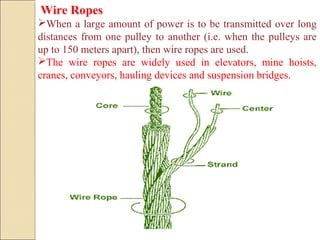

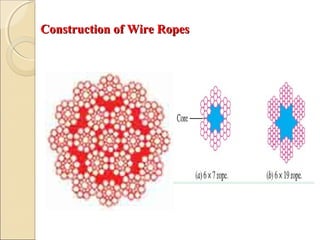

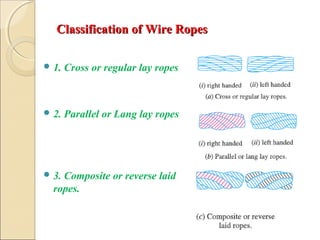

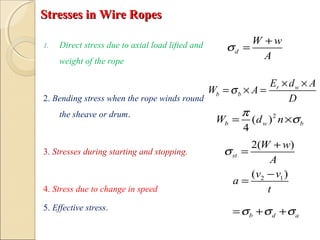

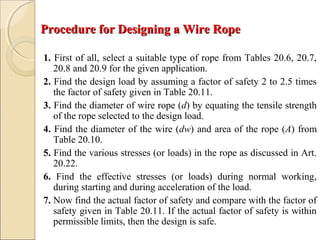

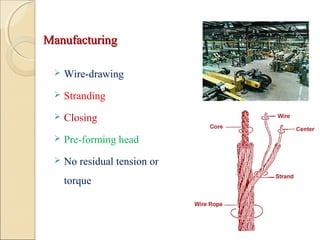

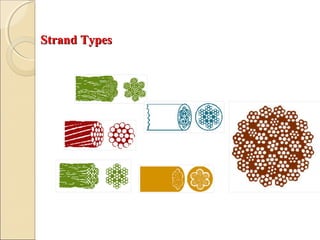

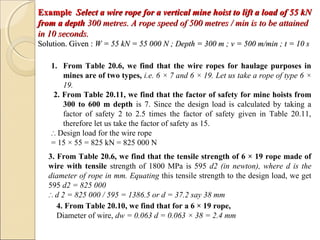

The document discusses the design and selection of wire ropes, including their construction with strands of wires twisted around a core, different types of wire ropes used for various applications like mining hoists and cranes, and factors to consider like breaking strength, flexibility, and fatigue resistance. Procedures for selecting a suitable wire rope include determining the design load based on a safety factor, calculating rope diameter and wire size, and checking stresses and safety factors.