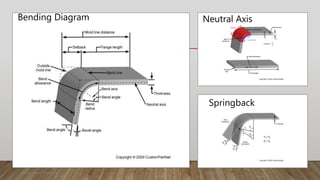

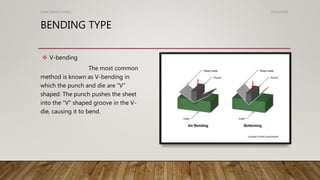

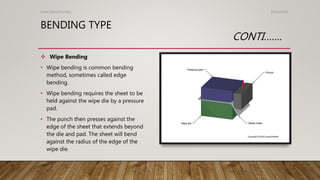

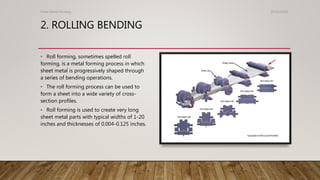

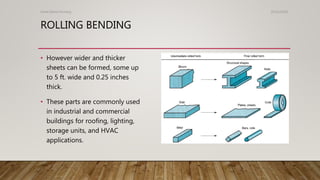

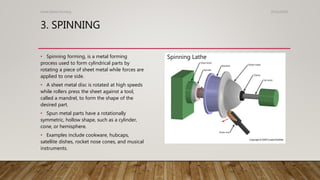

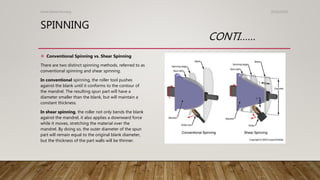

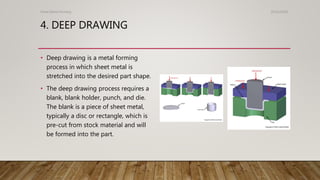

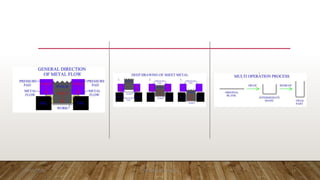

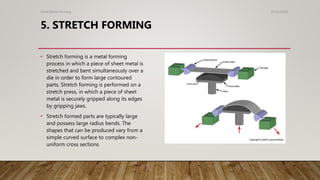

Sheet metal forming processes modify the geometry of sheet metal by applying force to stress the metal beyond its yield strength, causing plastic deformation. The main sheet metal forming processes are bending, roll forming, spinning, deep drawing, and stretch forming. Bending involves applying force to cause the metal to bend into the desired shape. Roll forming progressively shapes sheet metal through a series of bending operations to create long parts with complex cross-sections. Spinning forms cylindrical parts by rotating sheet metal and applying pressure with rollers against a mandrel. Deep drawing stretches sheet metal into shape using a blank, blank holder, punch, and die. Stretch forming simultaneously stretches and bends sheet metal over a die to form large contoured parts.