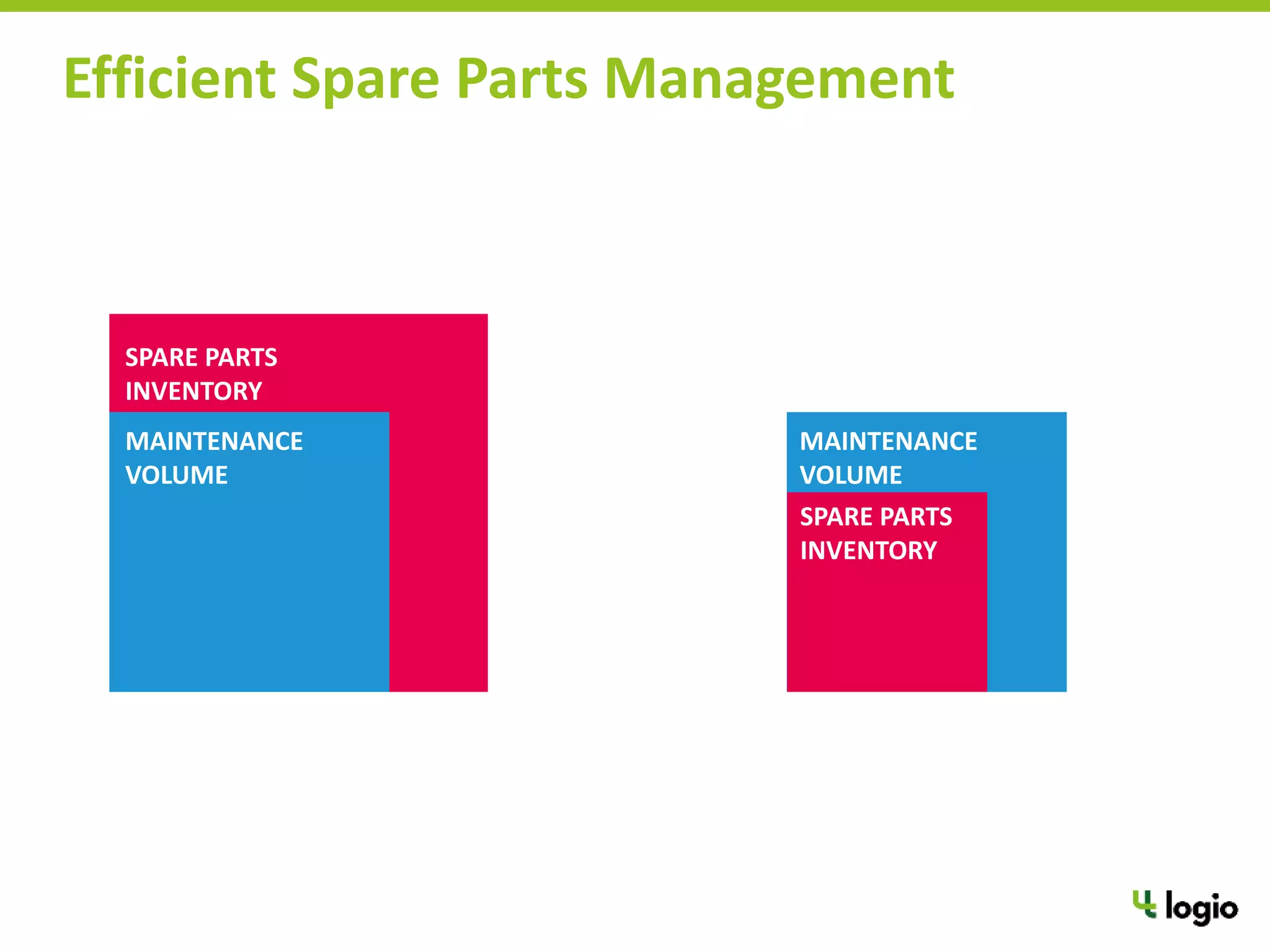

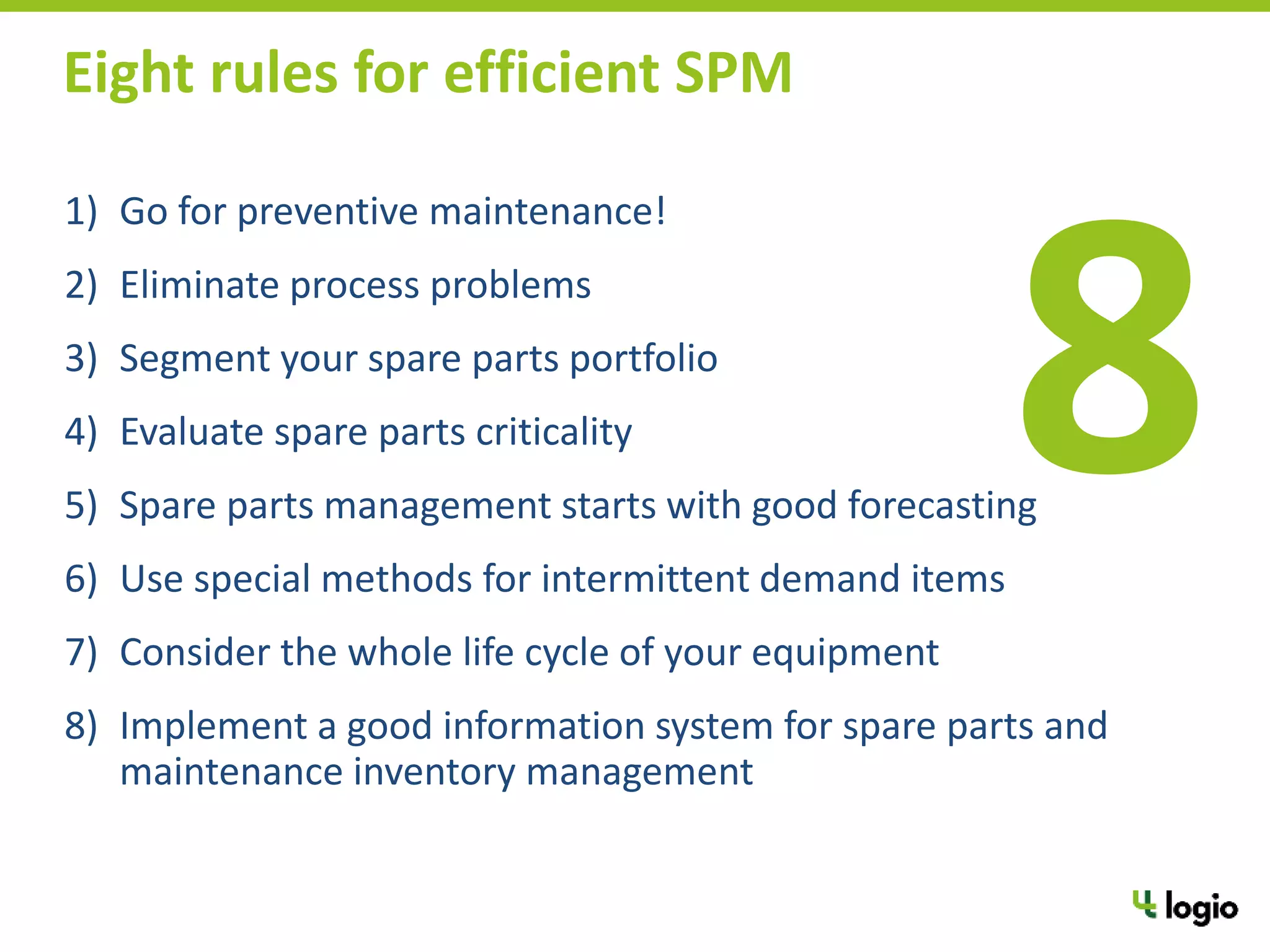

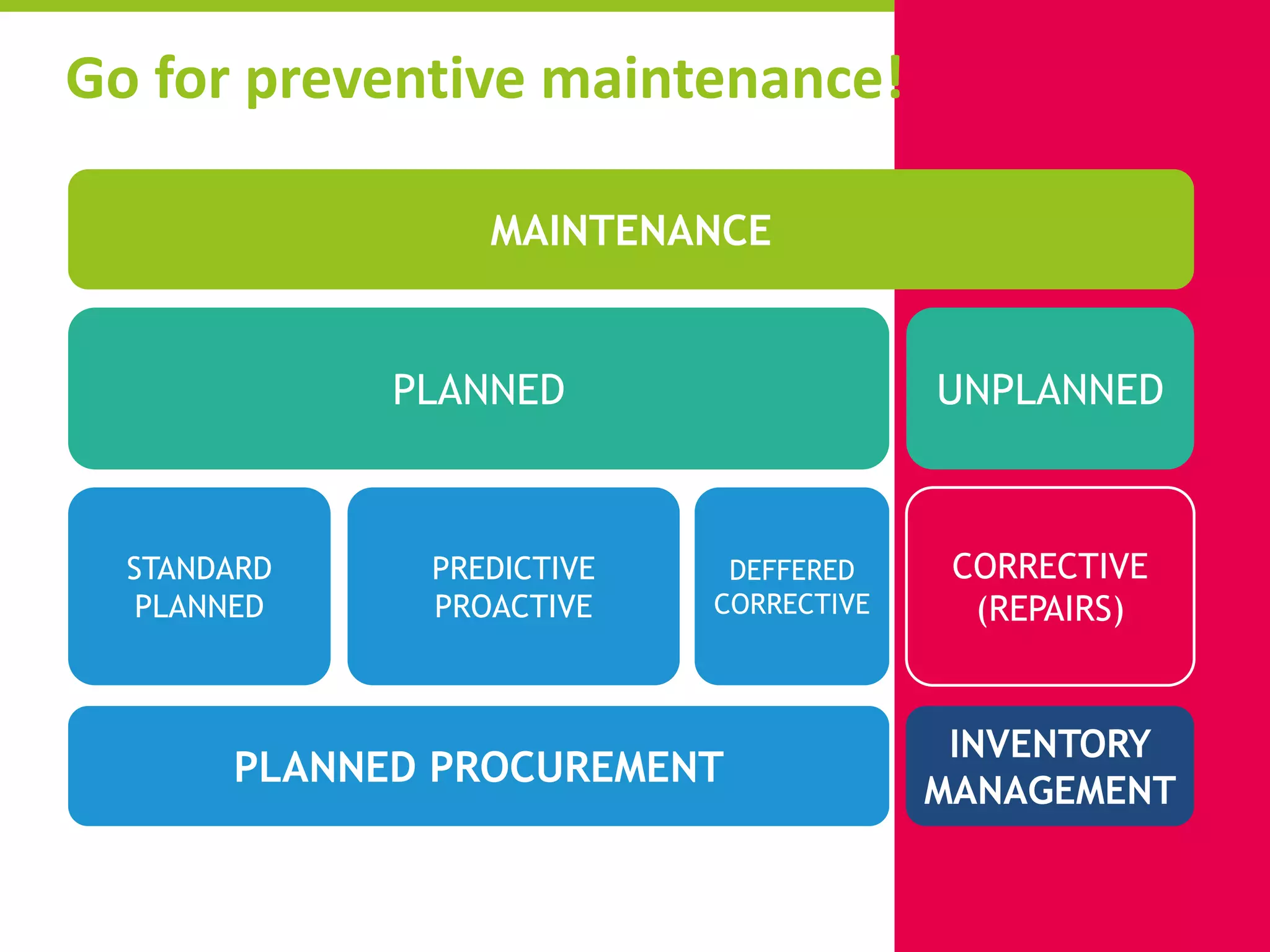

