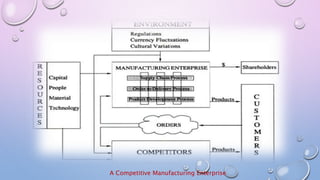

This document discusses strategies for reducing lead times in supply chains. It defines lead time as the time it takes to complete an operation or process. Long lead times are caused by factors like setup times, wait times, and decision-making delays. The key is to map the current supply chain process and identify non-value-added activities. Reducing lead times can increase capacity and sales by cutting bottlenecks. Strategies include line balancing to even out workloads, reducing complexity, and integrating processes through automation. Measuring and comparing production and customer demand times helps determine where to focus optimization efforts.