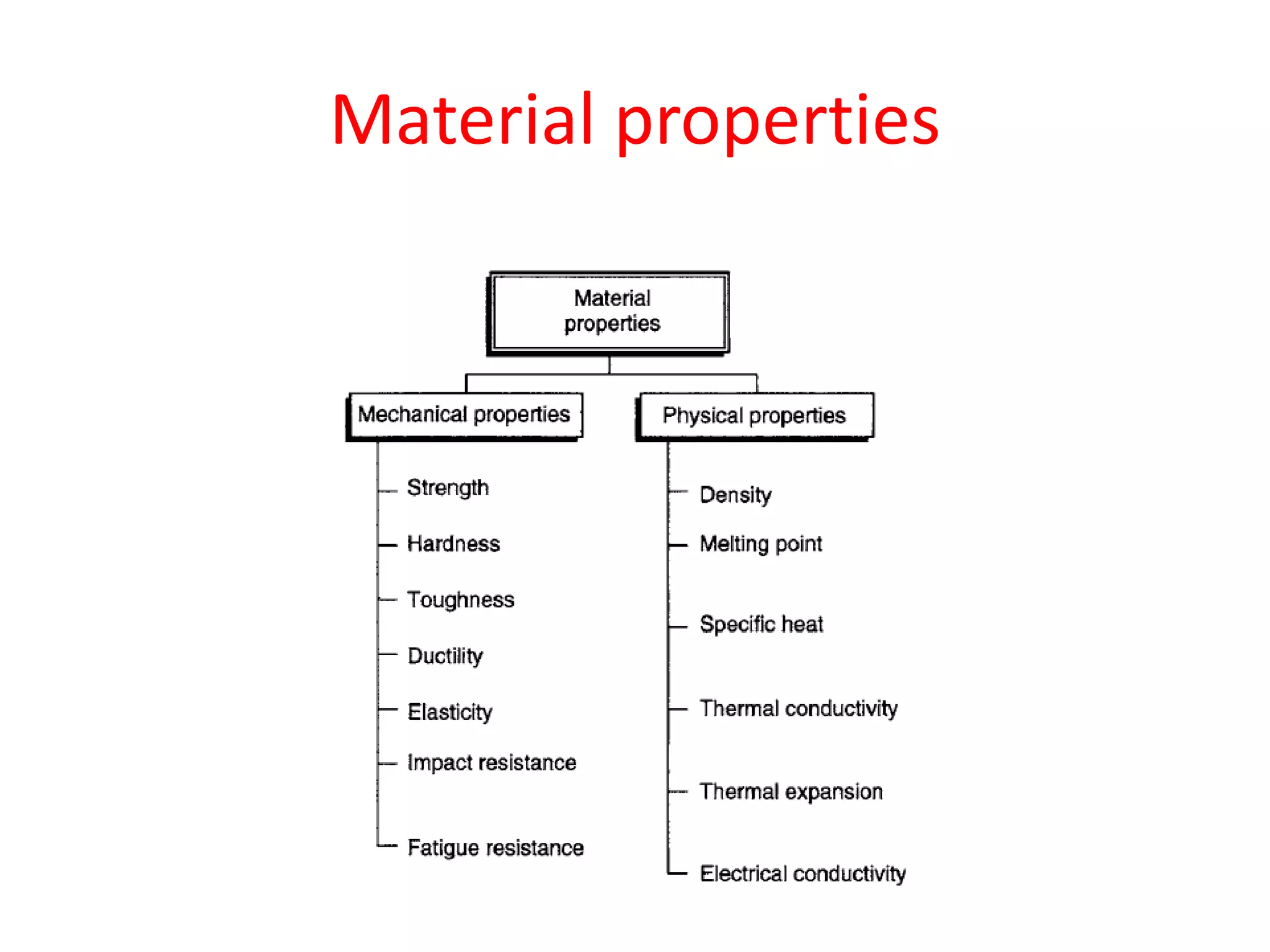

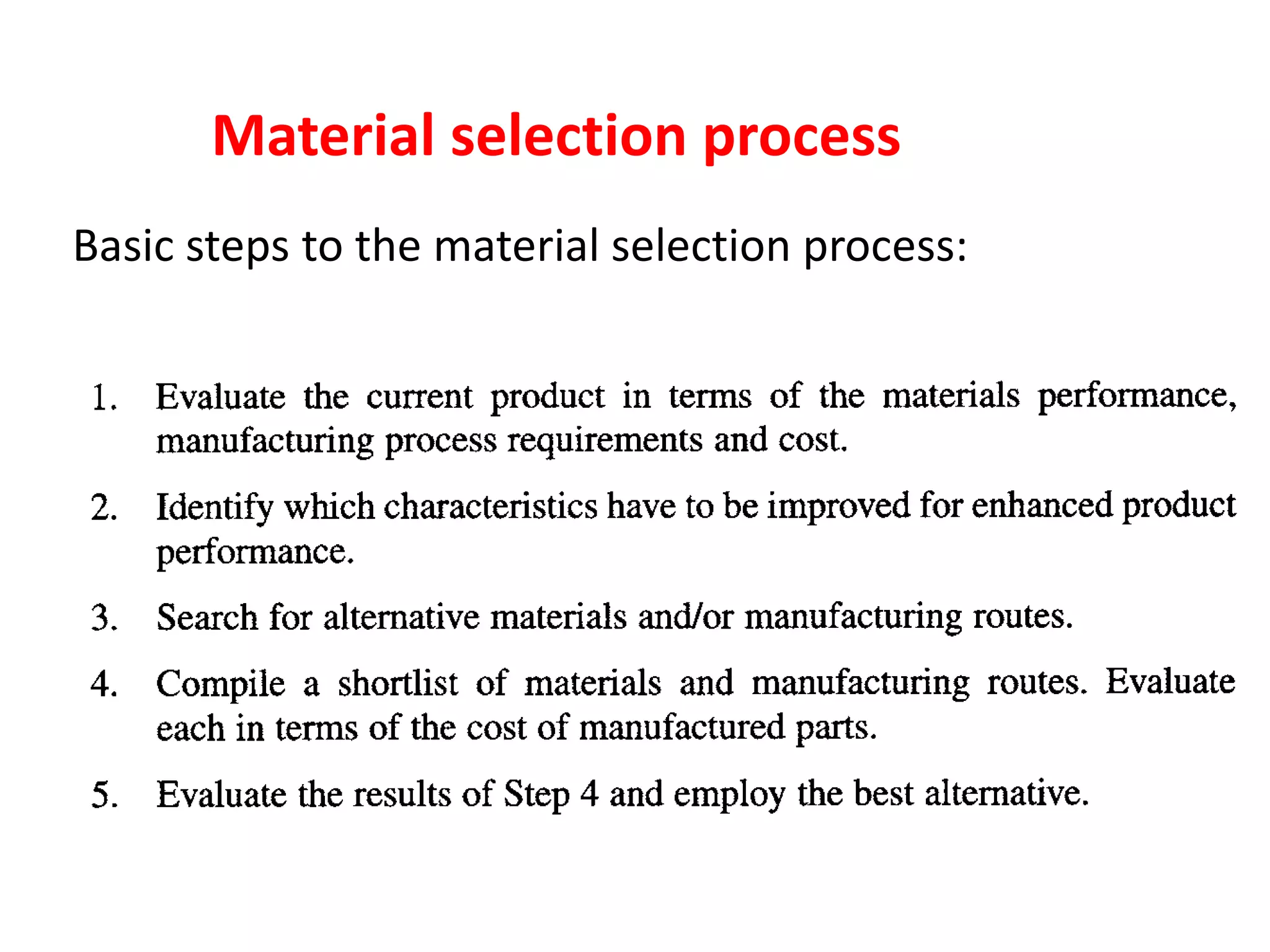

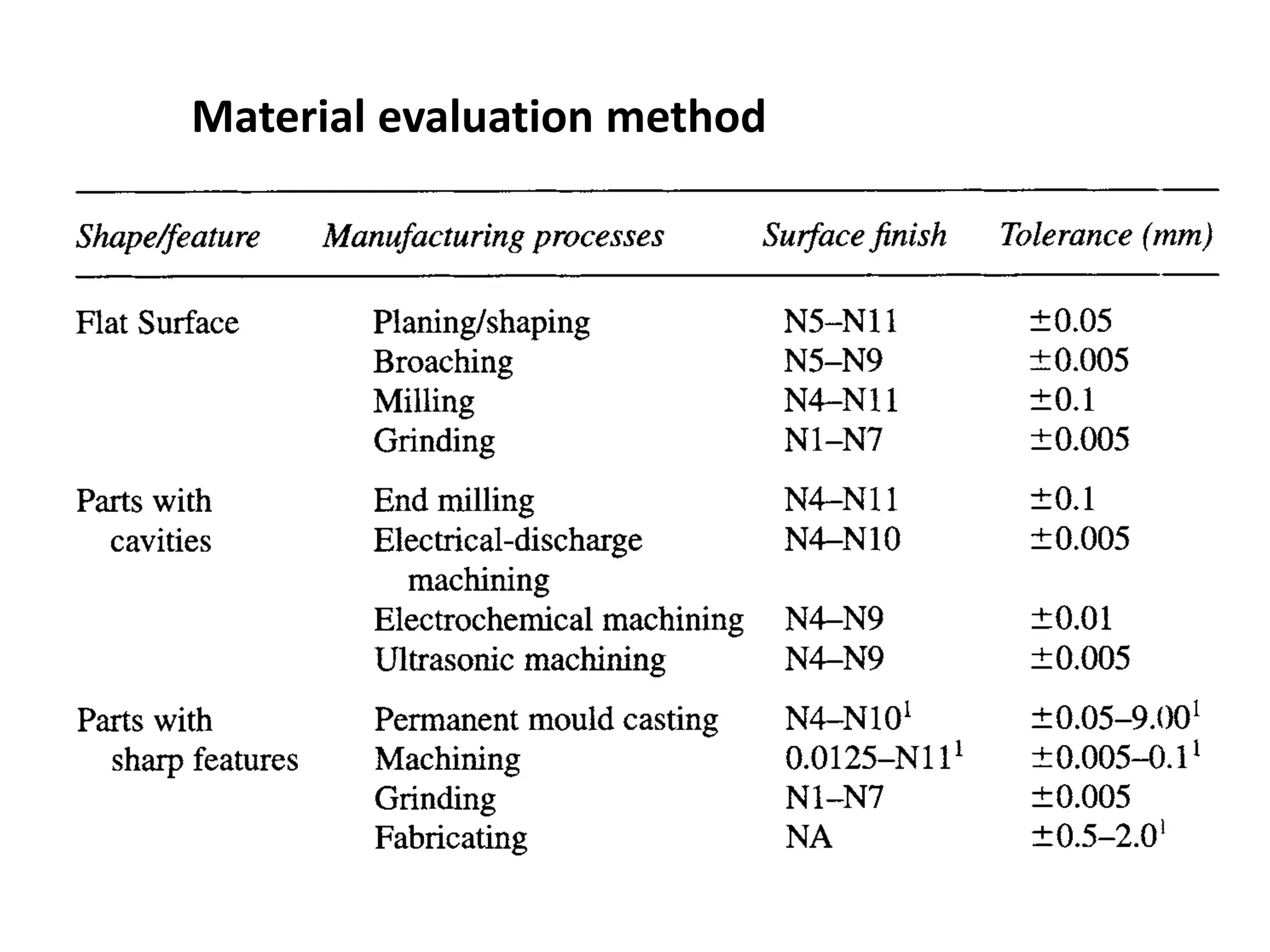

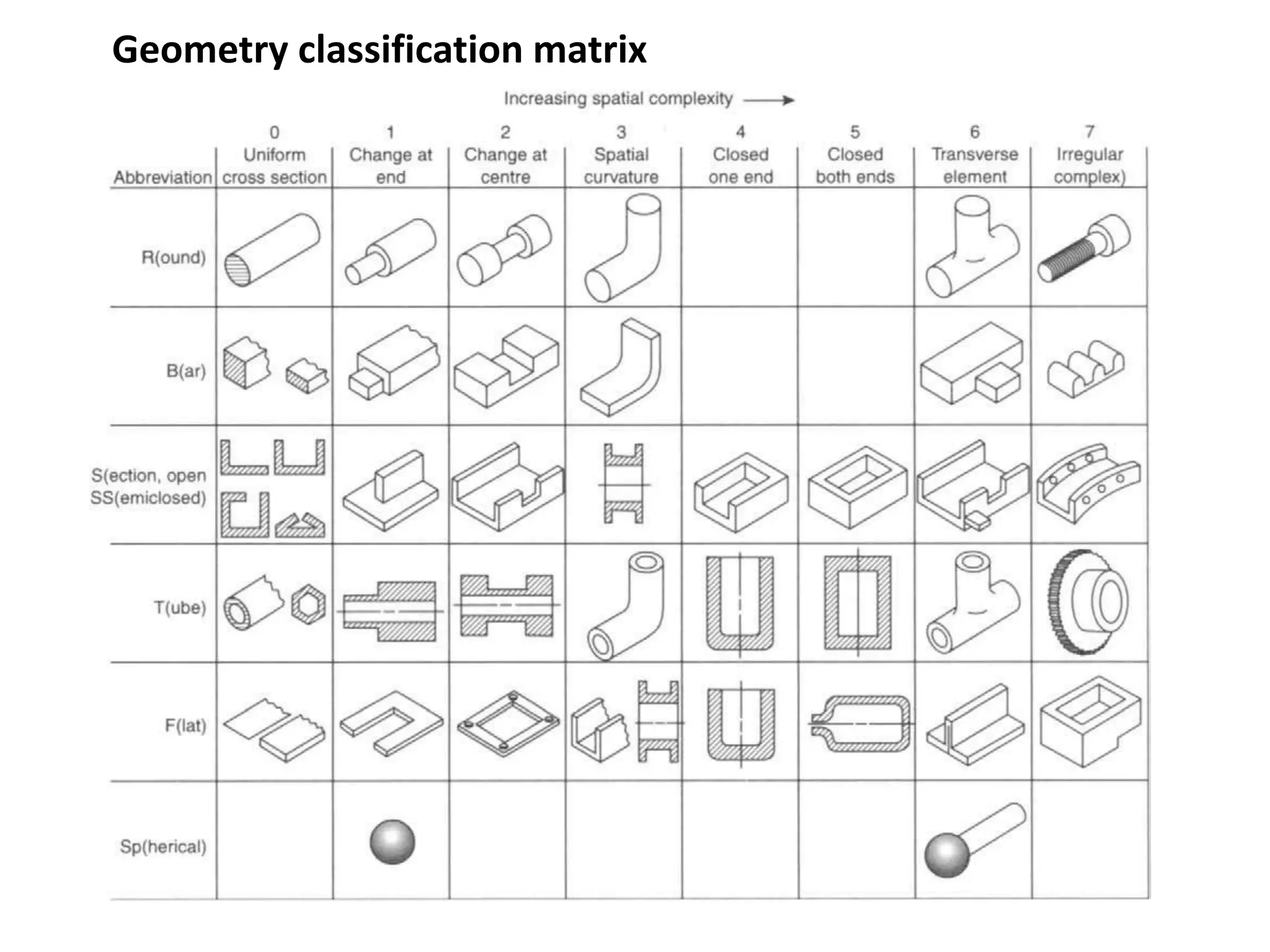

