Nawan Laboratories is a WHO-GMP certified pharmaceutical manufacturer located in Karachi, Pakistan that was established in 1994. It produces human and veterinary medicines and exports products to markets in the Middle East, Africa, and Asia. The company has expanded its operations and certifications over the years to include additional dosage forms and export markets.

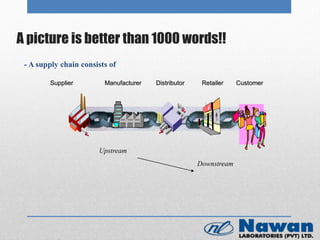

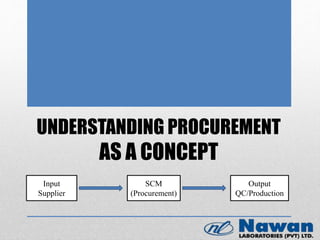

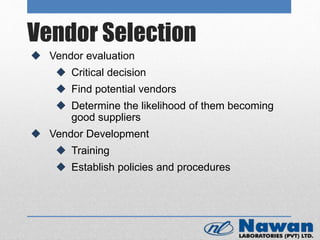

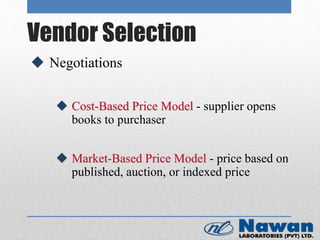

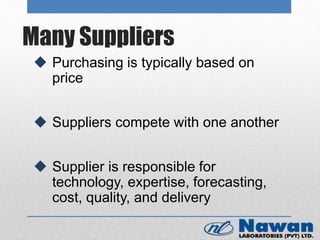

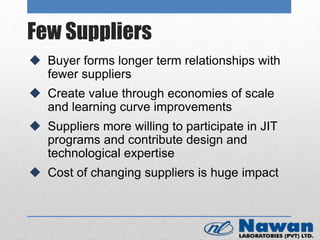

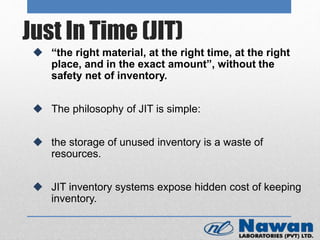

The procurement process at Nawan involves identifying needs, selecting and communicating with suppliers, negotiating purchases, issuing purchase orders, managing logistics and payments. Key elements of purchase orders include pricing, delivery terms, payments, quality specifications and other legal and commercial terms. Vendor selection is an important process that evaluates suppliers on various criteria to find reliable partners.