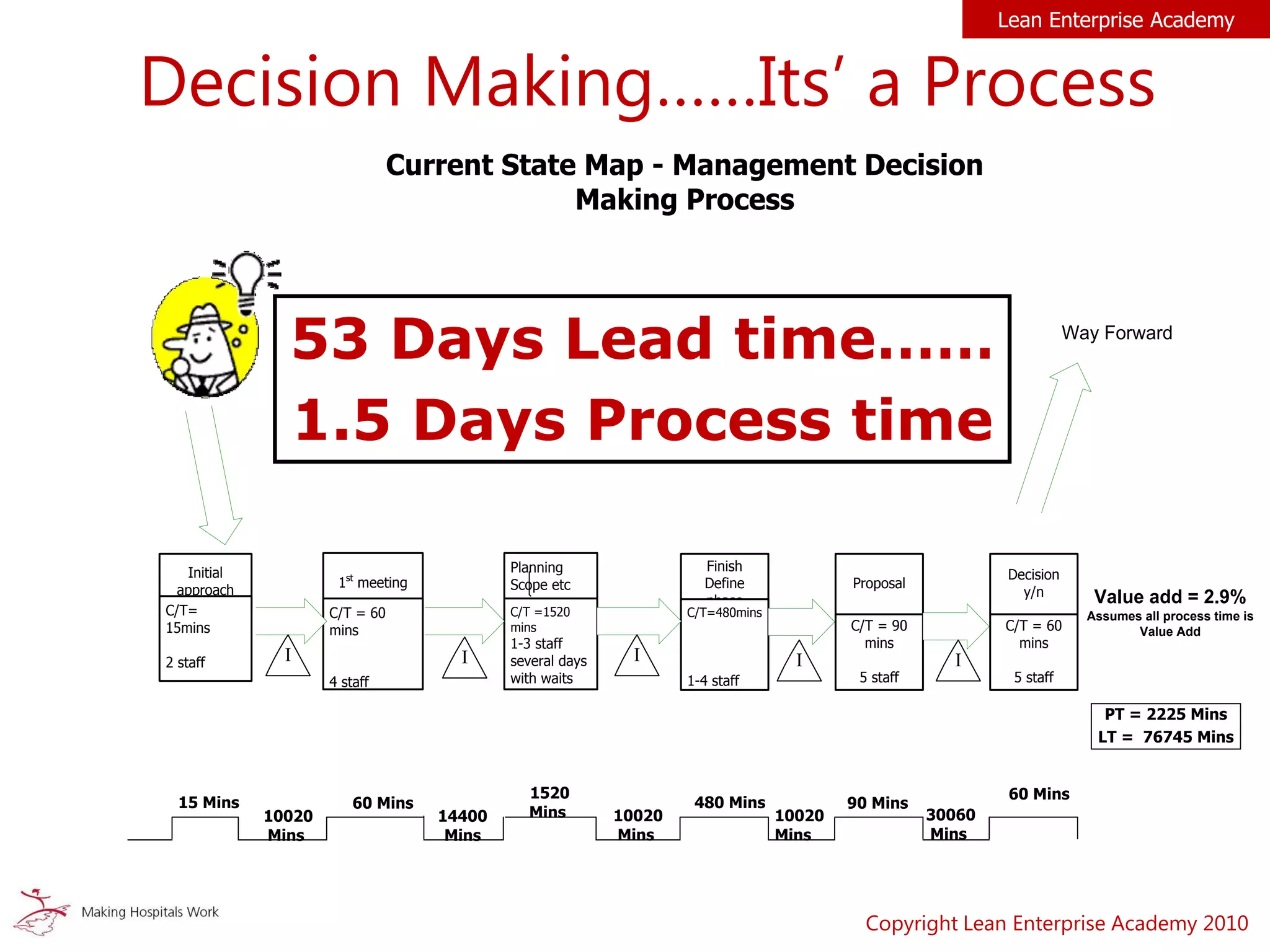

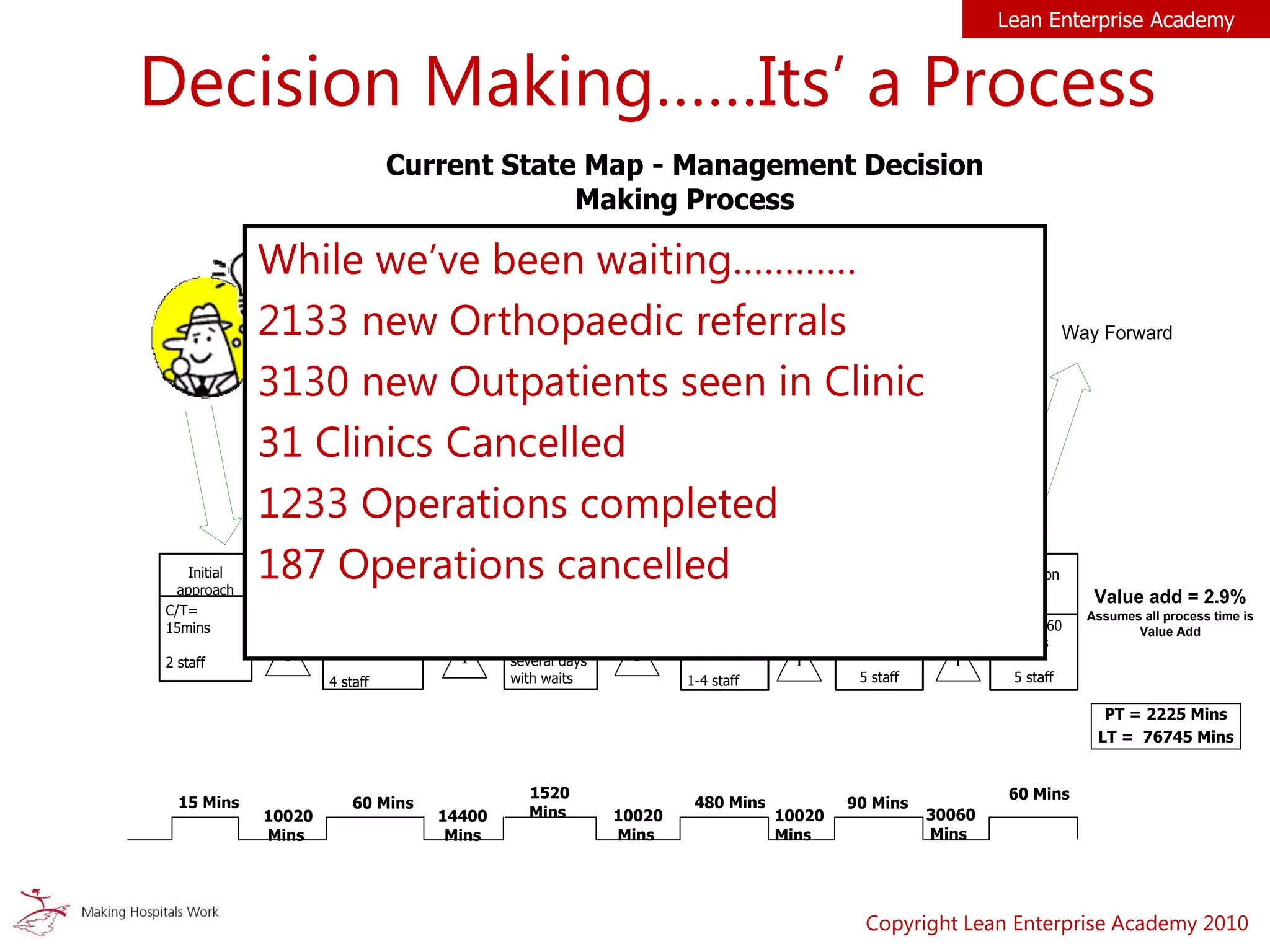

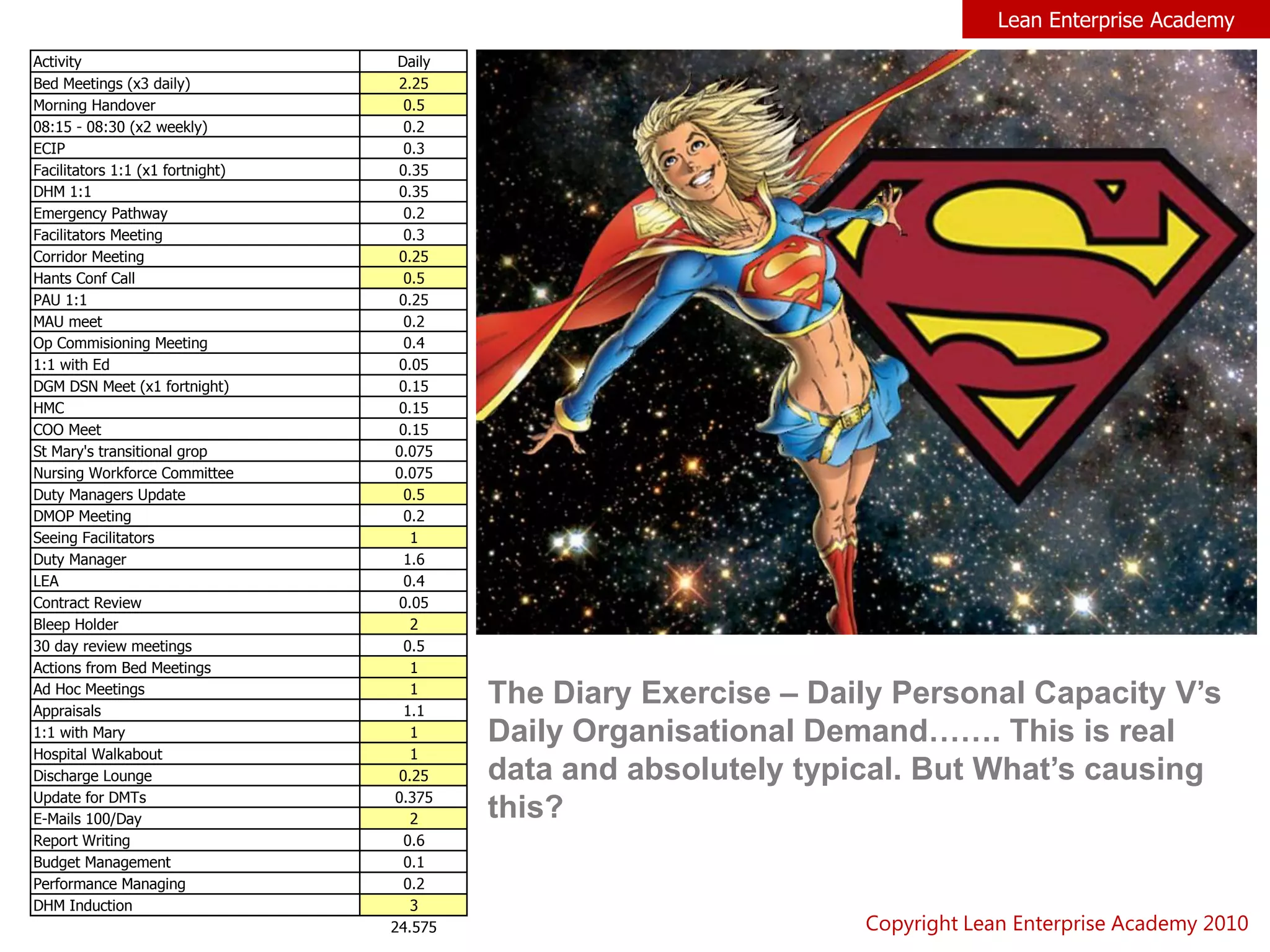

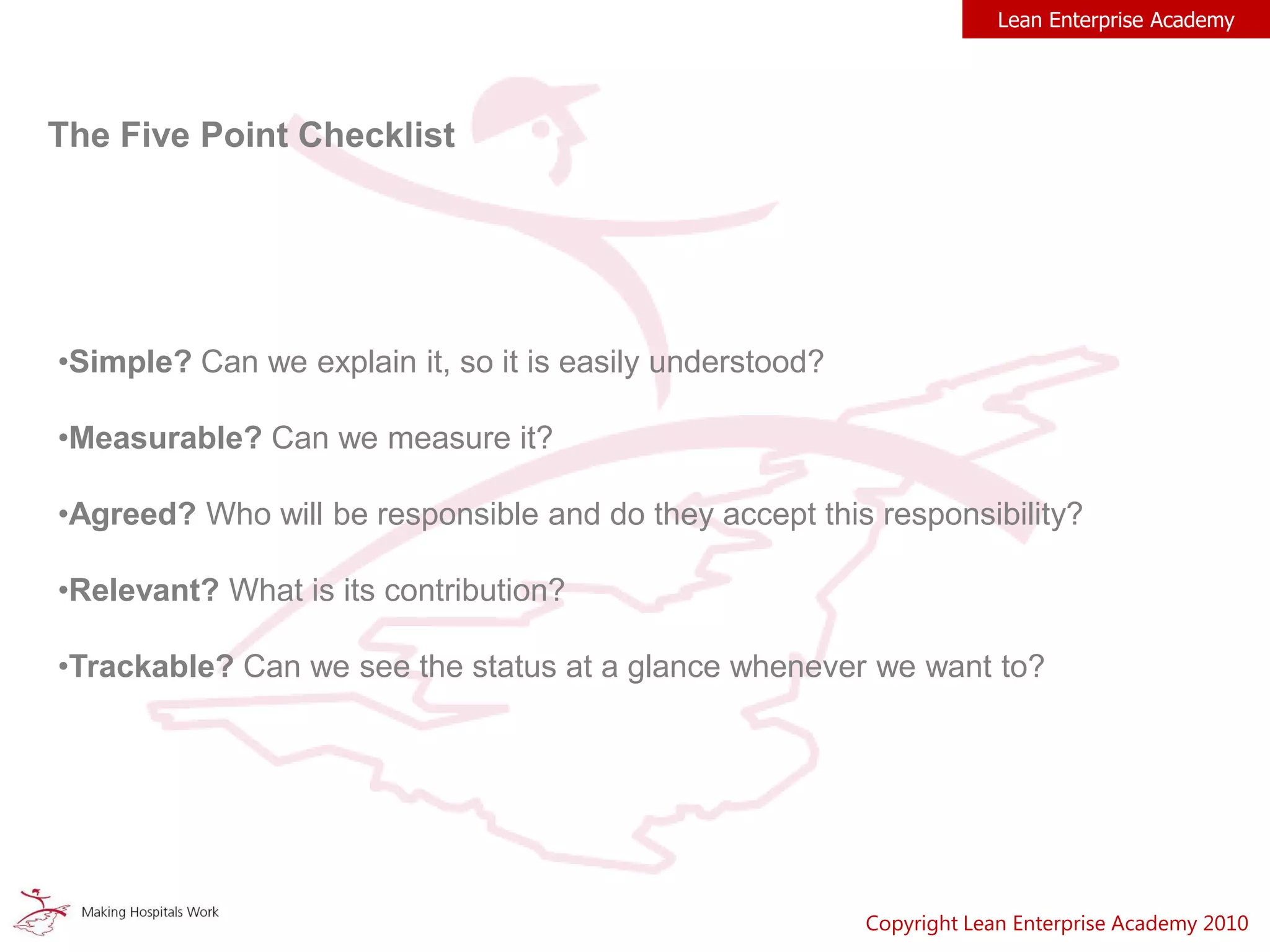