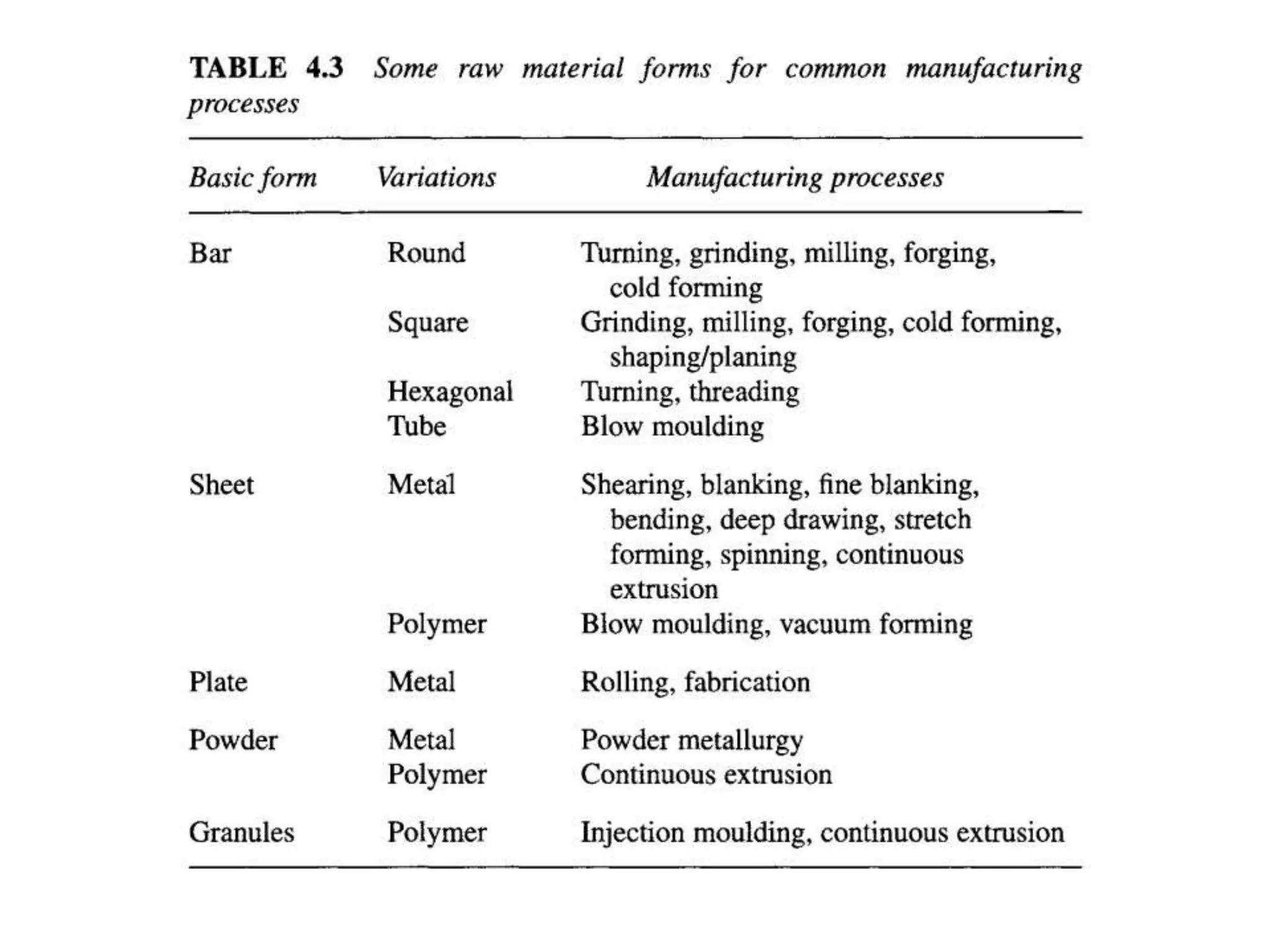

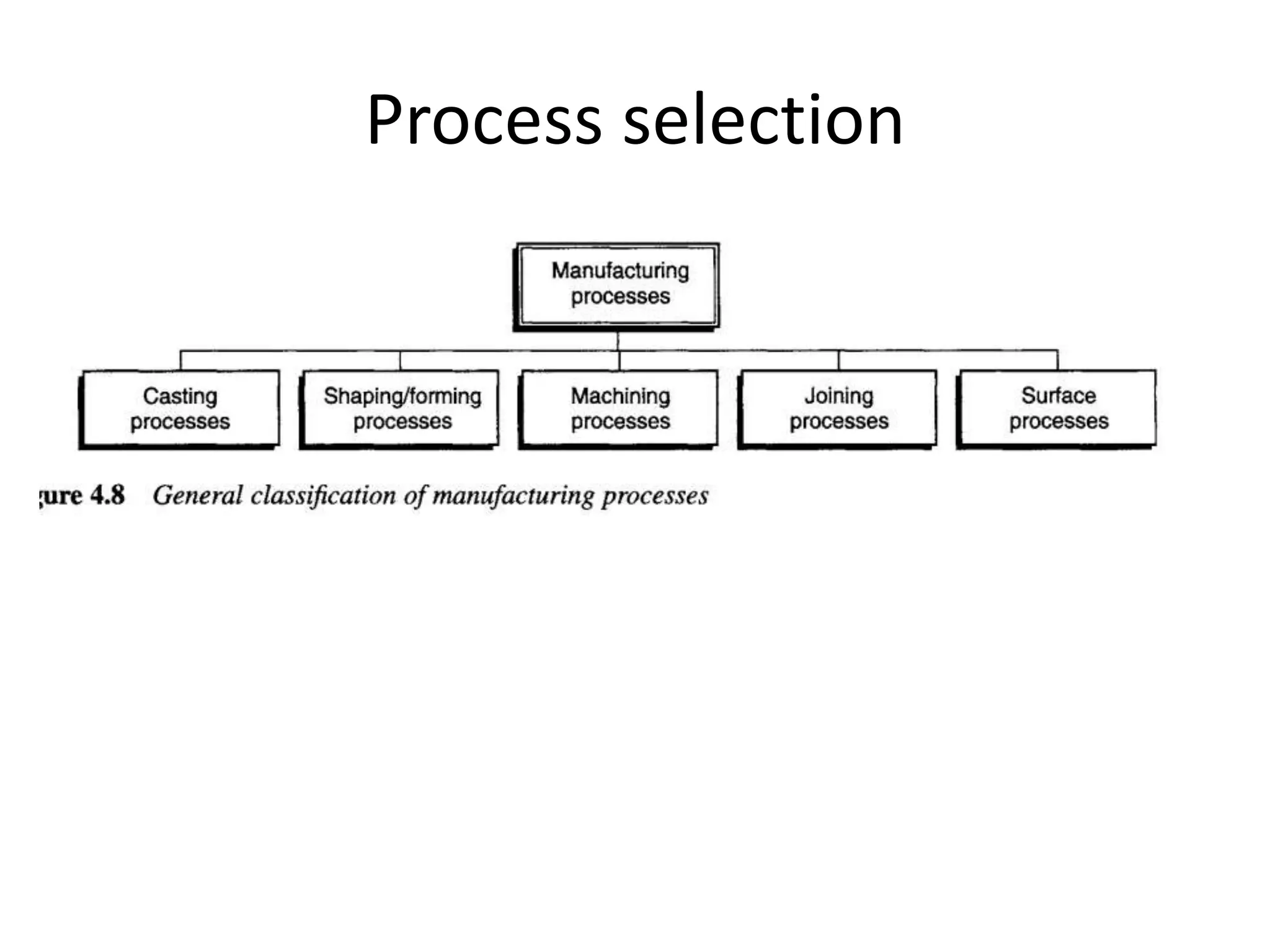

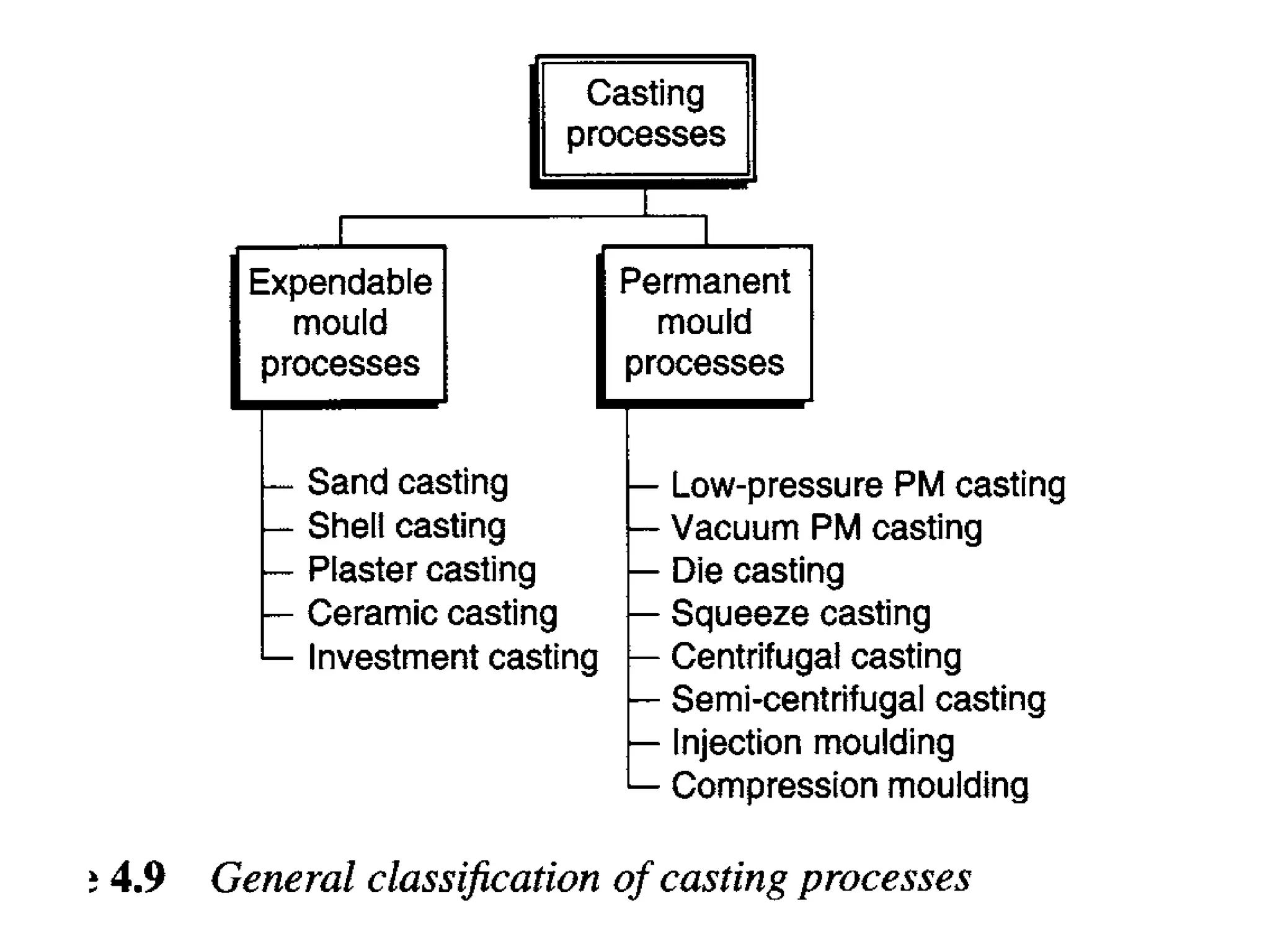

