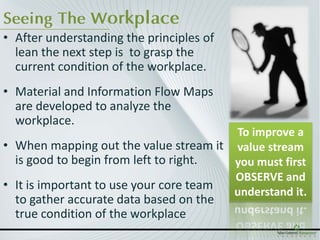

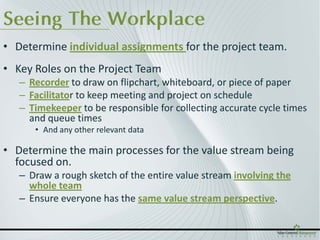

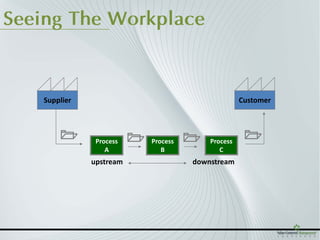

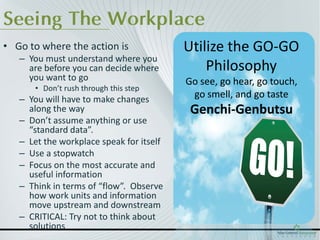

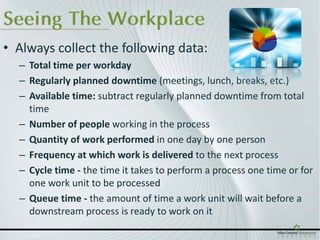

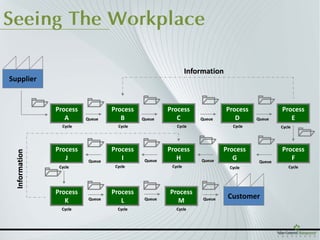

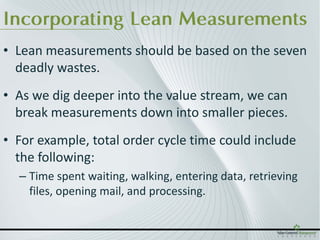

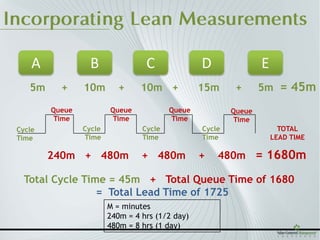

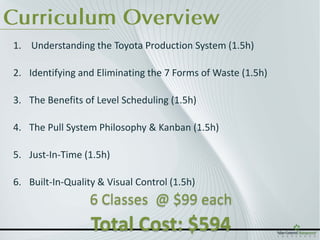

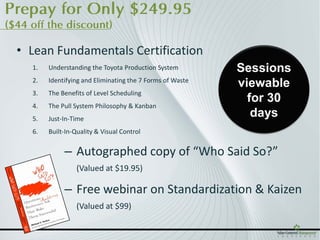

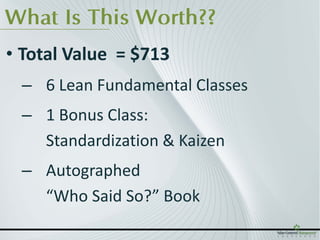

The document outlines a webinar presented by Michael E. Parker focusing on materials and information flow mapping as part of a value-centered solutions approach. It covers the importance of lean measurements, data collection for workplace analysis, and provides insights into lean certification and training offerings. Key topics include understanding the current workplace conditions, identifying lean metrics related to value stream processes, and improving efficiency through continuous improvement principles.