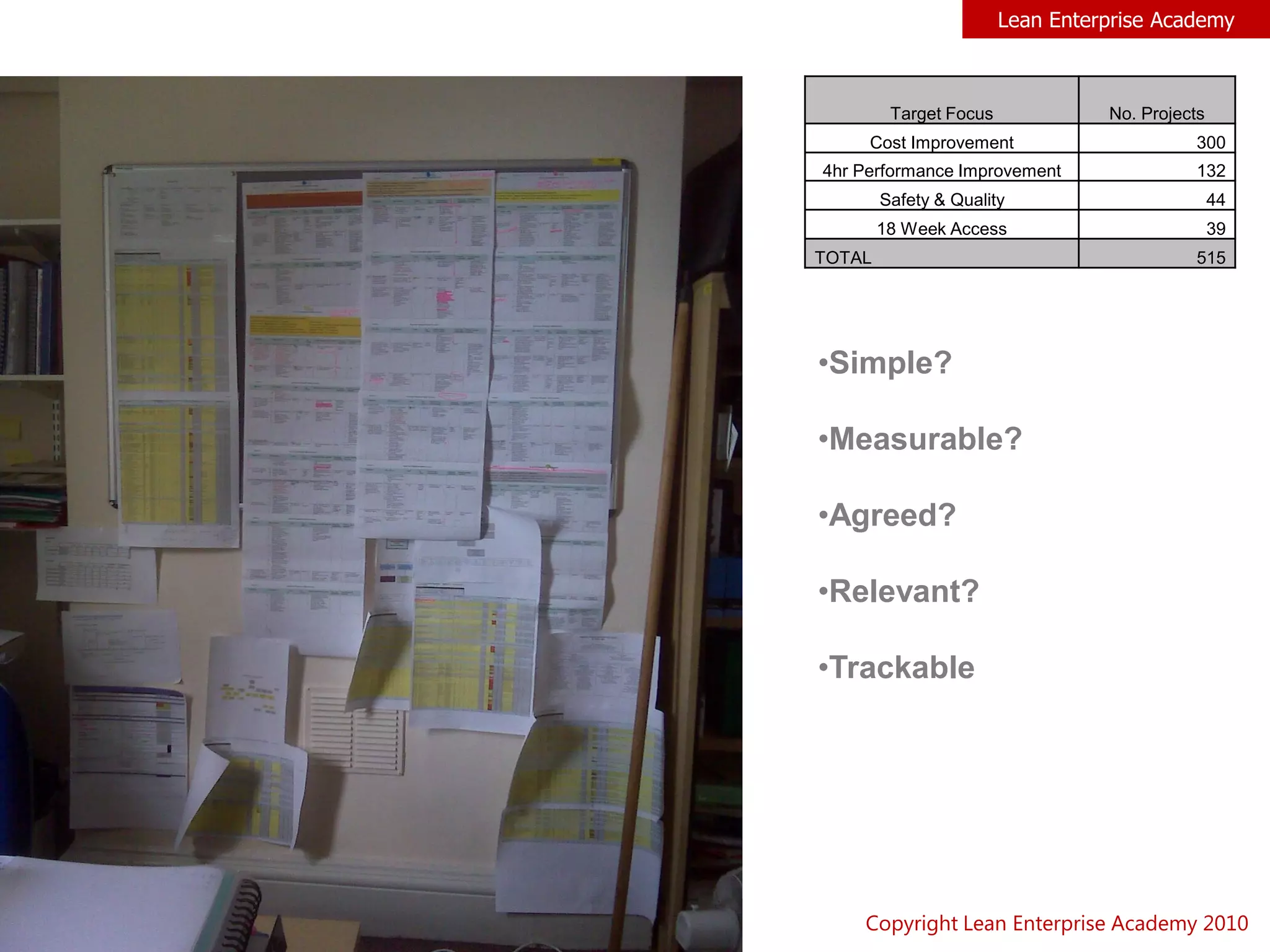

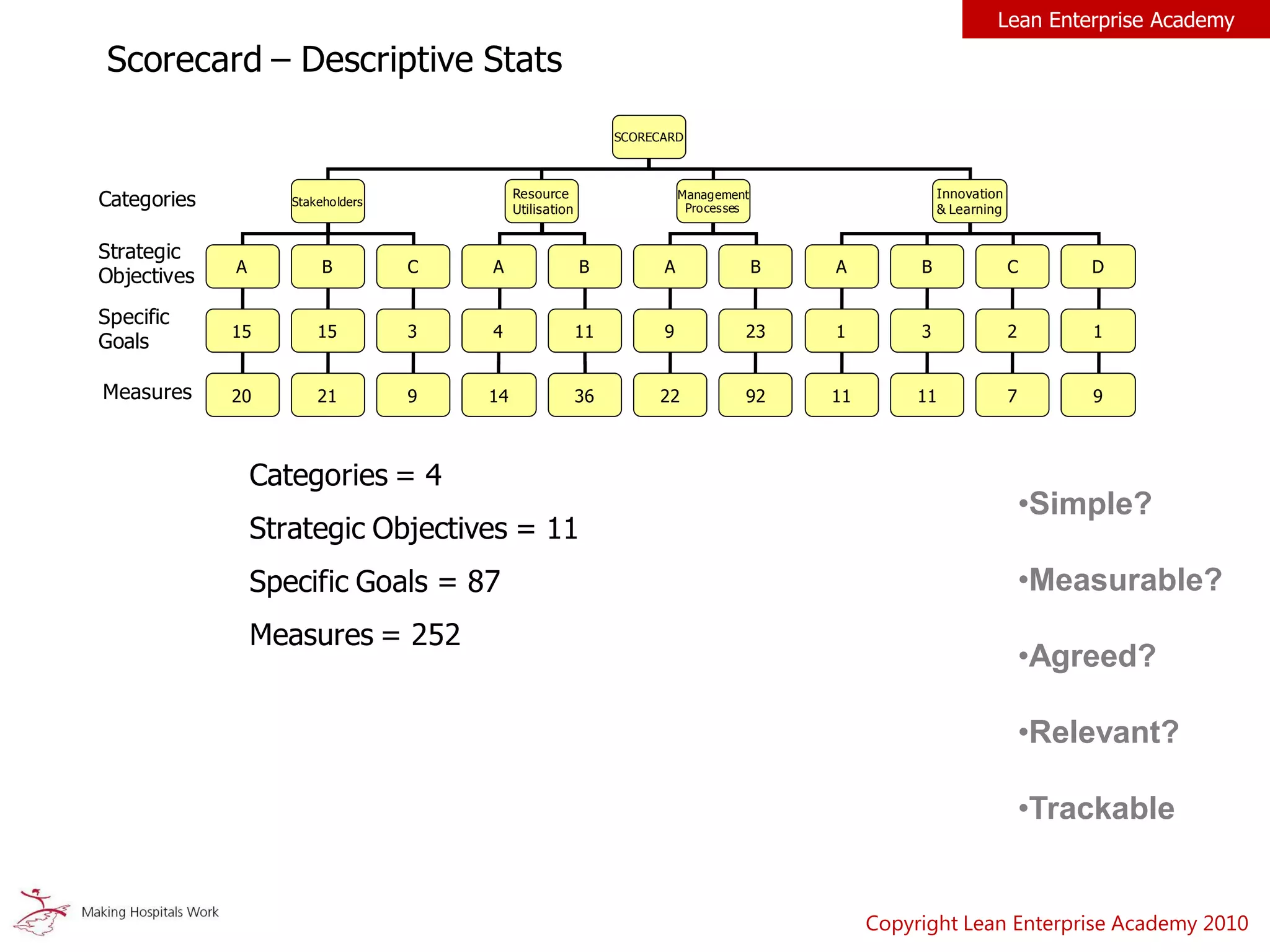

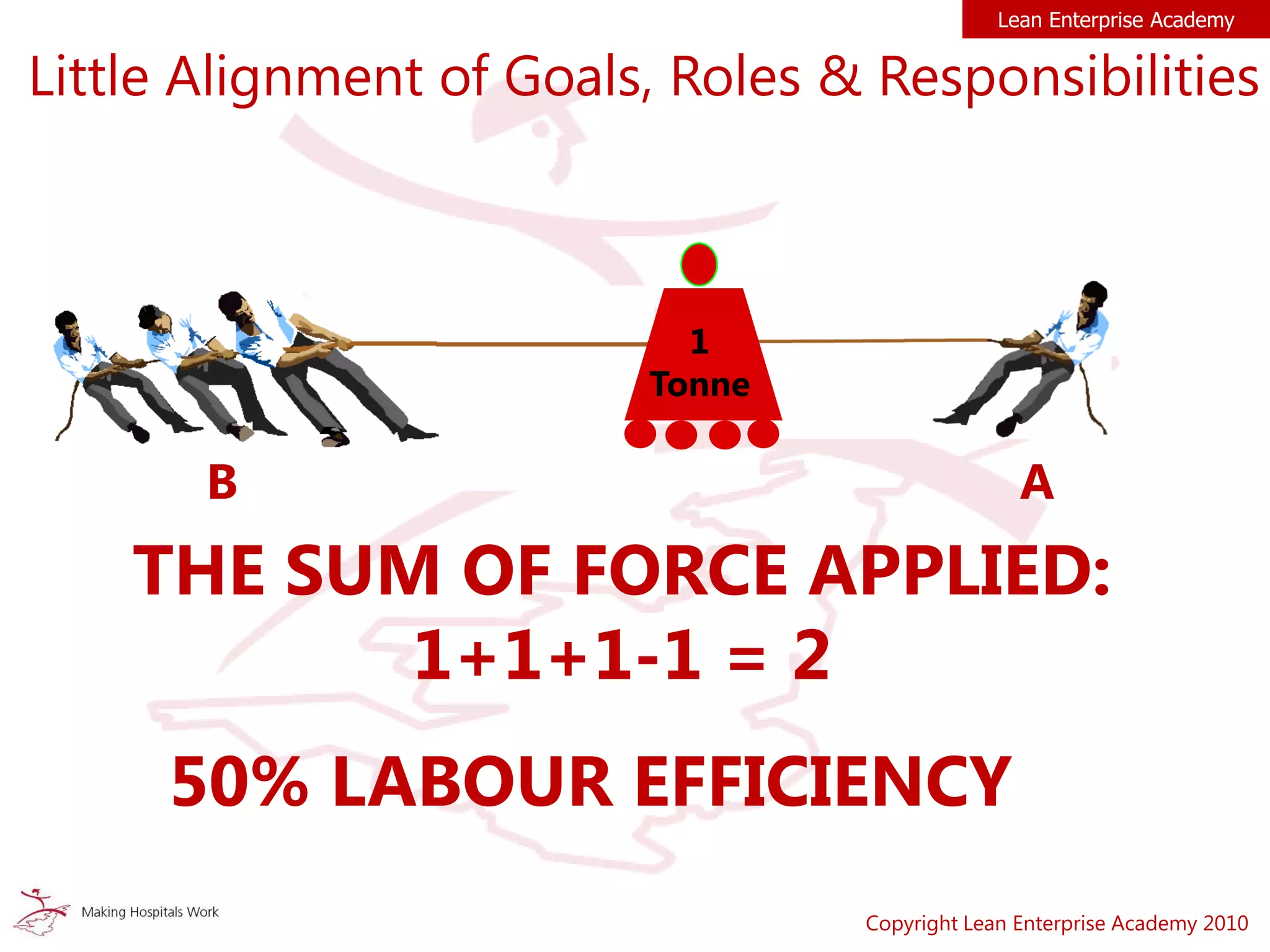