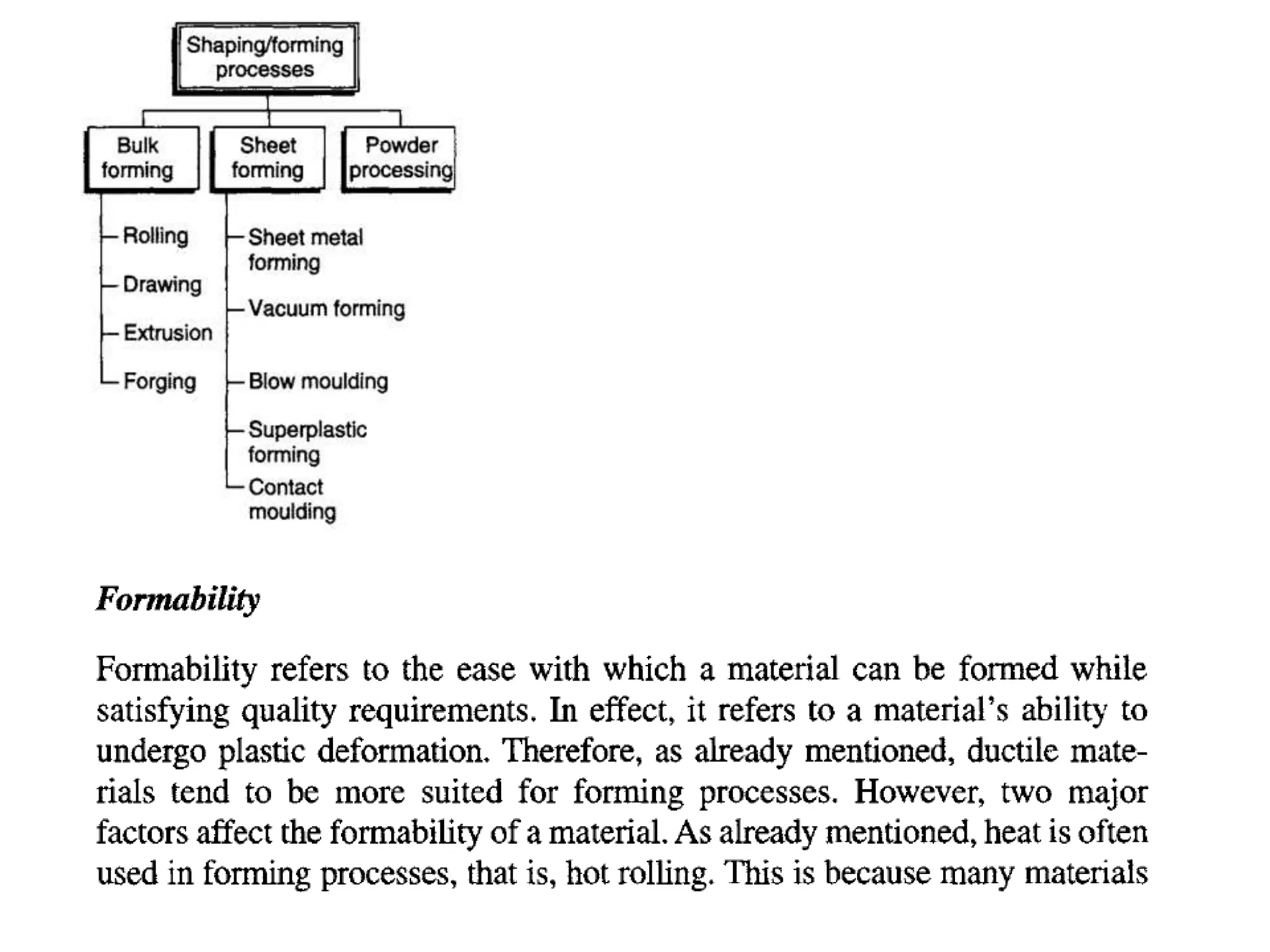

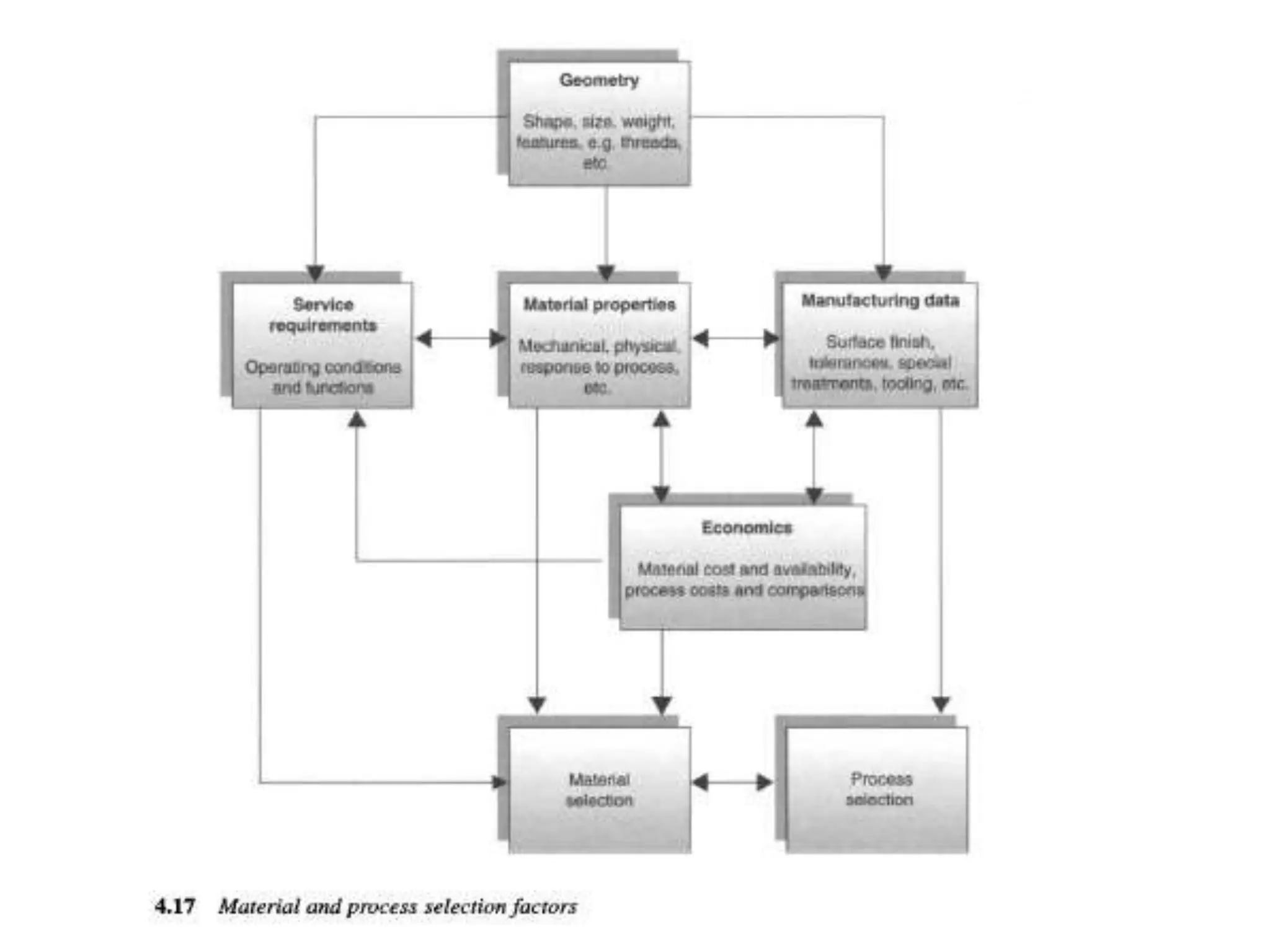

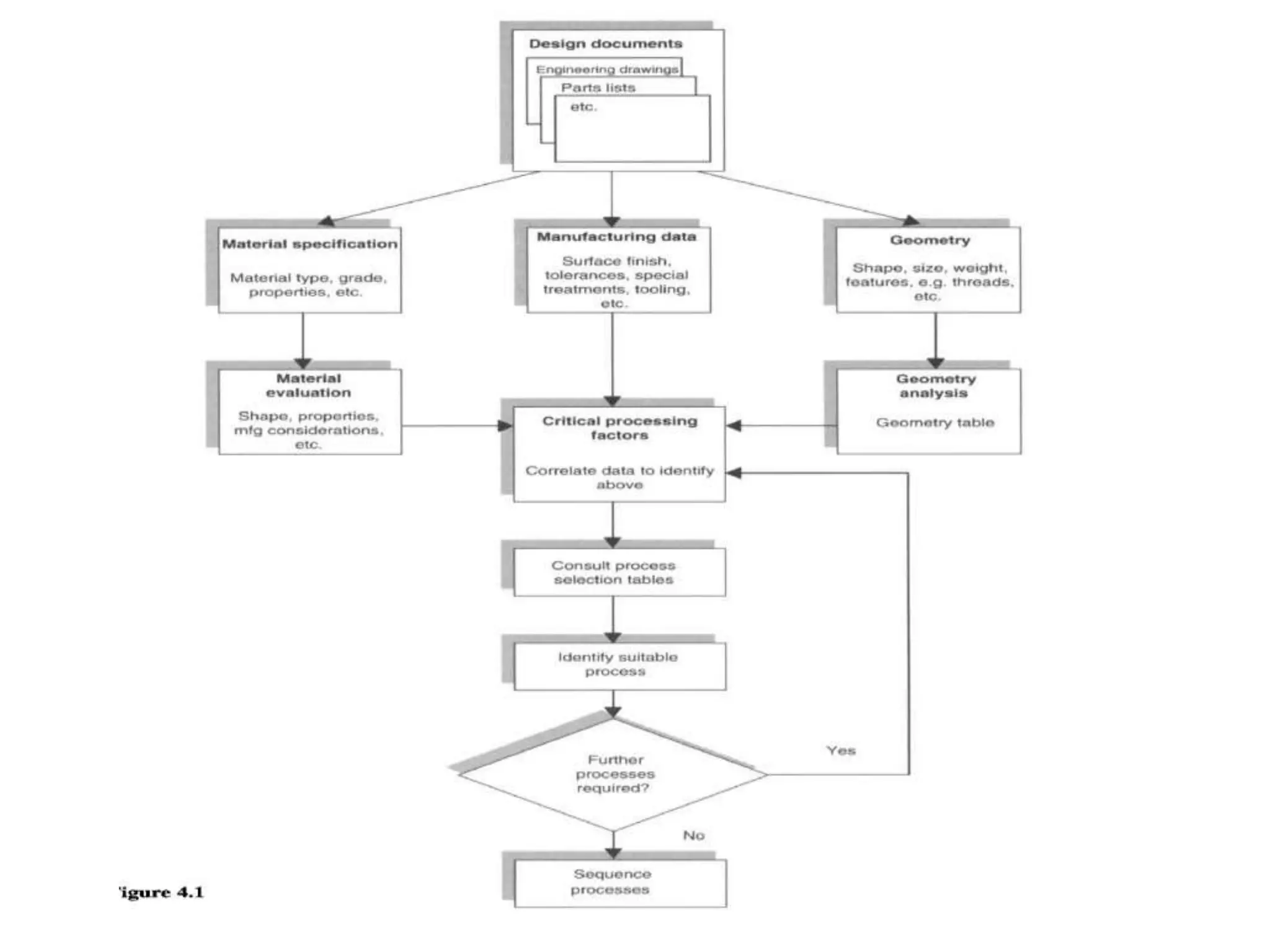

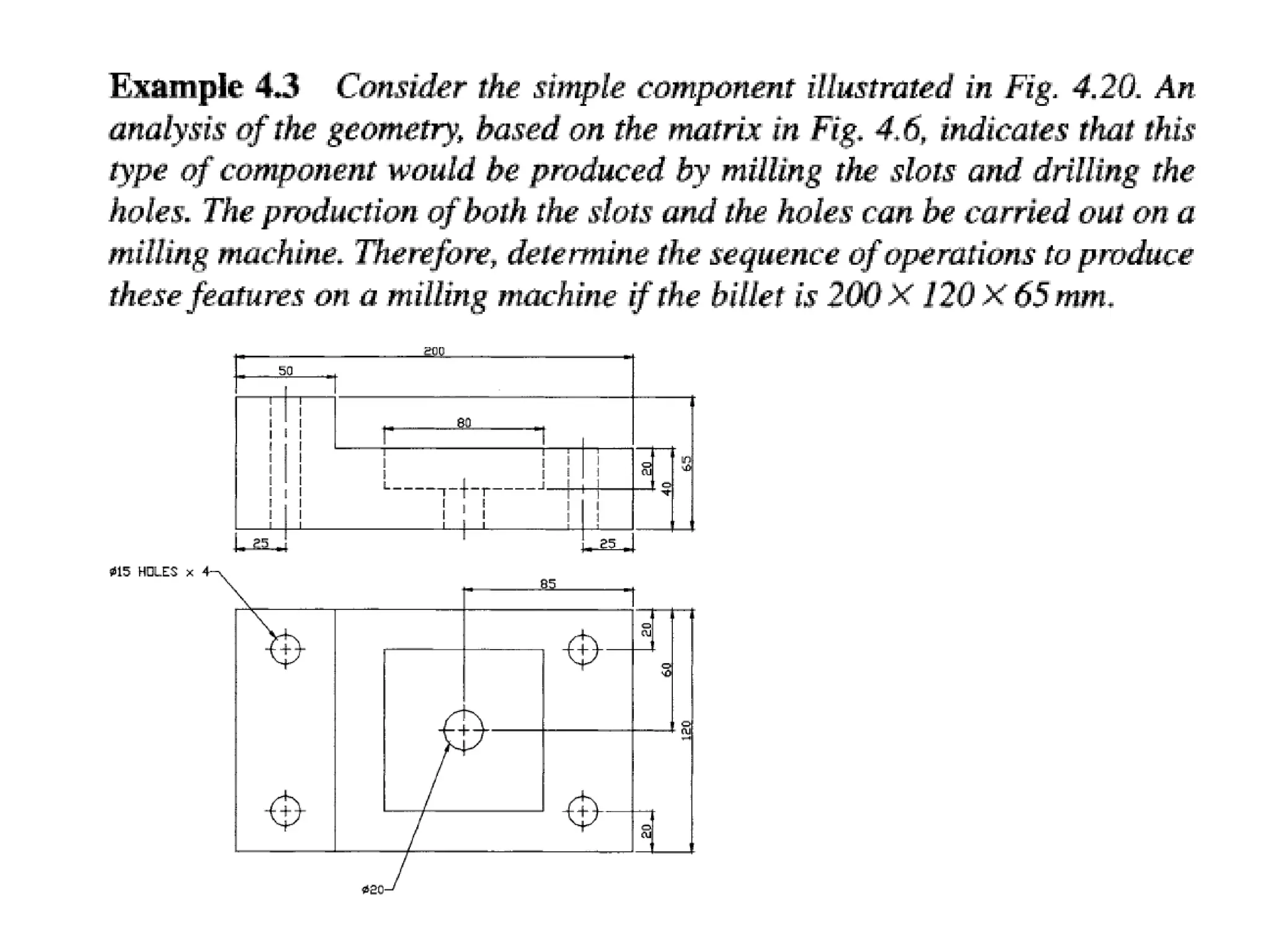