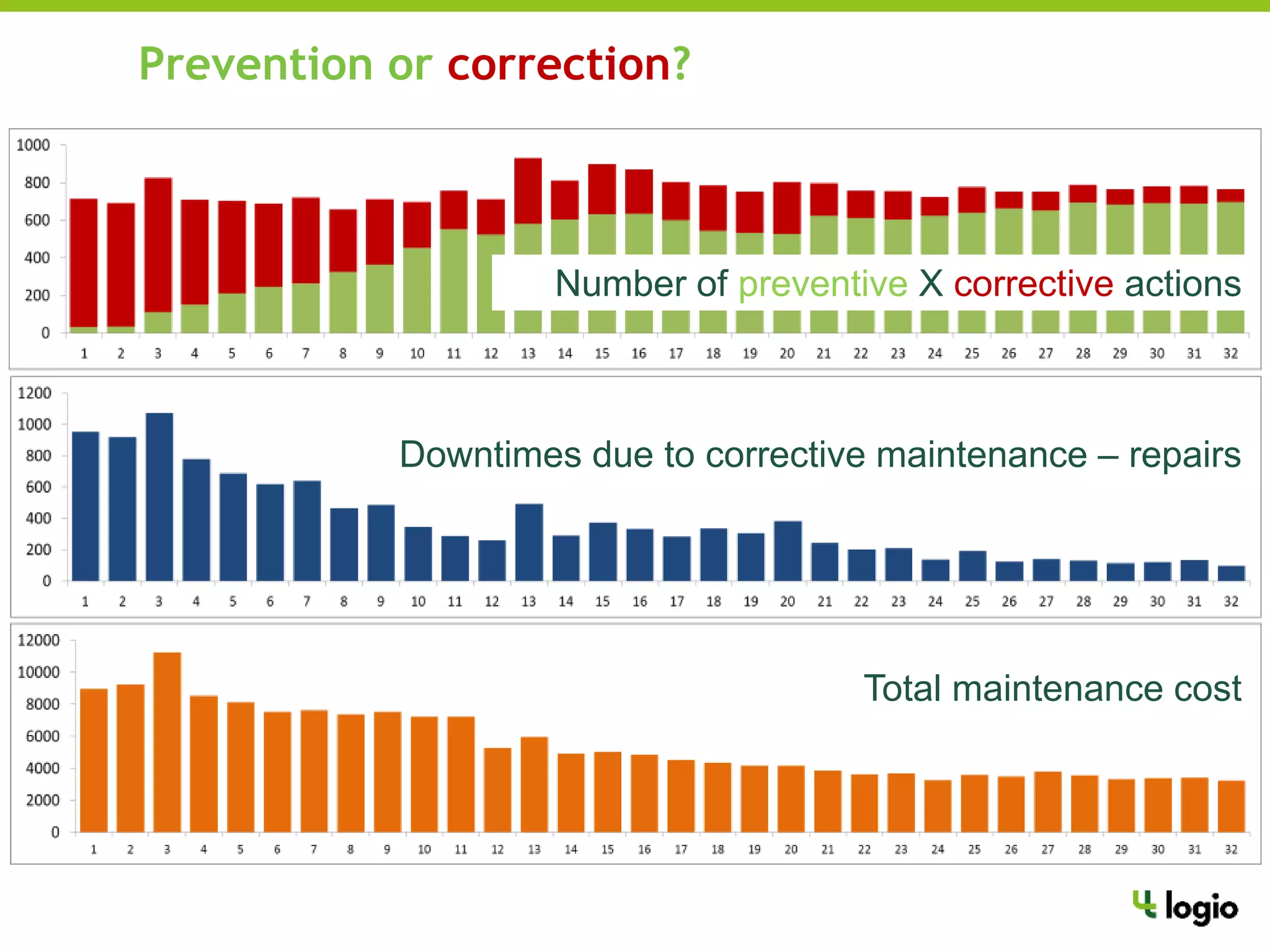

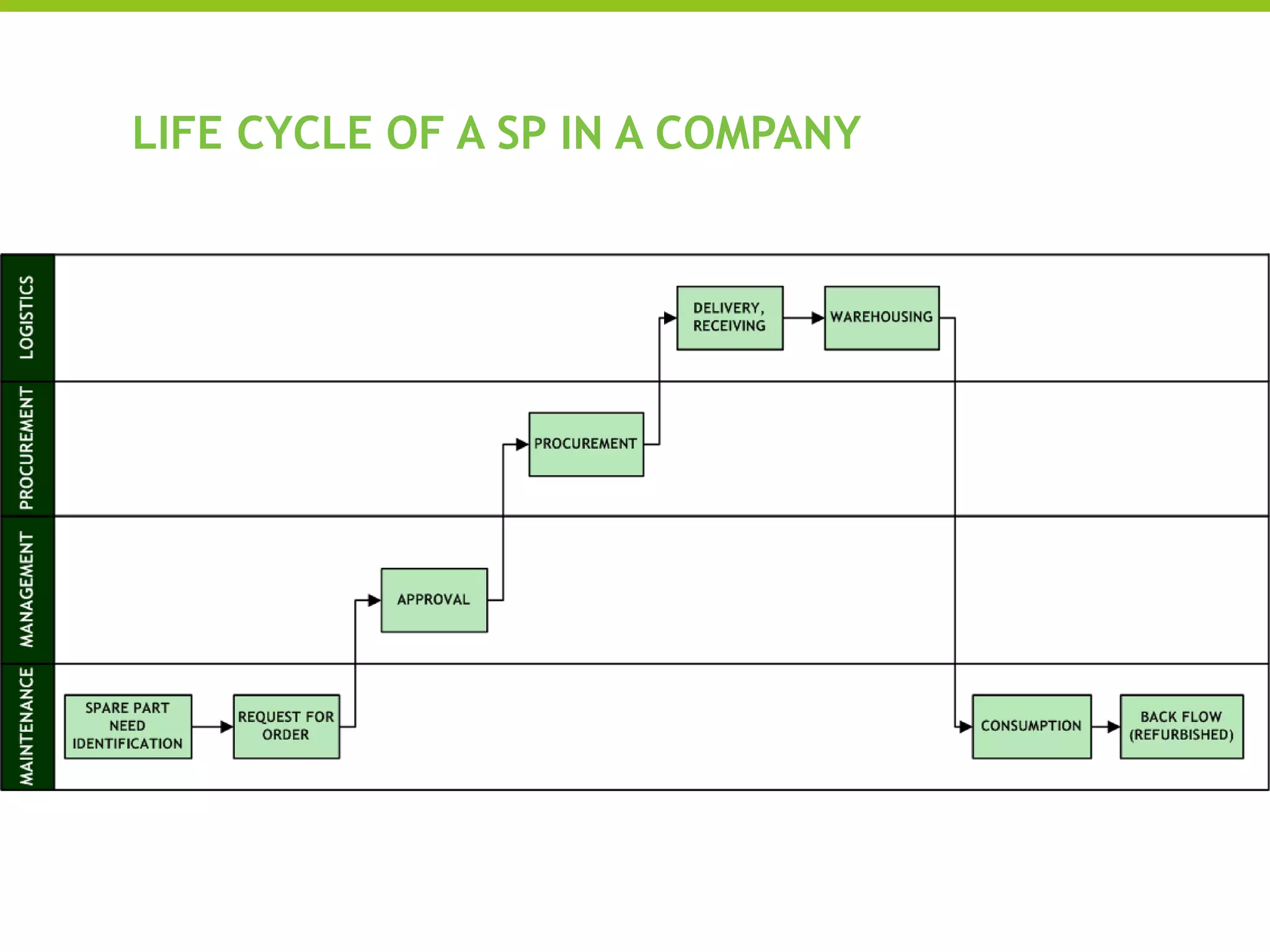

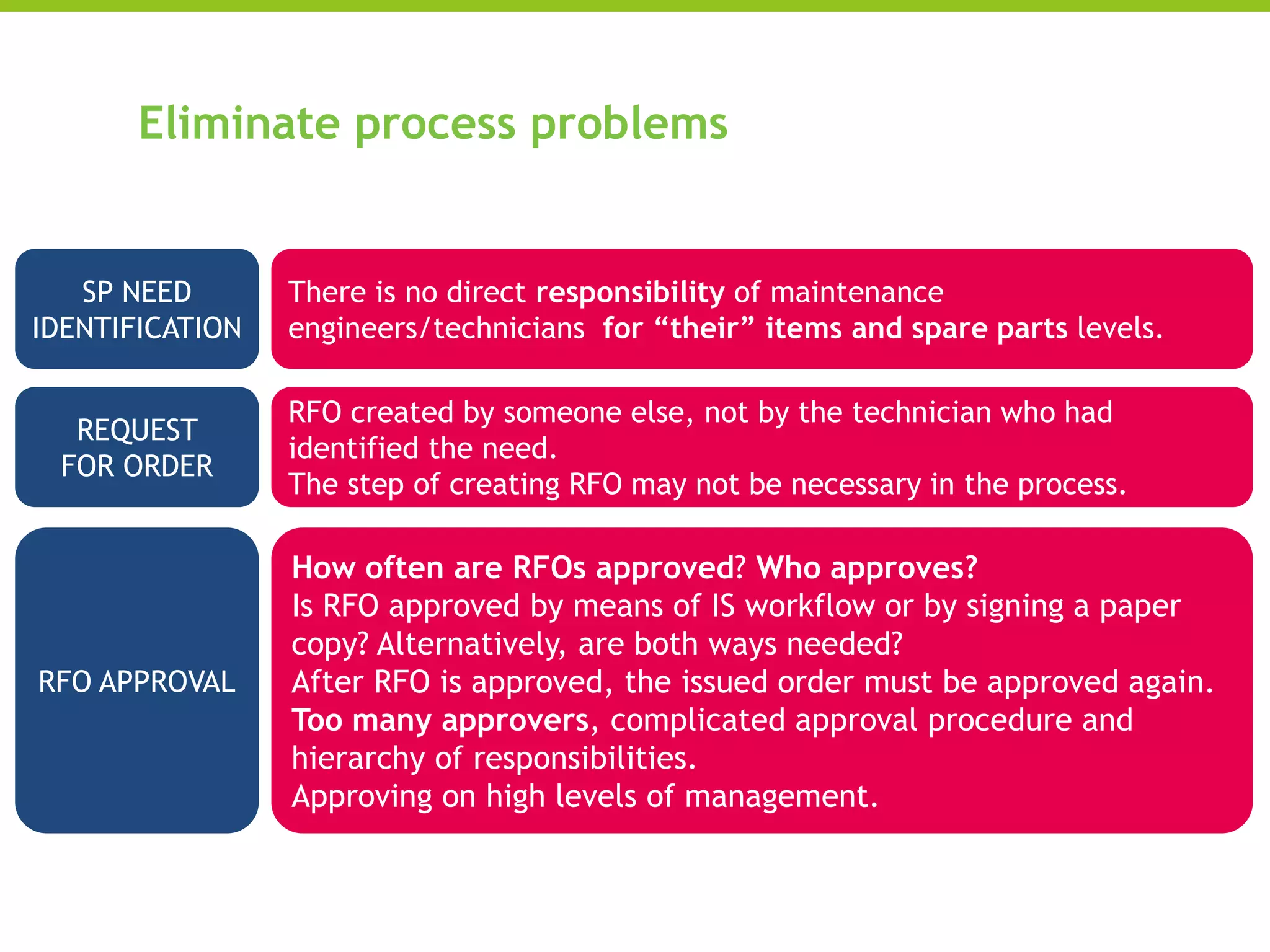

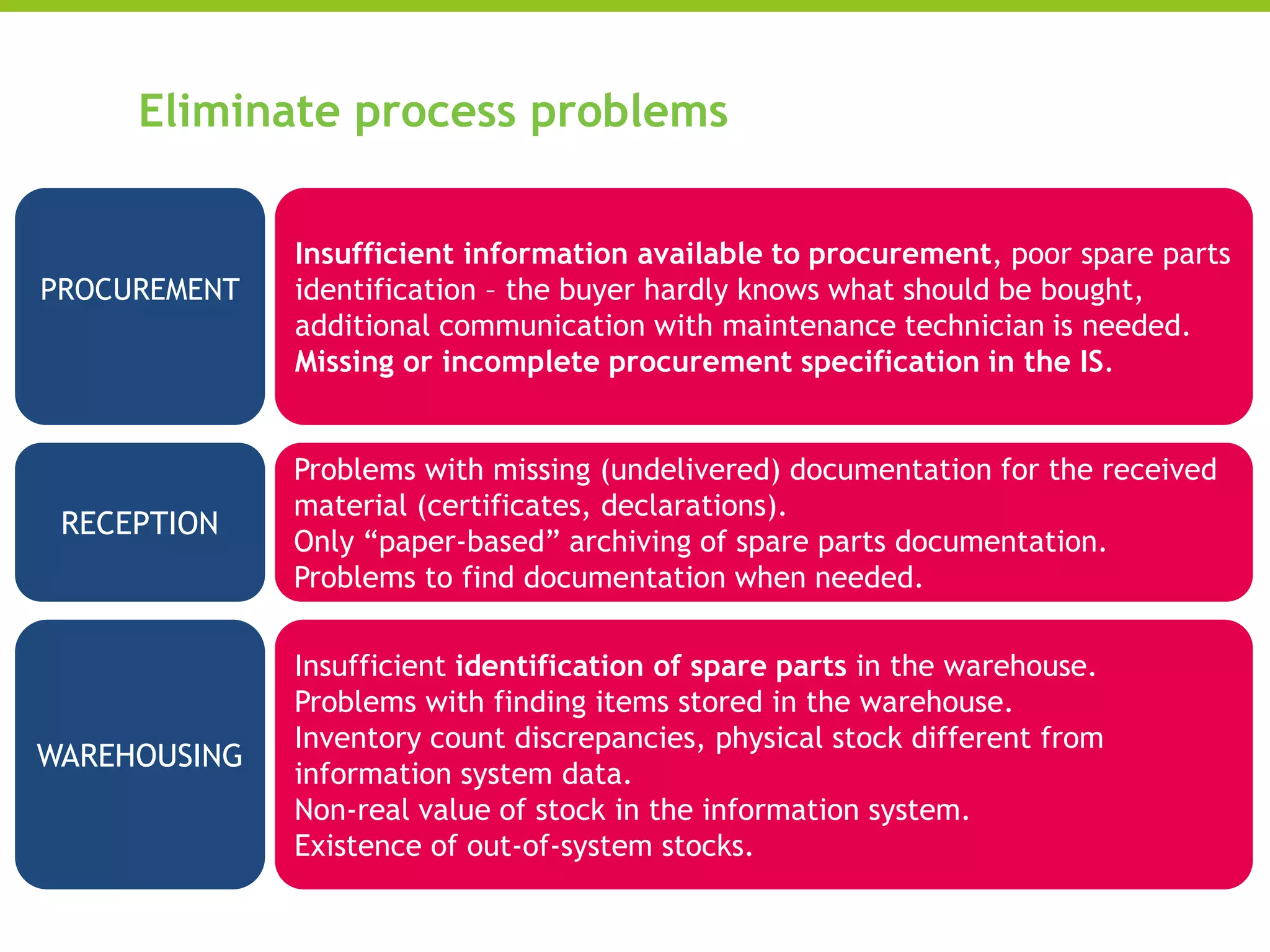

