The document outlines the syllabus for a Material Science course with the following aims:

1) Provide an understanding of the mechanics, physical and chemical properties of materials including metals, ceramics, polymers and composites.

2) Cover 18 modules on topics ranging from atomic structure and bonding to mechanical properties, phase diagrams, applications and processing of different materials.

3) Total of 60 lecture hours to cover the various modules and learning units within each module.

![Satish V. Kailas ME/MS 19

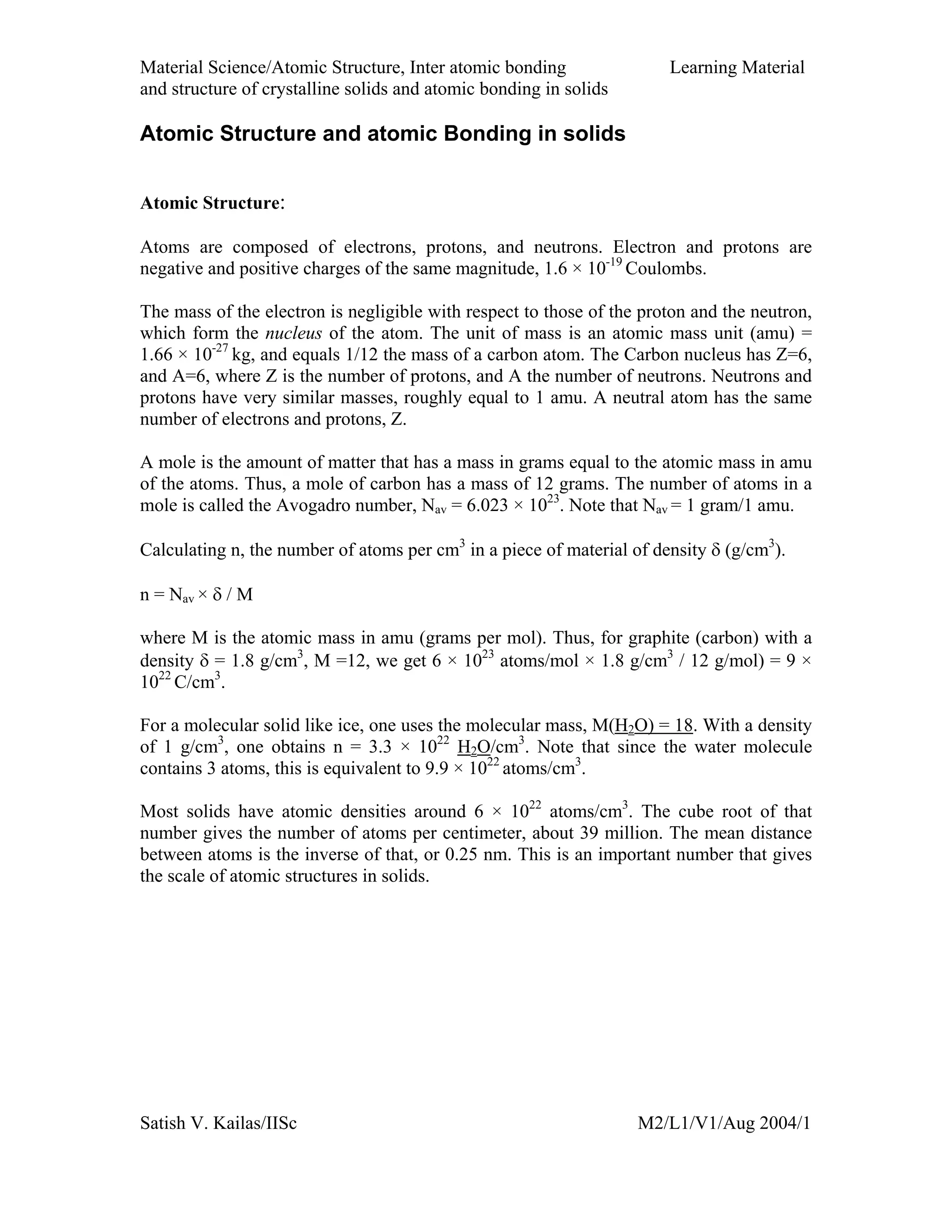

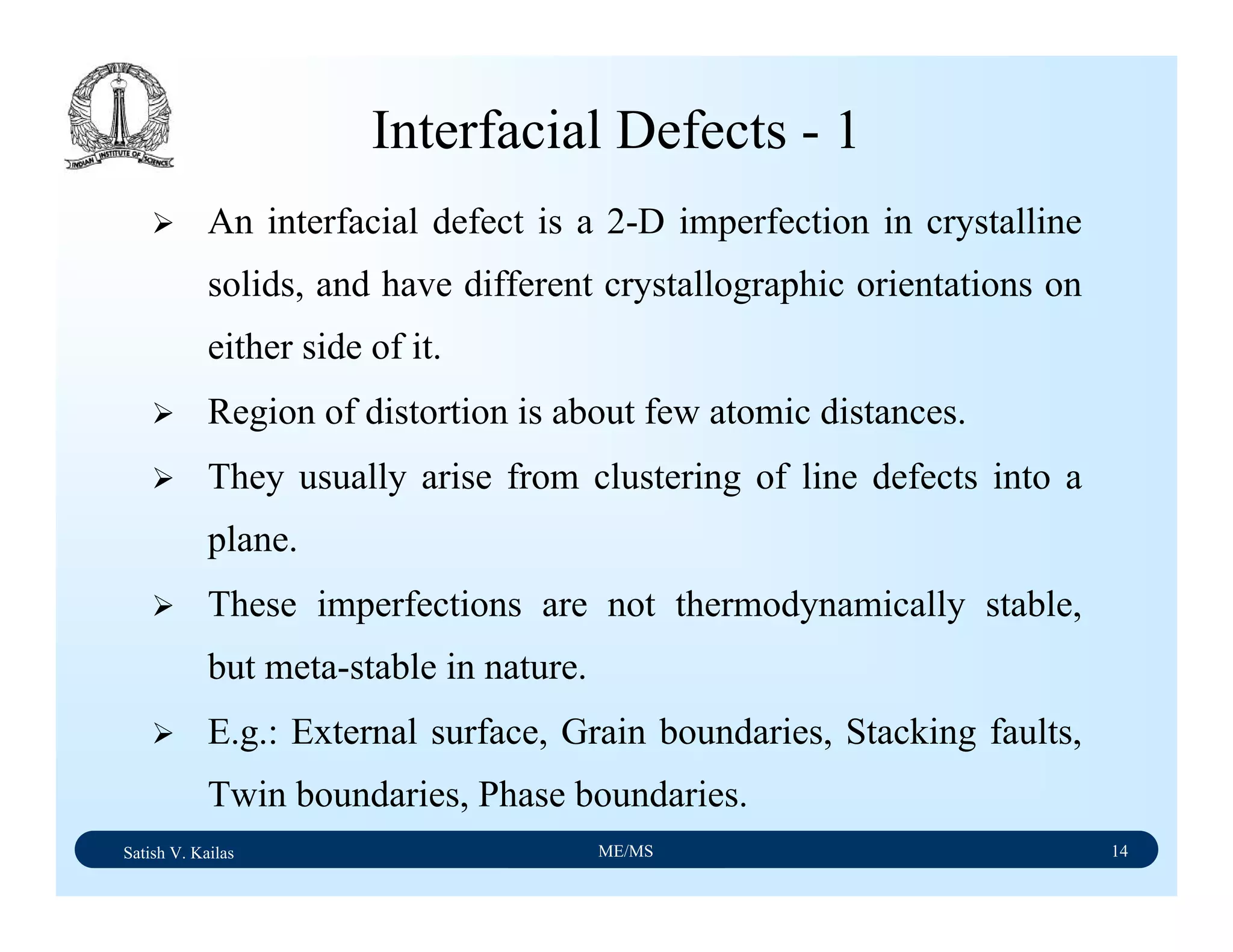

Miller Indices - Direction

A vector of convenient length is placed parallel to the

required direction

The length of the vector projection on each of three axes are

measured in terms of unit cell dimensions

These three numbers are made to smallest integer values,

known as indices, by multiplying or dividing by a common

factor

The three indices are enclosed in square brackets, [uvw].

A family of directions is represented by <uvw>](https://image.slidesharecdn.com/materialscience-160106071247/75/Material-science-notes-58-2048.jpg)

