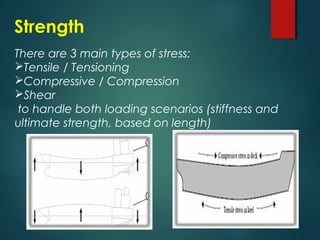

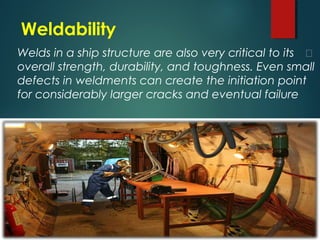

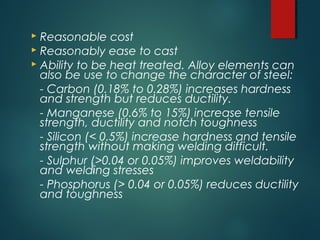

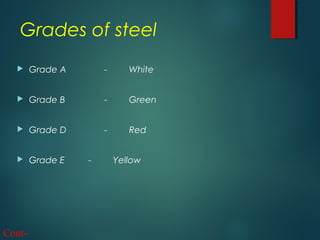

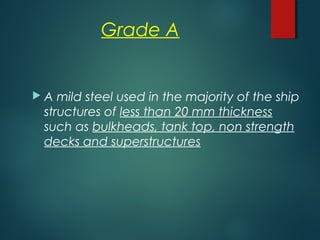

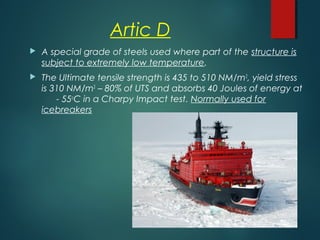

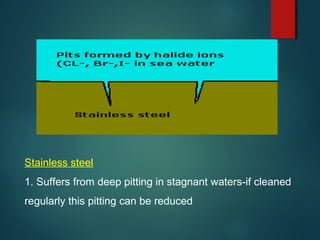

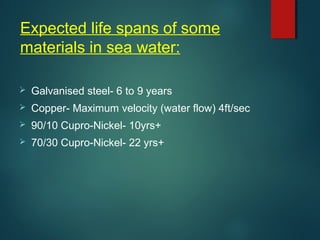

Steel is the most widely used material in shipbuilding, comprising about 90% of materials. The key properties materials must have include strength, weldability, toughness, resistance to marine corrosion, formability, and cost effectiveness. Various grades of steel are used - Grade A for thinner structures, Grade B for medium thickness, and Grades D and E for thicker, high-stress areas. Materials used in sea water systems include 90/10 cupro-nickel, which is resistant to corrosion and clogging, and stainless steel, which requires regular cleaning to prevent pitting. Expected lifespans are 6-9 years for galvanized steel and over 10 years for cupro-nickel alloys.