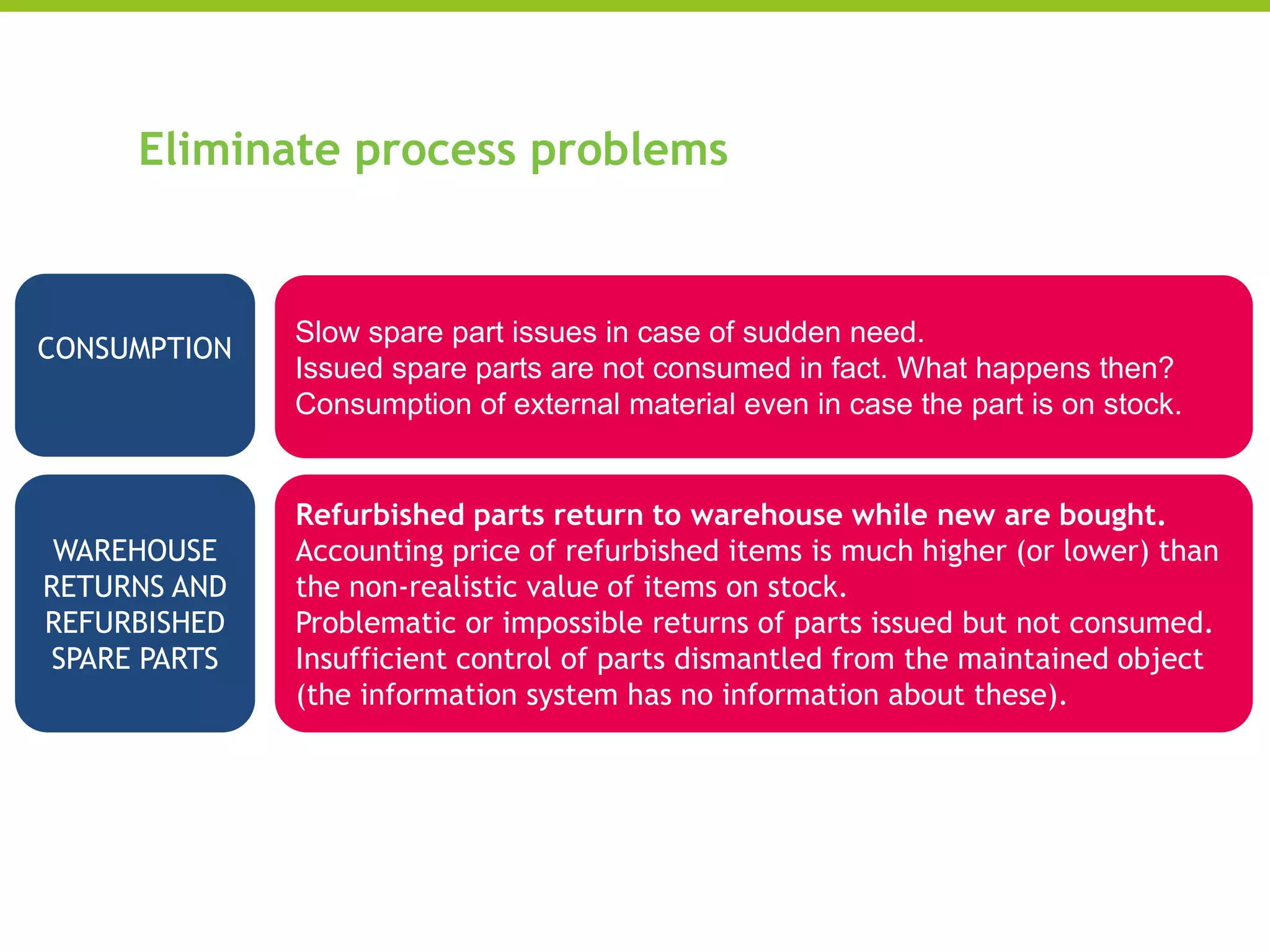

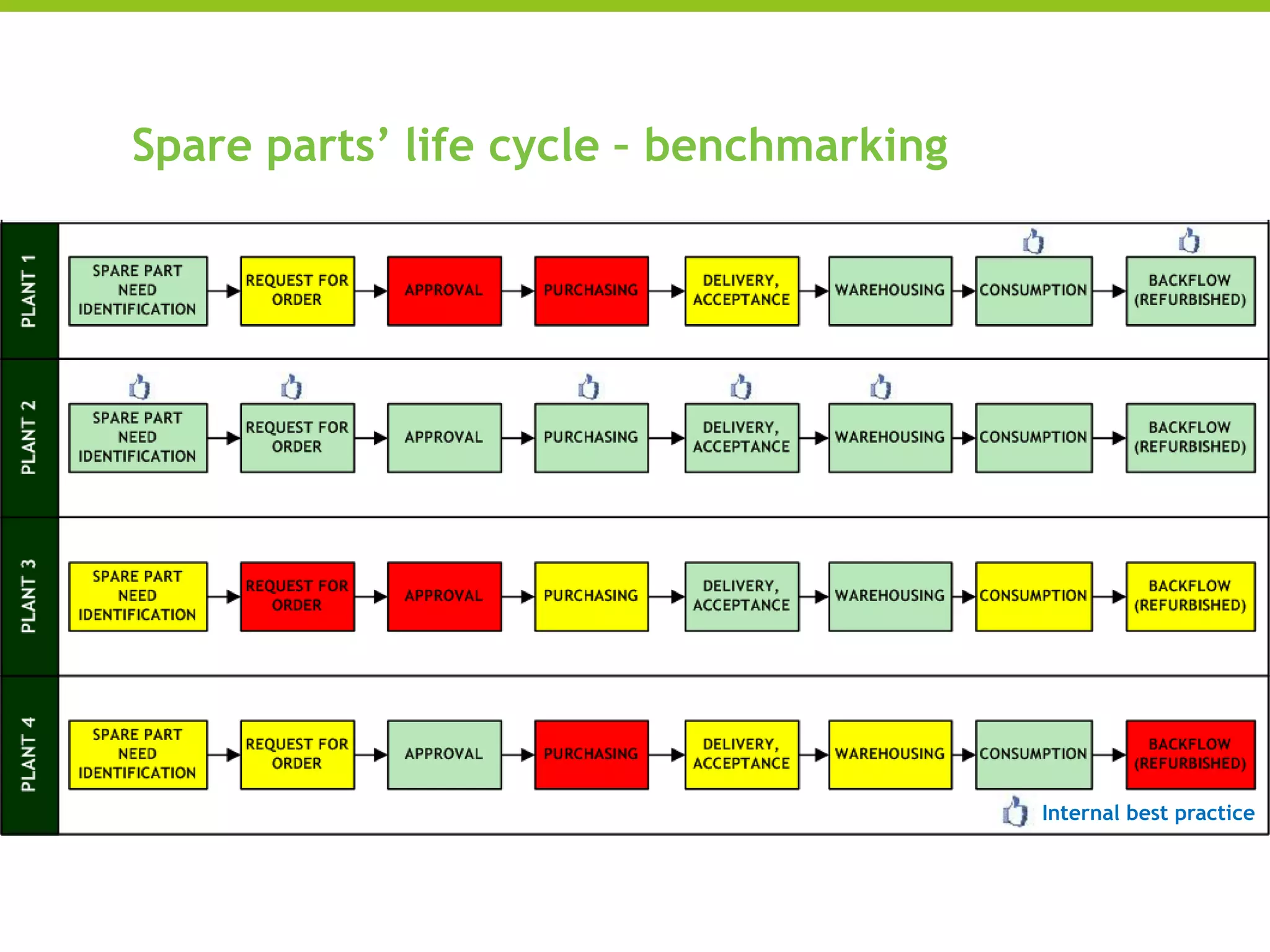

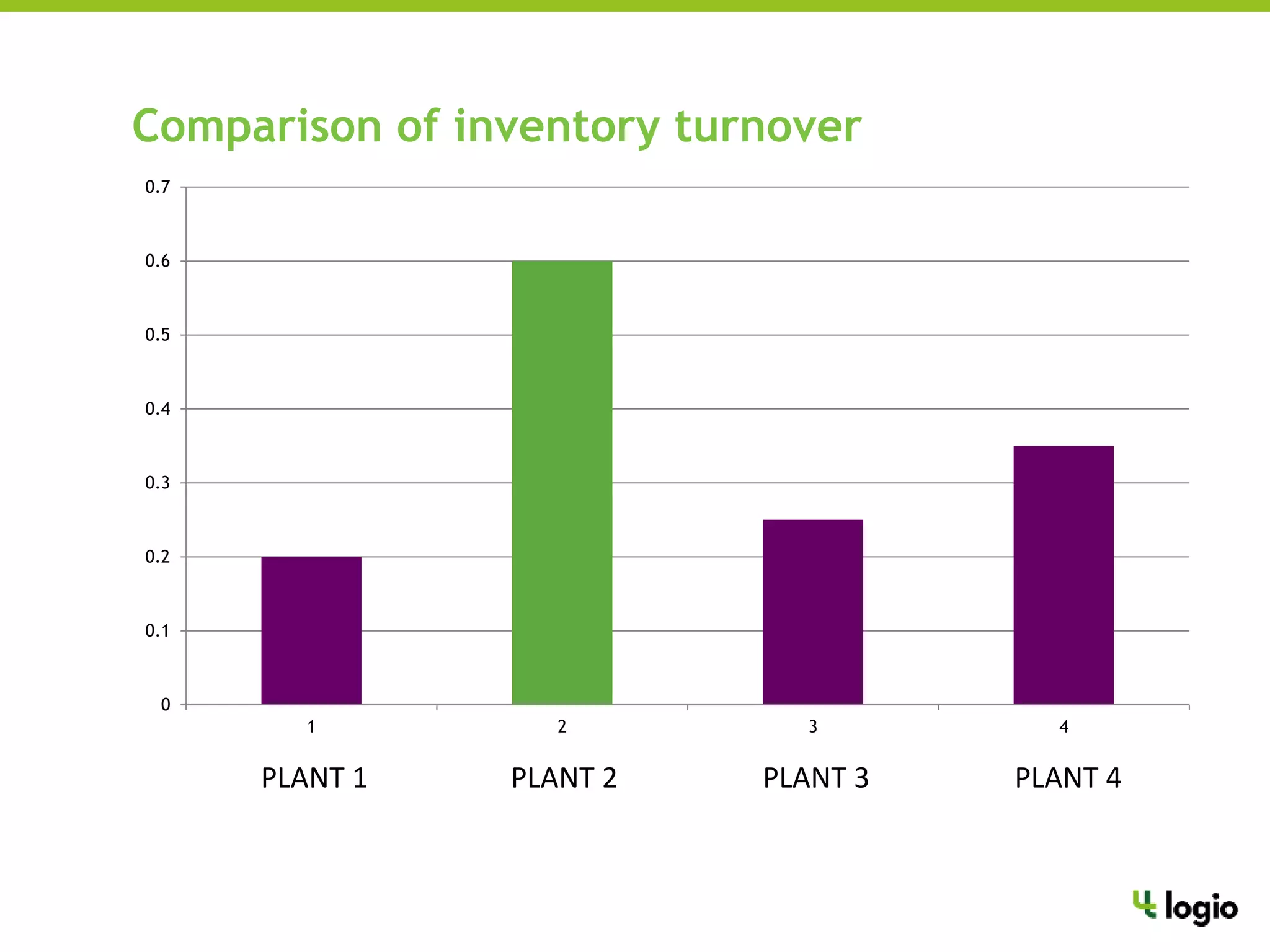

