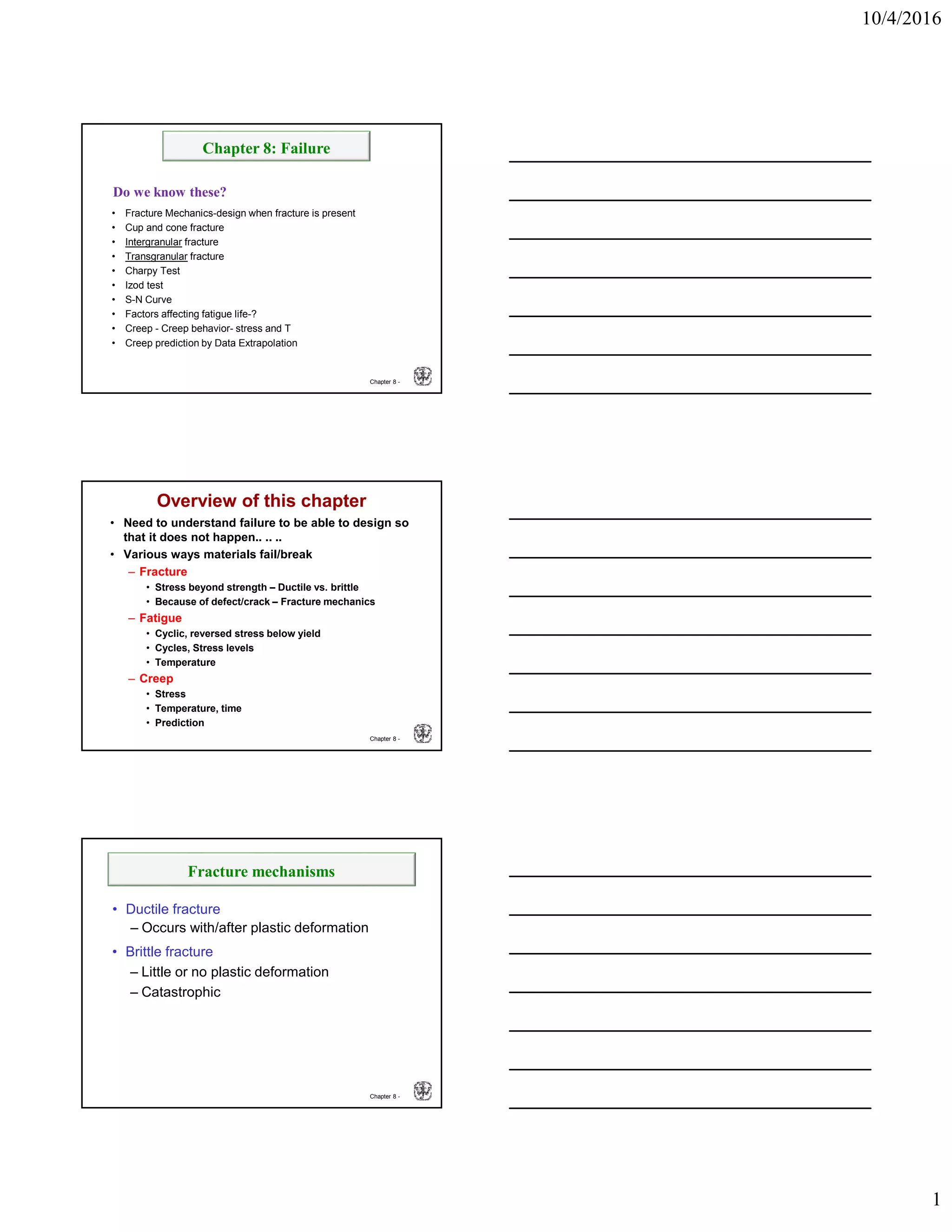

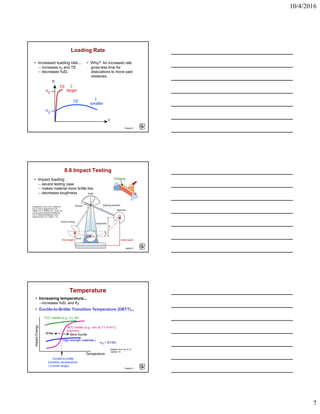

The document provides an overview of different failure mechanisms including fracture, fatigue, and creep. It discusses ductile versus brittle failure behavior and different types of brittle fractures such as intergranular and transgranular. Factors that influence failure properties are also covered, such as temperature, loading rate, and stress concentrators. Design considerations to prevent failure like avoiding sharp corners and reducing flaw sizes are presented.