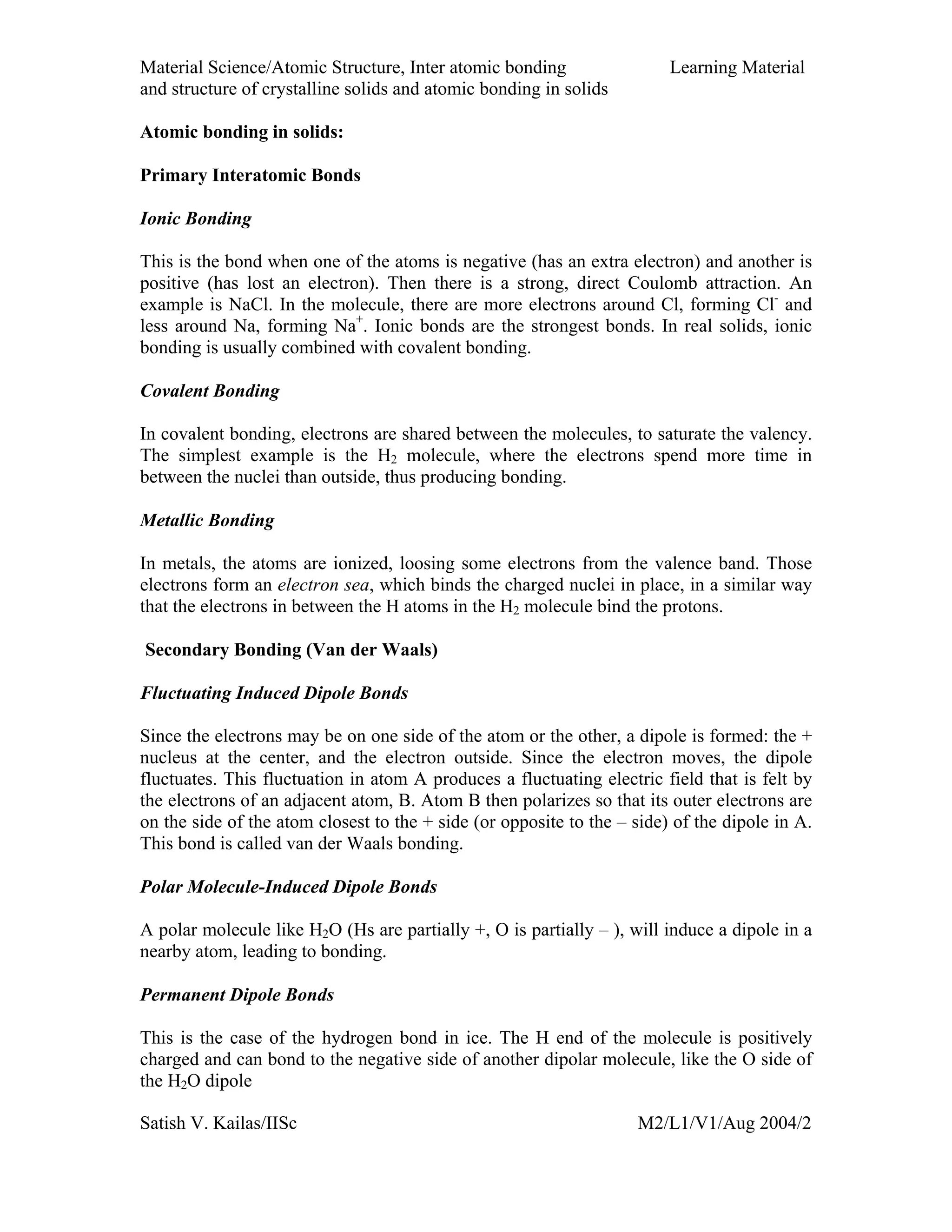

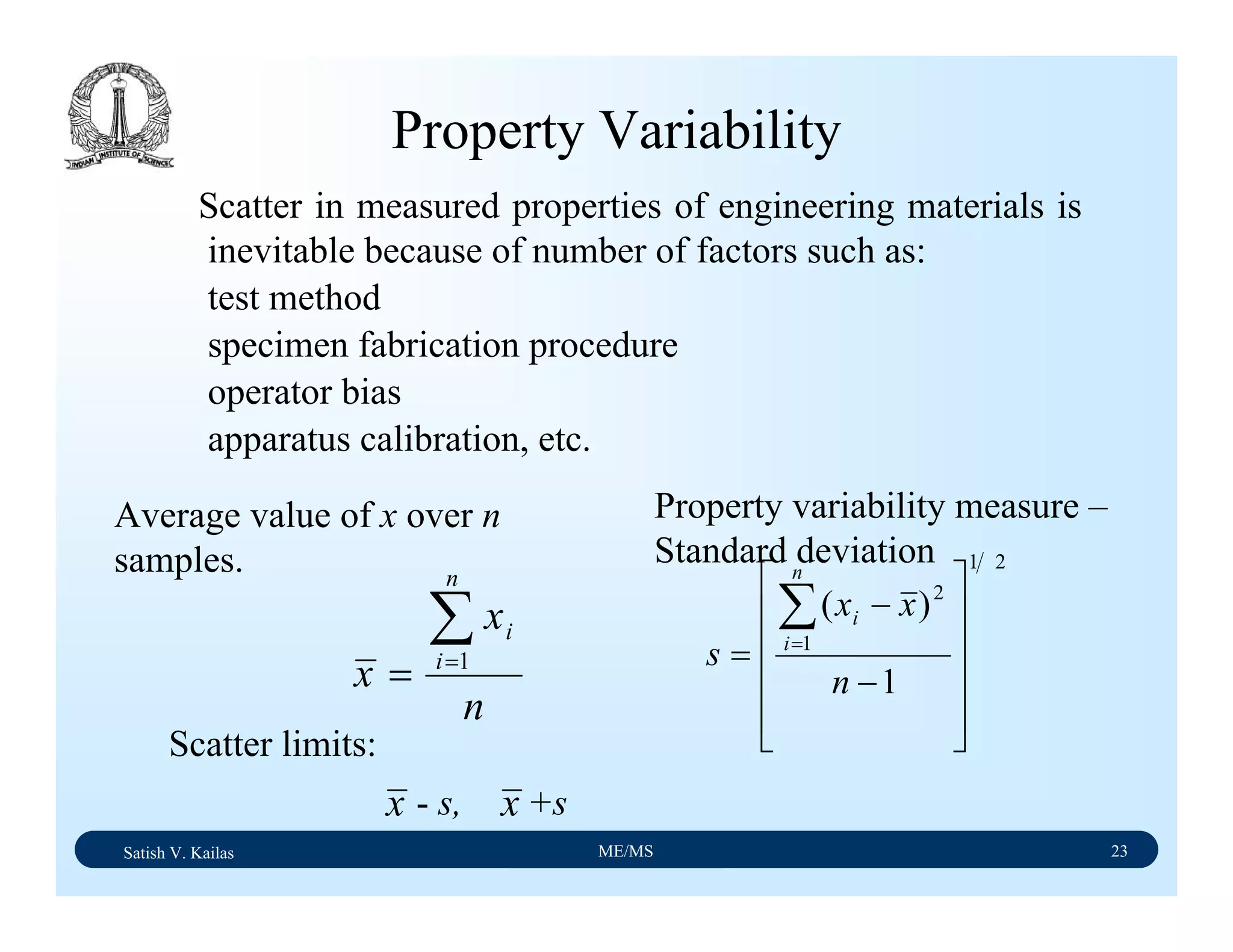

![Satish V. Kailas ME/MS 23

Useful Conventions For Cubic Crystals

[uvw] is normal to (hkl) if u = h, v = k, and w = l. E.g.: (111)

┴ [111]

[uvw] is parallel to (hkl) if hu + kv + lw = 0

Two planes (h1k1l1) and (h2k2l2) are normal if h1h2 + k1k2

+ l1l2=0

Two directions (u1v1w1) and (u2v2w2) are normal if u1u2 +

v1v2 + w1w2=0

Inter-planar distance between family of planes {hkl} is given

by:

Angle between two planes is given by:

222

}{

lkh

a

d hkl

++

=

2

2

2

2

2

2

2

1

2

1

2

1

212121

cos

lkhlkh

llkkhh

++++

++

=θ](https://image.slidesharecdn.com/materialscience-160106071247/75/Material-science-notes-62-2048.jpg)