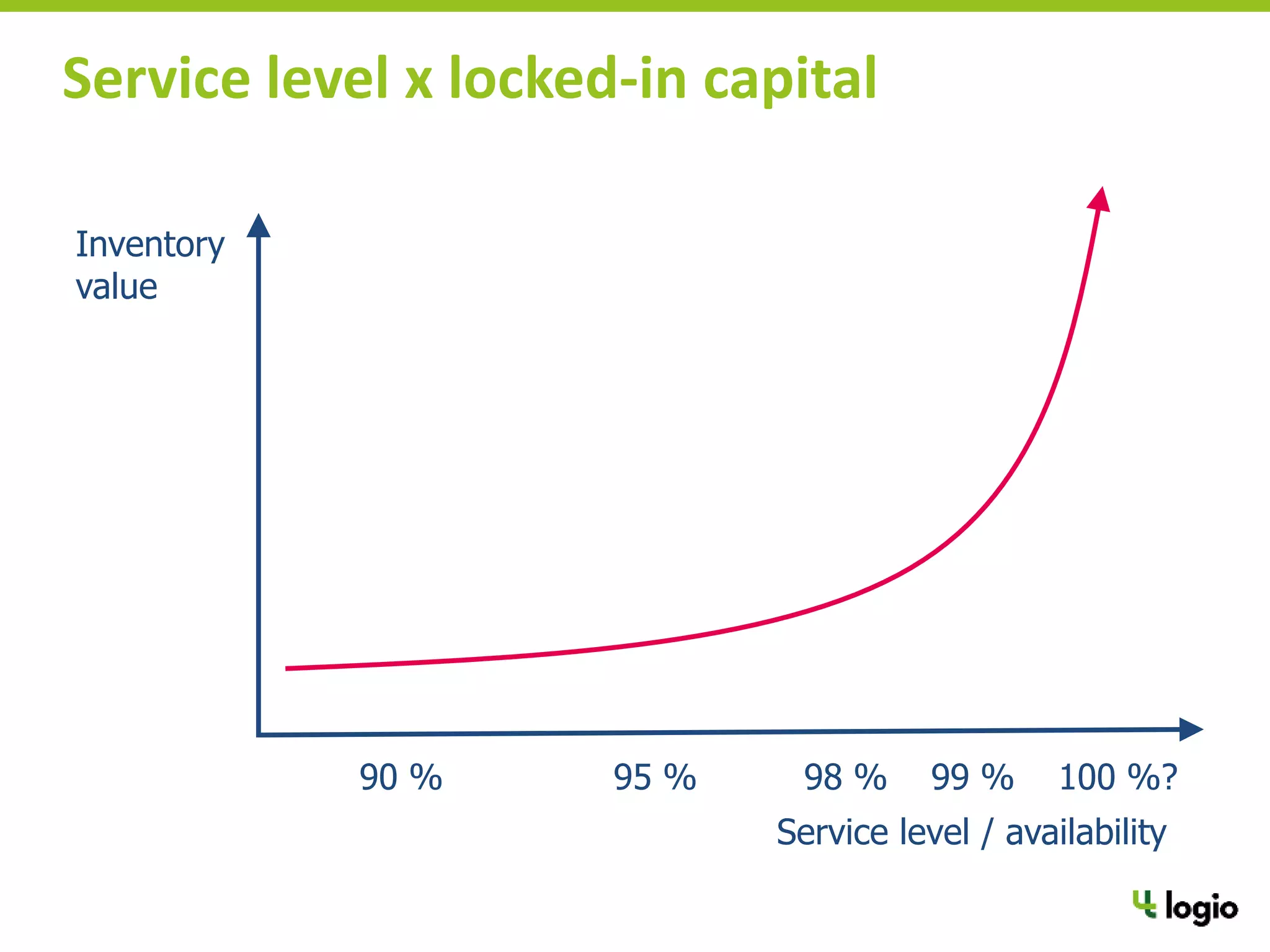

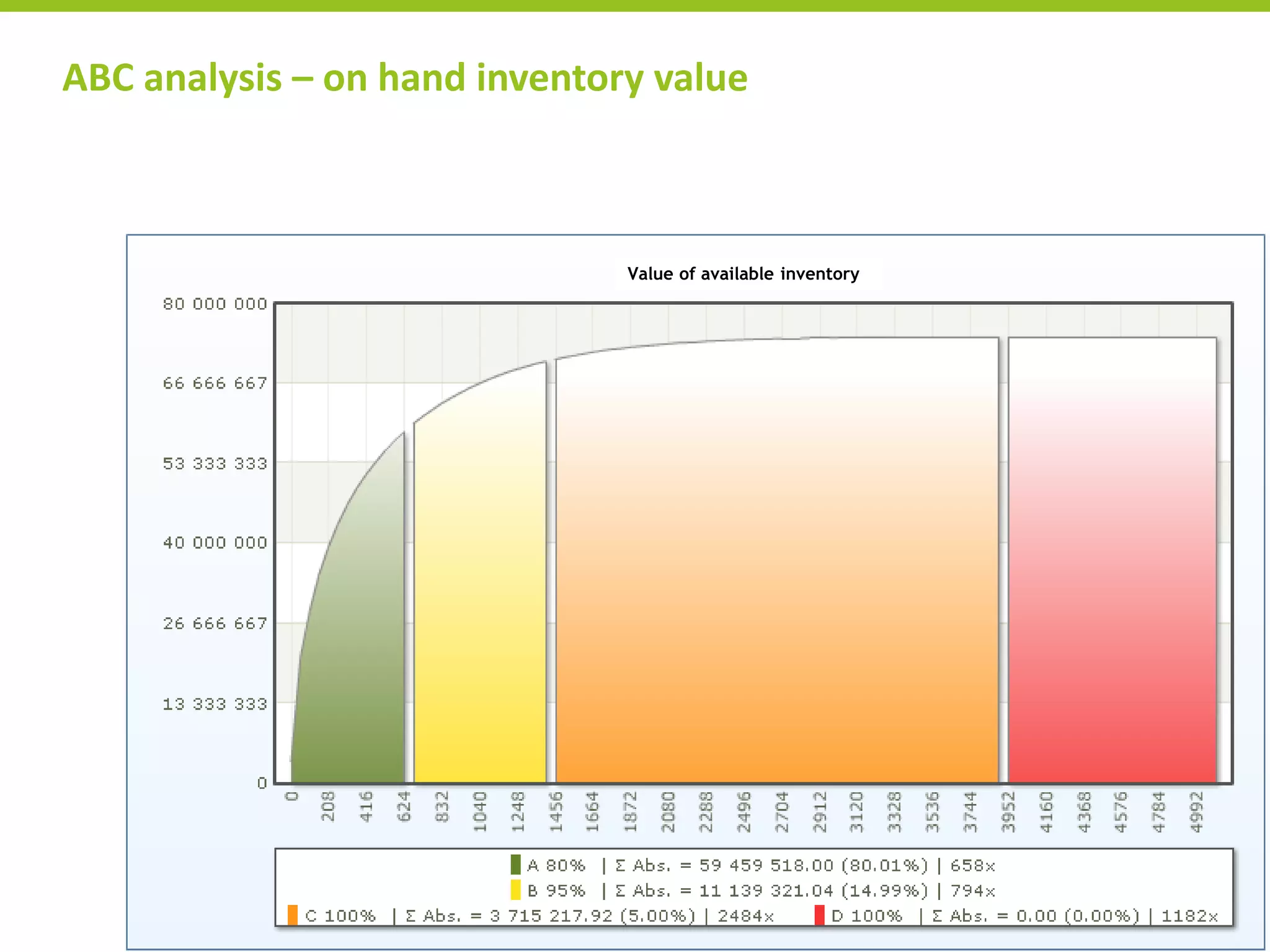

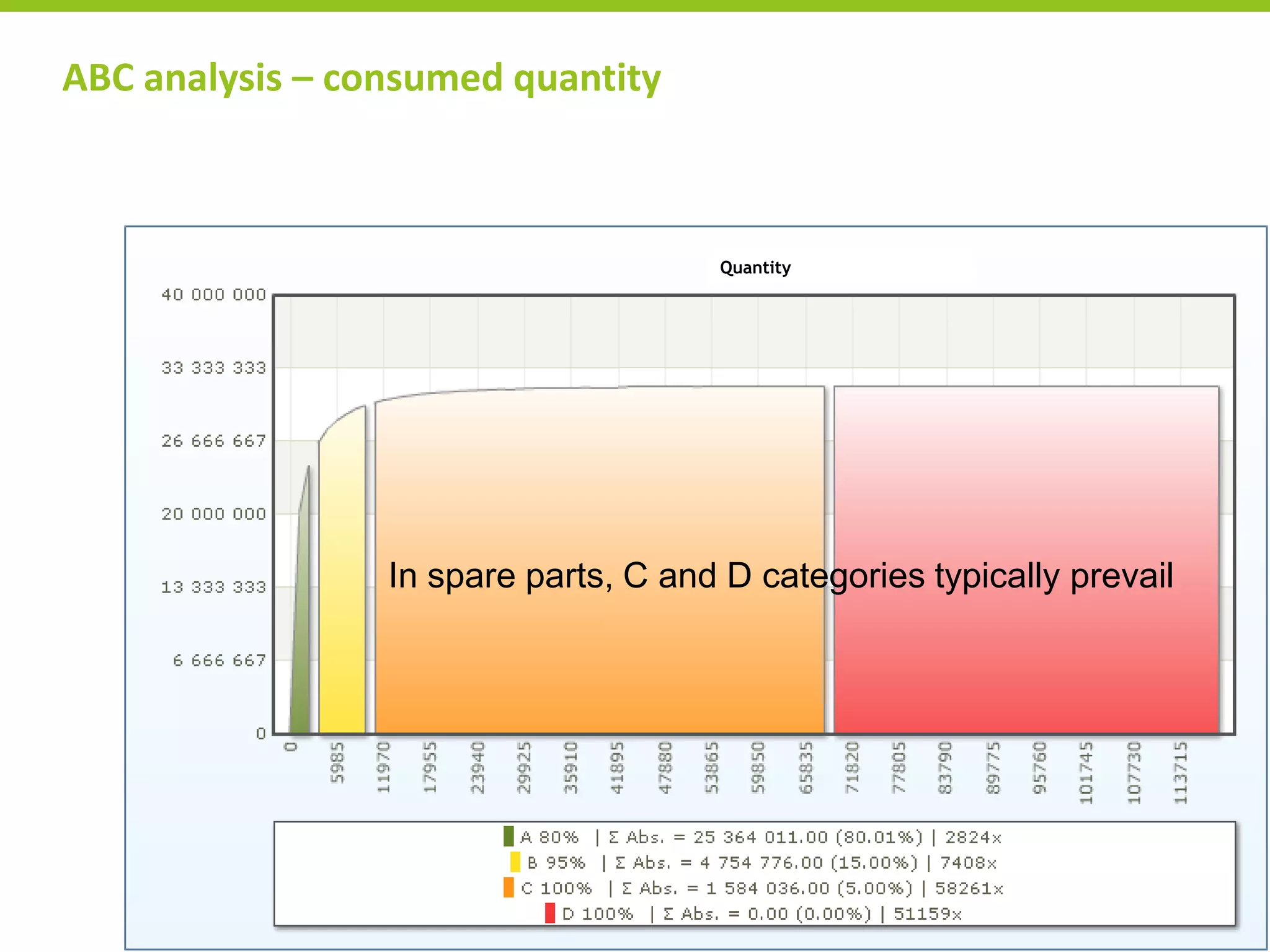

