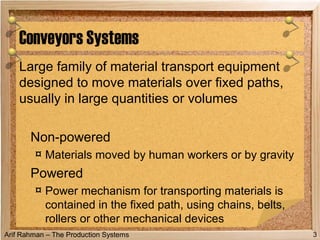

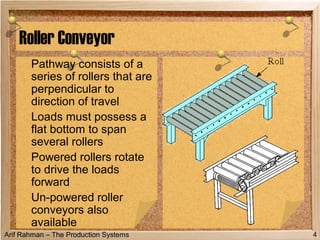

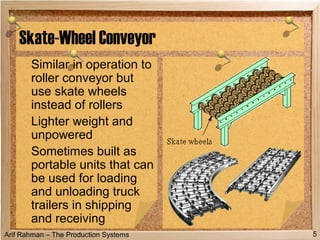

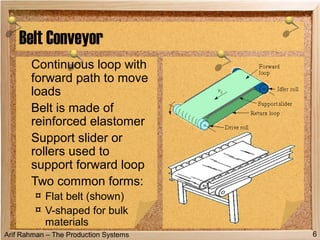

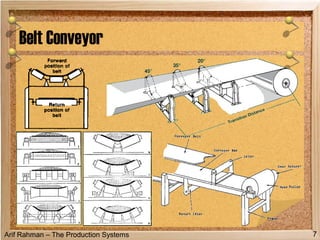

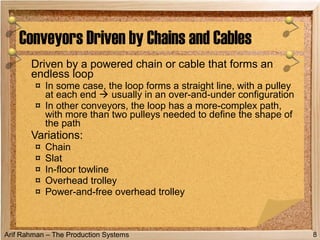

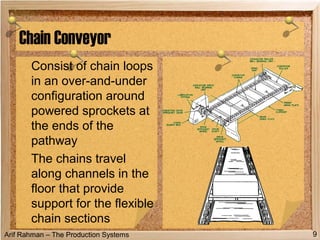

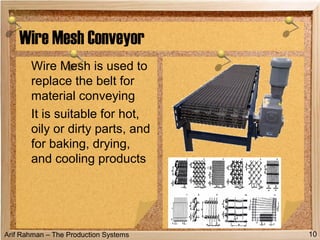

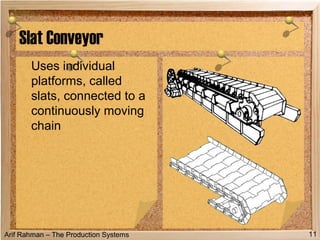

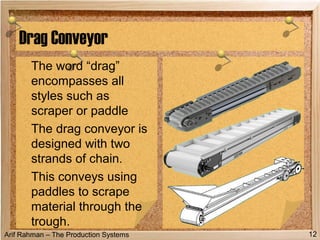

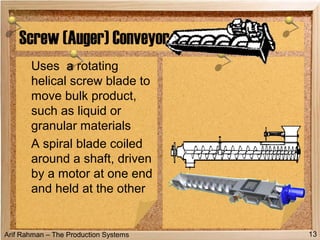

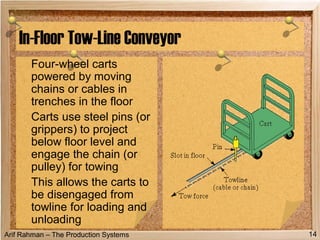

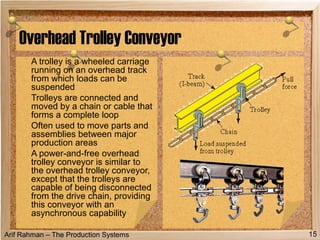

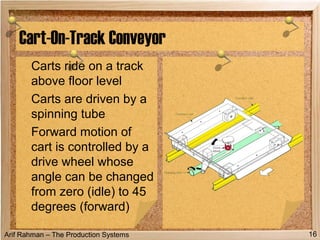

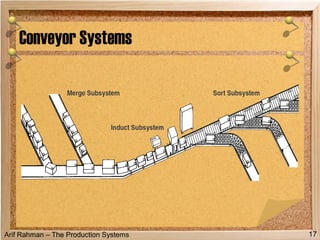

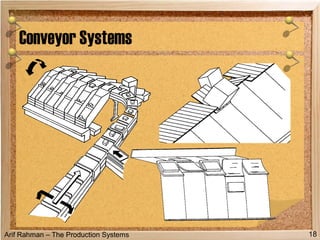

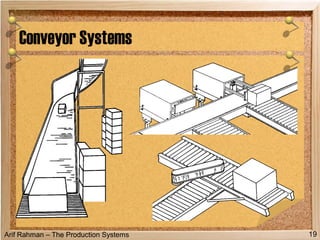

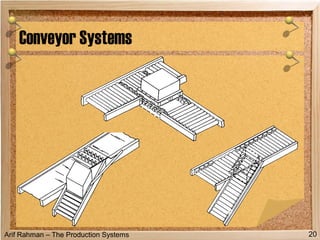

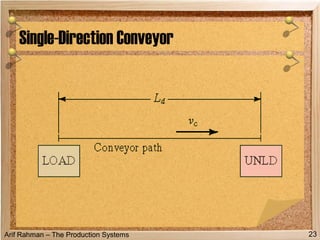

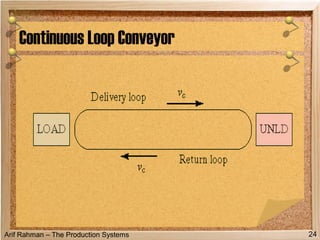