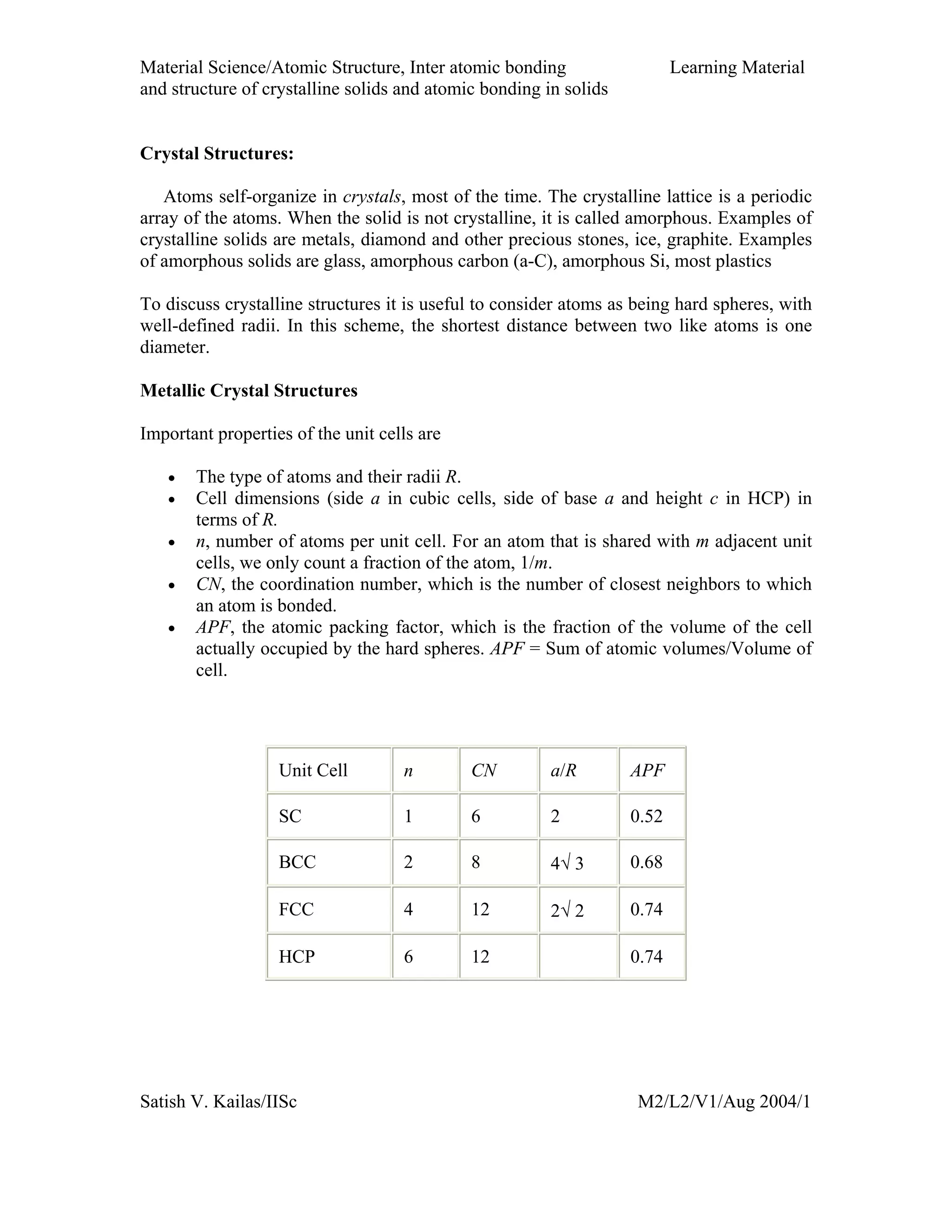

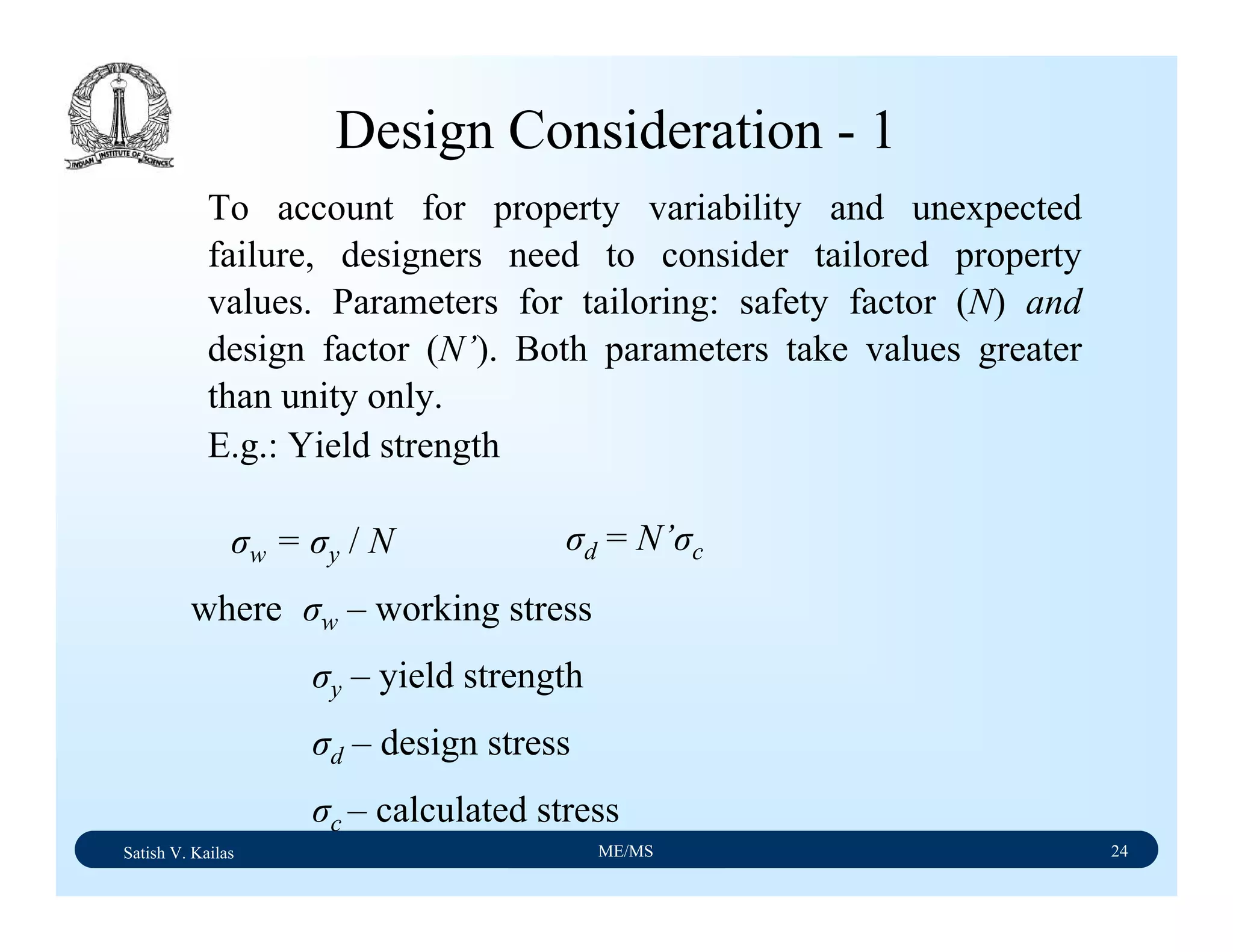

![Satish V. Kailas ME/MS 24

Miller-Bravis Indices

Miller indices can describe all possible planes/directions in

any crystal.

However, Miller-Bravis indices are used in hexagonal

systems as they can reveal hexagonal symmetry more clearly

Indices are based on four axes – three are coplanar on basal

plane at 120˚ apart, fourth axis is perpendicular to basal

plane

Both for planes/directions, extra index is given by

t = -(u+v), i = -(h+k)

where plane is represented as [uvtw], and a direction is

represented by (hkil)

E.g.: Basal plane – (0001), Prismatic plane – (10ֿ10)](https://image.slidesharecdn.com/materialscience-160106071247/75/Material-science-notes-63-2048.jpg)

