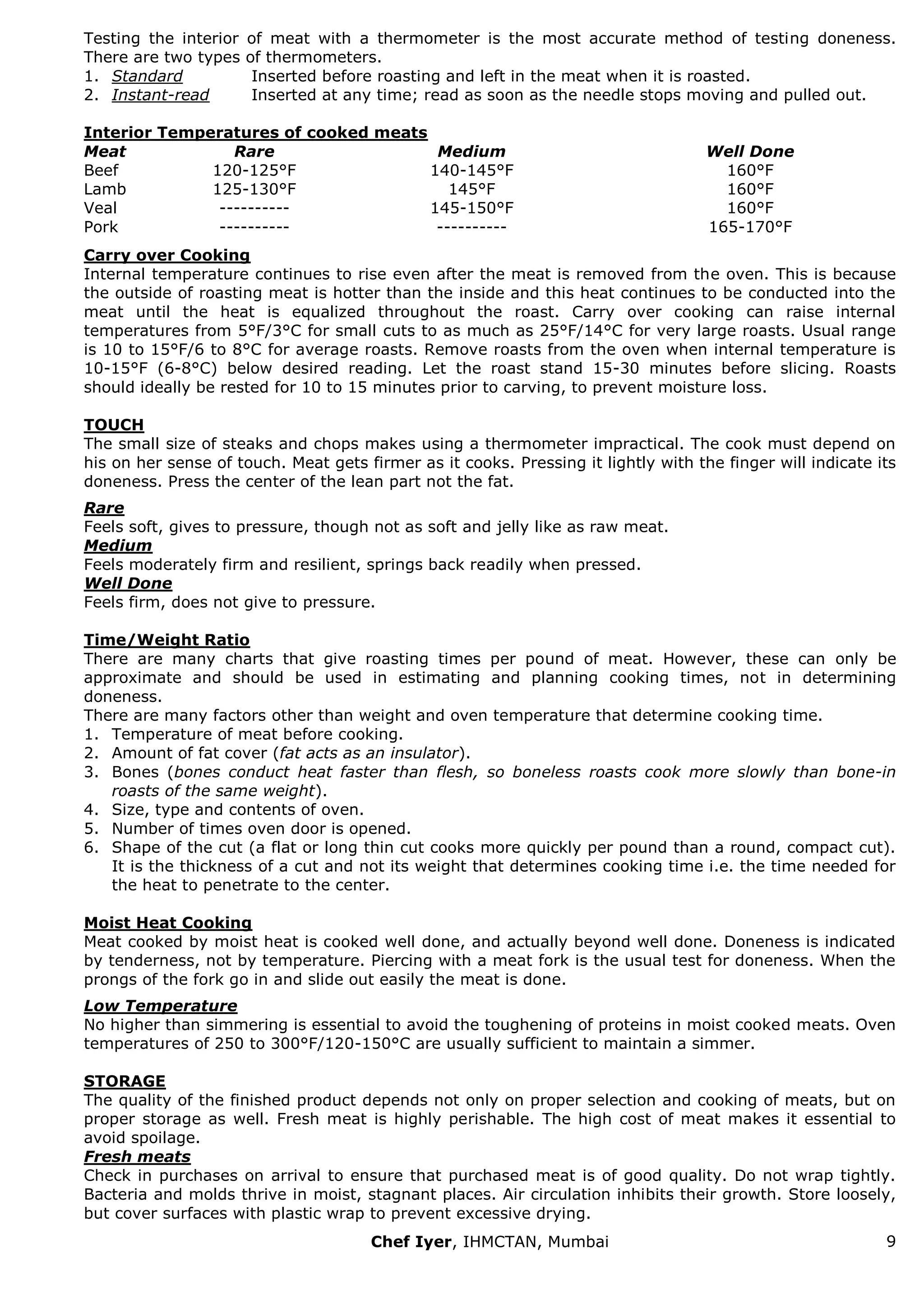

The document discusses the history and production of beef. It details how beef consumption evolved over time from being a luxury food for the wealthy to becoming more widely available in Europe. It then describes the classification and slaughter process for meat, including the inspection and handling of animal carcasses. Finally, it outlines the key components of skeletal muscle tissue that make up meat.