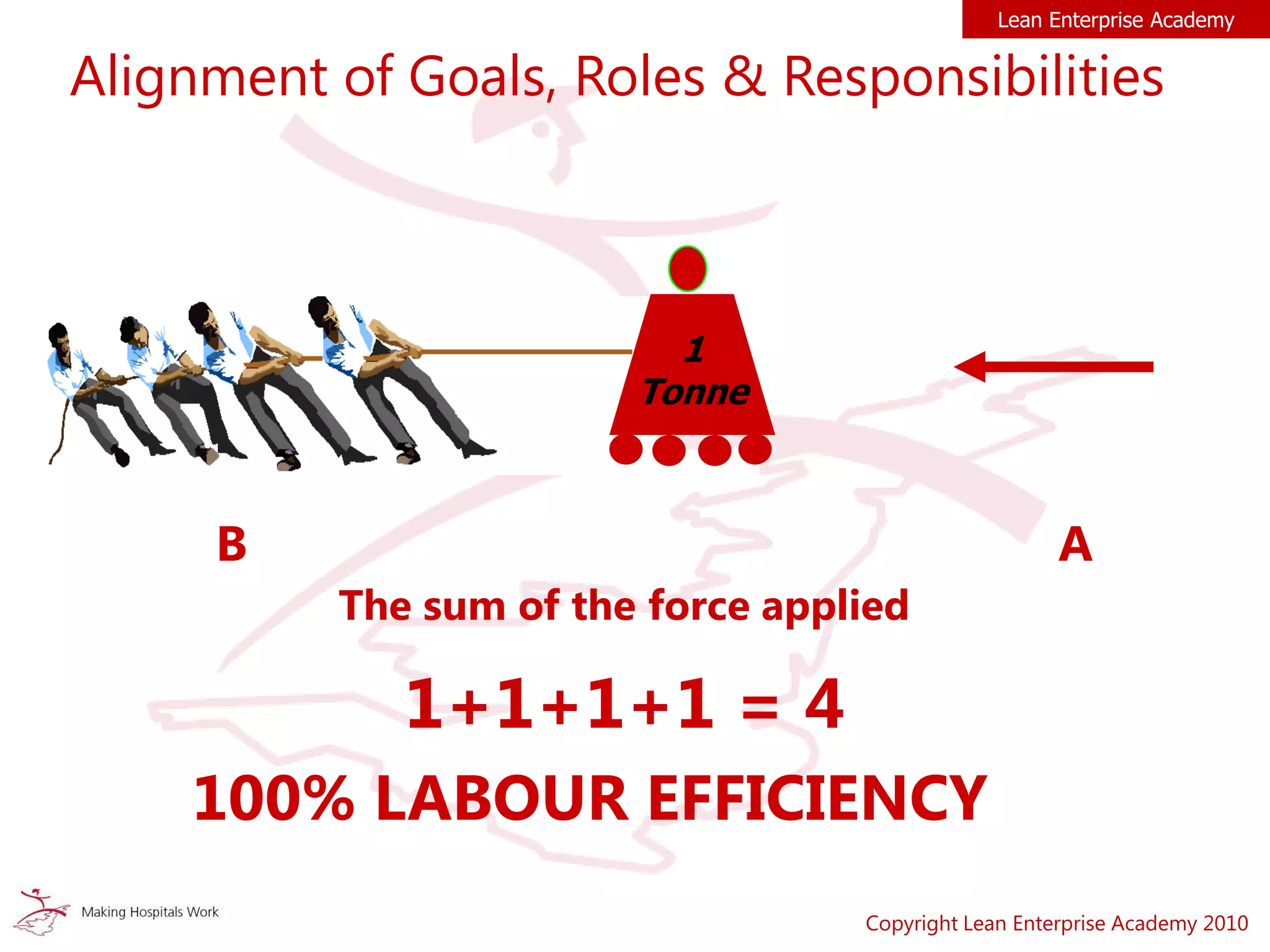

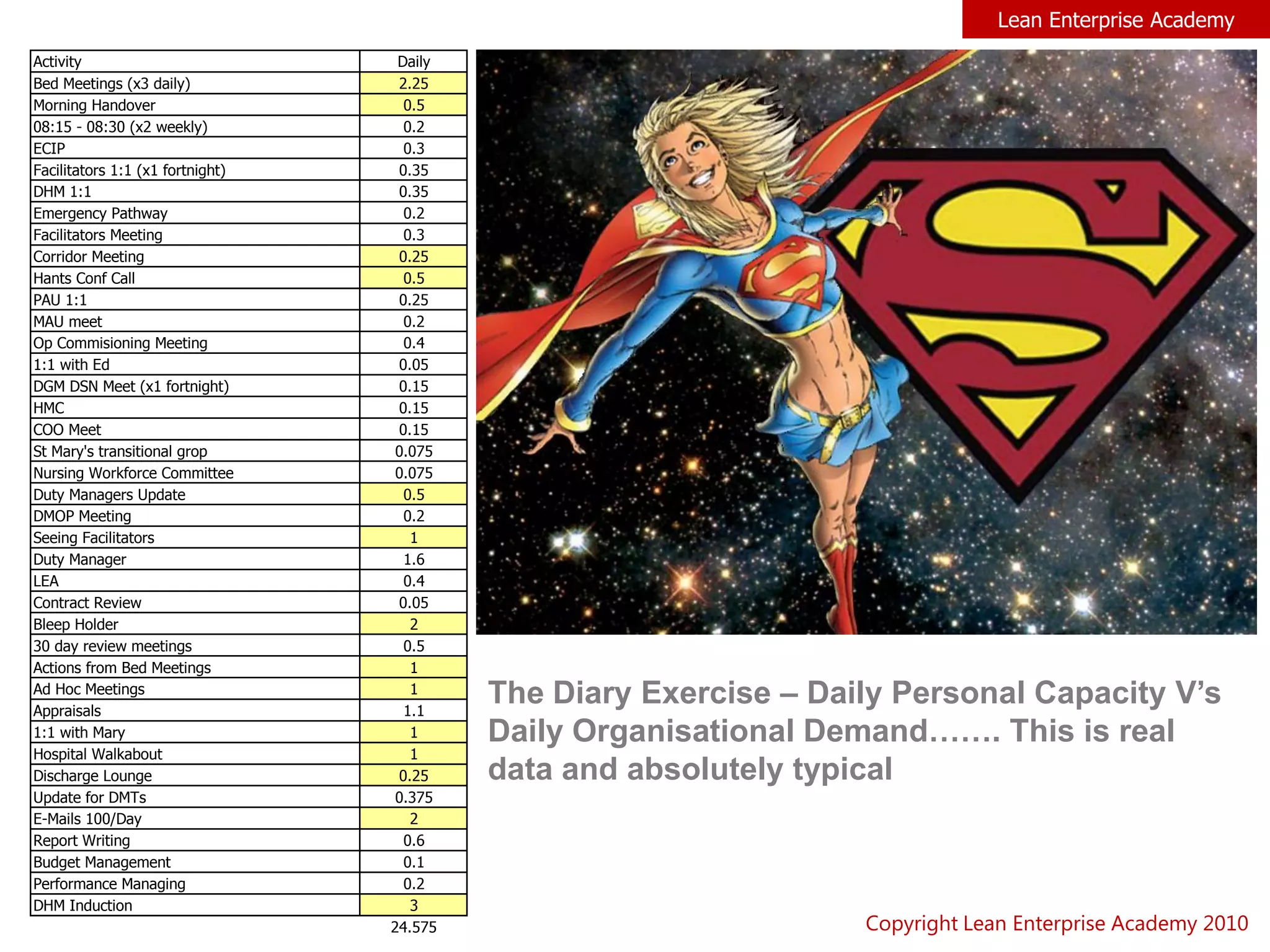

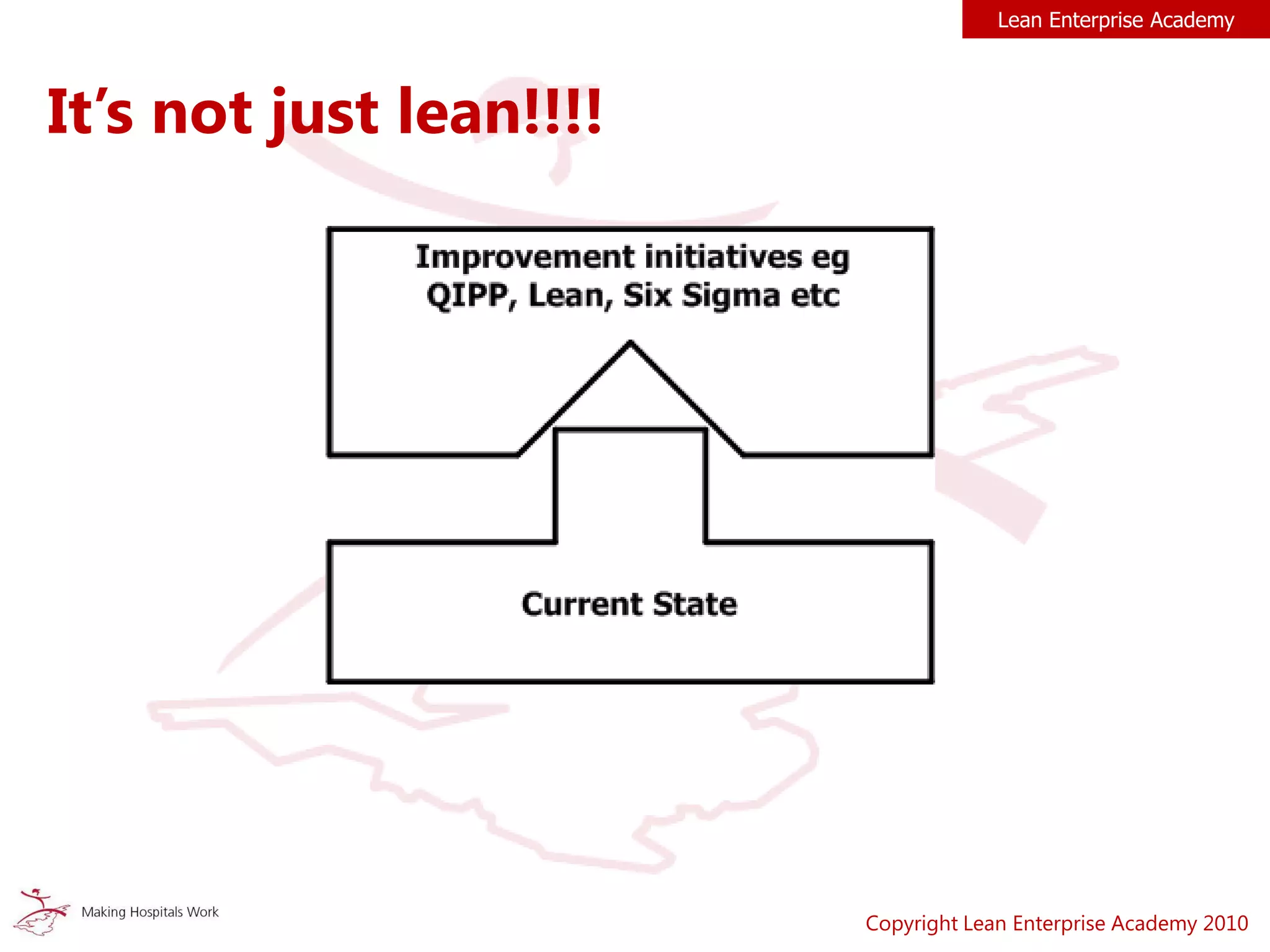

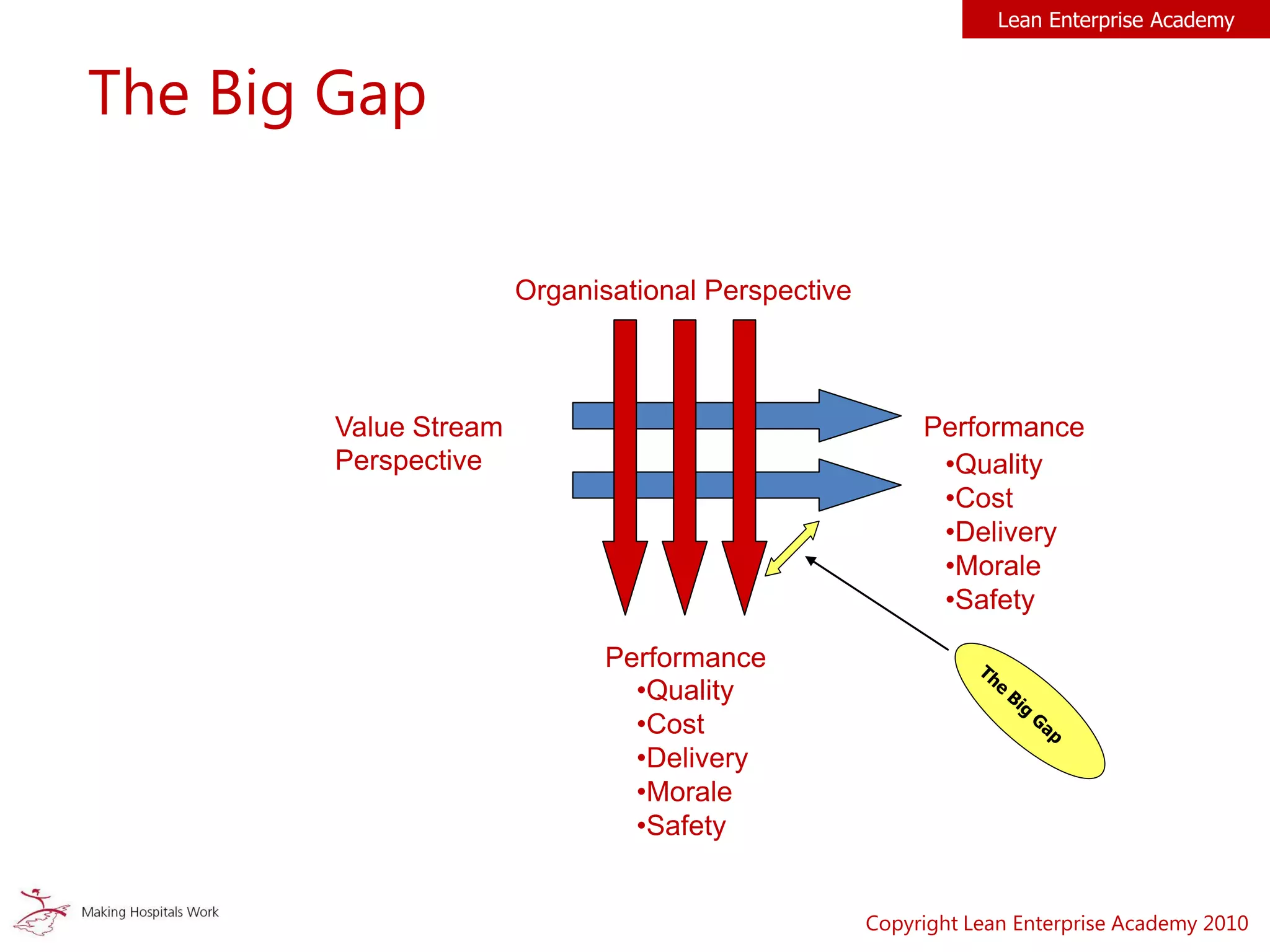