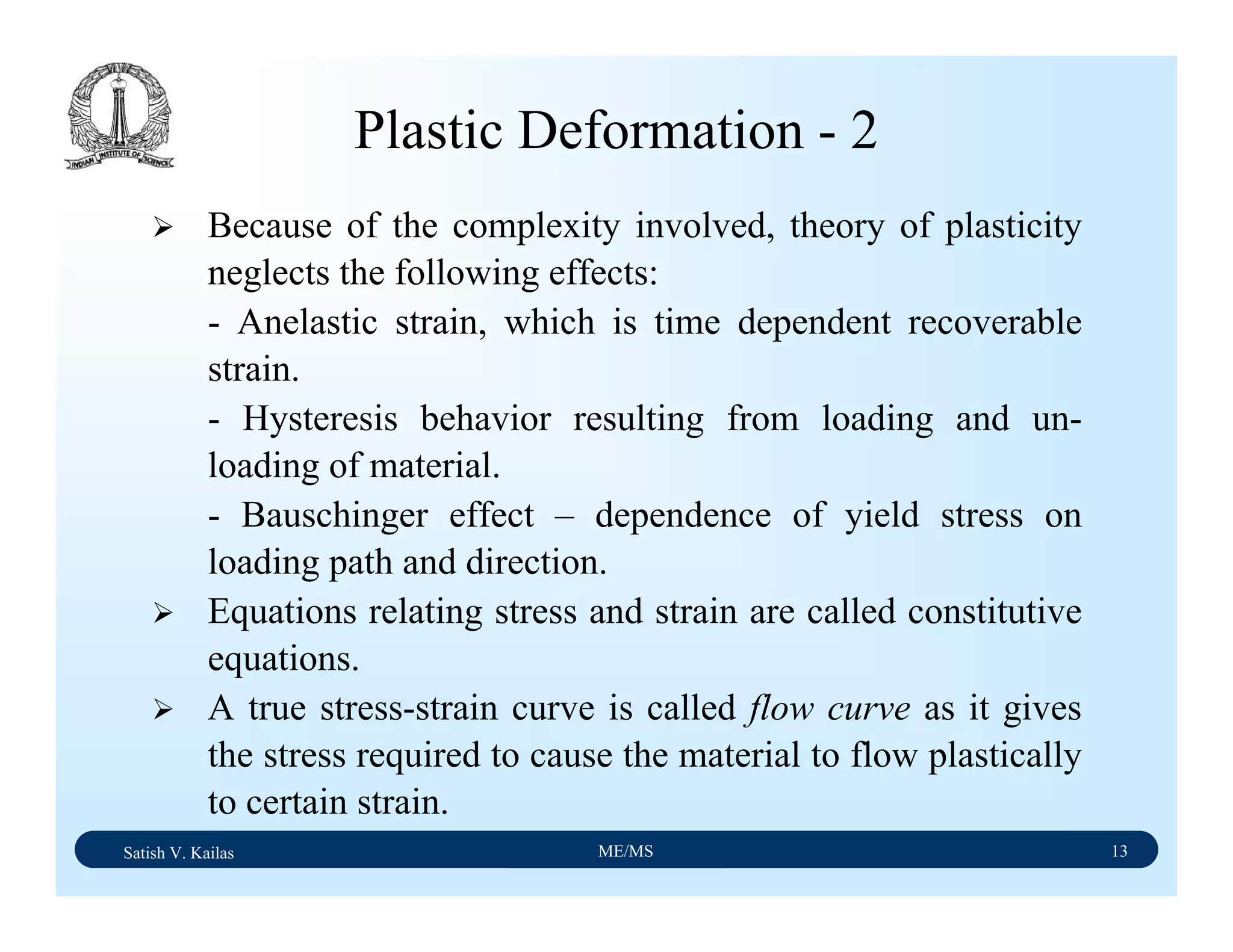

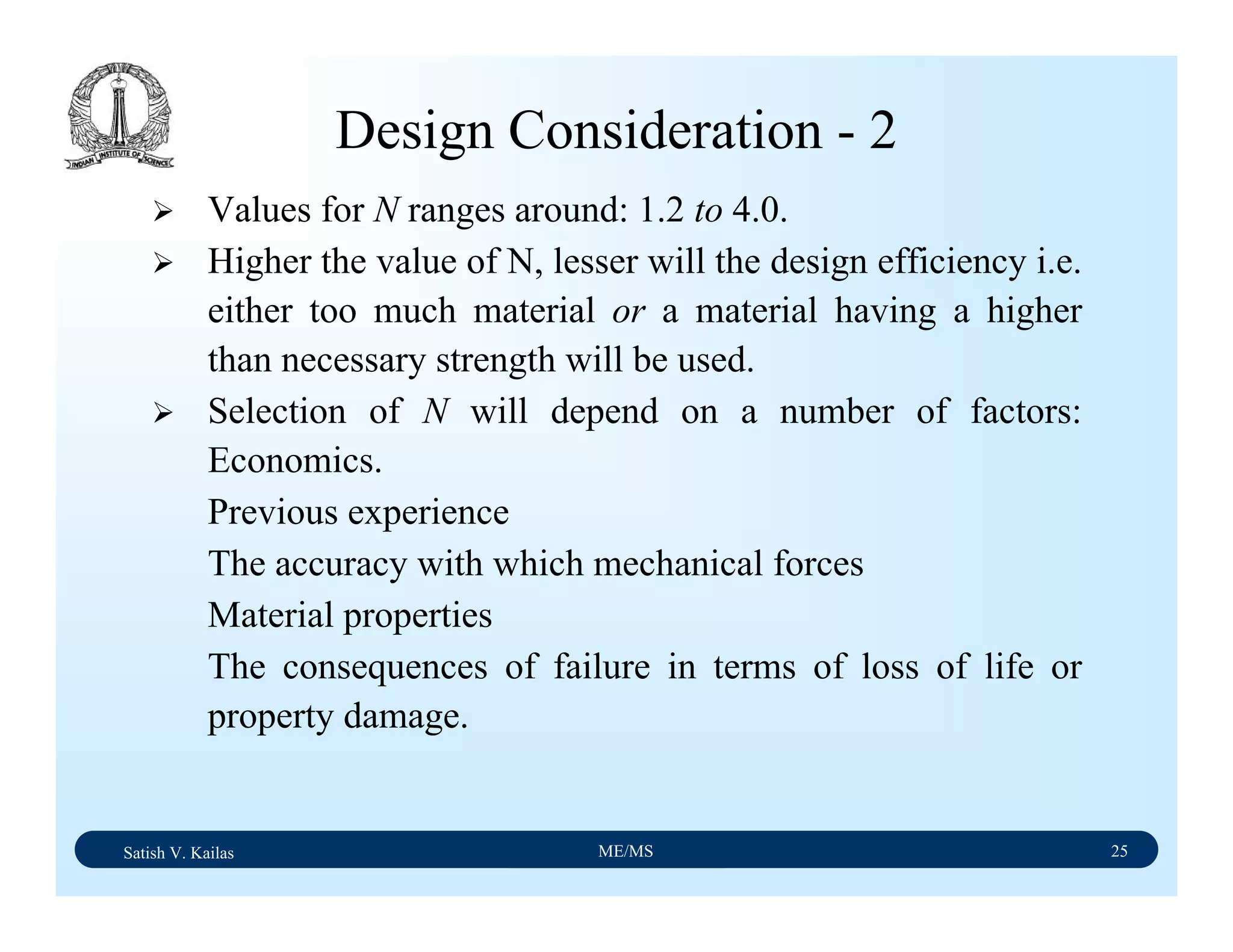

![Satish V. Kailas ME/MS 18

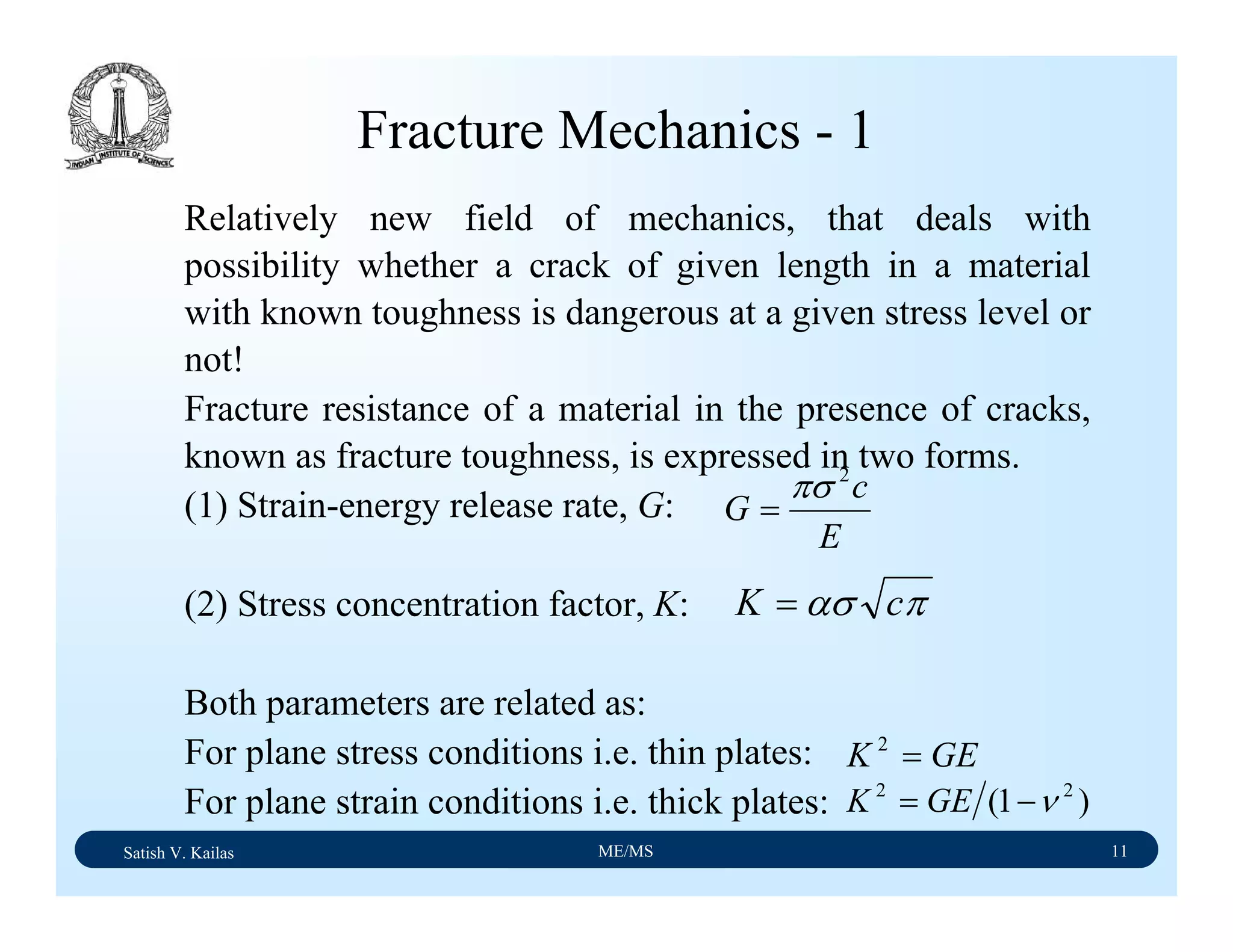

Yielding Under Multi-Axial Stress

With on-set of necking, uni-axial stress condition turns

into tri-axial stress as geometry changes tales place. Thus

flow curve need to be corrected from a point

corresponding to tensile strength. Correction has been

proposed by Bridgman.

[ ])2/1ln()/21(

)(

RaaR

avgx

++

=

σ

σ

where

(σx)avg measured stress in the axial direction,

a – smallest radius in the neck region,

R – radius of the curvature of neck](https://image.slidesharecdn.com/materialscience-160106071247/75/Material-science-notes-122-2048.jpg)

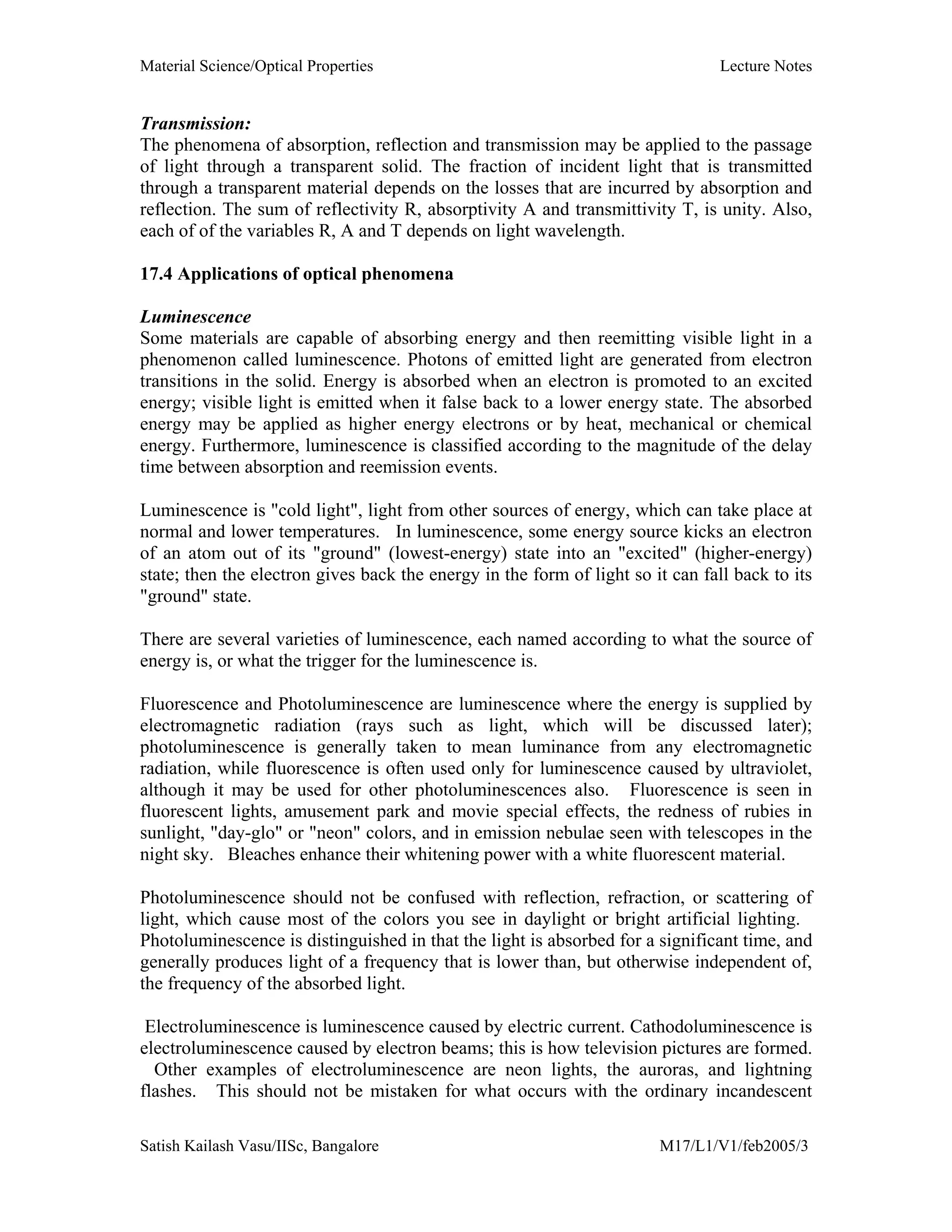

![Satish V. Kailas ME/MS 19

Yield Criteria - 1

Von Mises or Distortion energy criterion:

yielding occurs once second invariant of stress deviator

(J2) reaches a critical value. In other terms, yield starts

once the distortion energy reaches a critical value.

2

2 kJ = [ ]2

13

2

32

2

212 )()()(

6

1

σσσσσσ −+−+−=J

Under uni-axial tension, σ1 = σ0, and σ2= σ3= 0

[ ] 2

1

2

13

2

32

2

210

0

22

0

2

0

)()()(

2

1

3)(

6

1

σσσσσσσ

σσσ

−+−+−=⇒

=⇒=+ kk

00 577.0

3

1

σσ ==k where k – yield stress under shear](https://image.slidesharecdn.com/materialscience-160106071247/75/Material-science-notes-123-2048.jpg)

