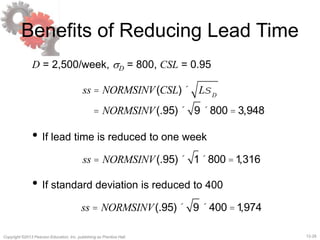

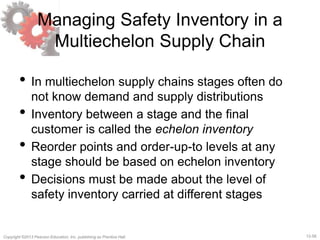

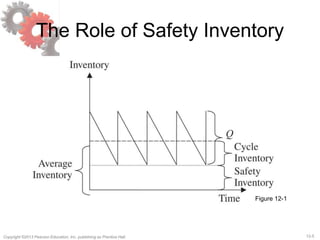

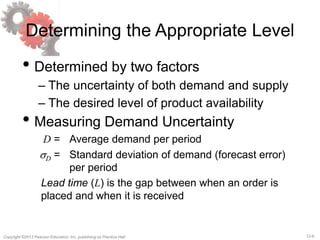

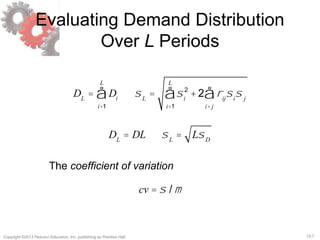

The document discusses managing uncertainty in supply chains through the use of safety inventory. It defines safety inventory as inventory carried to satisfy unexpected demand. The appropriate level of safety inventory is determined by the uncertainty in demand and supply as well as the desired level of product availability. Higher safety inventory improves availability but increases holding costs. The document provides formulas and examples for calculating safety inventory levels required to meet a desired cycle service level, fill rate, or both, given factors like demand uncertainty and lead time. Reducing lead time and demand uncertainty can lower the required safety inventory.

![12-16Copyright ©2013 Pearson Education, Inc. publishing as Prentice Hall.

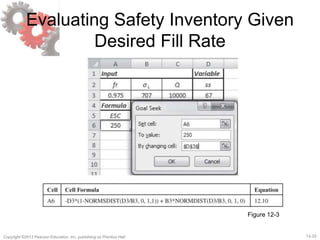

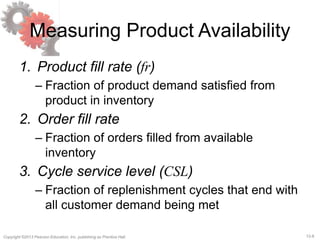

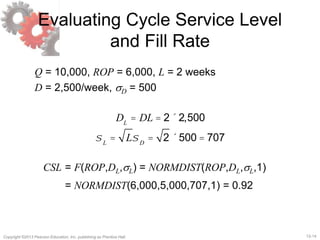

Evaluating Fill Rate Given a

Replenishment Policy

ESC = (x – ROP) f (x)dx

x=ROP

¥

ò

ESC = –ss 1– Fs

ss

sL

æ

è

ç

ö

ø

÷

é

ë

ê

ê

ù

û

ú

ú

+sL

fs

ss

sL

æ

è

ç

ö

ø

÷

ESC = –ss[1– NORMDIST(ss / sL

,0,1,1)]

+sL

NORMDIST(ss / sL

,0,1,0)](https://image.slidesharecdn.com/choprascm5ch12-150901040200-lva1-app6891/85/Supply-Chain-Management-chap-12-16-320.jpg)

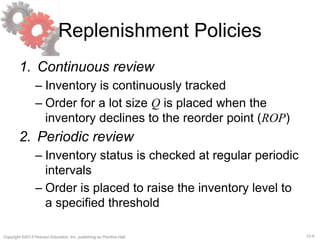

![12-17Copyright ©2013 Pearson Education, Inc. publishing as Prentice Hall.

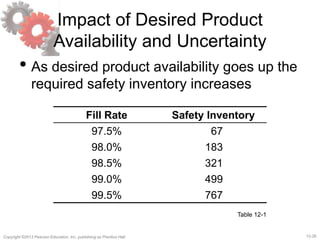

Evaluating Fill Rate Given a

Replenishment Policy

Lot size, Q = 10,000

Average demand during lead time, DL = 5,000

Standard deviation of demand during lead time, sL = 707

Safety inventory, ss = ROP – DL = 6,000 – 5,000 = 1,000

ESC = –1,000[1– NORMDIST(1,000 / 707,0,1,1)]

+707NORMDIST(1,000 / 707,0,1,0) = 25

fr = (Q – ESC)/Q = 110,000 – 252/10,000 = 0.9975](https://image.slidesharecdn.com/choprascm5ch12-150901040200-lva1-app6891/85/Supply-Chain-Management-chap-12-17-320.jpg)

![12-24Copyright ©2013 Pearson Education, Inc. publishing as Prentice Hall.

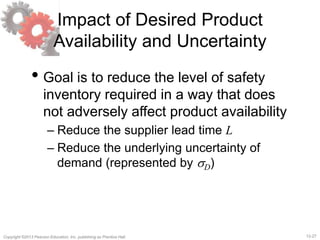

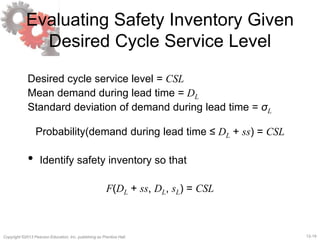

Evaluating Safety Inventory Given

Desired Fill Rate

ESC = 250 = –ss 1– Fs

ss

sL

æ

è

ç

ö

ø

÷

é

ë

ê

ê

ù

û

ú

ú

+sL

fs

ss

sL

æ

è

ç

ö

ø

÷

= –ss 1– Fs

ss

707

æ

è

ç

ö

ø

÷

é

ë

ê

ù

û

ú+ 707 fs

ss

707

æ

è

ç

ö

ø

÷

250 = –ss[1– NORMDIST(ss / 707,0,1,1)]

+707NORMDIST(ss / 707,0,1,0)

• Use GOALSEEK to find safety inventory ss = 67 boxes](https://image.slidesharecdn.com/choprascm5ch12-150901040200-lva1-app6891/85/Supply-Chain-Management-chap-12-24-320.jpg)