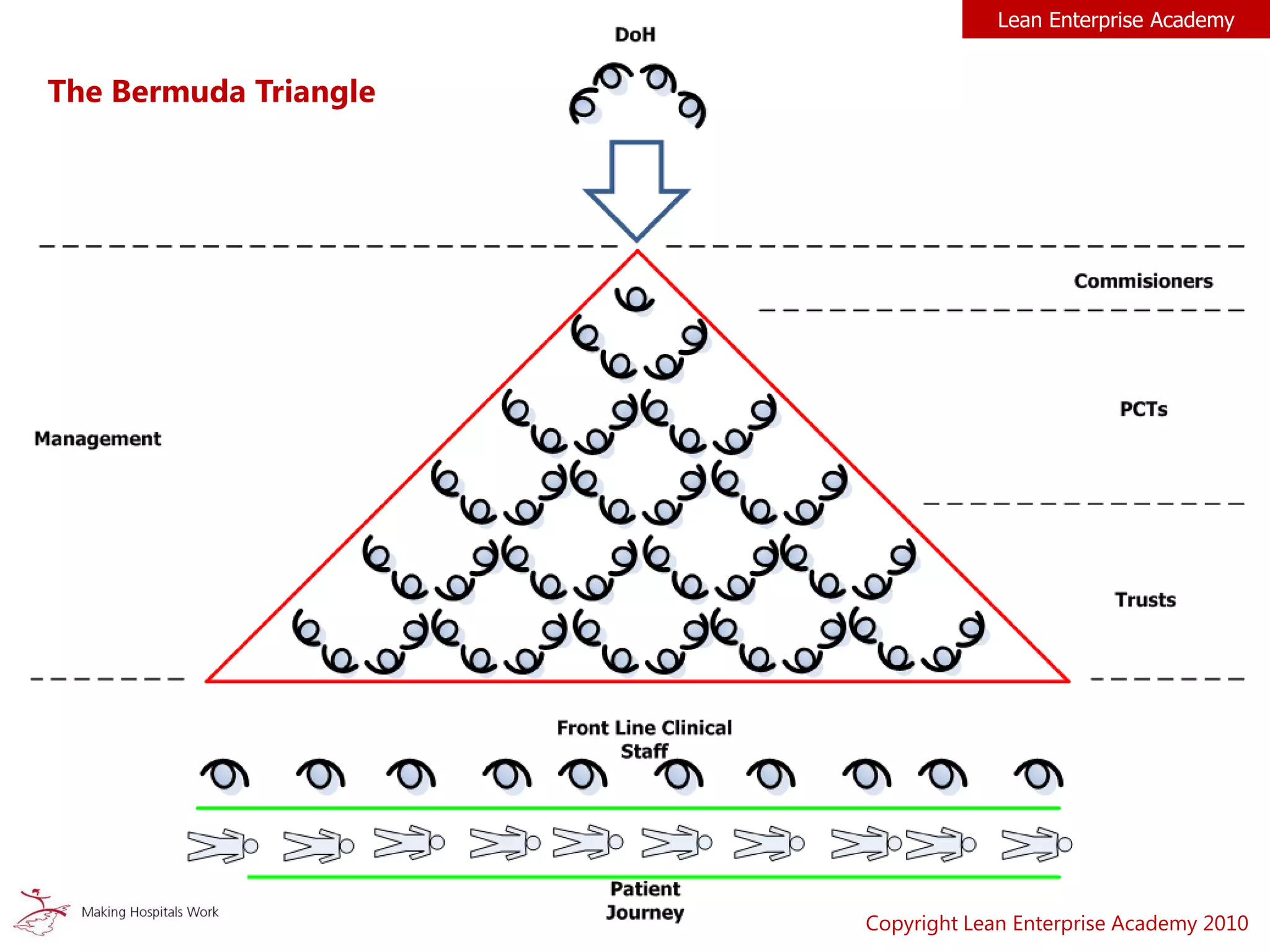

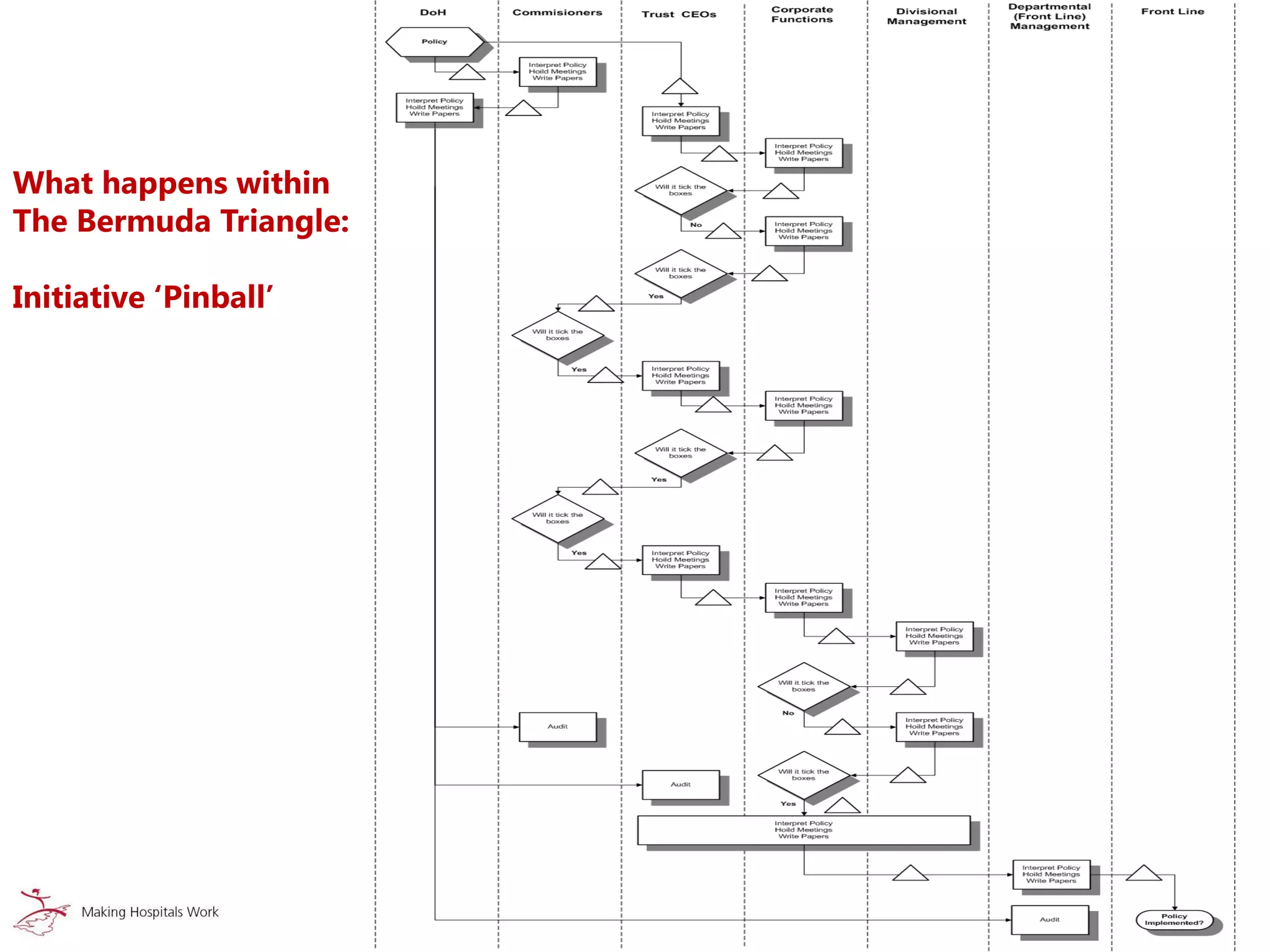

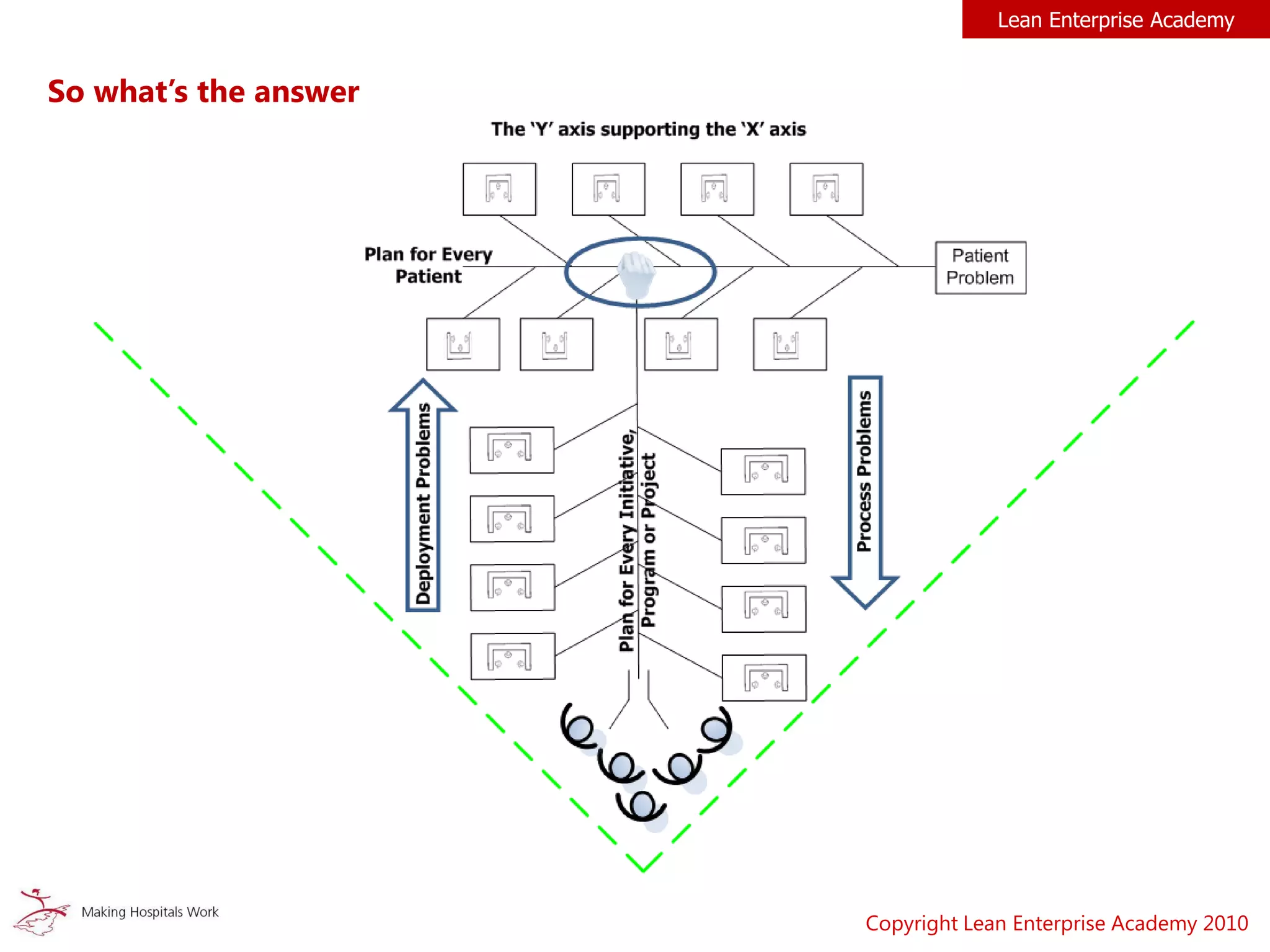

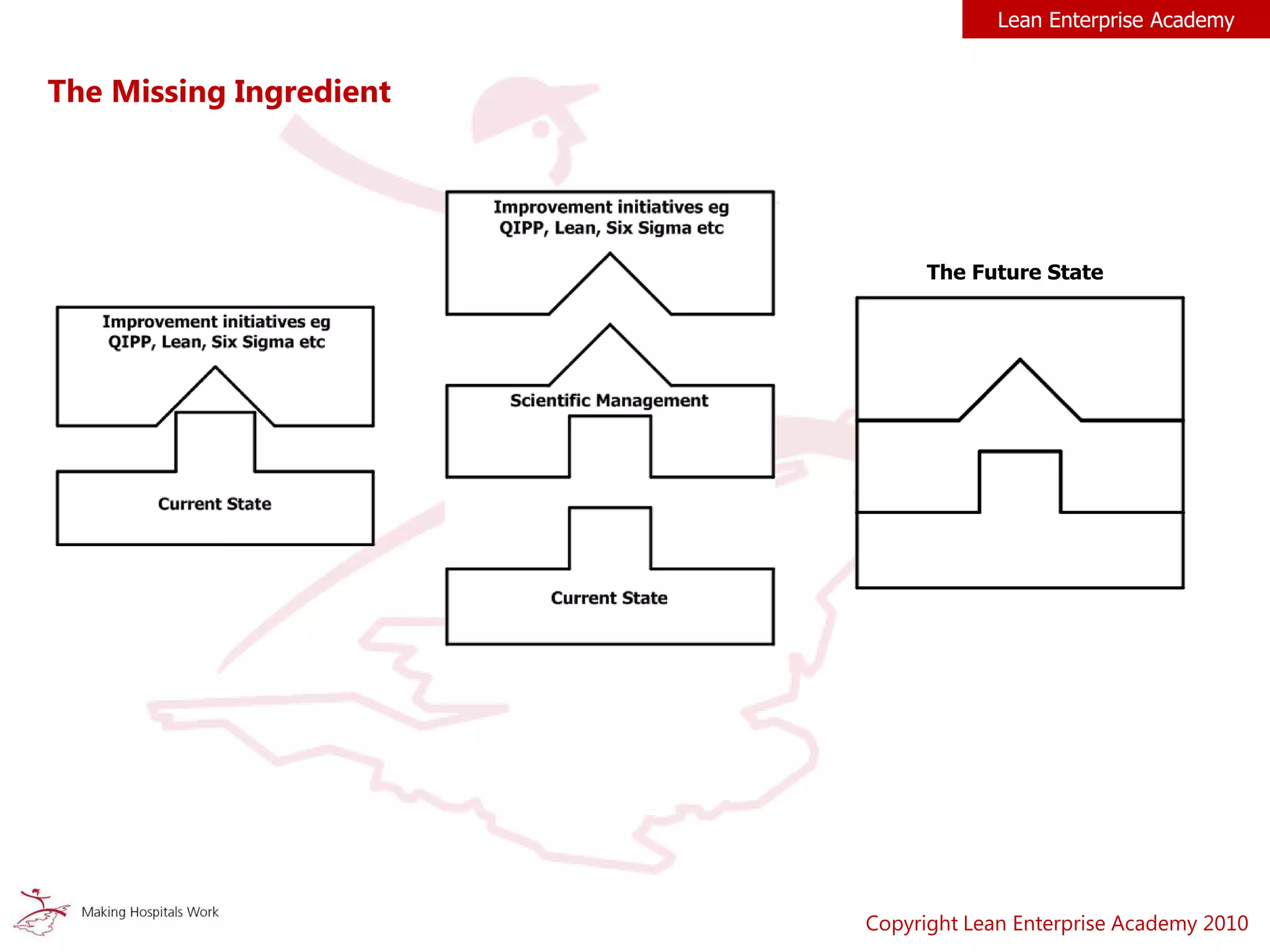