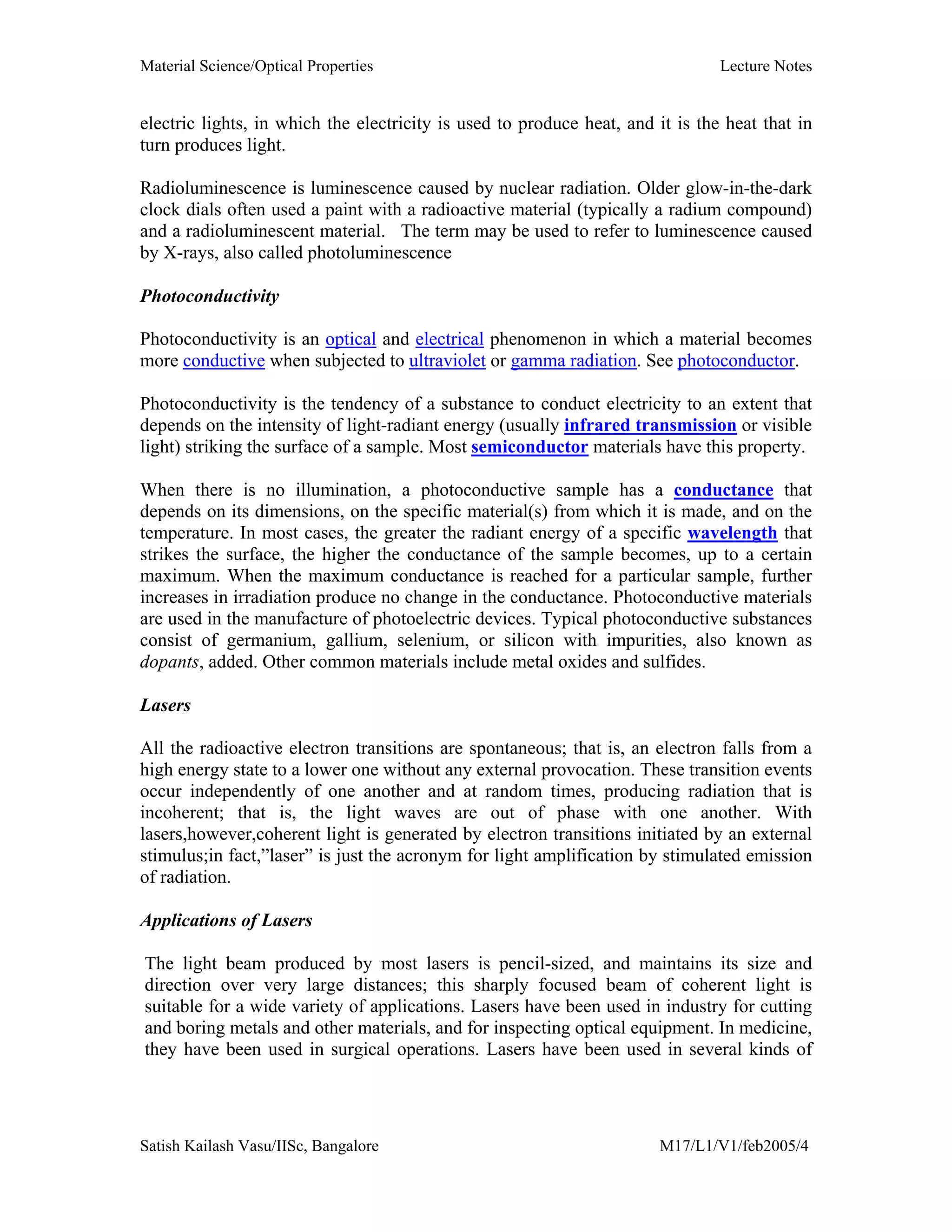

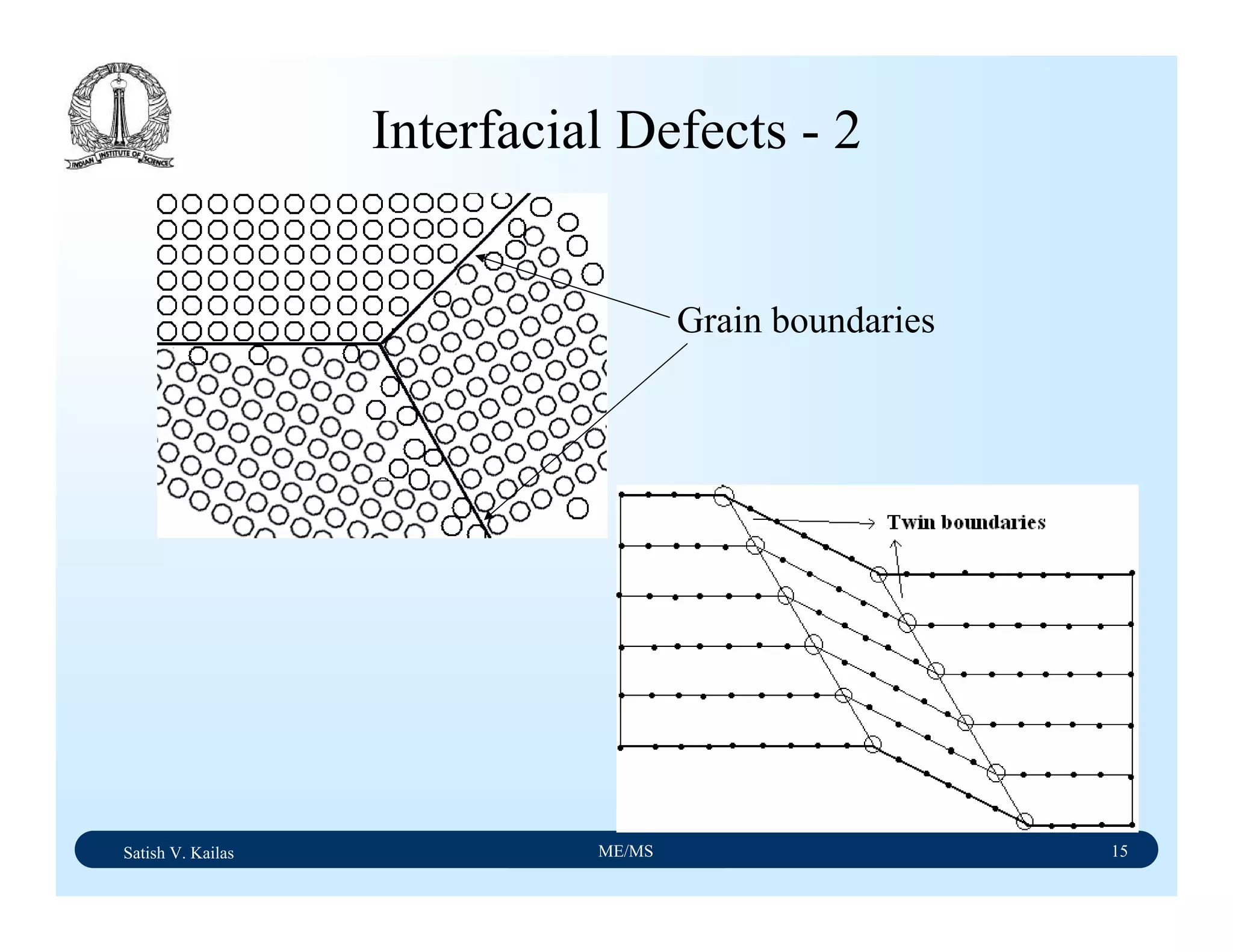

Zn, Cd, Mg, TiHCP

[111](112)α-Fe, TaBCC

[112](111)Ag, Au, CuFCC

Twin

direction

Twin planeExampleCrystal](https://image.slidesharecdn.com/materialscience-160106071247/75/Material-science-notes-159-2048.jpg)

