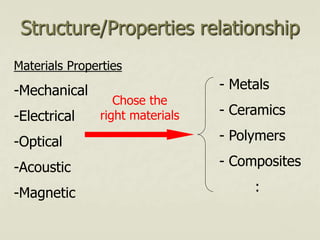

The document discusses the structure and properties of materials at different scales, from the atomic level to the macroscale. It explains that materials are made up of electrons, protons and neutrons and can have crystalline, amorphous or composite microscopic structures depending on their composition and processing. The structure of materials determines their mechanical, electrical, optical and other properties. Understanding the relationships between a material's processing, resulting microstructure and final properties is important for materials design and selection.