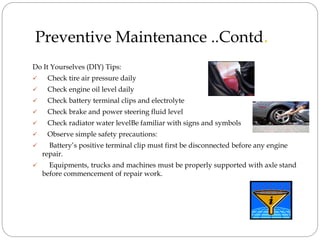

This document discusses maintenance of equipment and machinery. It begins by listing common machinery used in construction projects such as bulldozers, excavators, backhoe loaders, tipper trucks, tower cranes, and others. It then defines maintenance as activities to retain or restore equipment operability. The objectives of maintenance are to maximize equipment usefulness within its lifespan and keep it running efficiently at lowest cost. The document outlines different types of maintenance including preventive, corrective, breakdown, and turn-around maintenance. It provides examples and guidelines for each type. Safety equipment and cautions for maintenance are also discussed.