Embed presentation

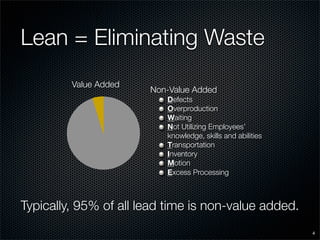

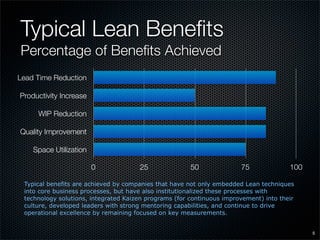

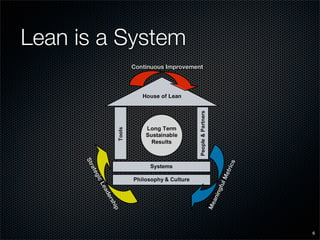

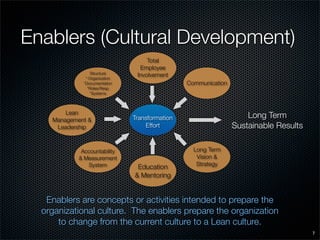

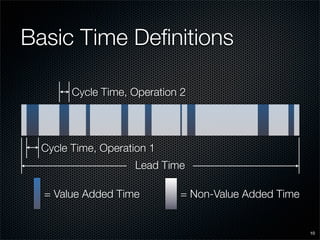

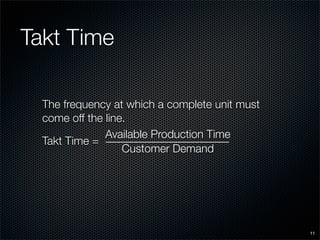

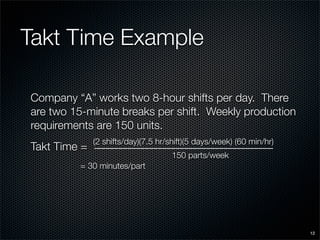

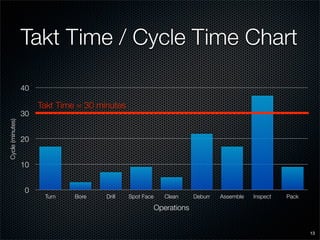

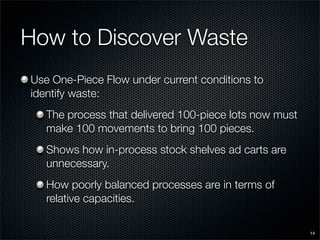

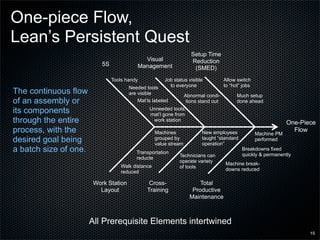

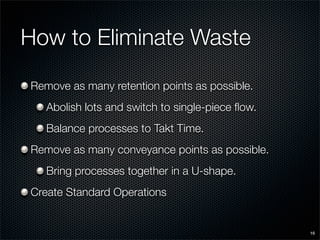

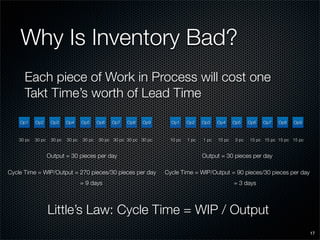

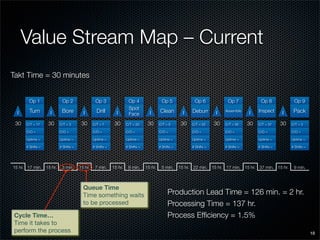

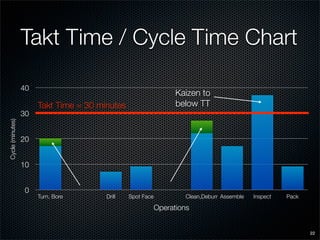

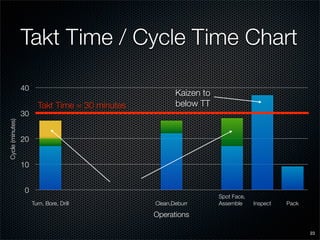

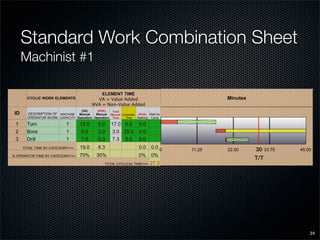

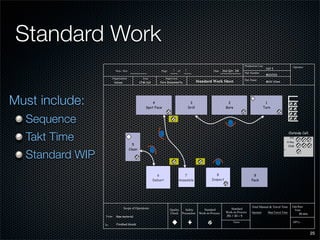

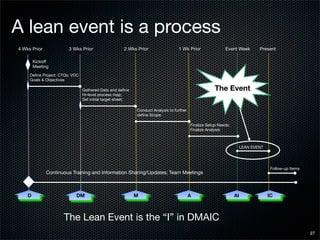

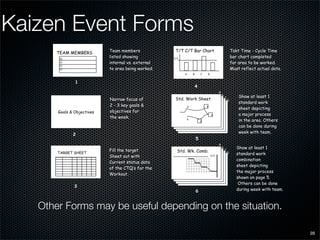

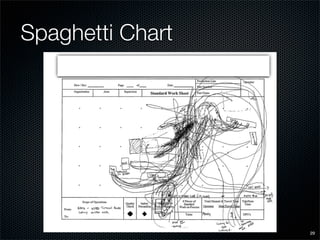

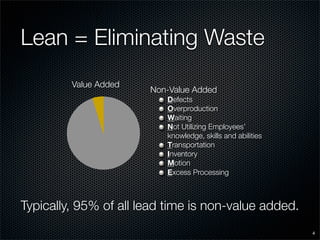

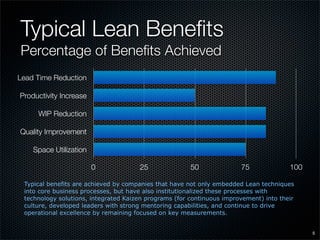

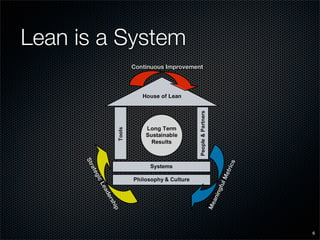

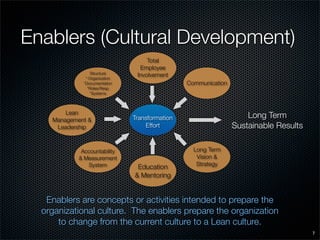