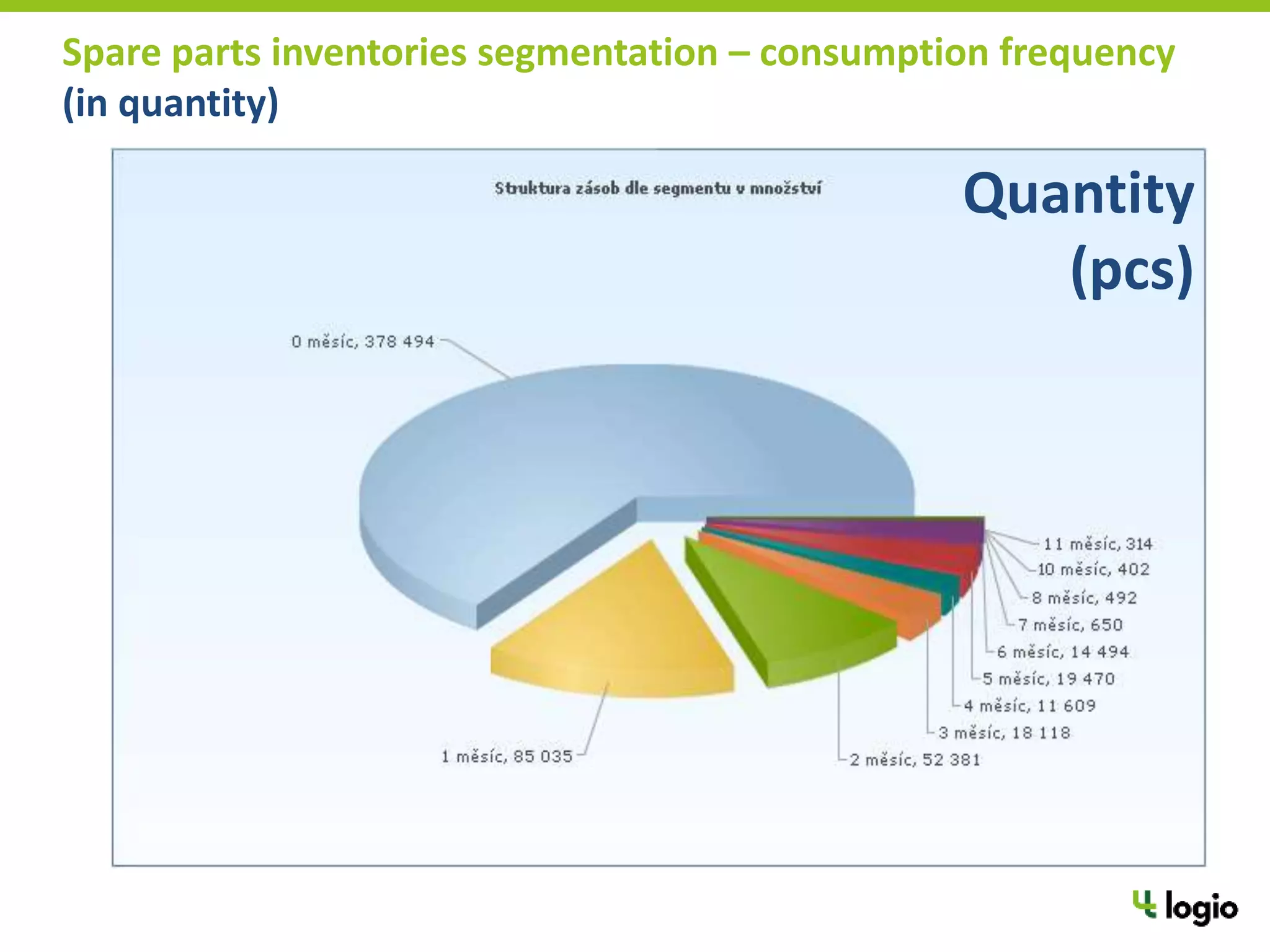

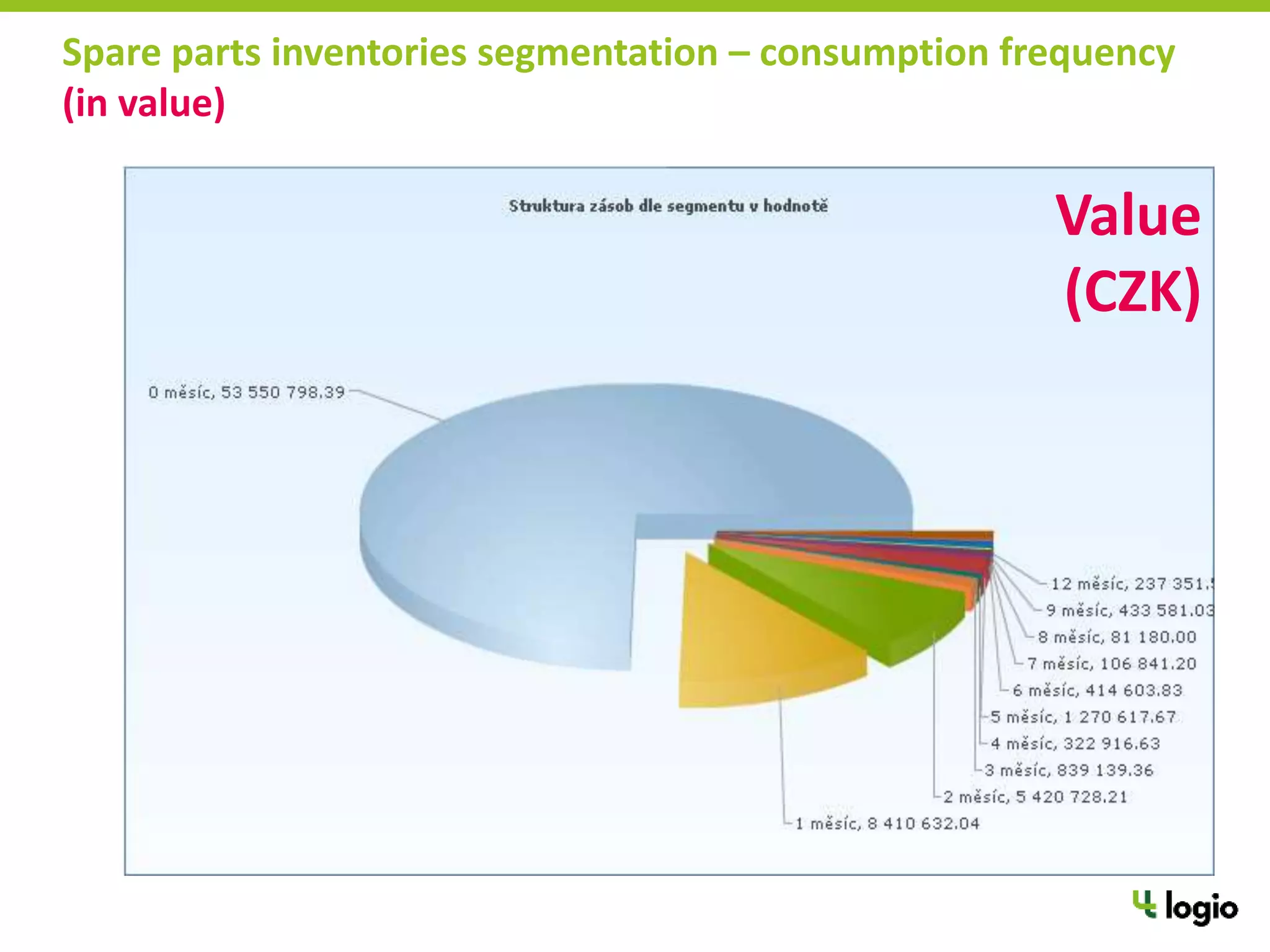

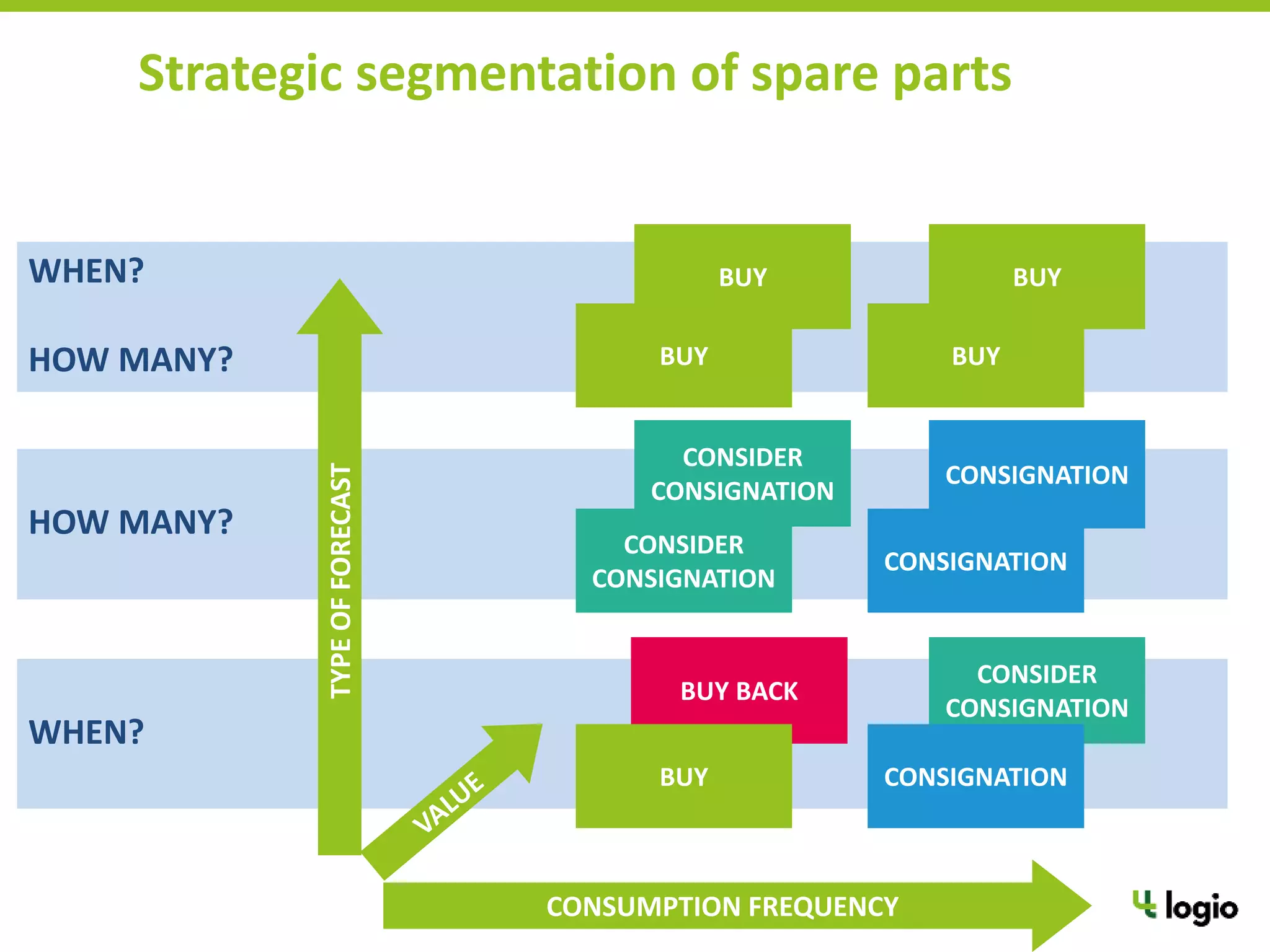

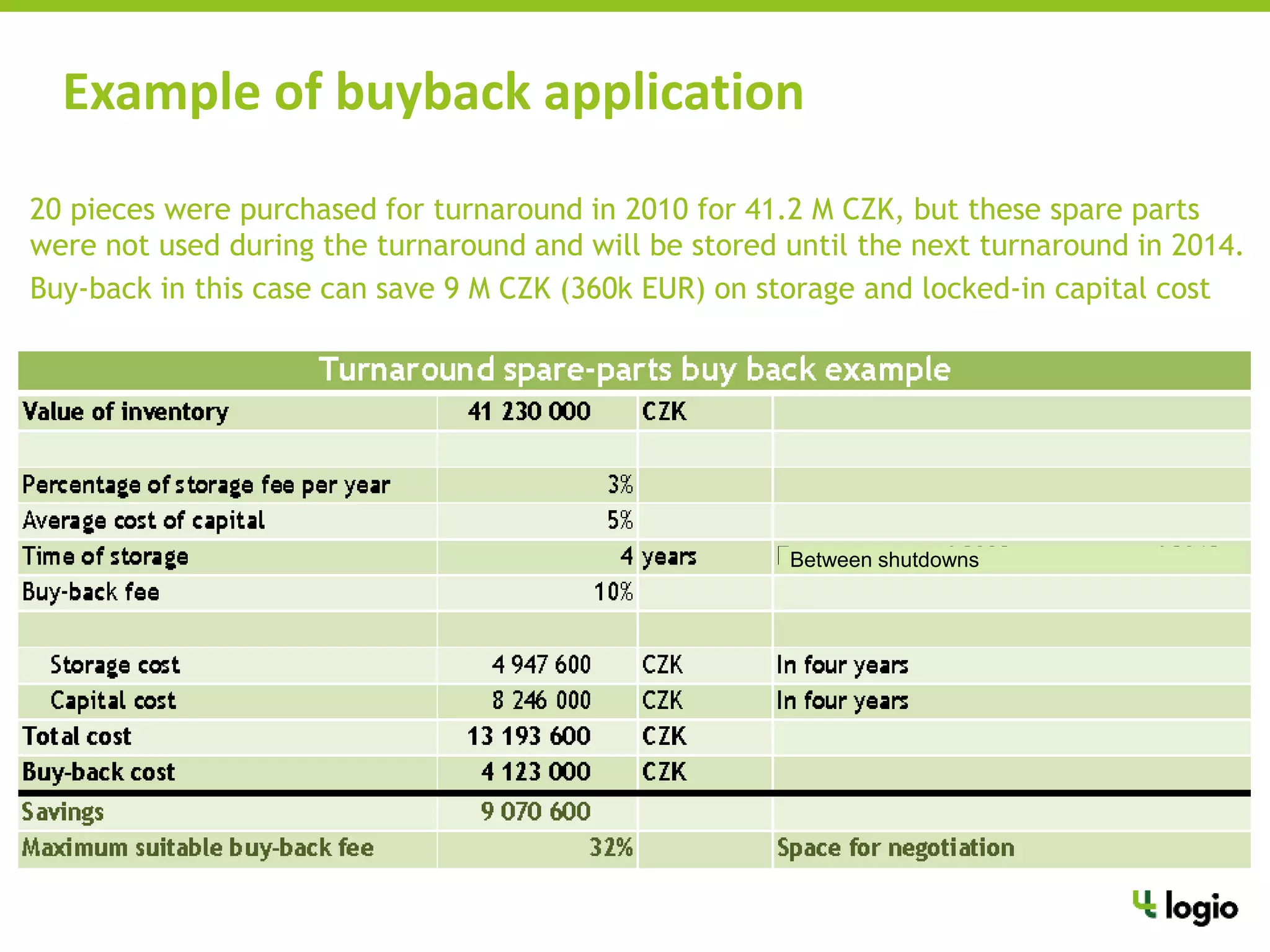

