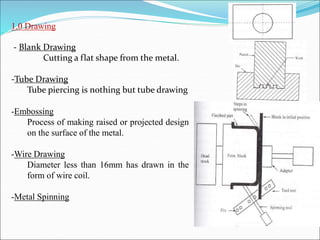

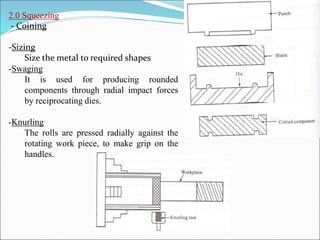

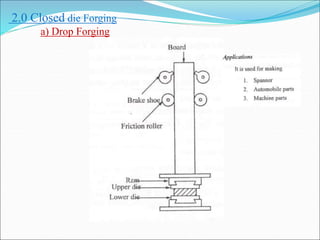

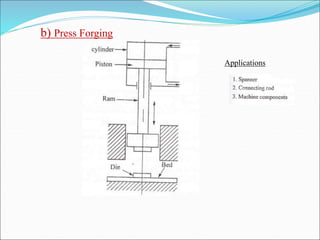

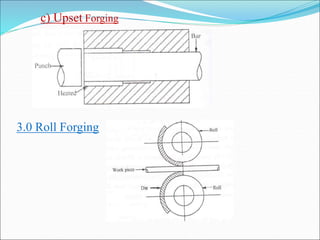

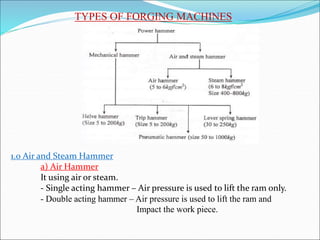

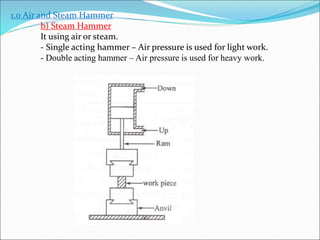

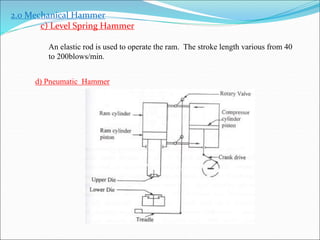

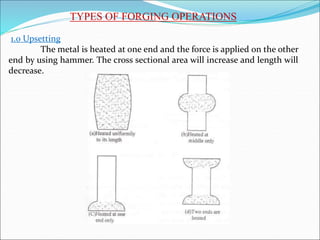

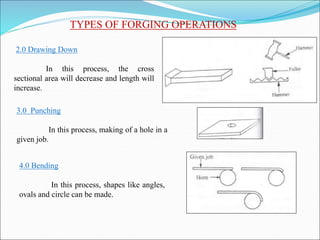

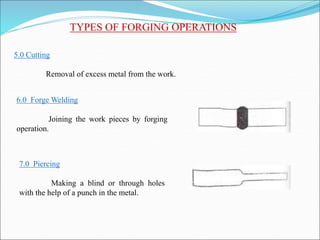

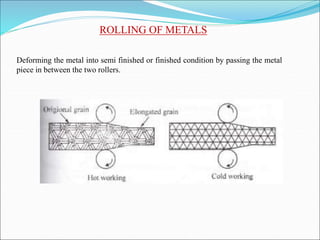

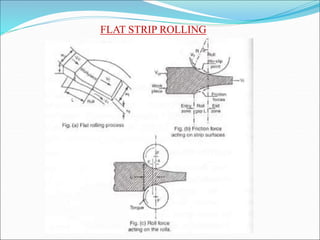

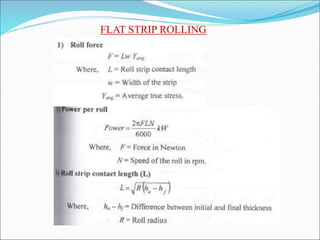

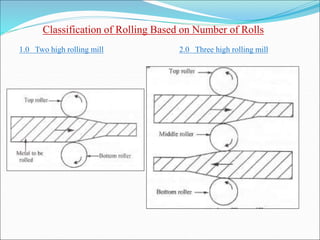

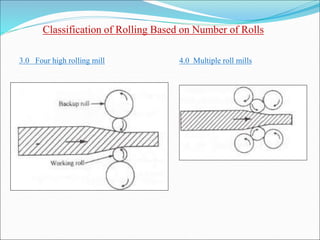

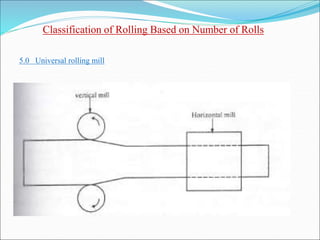

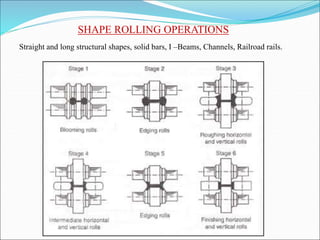

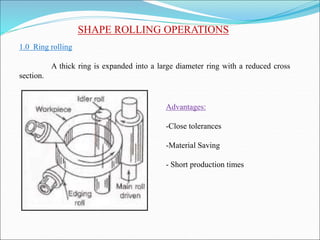

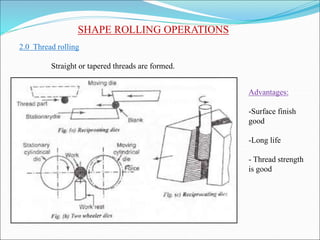

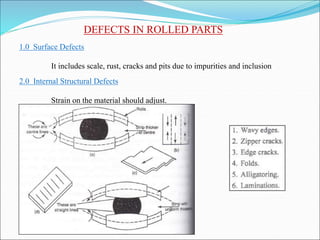

