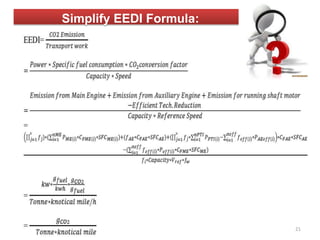

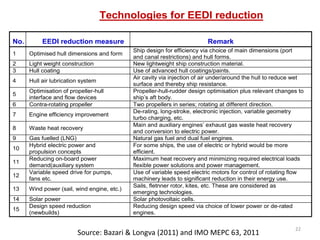

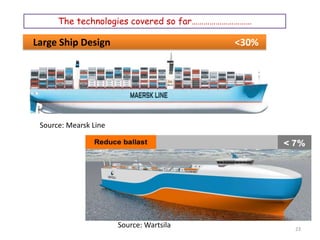

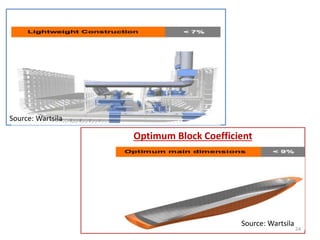

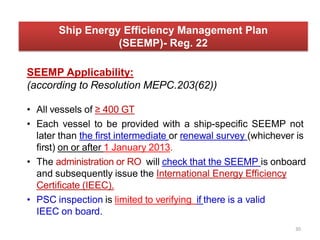

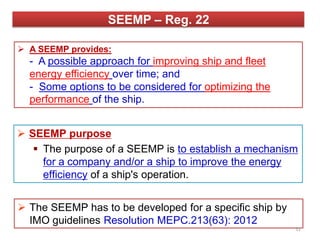

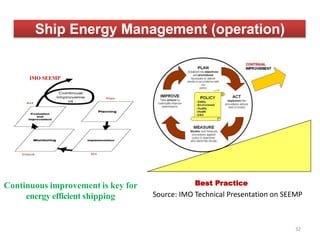

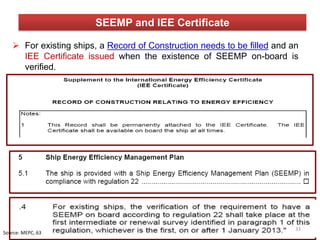

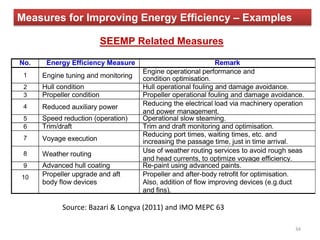

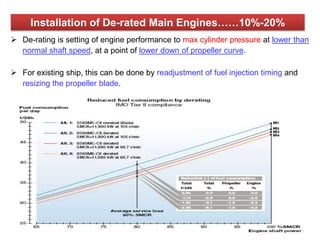

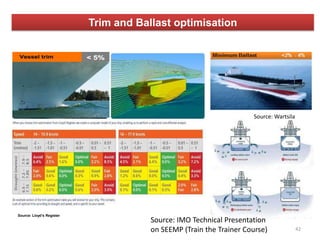

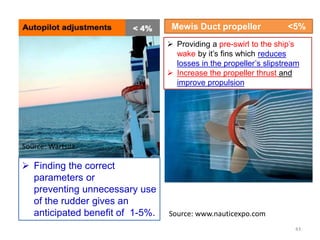

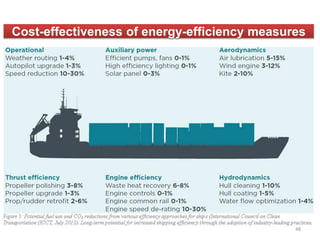

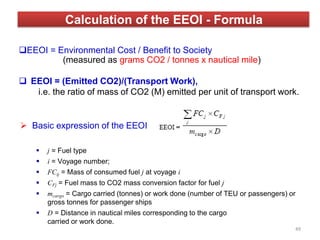

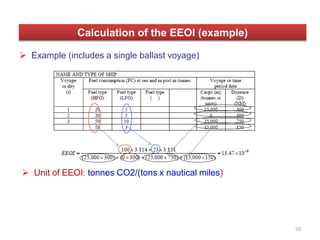

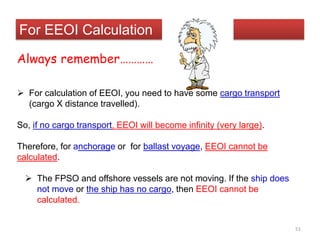

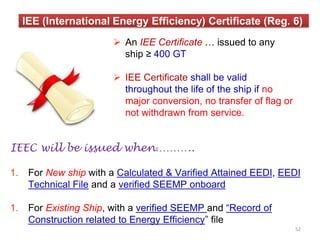

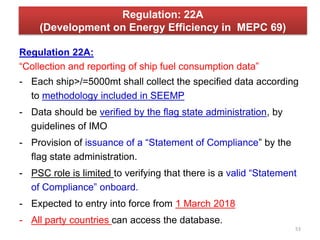

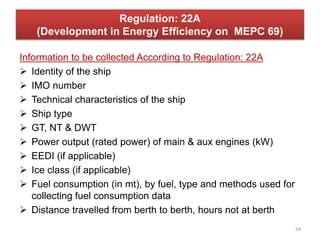

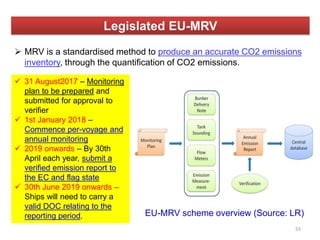

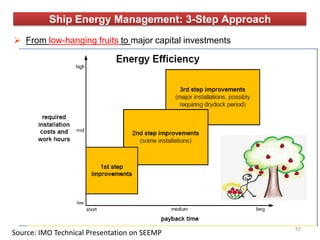

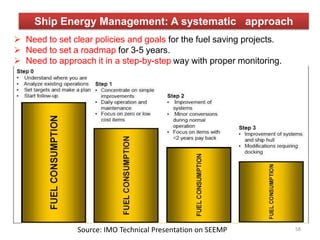

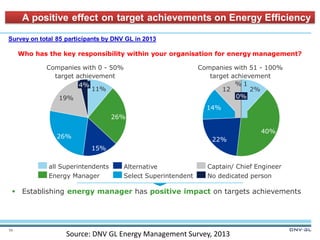

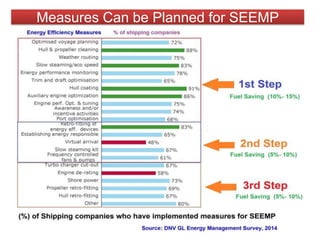

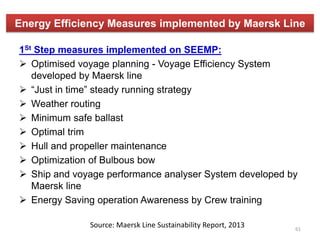

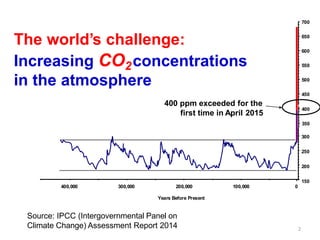

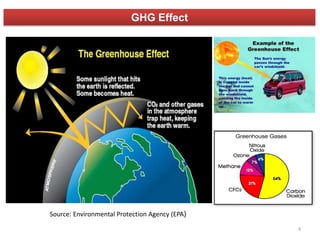

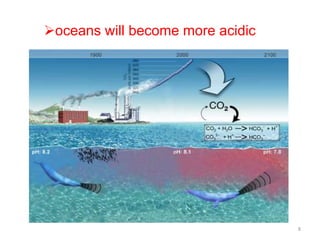

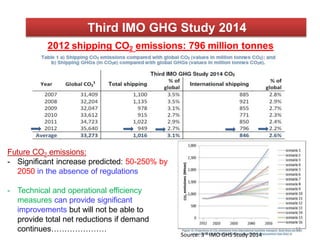

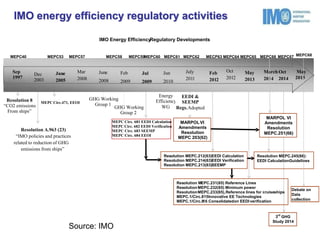

