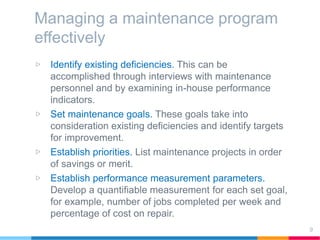

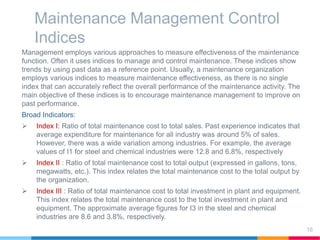

The document outlines the functions and management of maintenance departments in industrial settings, emphasizing the importance of effective maintenance management and control. It discusses the principles, objectives, and techniques necessary for managing maintenance programs, including planning, preventive maintenance, and performance measurement. Additionally, it introduces various indices to evaluate maintenance effectiveness and efficiency across different industries.