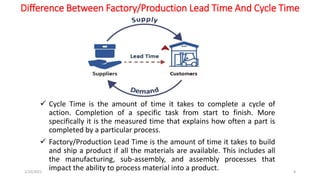

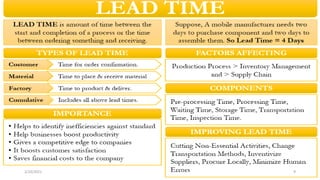

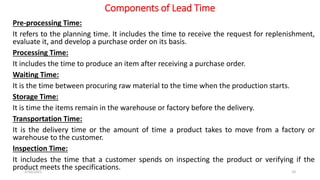

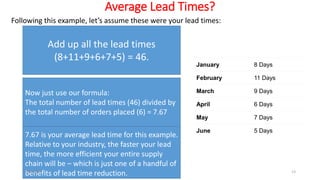

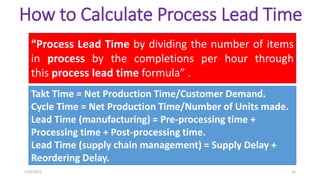

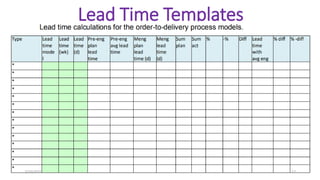

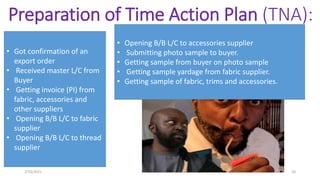

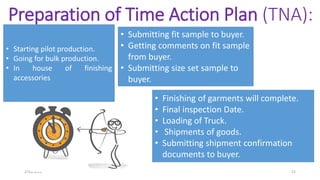

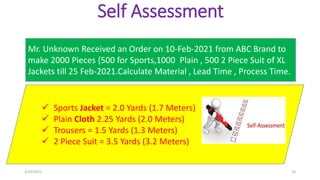

The document discusses various types of lead times including material, production, and customer lead times. It provides examples of how to calculate material and process lead times, and strategies for reducing lead times such as using domestic suppliers, increasing order frequency, and consolidating suppliers. The document also includes a template for creating a time and action plan to help ensure orders are delivered within lead times.