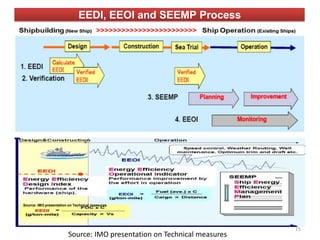

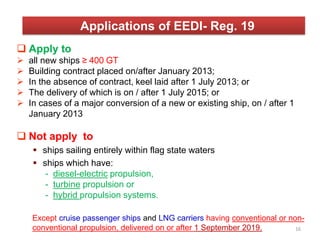

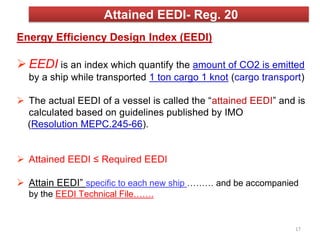

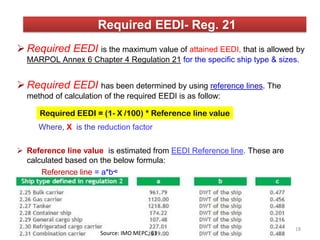

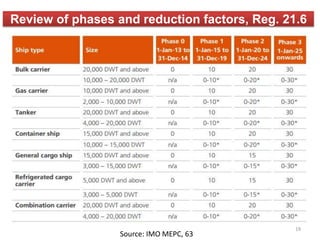

The document outlines the urgent need for improving ship energy efficiency to combat rising CO2 emissions and climate change, referencing key global frameworks and the International Maritime Organization's (IMO) policies. It details various energy efficiency measures, such as the Energy Efficiency Design Index (EEDI) and Ship Energy Management Plan (SEEMP), aimed at reducing greenhouse gas emissions from maritime operations. The text emphasizes the significance of adopting innovative technologies and operational strategies to enhance performance and minimize environmental impacts in shipping industries.

![Main Engine(s) Aux

Engine(s)

Innovative Energy Eff.

Power Gen.

Technologies

Innovative

Energy Eff.

Propulsion

Technologies

Boilers are excluded from EEDI

EEDI =

[gCO2/(tonne.nm)]

fc.

Attained EEDI: Calculation formula

Source: IMO presentation on

Technical measures

20](https://image.slidesharecdn.com/shipenergyefficiencymanagement-160530011330/85/Ship-Energy-Efficiency-Management-2016-20-320.jpg)