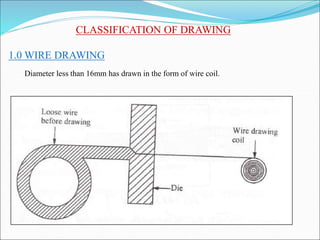

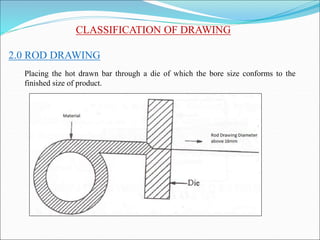

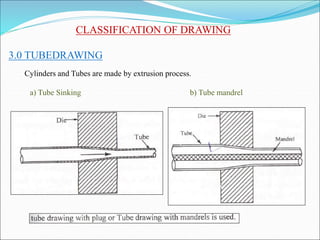

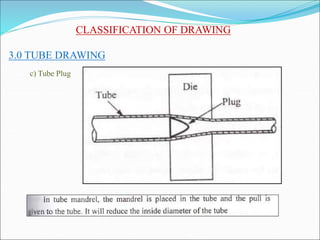

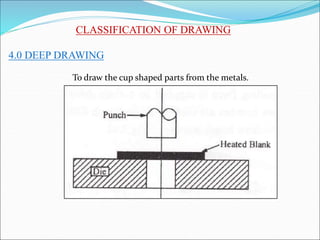

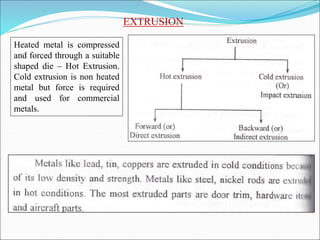

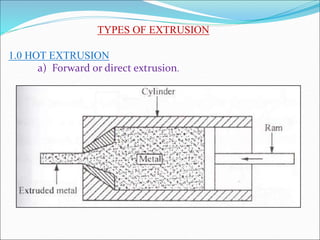

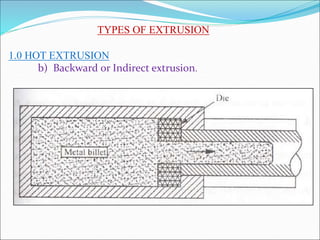

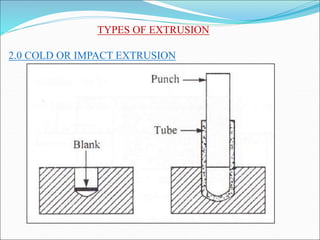

The document details metal forming processes, including hot and cold working techniques such as forging, rolling, drawing, and extrusion, with a focus on different methods and types for each process. It explains the principles behind each process, the machines used, and common operations involved, as well as potential defects in the final products. Detailed descriptions are provided for operations such as drawing, bending, forging, and various types of rolling, informing readers about their applications and significance in metalworking.