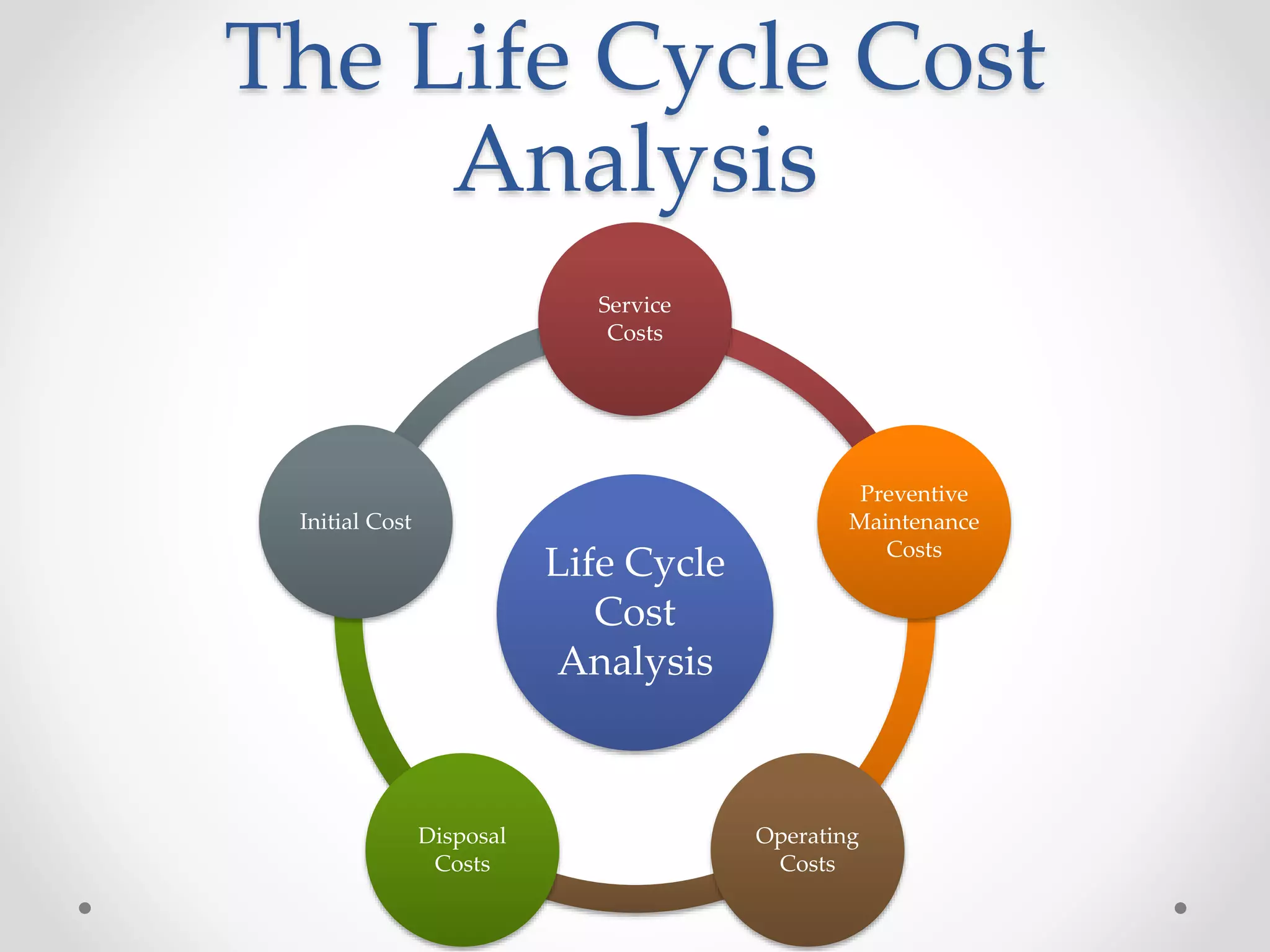

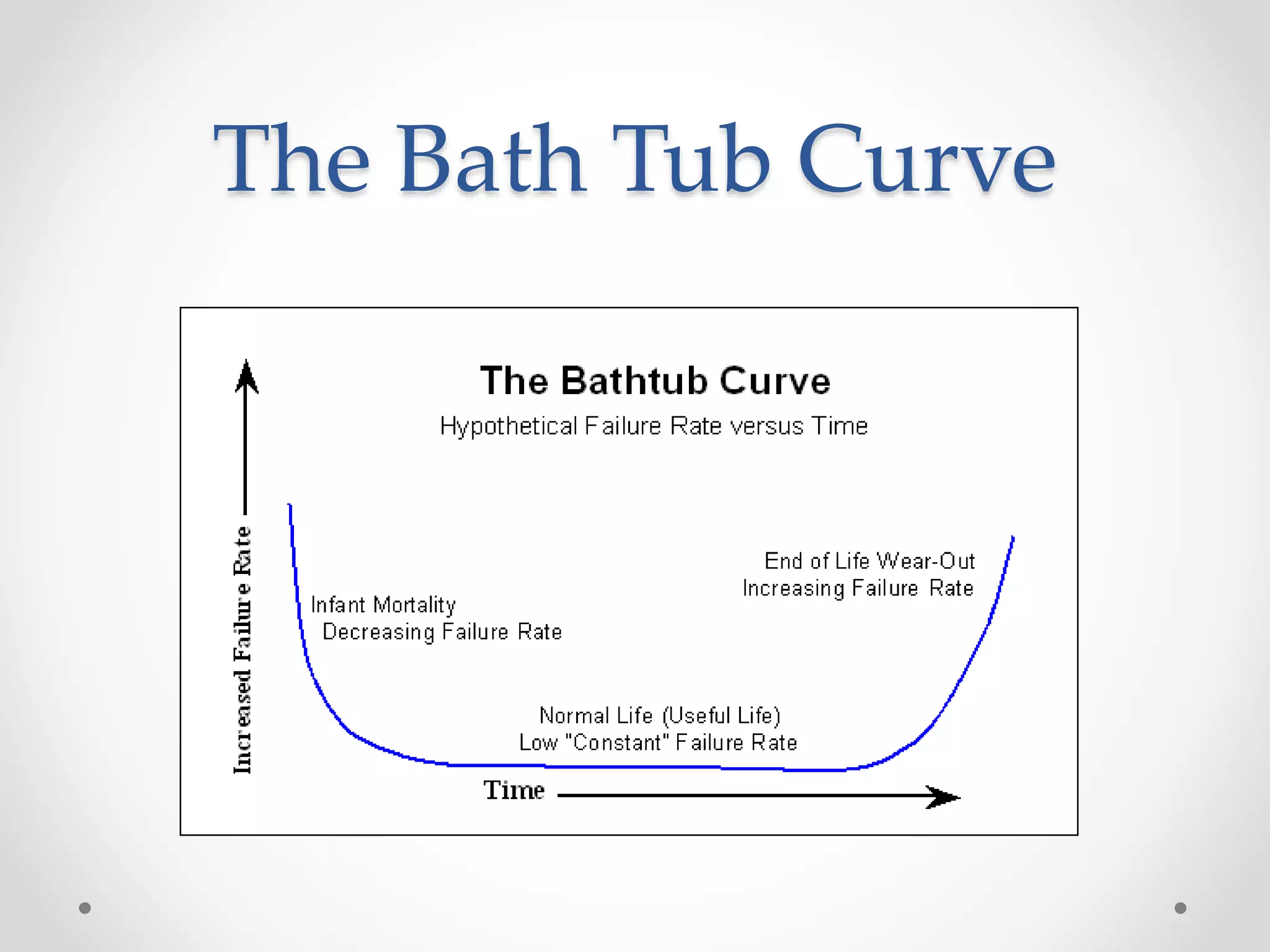

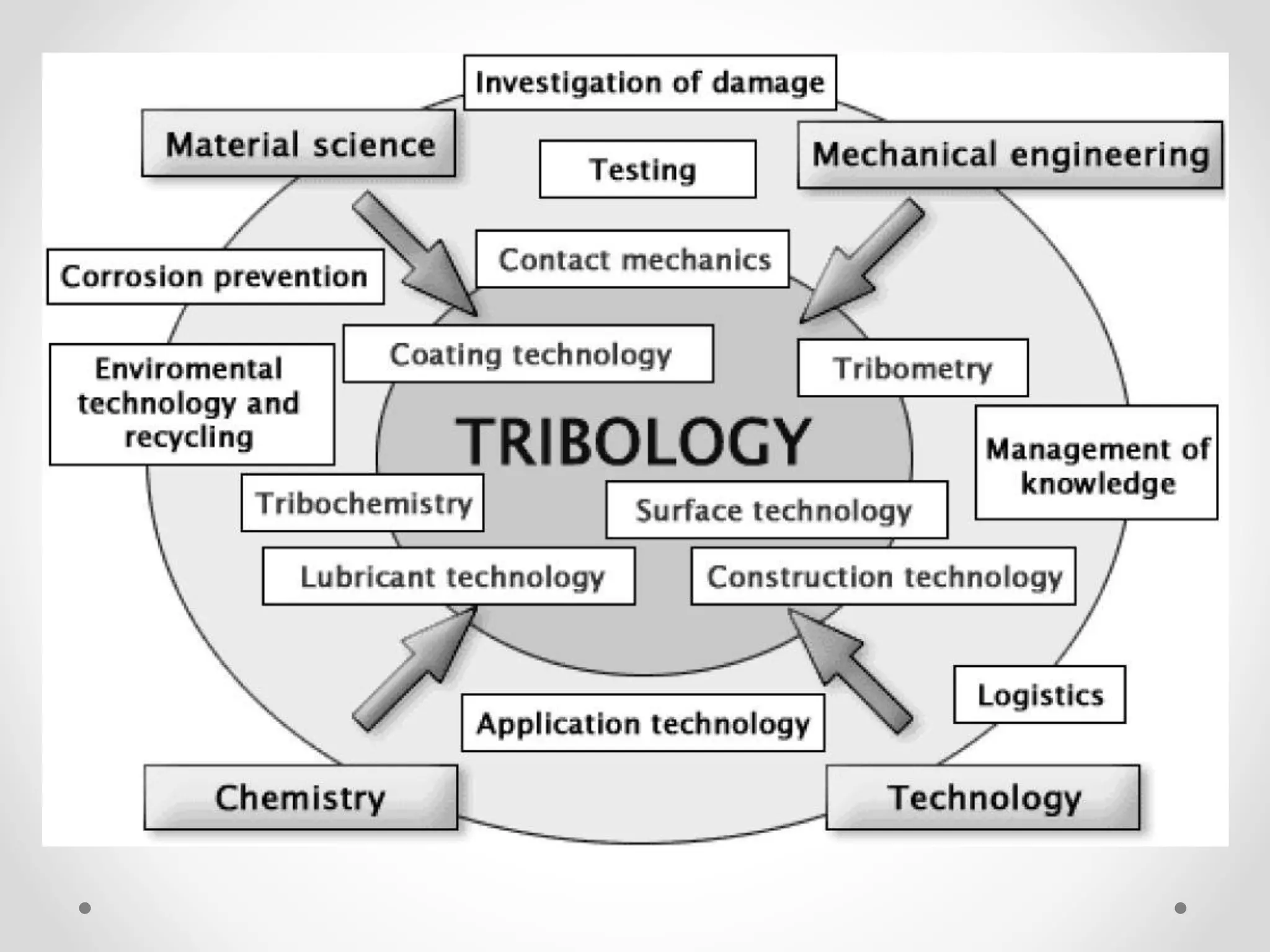

Terotechnology is the applied science of measuring the operational values of physical assets over their lifecycle. It involves installation, maintenance, and replacement, with a focus on life-cycle costing which adds up all positive and negative costs over a period of time. Tribology is the science of interacting surfaces in relative motion, including friction, lubrication, and wear. It aims to minimize wear through surface engineering and lubrication. Both fields analyze physical assets and interactions to optimize maintenance and lifespan for cost savings.