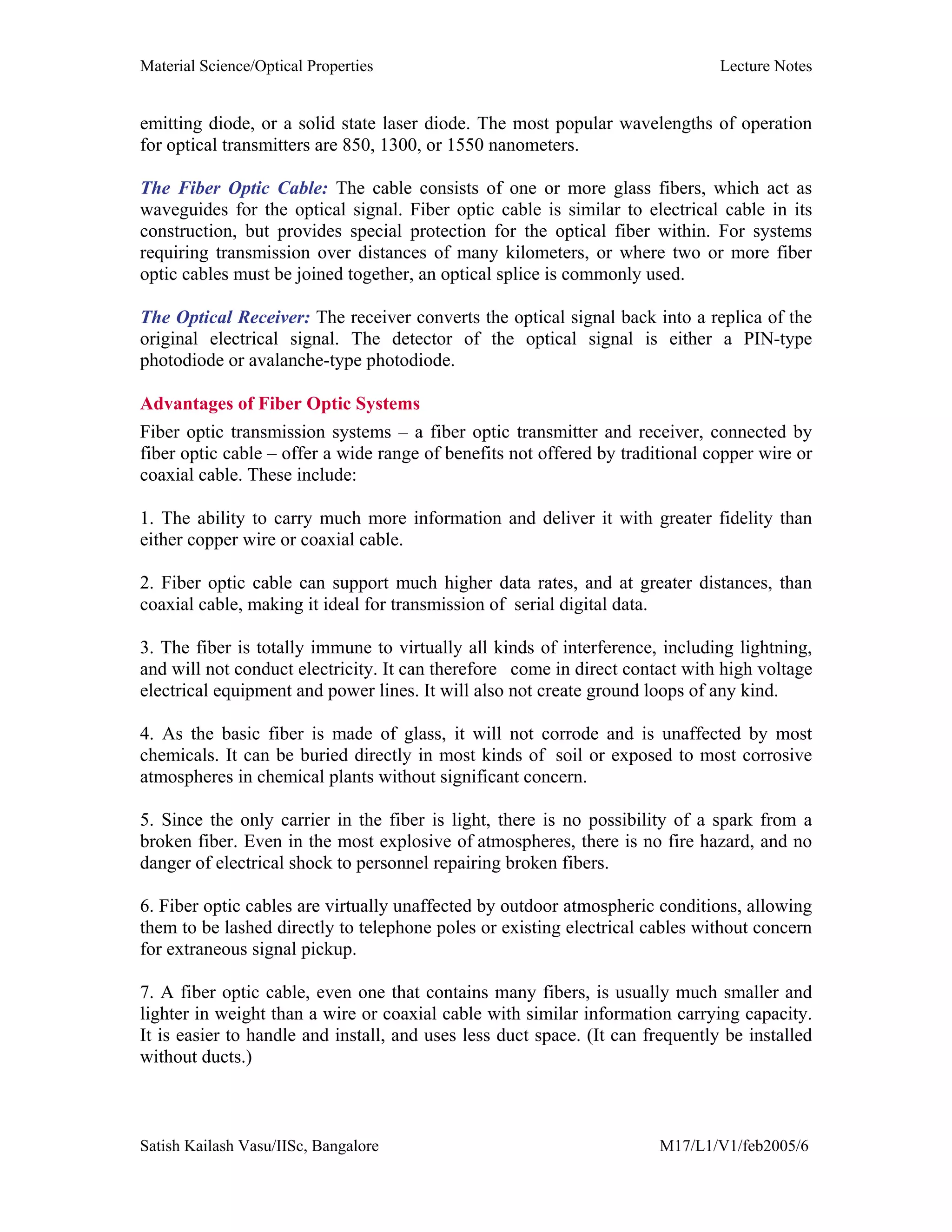

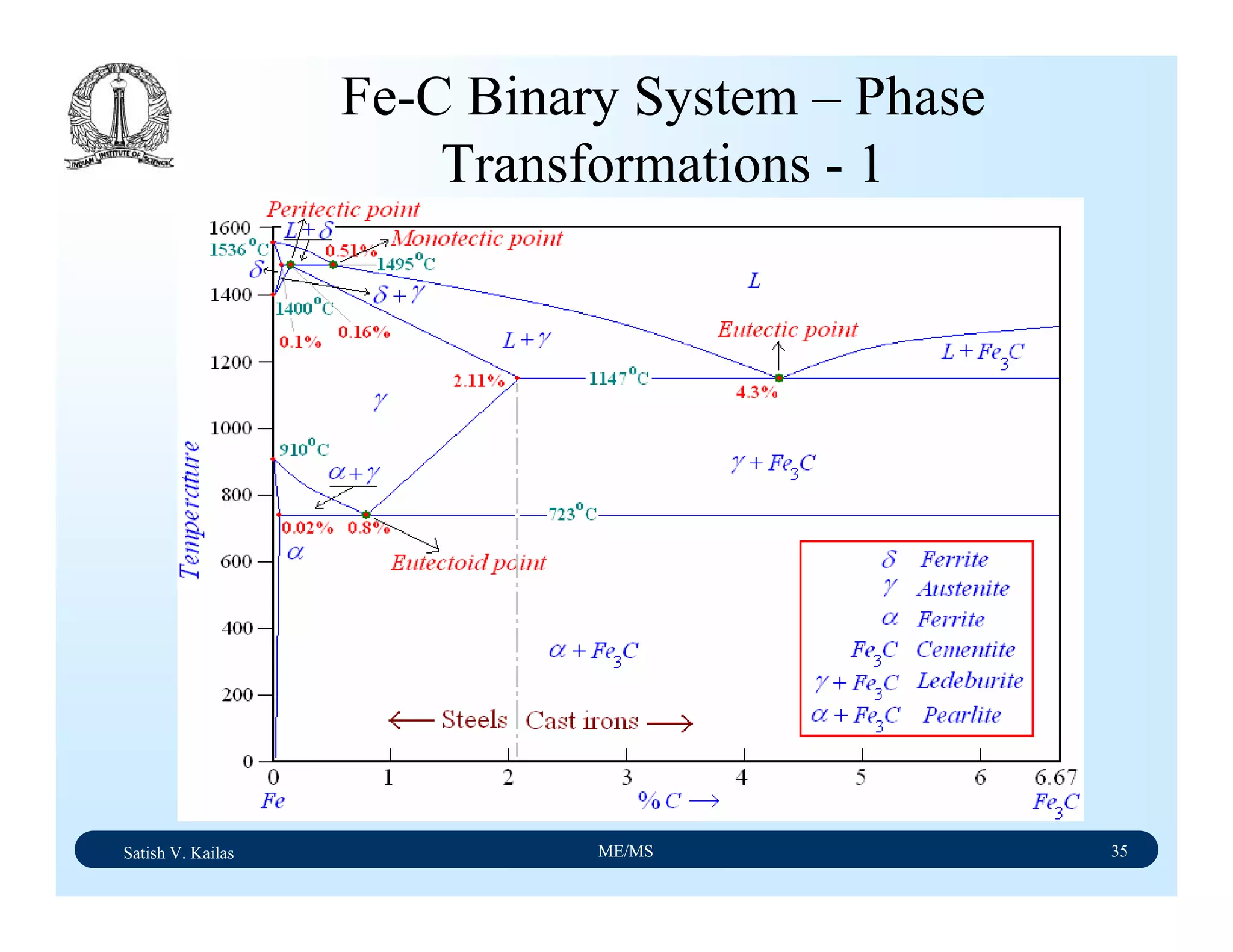

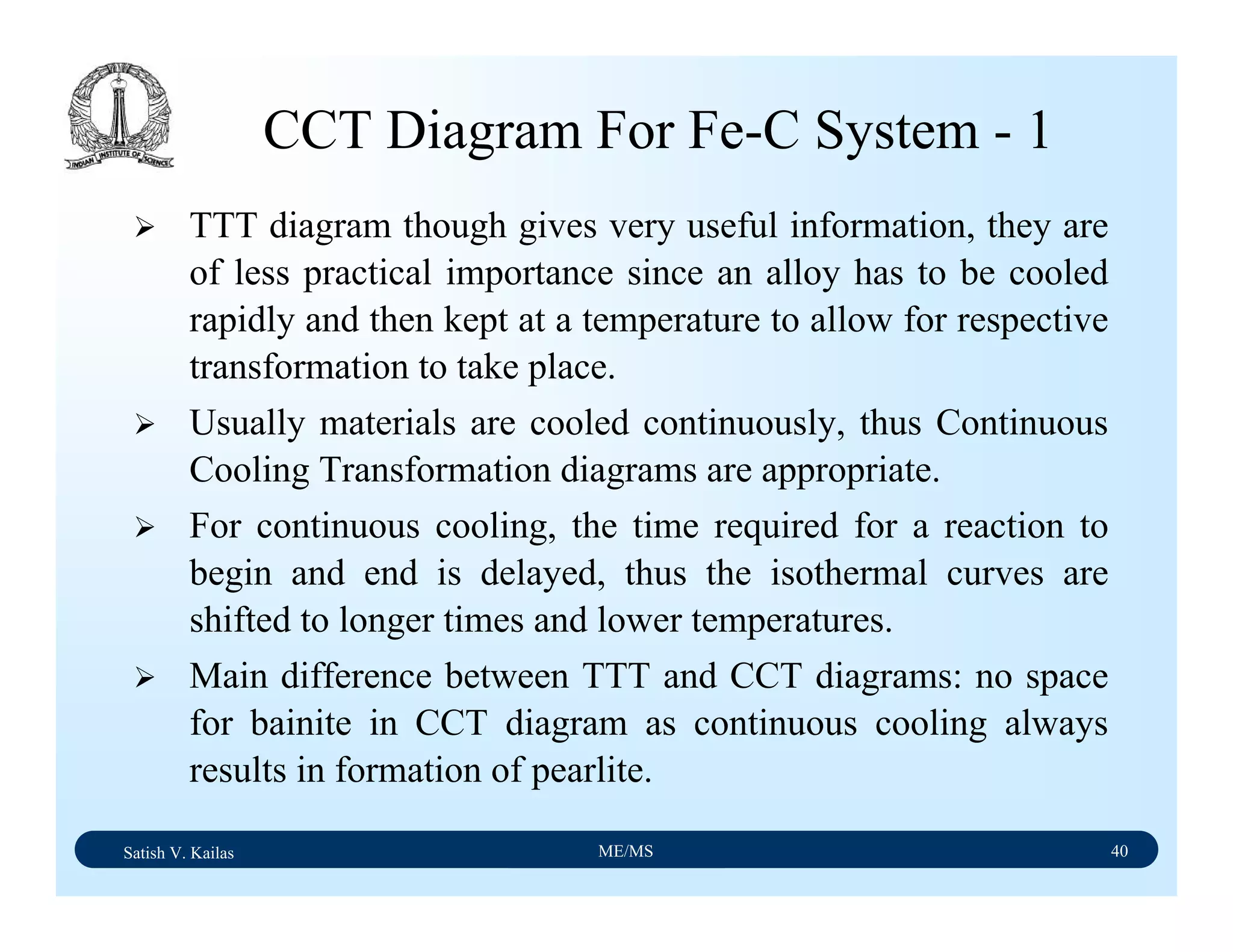

![Satish V. Kailas ME/MS 36

Fe-C Binary System – Phase

Transformations - 2

Fe-Fe3C phase diagram is characterized by five individual

phases,: α–ferrite (BCC) Fe-C solid solution, γ-austenite

(FCC) Fe-C solid solution, δ-ferrite (BCC) Fe-C solid

solution, Fe3C (iron carbide) or cementite - an inter-metallic

compound and liquid Fe-C solution and four invariant

reactions:

- peritectic reaction at 1495 ْC and 0.16%C, δ-ferrite + L

↔ γ-iron (austenite)

- monotectic reaction 1495 ْC and 0.51%C, L ↔ L + γ-iron

(austenite)

- eutectic reaction at 1147 ْC and 4.3 %C, L ↔ γ-iron +

Fe3C (cementite) [ledeburite]

- eutectoid reaction at 723 ْC and 0.8%C, γ-iron ↔ α–

ferrite + Fe3C (cementite) [pearlite]](https://image.slidesharecdn.com/materialscience-160106071247/75/Material-science-notes-223-2048.jpg)