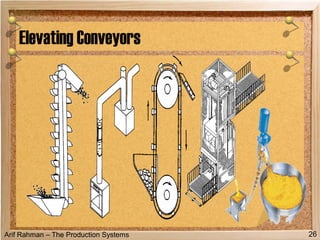

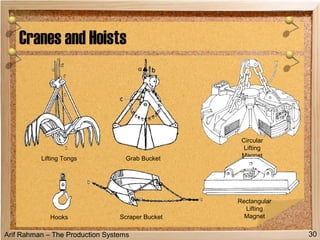

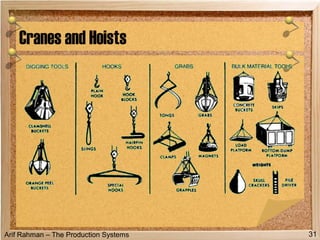

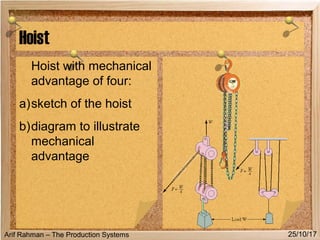

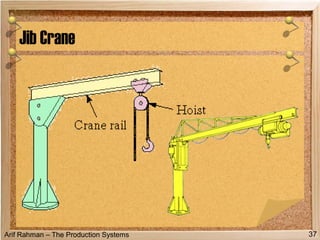

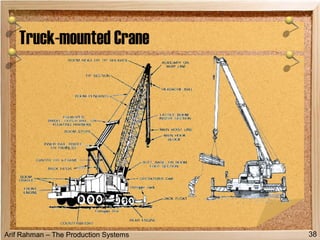

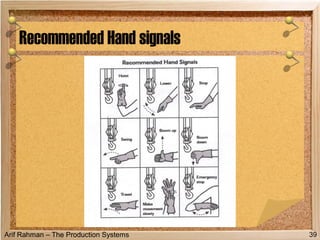

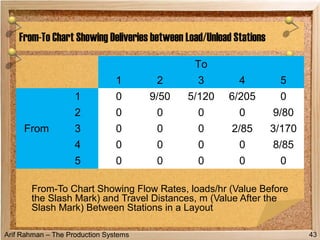

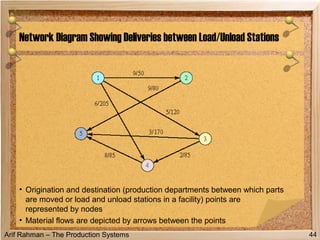

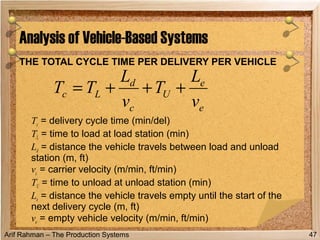

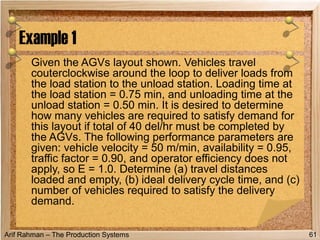

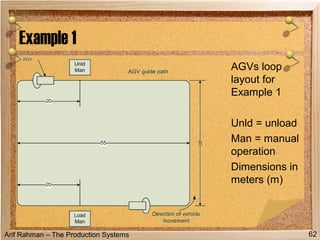

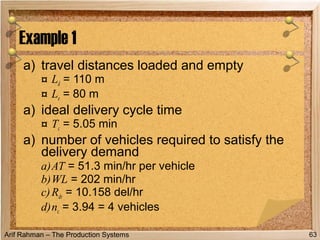

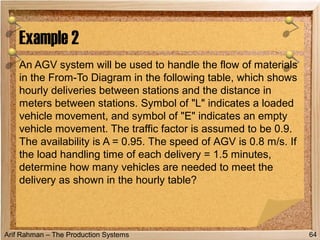

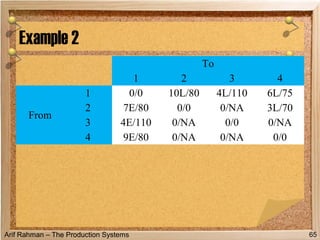

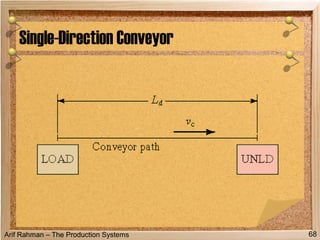

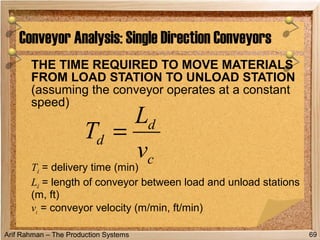

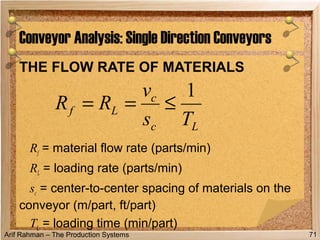

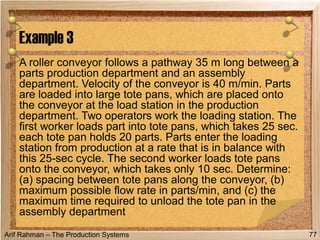