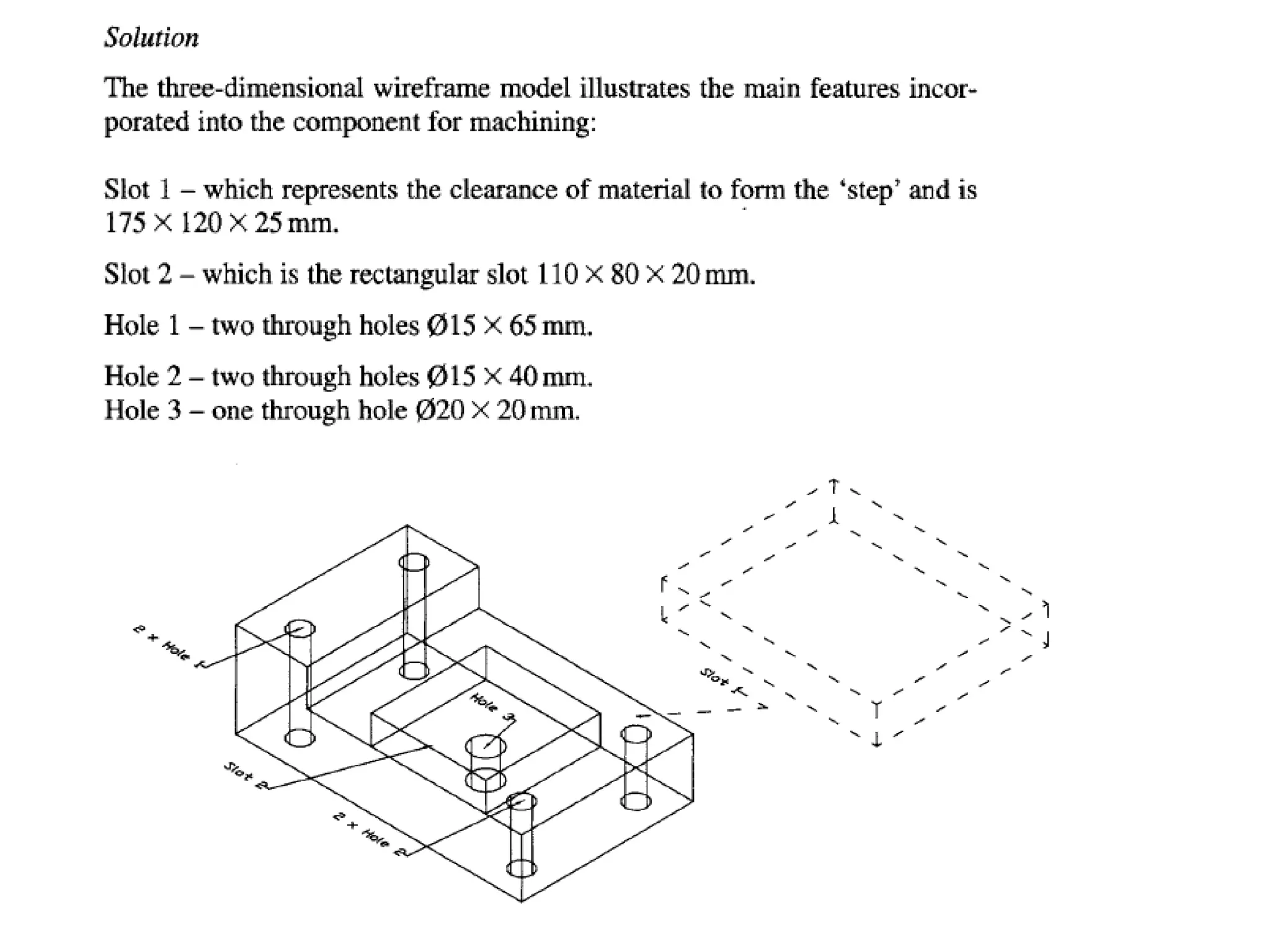

The document discusses four key factors that influence material selection for manufacturing: product design requirements, appropriate material properties, suitable manufacturing processes, and how the material responds during manufacturing and use. It then provides an overview of important material properties like strength, ductility, elasticity, impact and fatigue resistance, as well as physical properties including density, melting point, specific heat, thermal conductivity, and thermal expansion. The document concludes with an overview of the basic steps for material selection and evaluation, including considering geometry, material requirements, manufacturing considerations, and selecting appropriate processes.