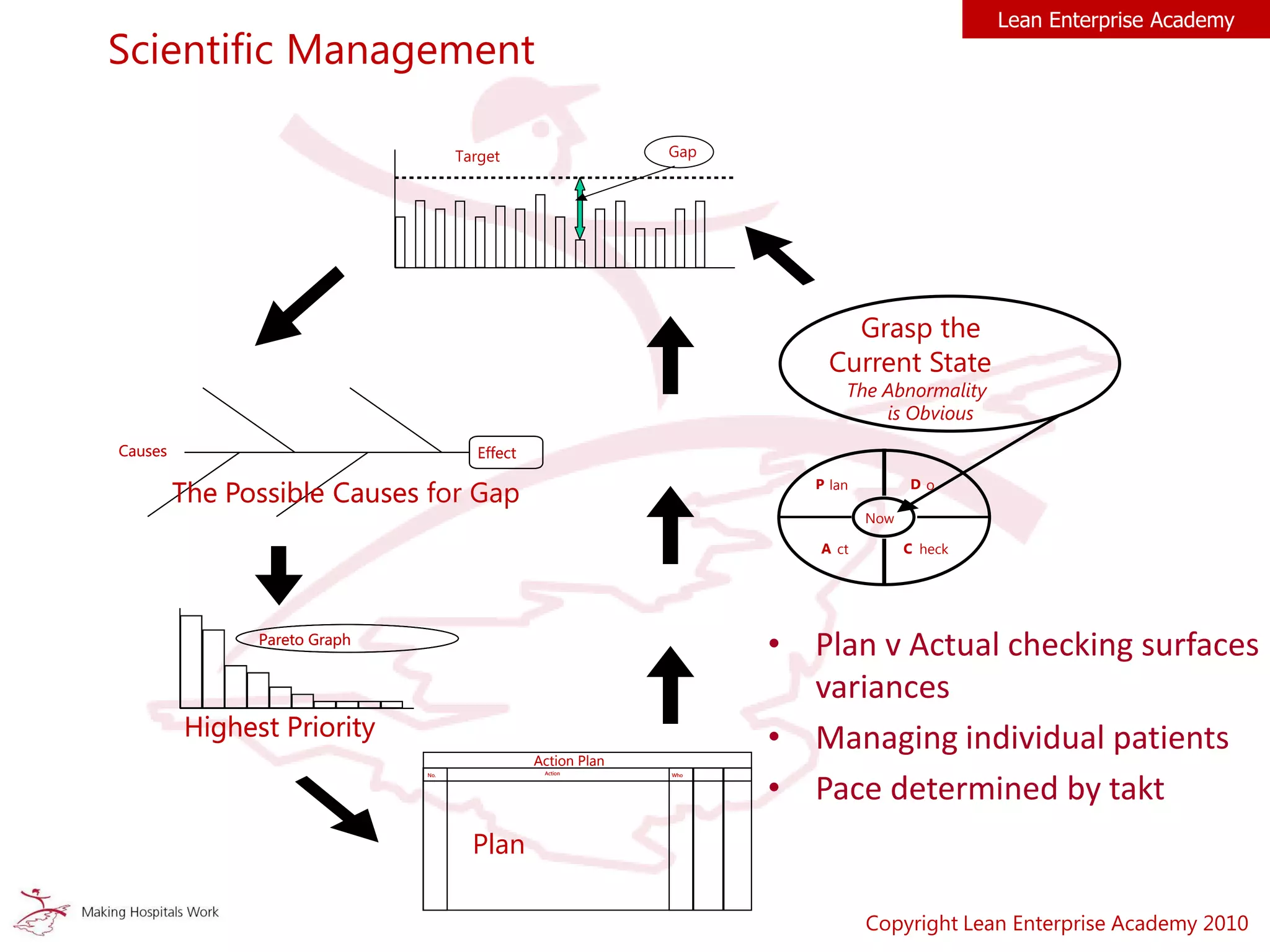

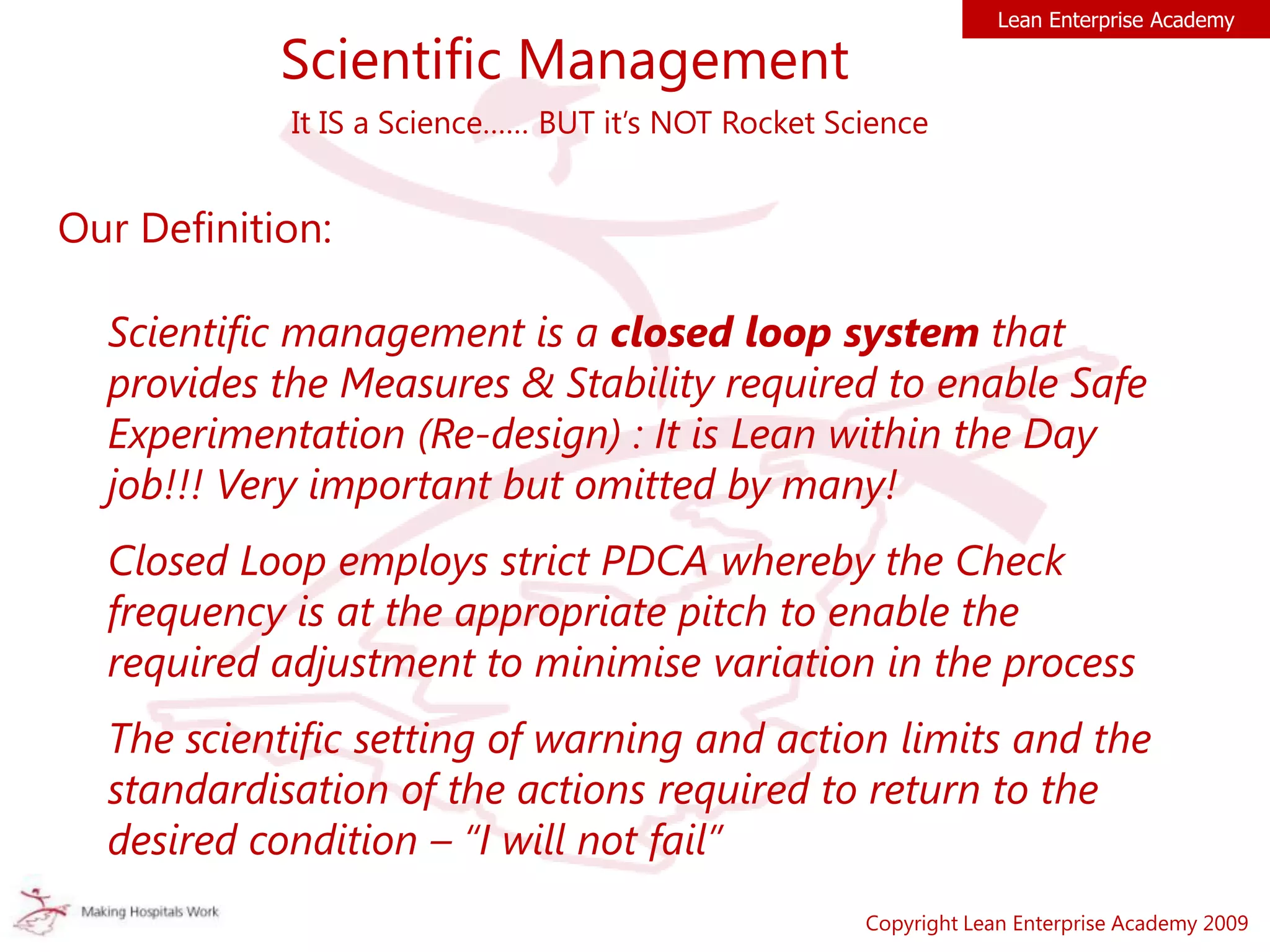

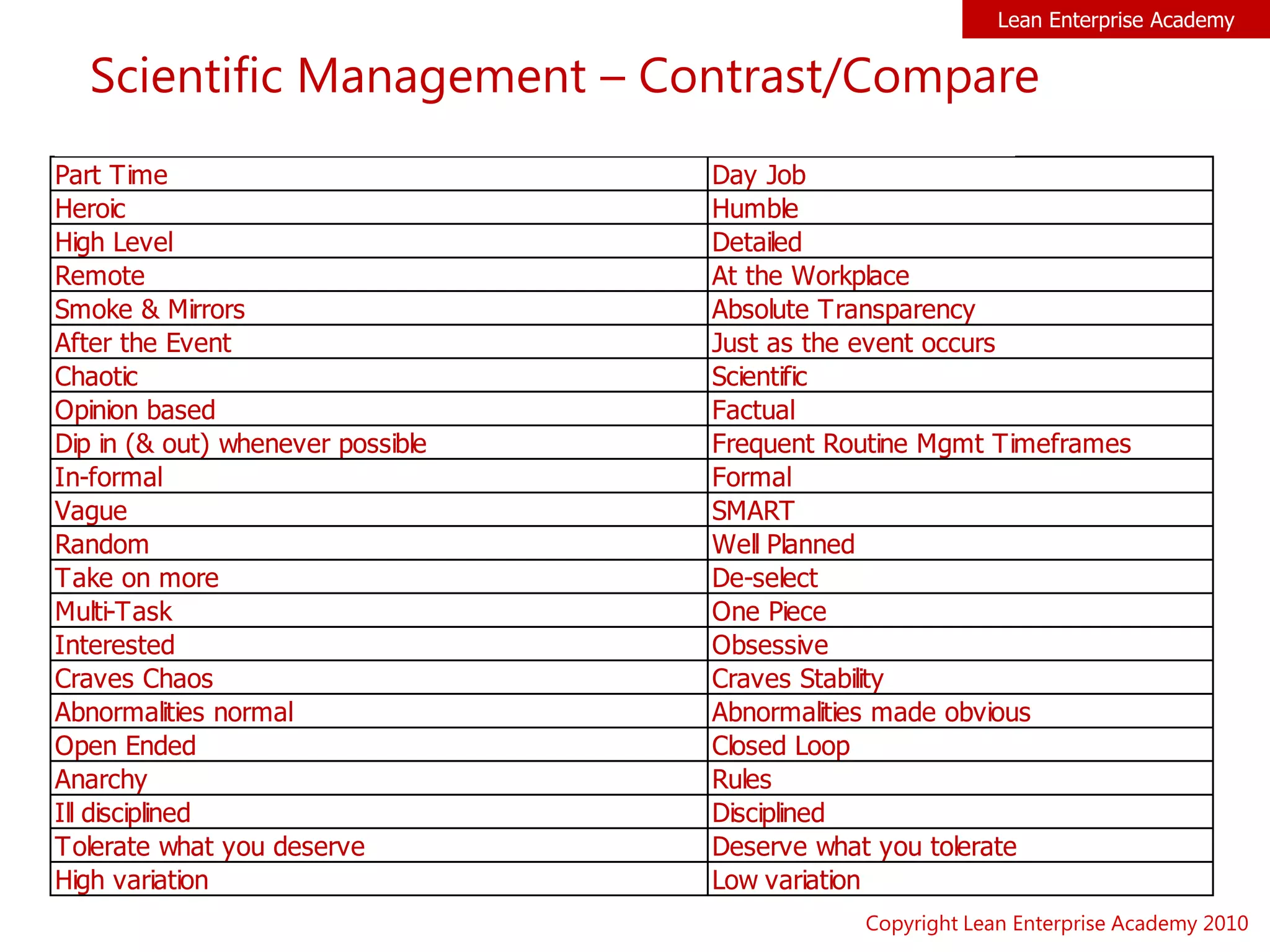

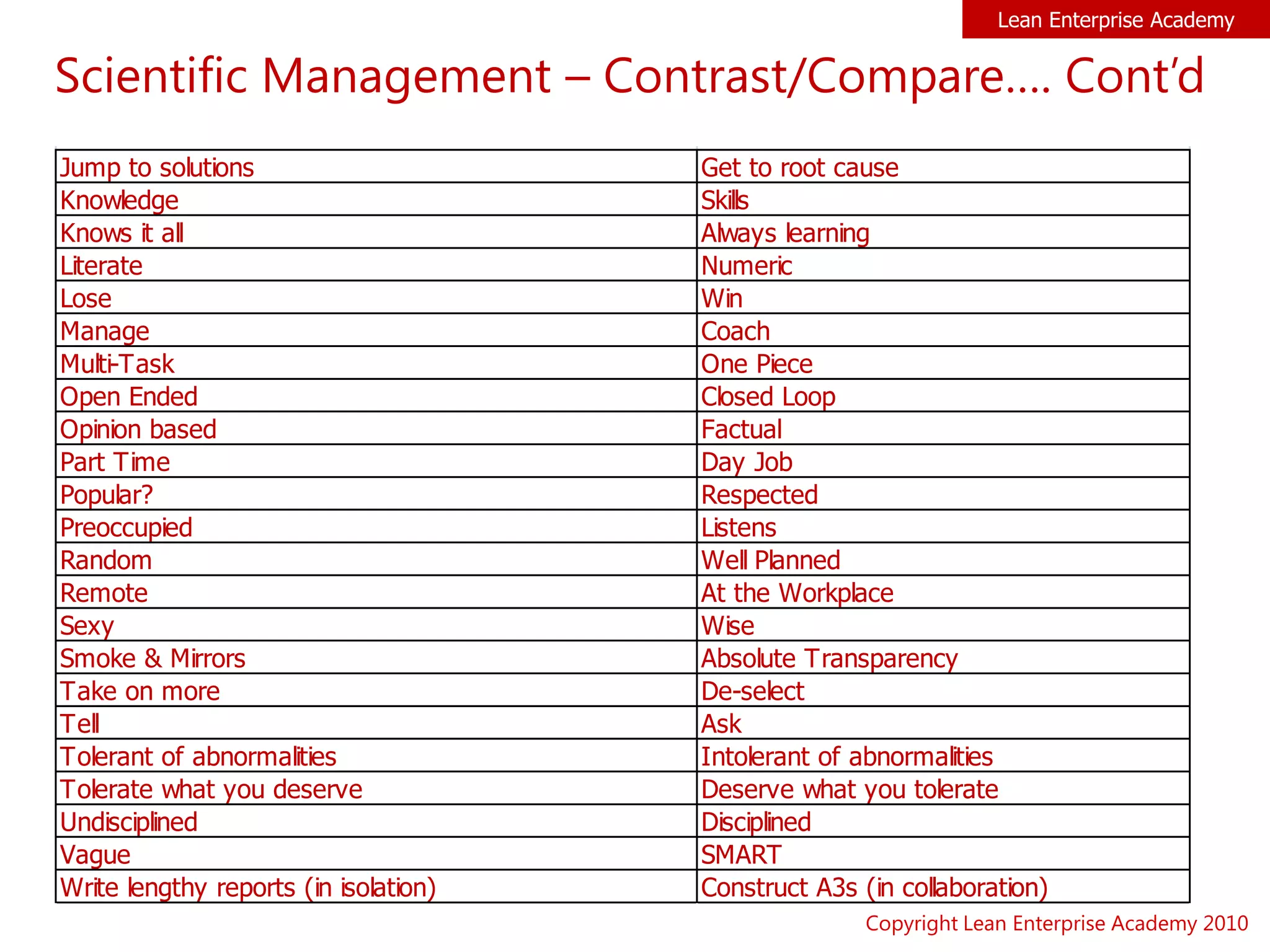

The document discusses the application of lean thinking in healthcare, highlighting its potential to improve patient care, costs, and quality. It emphasizes the challenges of implementing lean principles due to a lack of commitment from senior management and the current management structure. The document outlines various management processes, performance metrics, and the need for a cultural shift to successfully embed lean practices in healthcare operations.