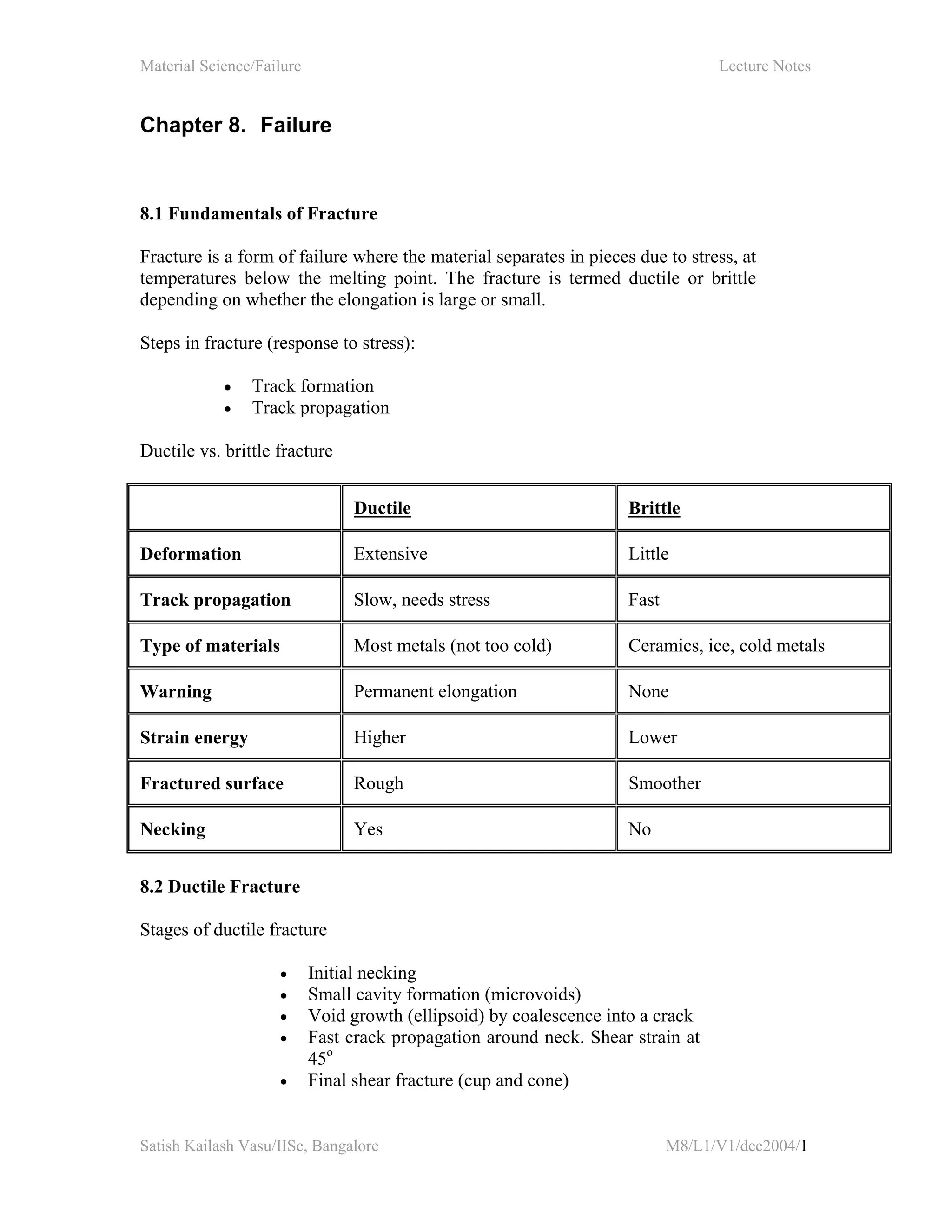

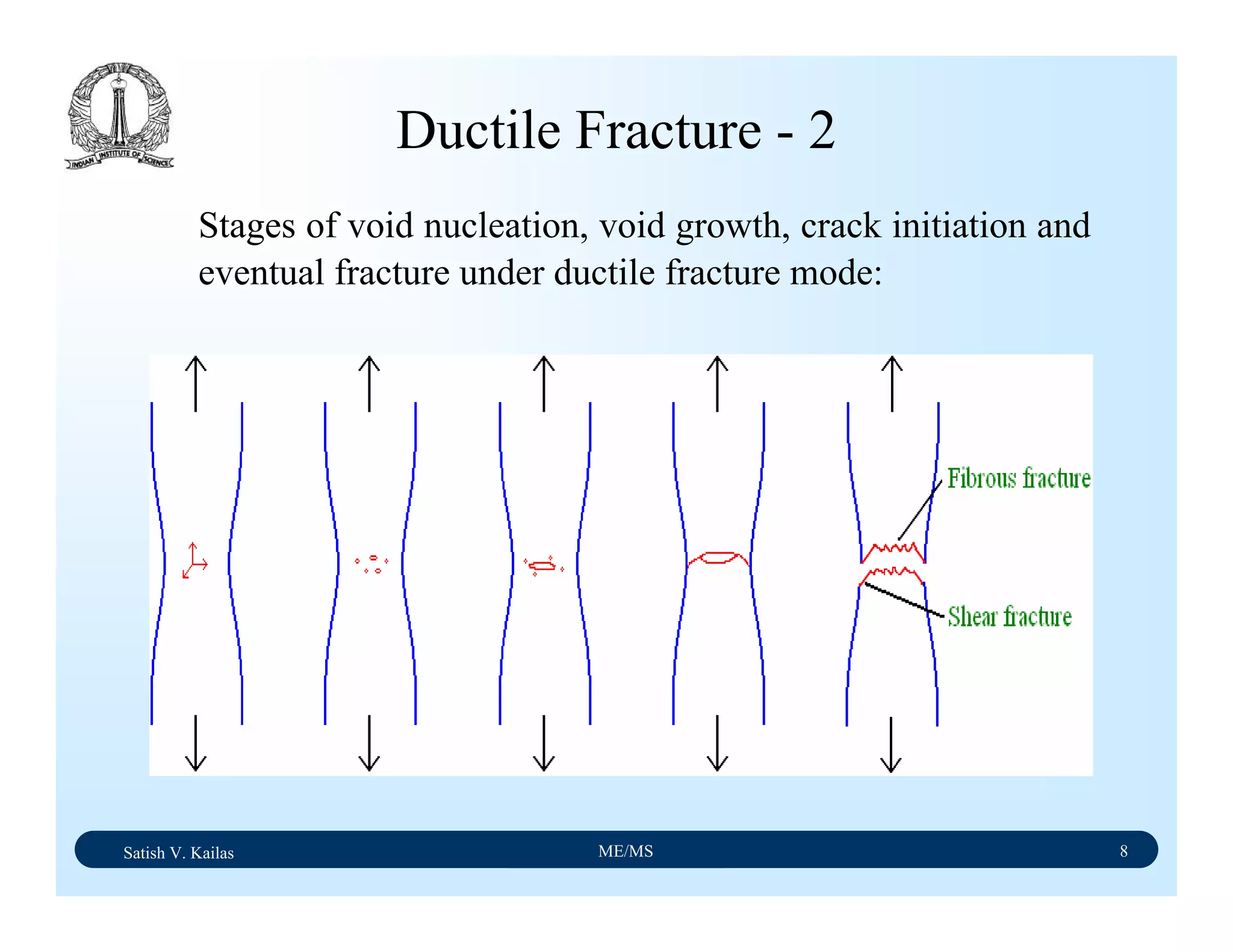

![Satish V. Kailas ME/MS 7

Ductile Fracture - 1

Ductile fracture in tension occurs after appreciable plastic

deformation.

It is usually preceded by necking.

It exhibits three stages - (1) formation of cavities (2)

growth of cavities (3) final failure involving rapid crack

propagation at about 45ْto the tensile axis.

Fractography of ductile fracture reveals numerous spherical

dimples separated by thin walls on the fractured surface.

McClintock’s strain to ductile fracture, εf,

[ ])32()()1(sinh

)2ln()1( 00

σσσ

ε

ba

f

n

bln

+−

−

=](https://image.slidesharecdn.com/materialscience-160106071247/75/Material-science-notes-242-2048.jpg)

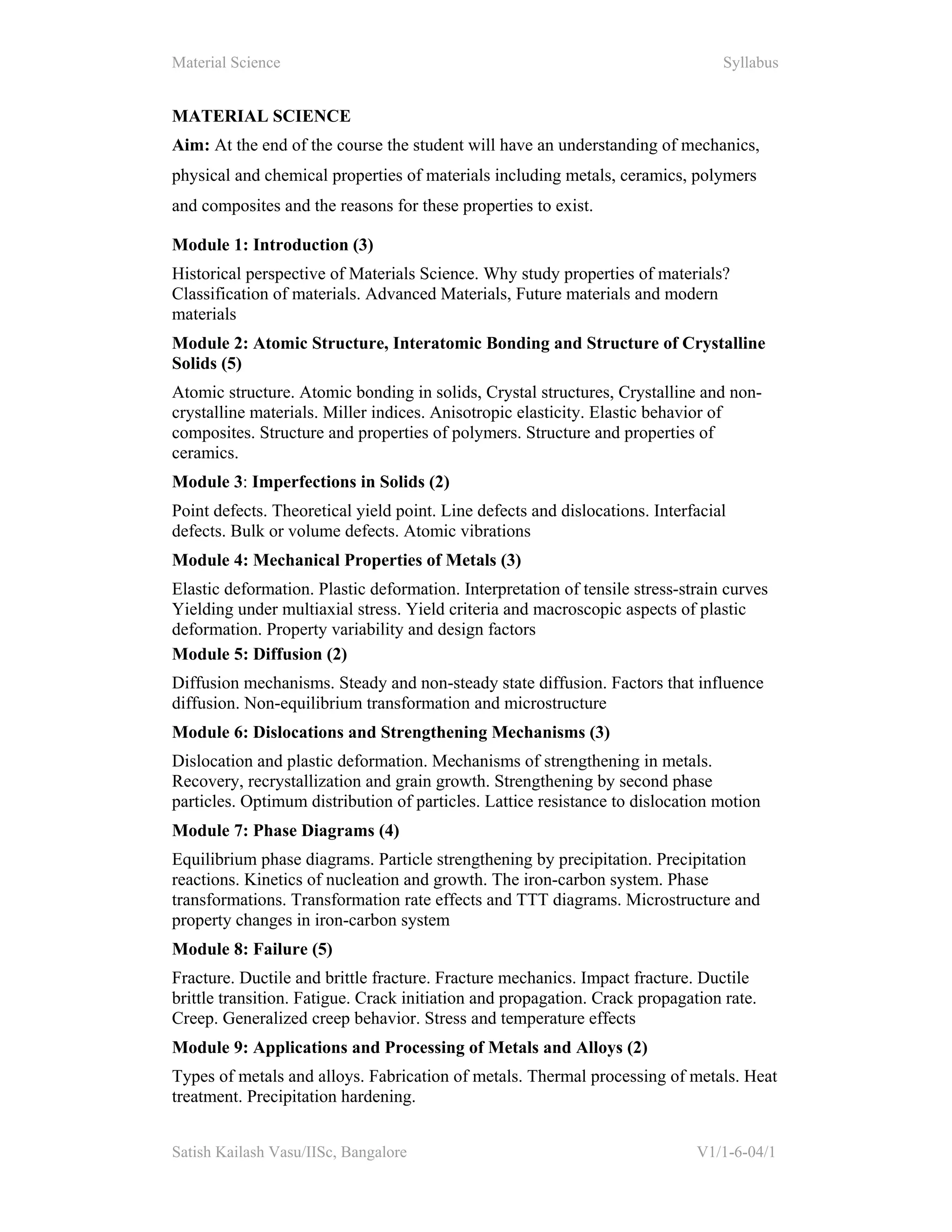

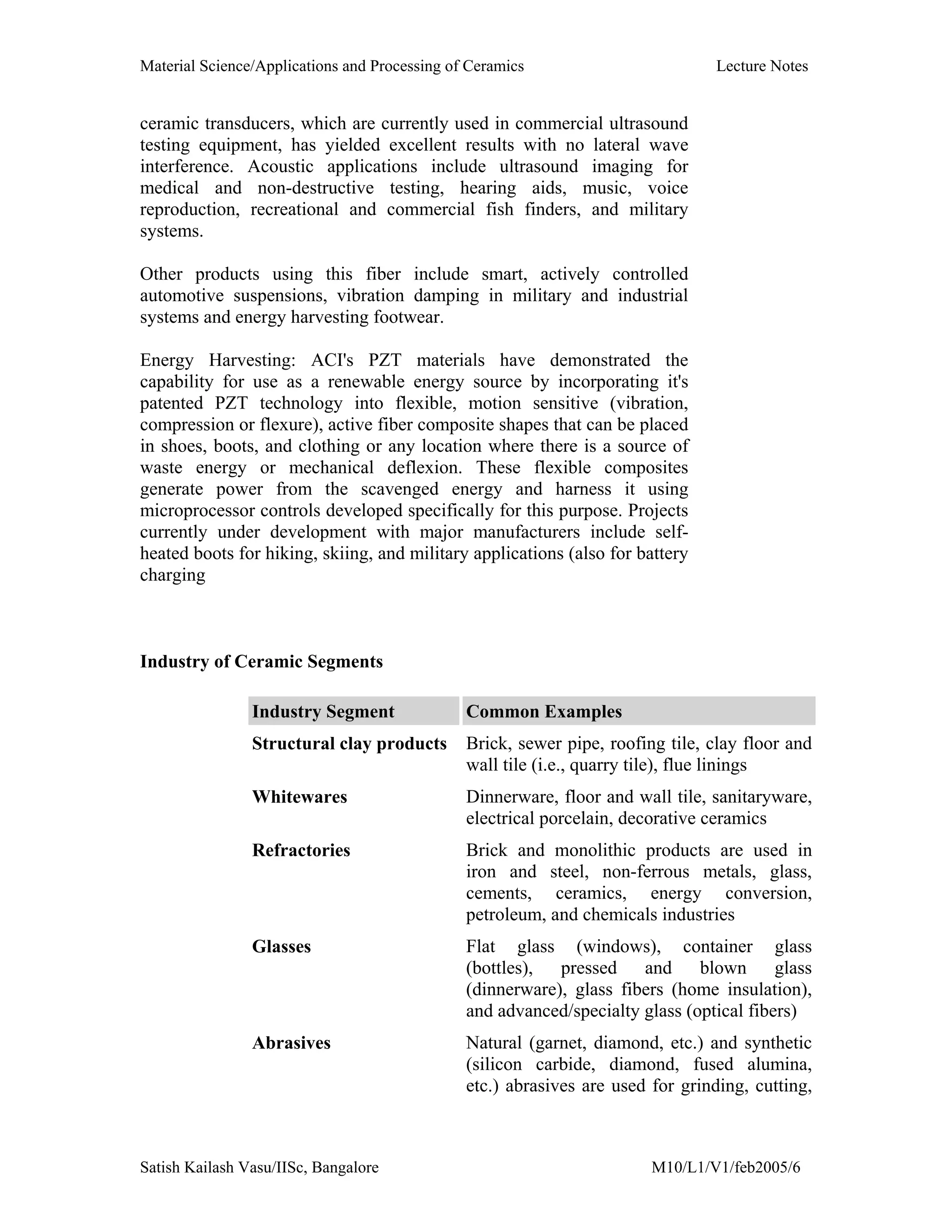

![Material Science/Applications and Processing of Ceramics Lecture Notes

Satish Kailash Vasu/IISc, Bangalore M10/L1/V1/feb2005/2

compounds, including sulfur and carbon. The powder and petrurgic methods were

explored, and gave us products with different phases and microstructures. For the

sintering experiments, we mixed calcined ash powder with various amounts (10-50wt%)

of borosilicate (Pyrex) glass. The powder mixtures were uniaxial cold pressed to a

cylindrical shape and sintered in air at temperatures in the range of 1,000-1,500°C for

periods of up to 15 hours. Using the petrurgic method, coal ash was mixed with soda-

lime glass powder. The mixture was melted at 1,500°C and cooled to room temperature

at rates of between 1-10°C per minute.

Glass-Ceramic Composites

Work to date has largely concentrated on composites with a matrix of the slag-based

Silceram glass-ceramic (a glass-ceramic for floor and wall tiles and wear components).

We have investigated both particulate- (SiC and TiC) and fibre-reinforcement (SiC).

Properties measured include the fundamental mechanical properties but also more

complex properties such as thermal shock resistance and erosion resistance. As

mentioned previously, the thermal shock resistance of glass-ceramics is superior to the

parent glasses, and the shock resistance is further improved by particulate reinforcement.

For example, monolithic Silceram has a thermal shock critical temperature of 180°C,

whereas a 20wt%SiC composite has a value of 270°C. Erosion resistance may also be

improved by particulate reinforcement, e.g., for TiC reinforced Silceram - the larger the

reinforcement particle size and the greater the volume fraction, the lower the erosion rate.