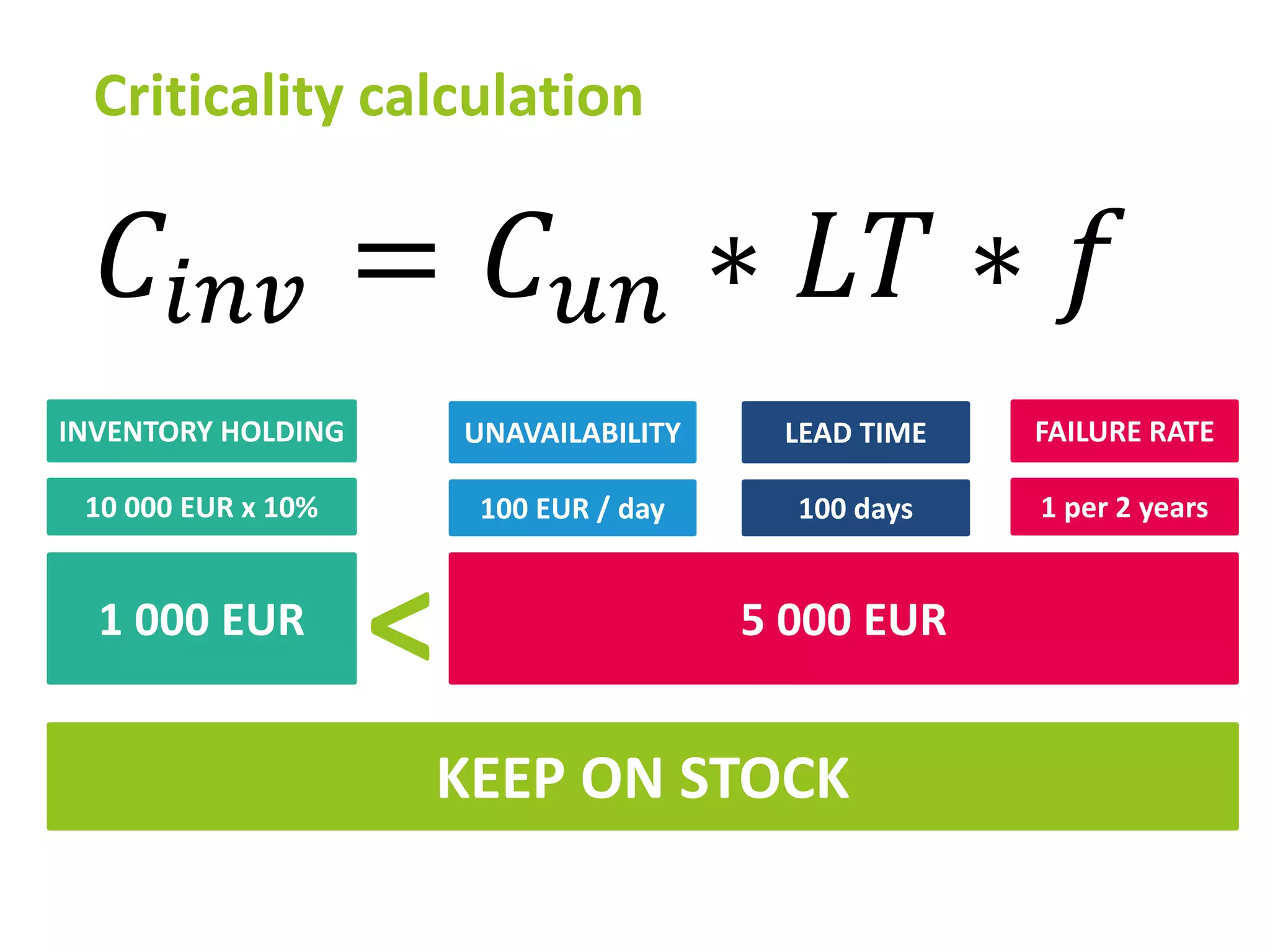

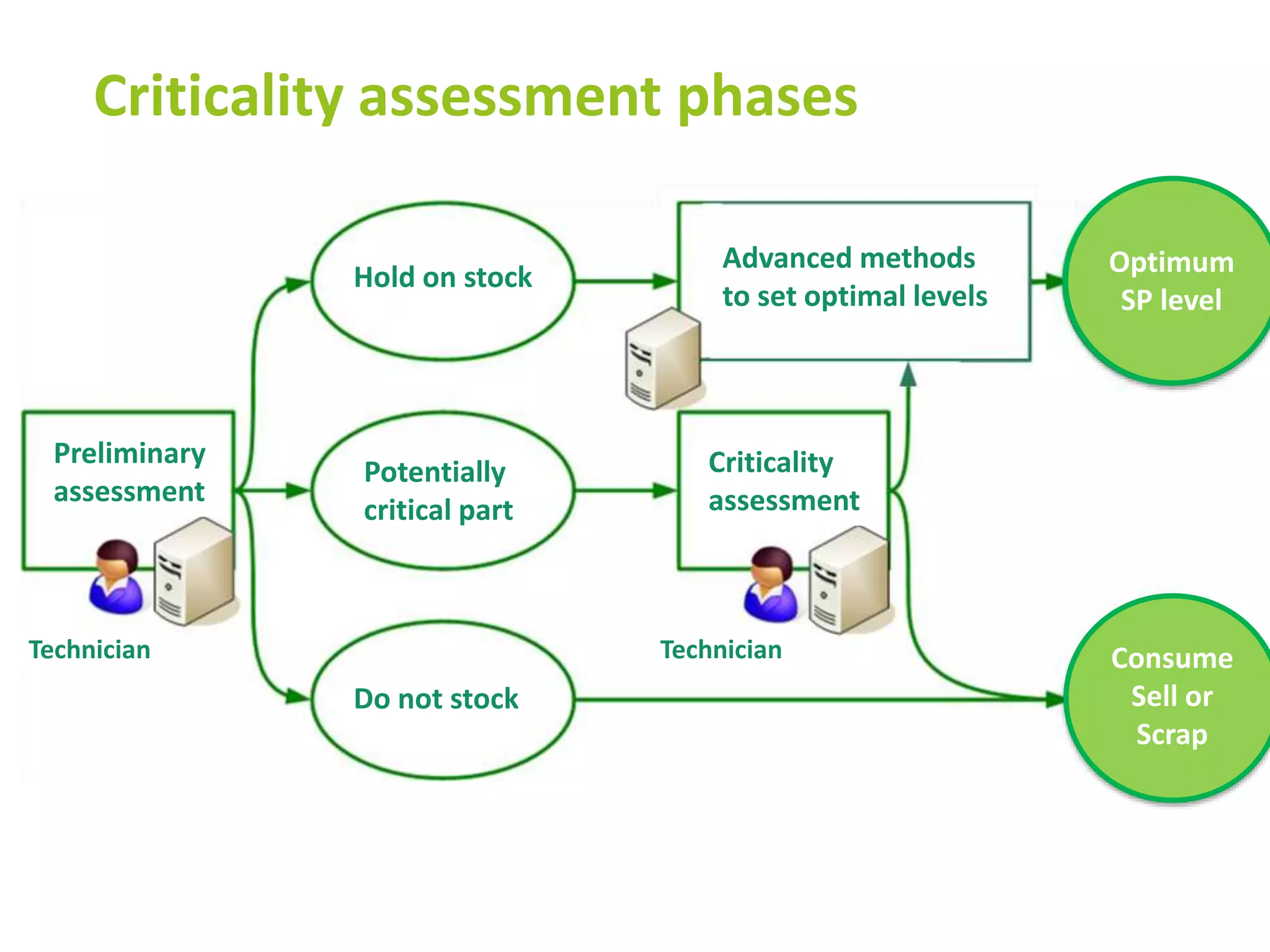

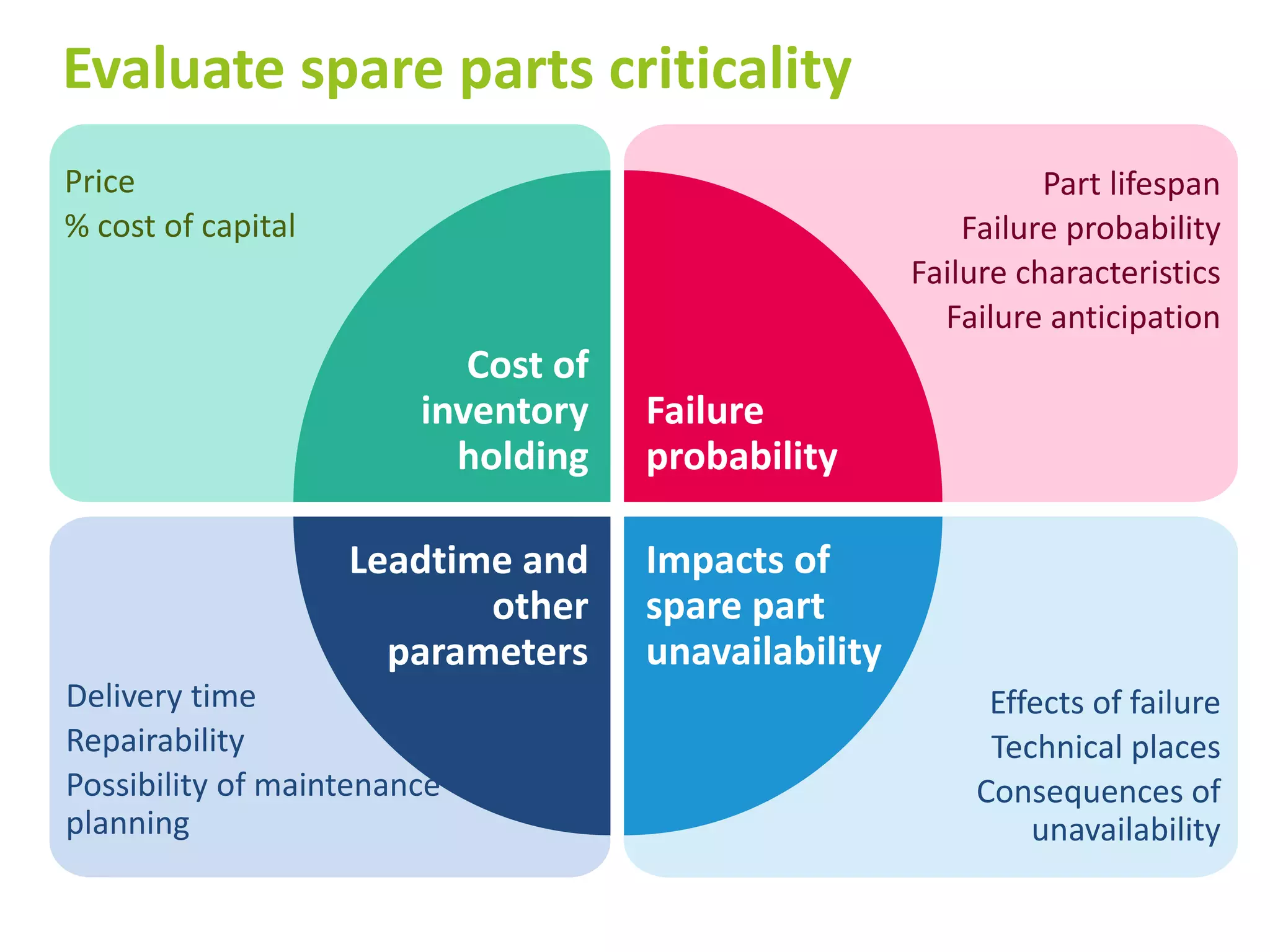