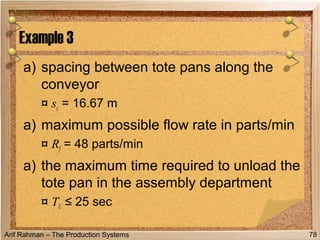

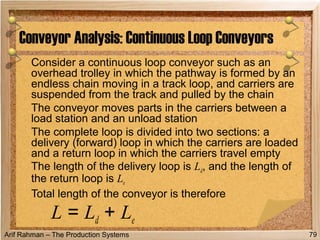

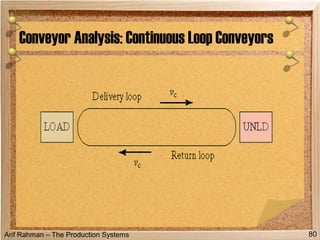

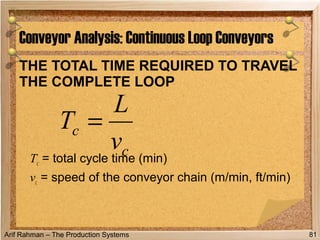

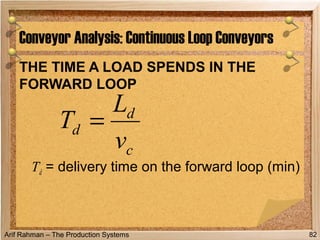

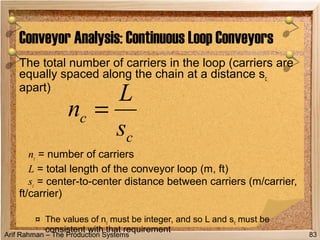

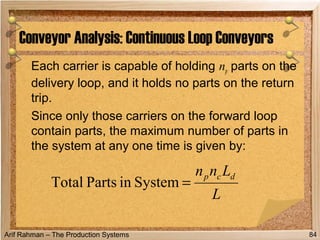

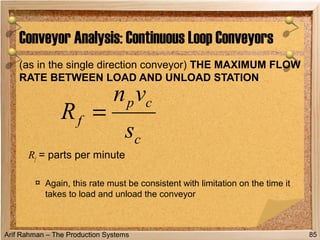

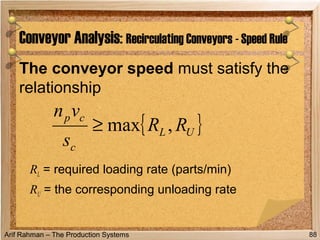

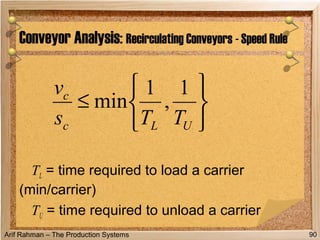

This document discusses different types of material handling equipment used in production systems, including various conveyor types and cranes/hoists. It provides descriptions and diagrams of common conveyor types like roller conveyors, belt conveyors, chain conveyors, and screw conveyors. It also covers analysis of material transport systems using from-to charts, network diagrams, and equations to calculate cycle times.