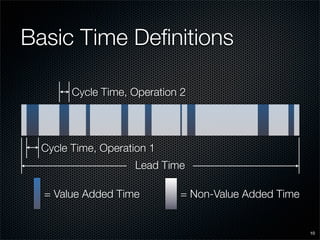

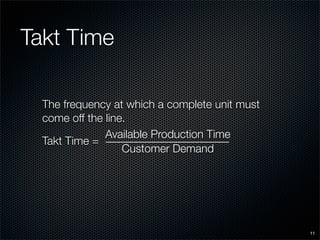

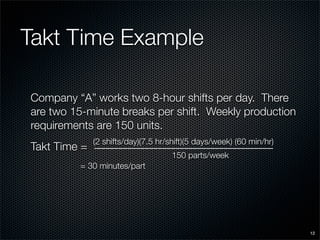

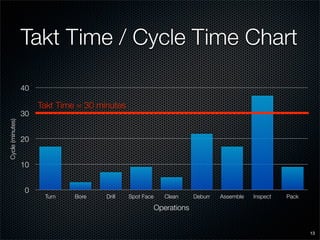

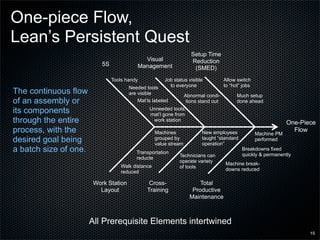

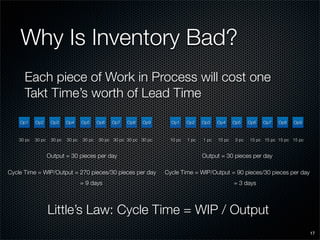

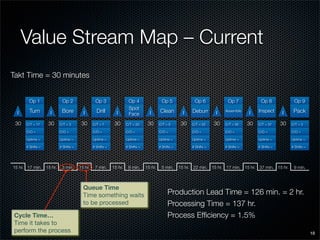

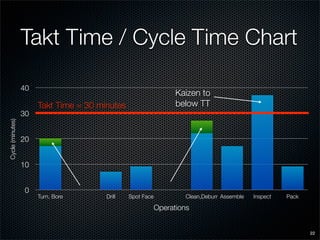

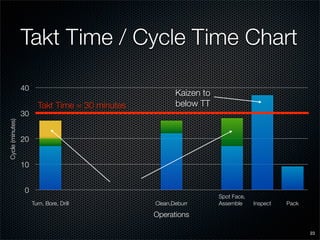

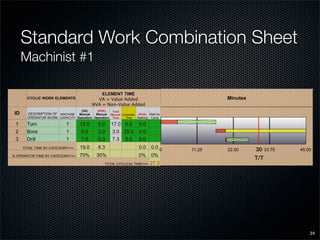

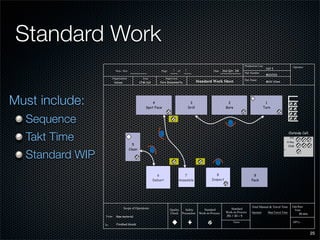

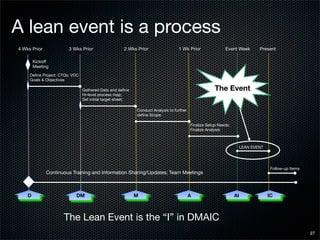

The document provides an overview of lean transformations, emphasizing the systematic approach of identifying and eliminating waste through continuous improvement driven by customer demand. Key elements include cultural change, practical tools for efficiency, and the importance of leadership involvement, education, and the right mindset to facilitate transformation. It outlines typical benefits, requirements for successful implementation, and various techniques like value stream mapping and takt time analysis to streamline processes and enhance productivity.