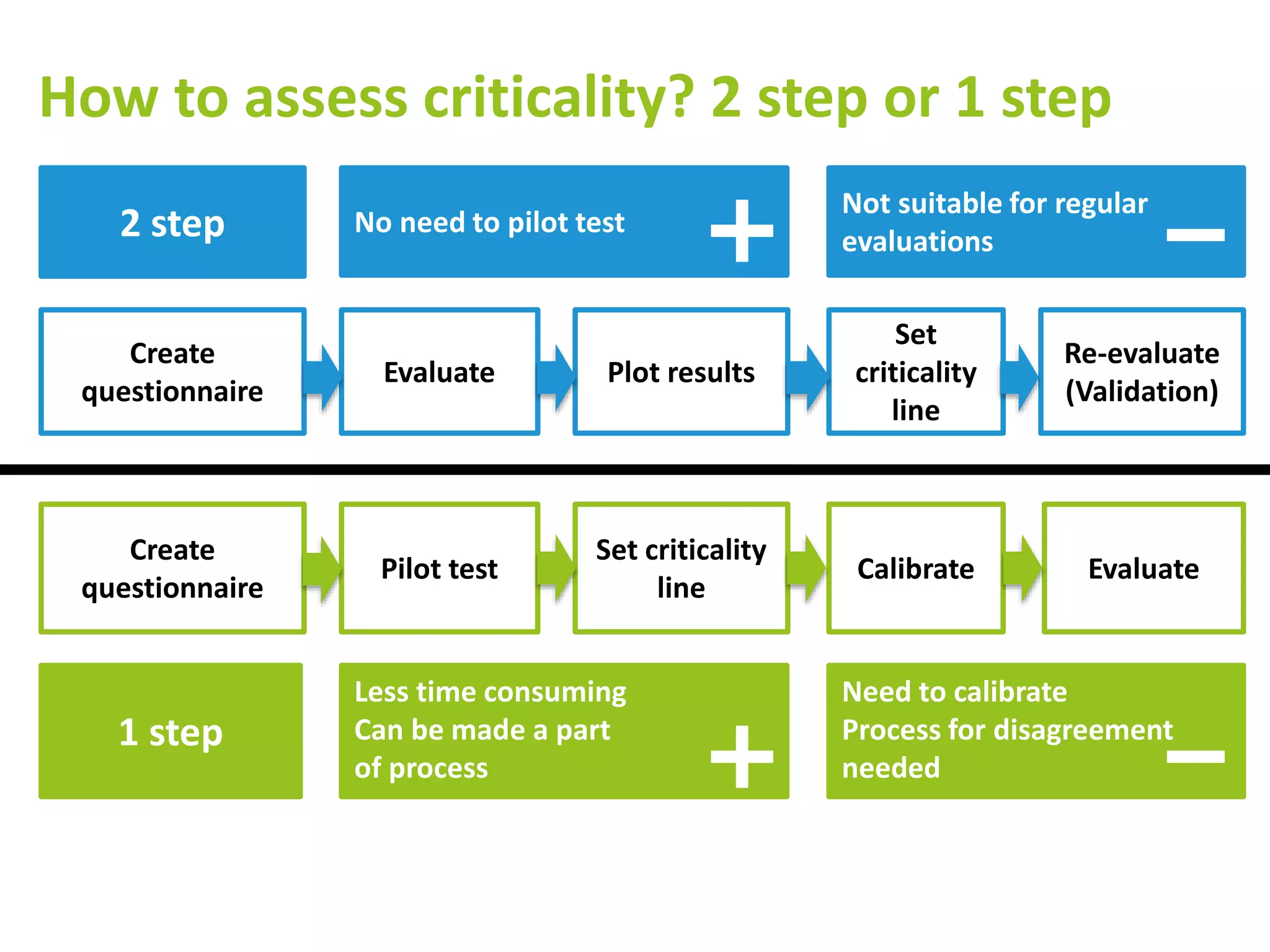

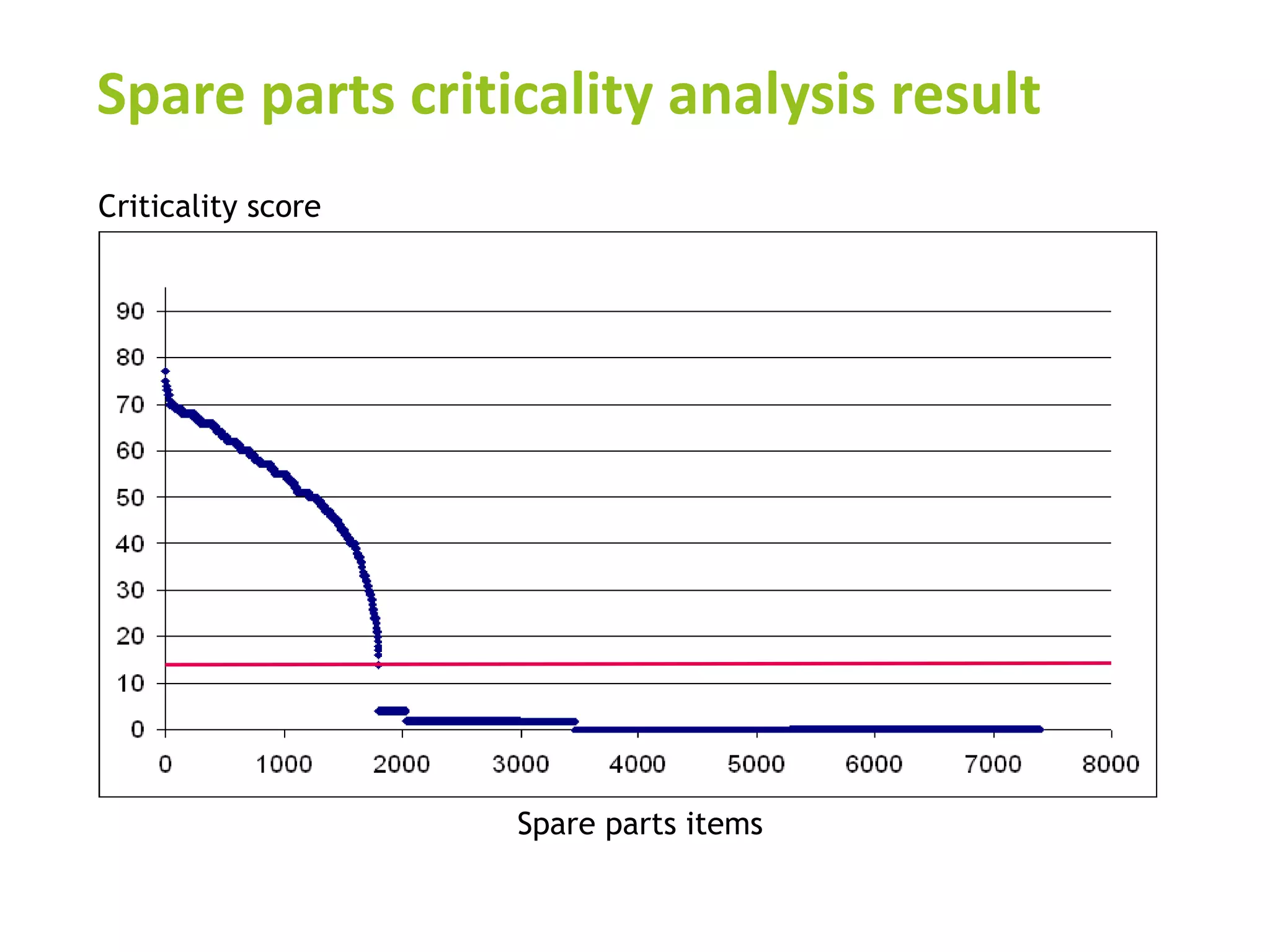

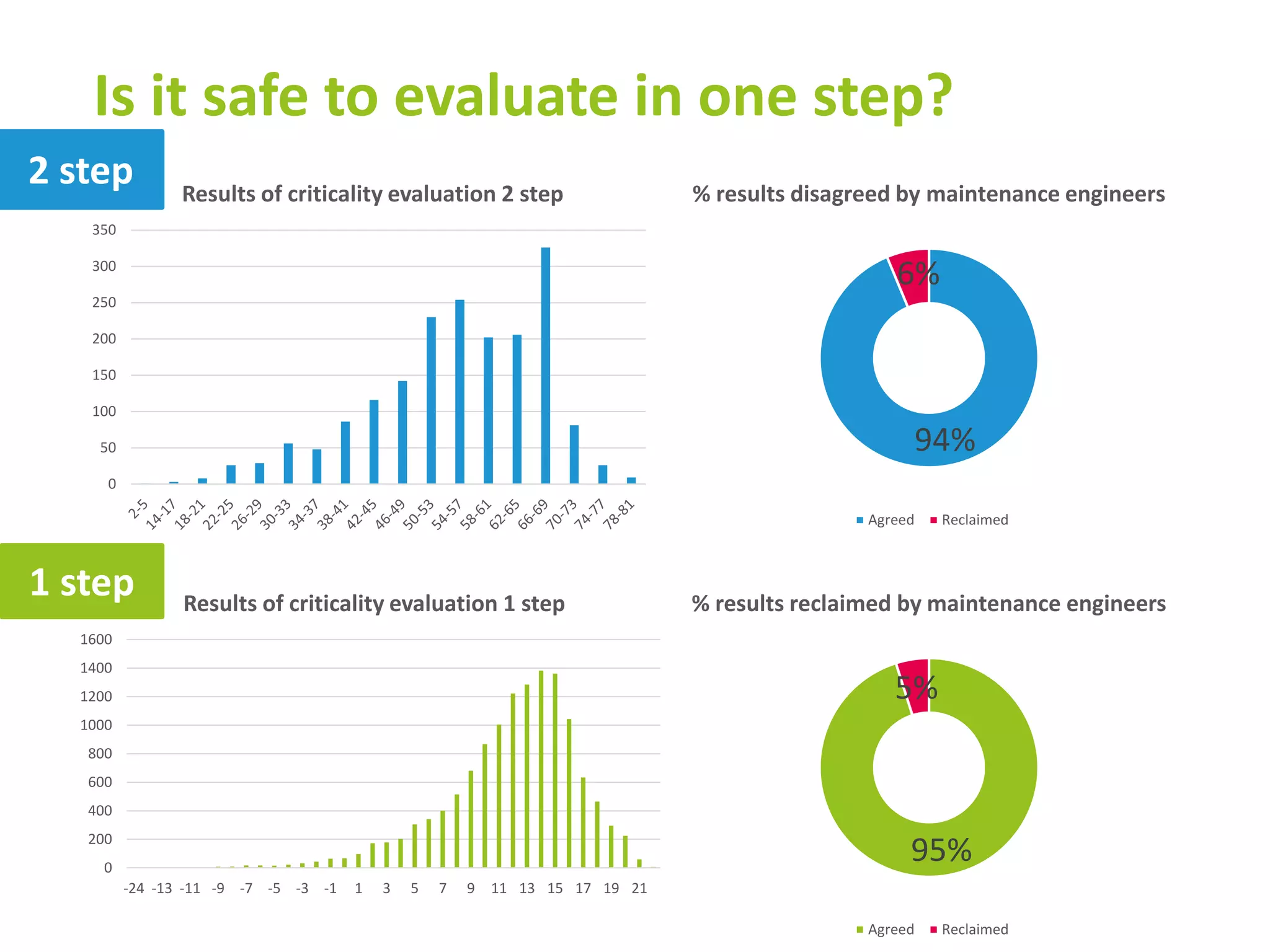

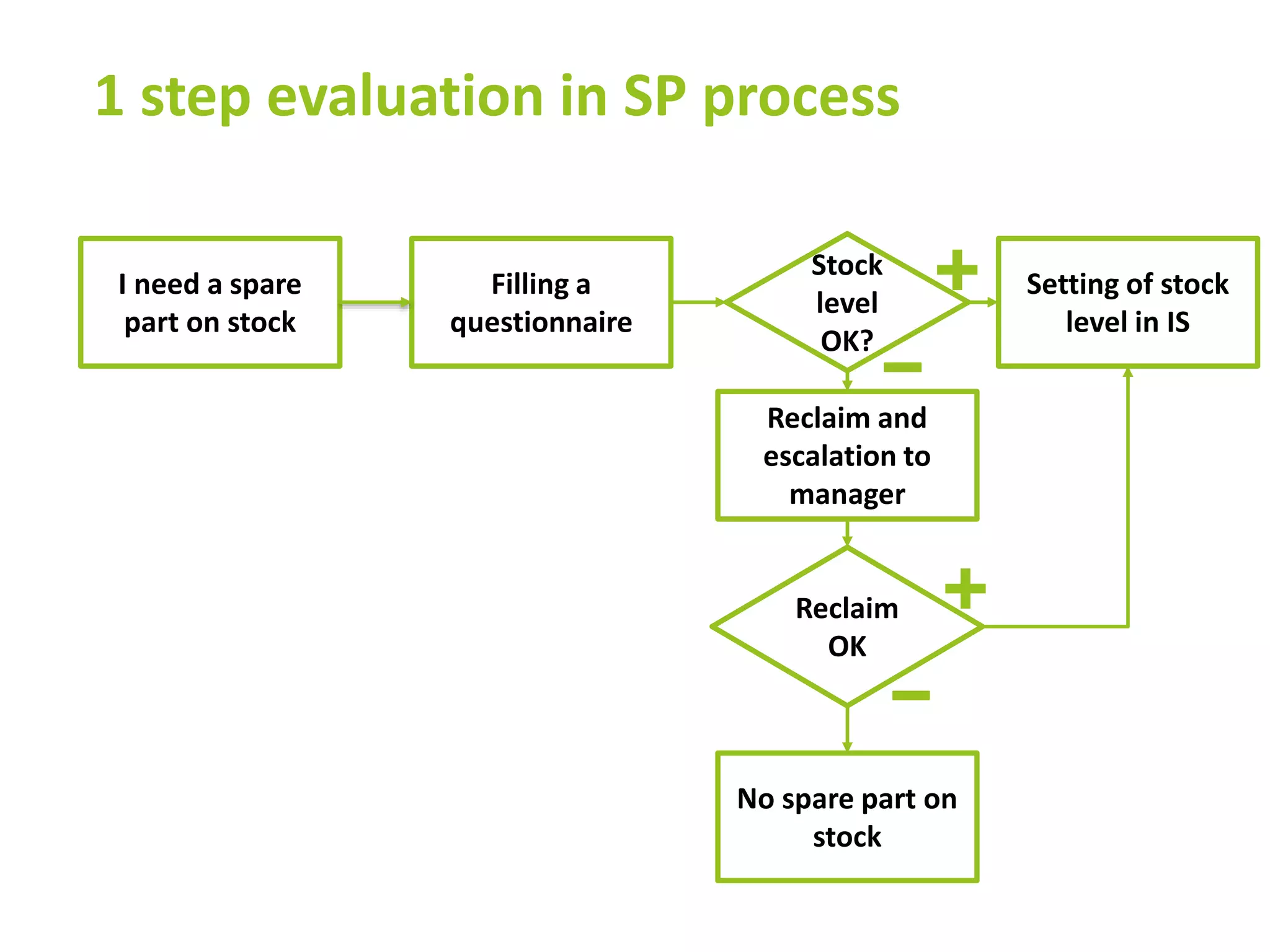