Results indicate a way for transforming vitrified silicate residues into useful products

with broad application potential. The glass-ceramics obtained are candidate materials for

applications in floors of industrial buildings and in construction, and for outside and

inside facing walls. We are currently addressing issues associated with the effect of

environmental influences on the chemical durability and toxic potential of the materials,

which may be compromised by the presence of heavy metals incorporated in the glass or

crystalline phases. Public acceptance of the use and exploitation of glass-ceramic-based

materials in such applications will strongly depend on a satisfactory consideration of

these issues.

2) Refractories -Refractories are materials needed for handling high temperature liquids,

gases and solids, e.g., for industrial processing. Applications include solar furnaces,

casting molds for molten materials, heat exchangers, and aerobraking heat shields.

Industrial refractory needs can be satisfied by sintered calcia (CaO), silica (SiO2),

magnesia (MgO), alumina (Al2O3) and titania (TiO2), with the desired porosity. Of

course, these stable materials are commonly used on Earth for the same purposes, due to

their great resistance to heat, oxidation (they are already fully oxidized), corrosion and

abrasion. Minerals such as olivine [(MgFe)2SiO4] and anorthite (CaAl2Si2O8) are also

useful for making refractory bricks and ceramics. Some refractories and their ceramics

have low expansion due to heat and are attractive for space environments where a wide

range of temperatures are experienced.](https://image.slidesharecdn.com/materialscience-160106071247/75/Material-science-notes-293-2048.jpg)

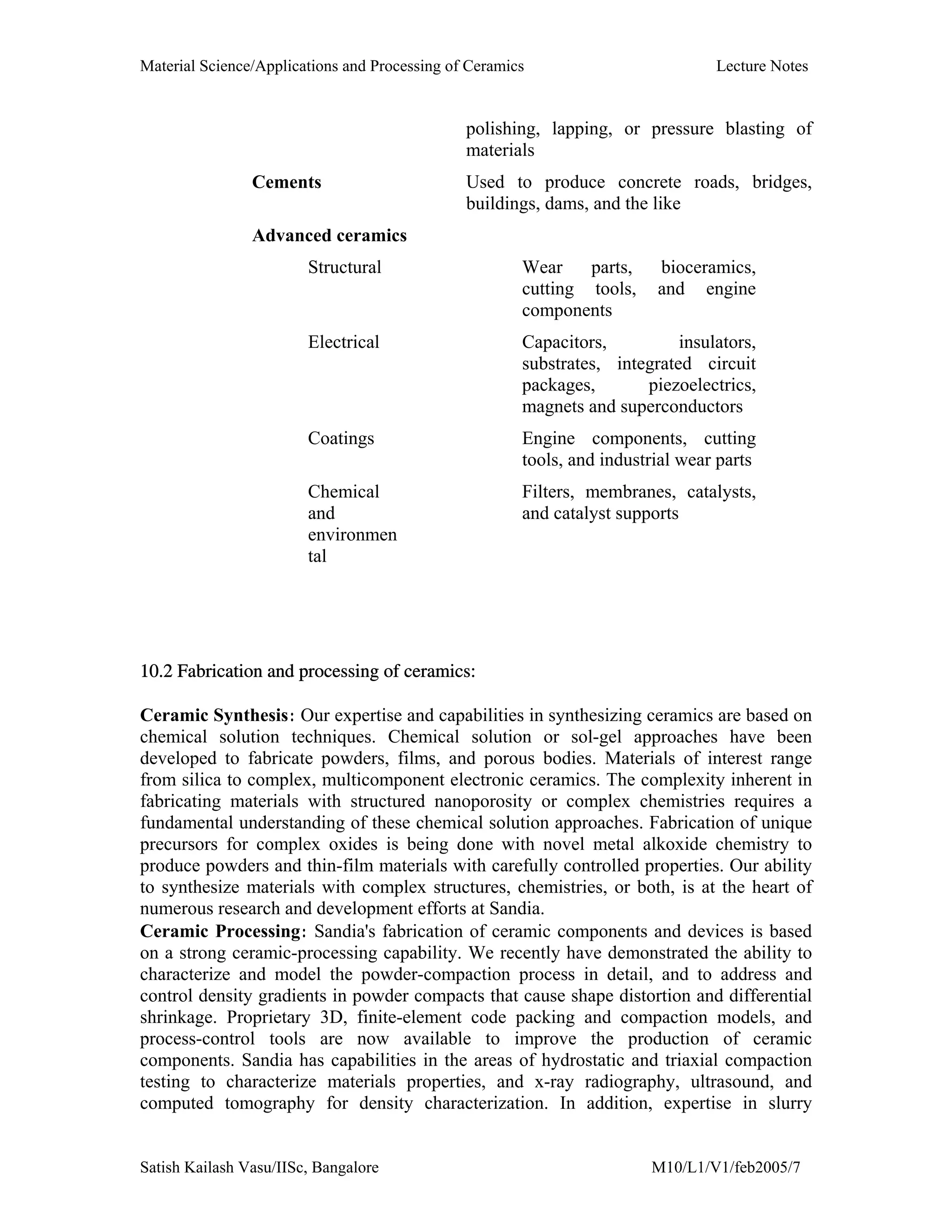

![Material Science/Applications and Processing of Ceramics Lecture Notes

Satish Kailash Vasu/IISc, Bangalore M10/L1/V1/feb2005/8

processing has enabled the development of direct-fabrication processes. Furthermore, we

are developing phenomenological sintering models to enhance both ceramic component

design and manufacturing capability.

Ceramic Synthesis and Processing Research Briefs:

Constrained Sintering of Multi-Material Systems

Development of A Predictive Model for Ceramic Powder Compaction

ESP (Engineered Stress Profile) Glass - Unique Opportunities for Performance

and Reliability

Molecular Dynamics Simulations of Reactive Wetting in Ceramic-Metal Systems

PZT 95/5 Material Development for Neuron Generator Applications

Precursor's Structure Effects on Thin-Film Densification of TiO2

Relationship between Interfacial Interactions and Fracture Stress for Adhesive

Joints in Mode II Loading

Robocasting : Layered Manufacturing by Slurry Extrusion

Synthesis and Processing of Composites by Reactive Metal Penetration

10.3 Electrical conduction in ionic ceramics and in polymers:

This requires creation of electron [e'] and hole [h⋅] pairs in ionic solid according to the

symbolic chemical reaction, which describes creation of carriers due to thermal activation

(this process results in intrinsic conductivity):

nil ⇔ e' + h⋅

K = [e'] + [h⋅ ] = n . p = exp (- ∆G0

/RT) = exp (∆S0

/R) exp (-Eg /RT)

Accordingly, a supply of "band gap" energy Eg is necessary, hence the strong

dependence of conductivity on temperature. The equilibrium constant of the above

reaction can be approximately expressed as: n.p ≈ 1019exp(Eg/kT), or, the carrier

concentration (assuming the same concentration of holes p and electrons e), c ≈

109.5exp(Eg/2kT).](https://image.slidesharecdn.com/materialscience-160106071247/75/Material-science-notes-299-2048.jpg)

![Material Science/Applications and Processing of Ceramics Lecture Notes

Satish Kailash Vasu/IISc, Bangalore M10/L1/V1/feb2005/9

The magnitude of the band gap Eg determines ability of a material to conduct. For Eg > 6

eV, materials are considered as insulators . This wide energy gap is typical for the

ionic oxides of metals having a single stable oxidation state: groups IA, IIA, IIIA. The

electrical resistivity of most stable insulators correlates with the ionic character of their

bond: the larger difference of electronegativity, the larger % of ionic bond, and the larger

energy gap Eg.

The band gap magnitude correlates also with the ionic bond energy, i.e. the most stable

ionic ceramic are also the best insulators. For example, the bond energy of alumina is

~6eV/equivalent (1/3 Al2O3) and Eg = ~7eV; the bond energy of one equivalent of

cadmium oxide (CdO) is ~4 eV/equivalent and Eg = ~2eV.

The oxides of metals able to have multiple oxidation states (such as transition elements,

with partially filled "d" orbitals) have narrower band gaps of the order of 2-5eV, resulting

in intrinsic semiconducting properties. The presence of point defects in ionic solids

(such as solutes, vacancies, interstistials) can dramatically decrease the energy required

for the creation of electron/hole pairs.

This is because these defects are typically located “within” the energy gap, either close to

the valence band (acceptors) or conduction band (donors). An example is KCl

containing VK', VCl

•, CaK

• , or MgO containing VMg'', VO

•,VMg', VC

0, AlMg

•.

The point defects are the key feature of extrinsic semiconductors, the basic components

of modern electronics.

Mixed and Ionic Ceramic Conductors

The variety of point defects present in ceramics gives frequently a mixed ionic and

electronic type of electrical conduction. To some extent, every ionic crystal is a mixed

conductor, but the share of electronic conductivity, expressed through the charge

transference number for electrons, can be negligible. If Ohm’s law is expressed in

terms of current density J [A/m2

], material conductivity σ [A/Vm] and electric field Ee,

[V/m] following relationship results:

J = - σ.Ee](https://image.slidesharecdn.com/materialscience-160106071247/75/Material-science-notes-300-2048.jpg)

![Material Science/Applications and Processing of Ceramics Lecture Notes

Satish Kailash Vasu/IISc, Bangalore M10/L1/V1/feb2005/10

where, for mixed a conductor, σ = Σσi, the sum of conductvities due to the various

charge-carrying species, i.e. ions, holes and electrons. The transference number ti of a

given species is then defined as: tj = σj/Σσi

For ionic conductors, the aim is to maximize the charge transference due to the

movement of ions and minimize the transference due to electrons and holes movement.

That is, tion ≈ 1 , te,h ≈ 0 . This is principle behind the operation of solid

electrolytes. The sub-class of solid electrolytes useful for solid-state electrochemical

devices (batteries, sensors) can be defined as "fast ionic conductors" as long as:

1. The activation energy Ed for diffusion is LOW, less than ~0.1 eV/atom, or

2.5 kcal/mole, or 10 kJ/mole, or ~10% of the energy needed to form a point defect in a

close packed ionic solid.

2. The corresponding D0 value (diffusion coefficient D = D0exp[-Ed/kT], so

D = D0 at T = ∞) is HIGH (D0 >10-4 cm2/s) and therefore the corresponding σ0 value

(ionic conductivity σ=σ0exp[-E/kT]) is HIGH, σ0 > 0.1 1/Ω.cm.

If the above conditions are fulfilled, the diffusivity at room temperature will be D > 10-6

cm2/s, and room temperature ionic conductivity will be σ > 0.01 1/Ωcm, or resistivity ρ

= 100 Ωcm . This magnitude of conductivity allows the use of solid state ionic

conductors in devices like batteries, sensors and fuel cells.

The resistivity of ionic conductor is the primary factor that determines internal resistance

of the cell, and thus maximum current that can be drawn from the cell. As resistance R

= ρ L/A (L being electrolyte thickness, typically 0.1-1 cm, and A area, typically 10-1000

cm2

), then the internal resistance of such battery is typically 1 Ω .](https://image.slidesharecdn.com/materialscience-160106071247/75/Material-science-notes-301-2048.jpg)