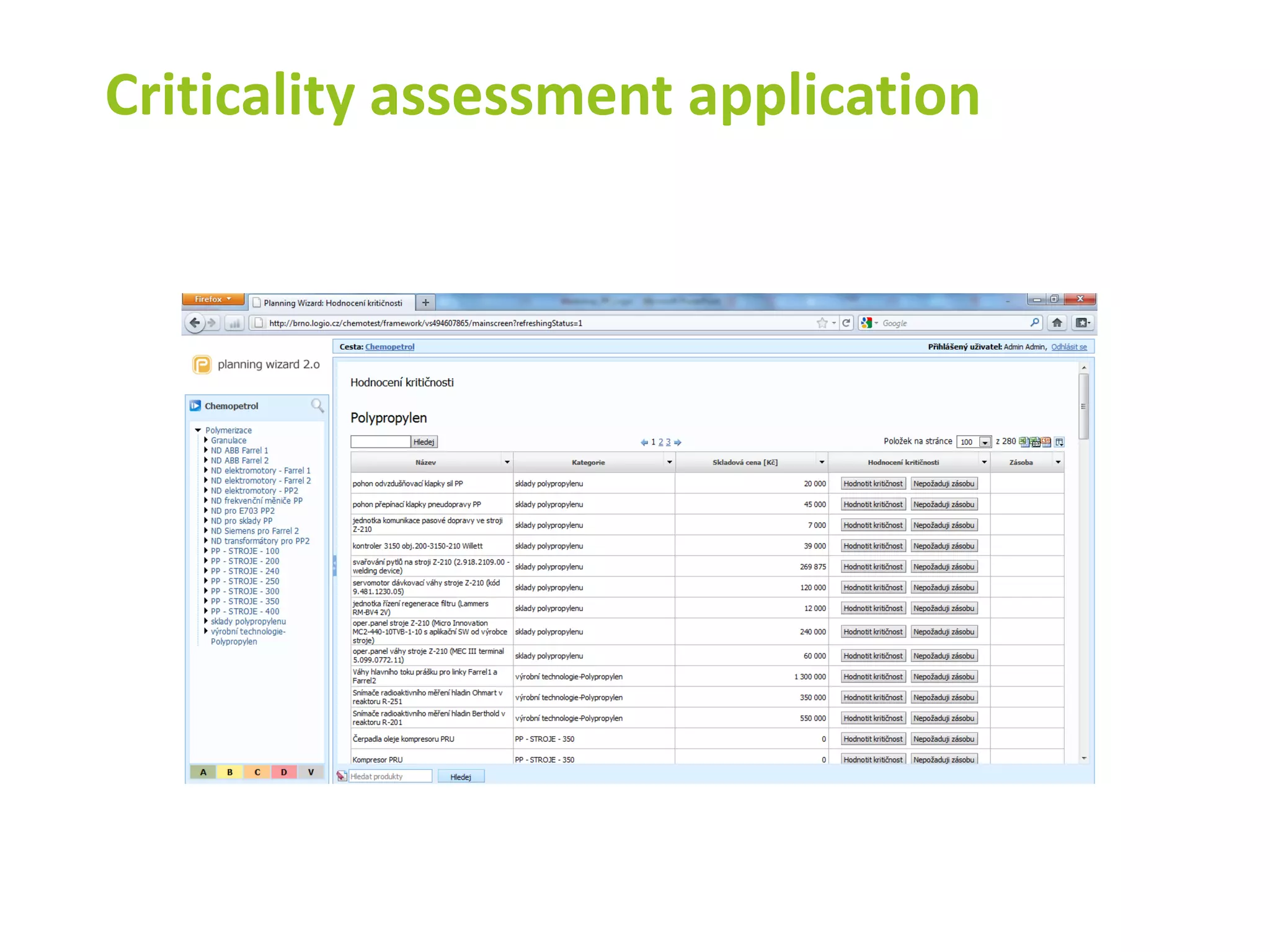

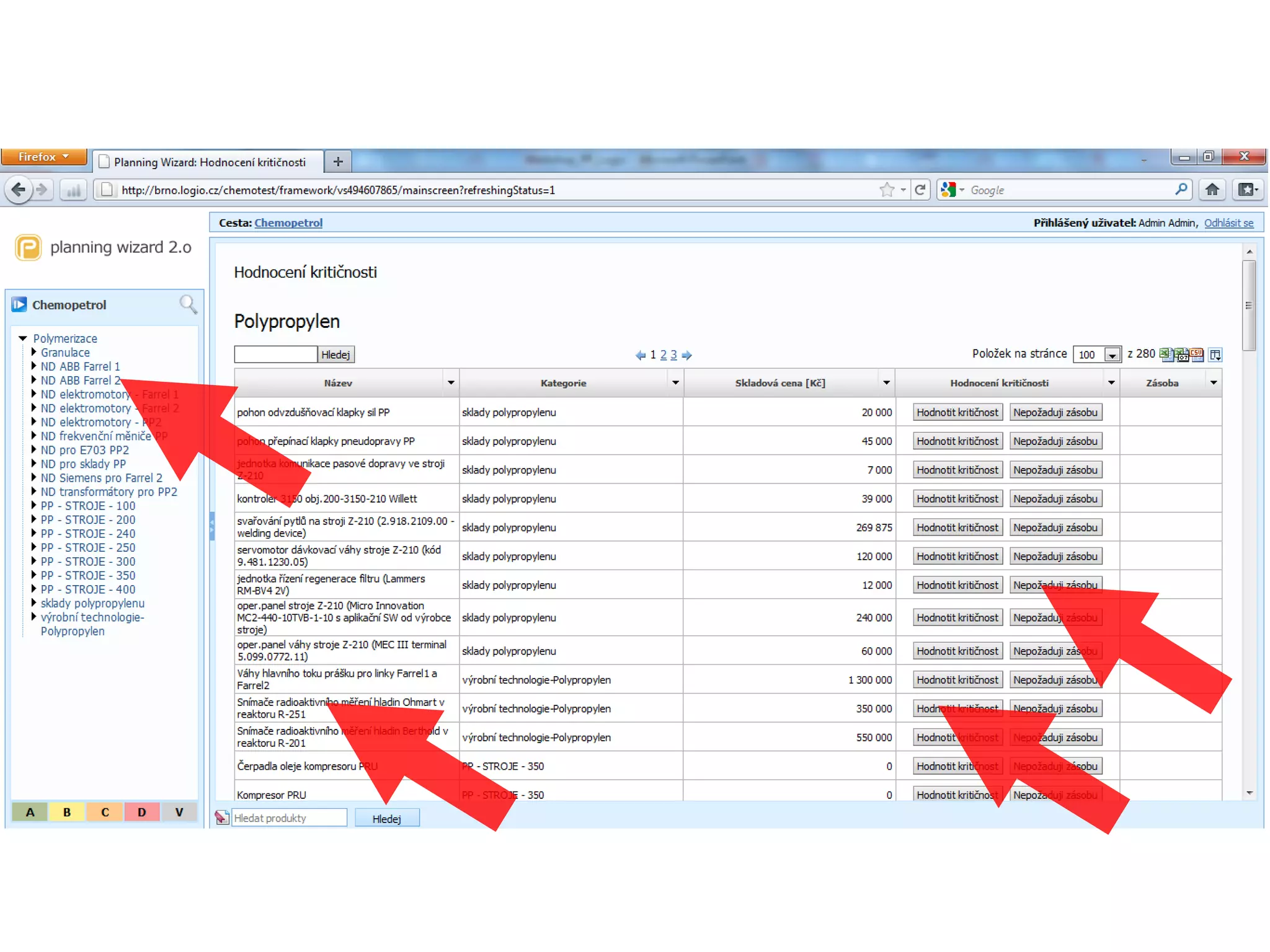

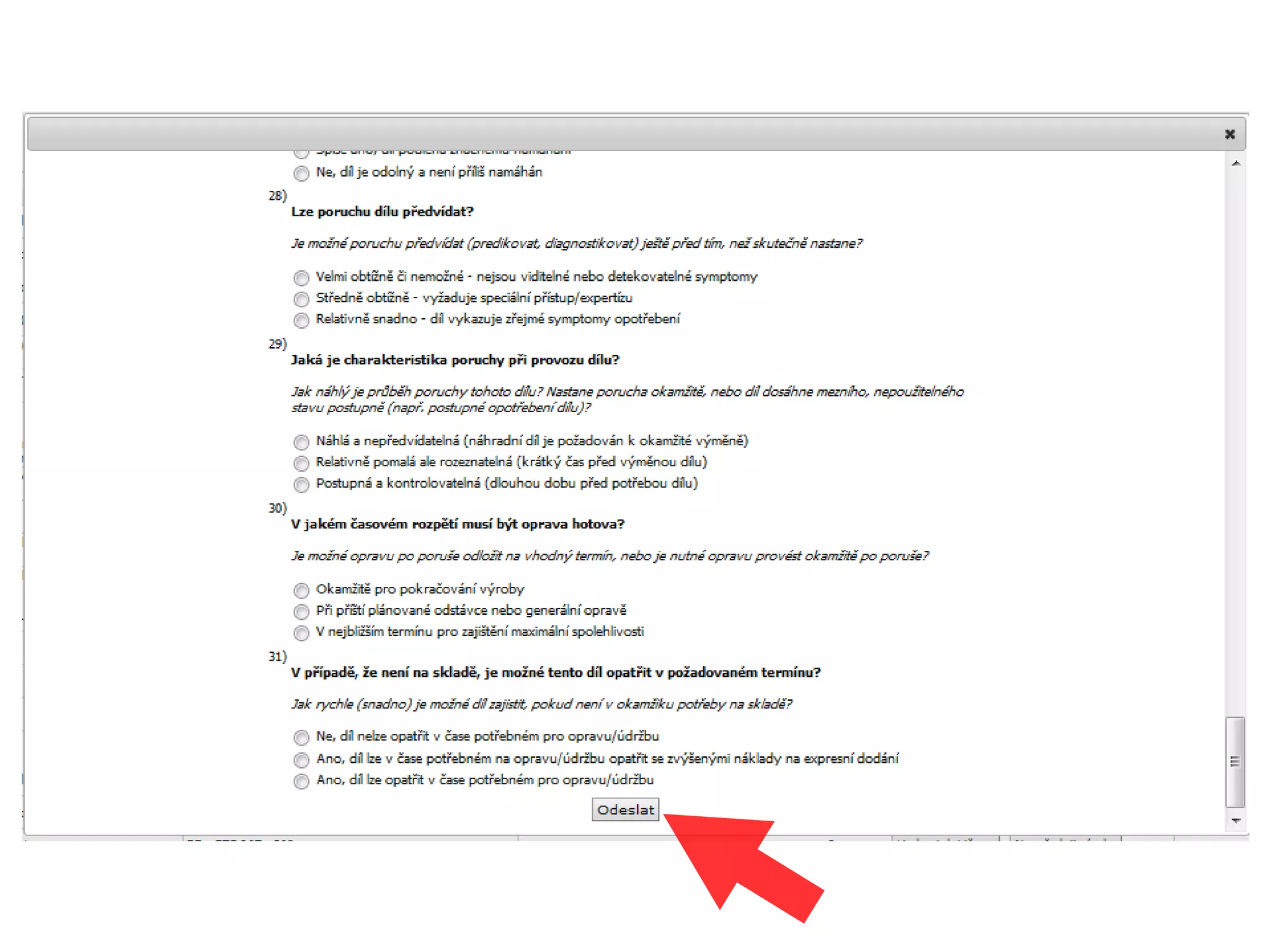

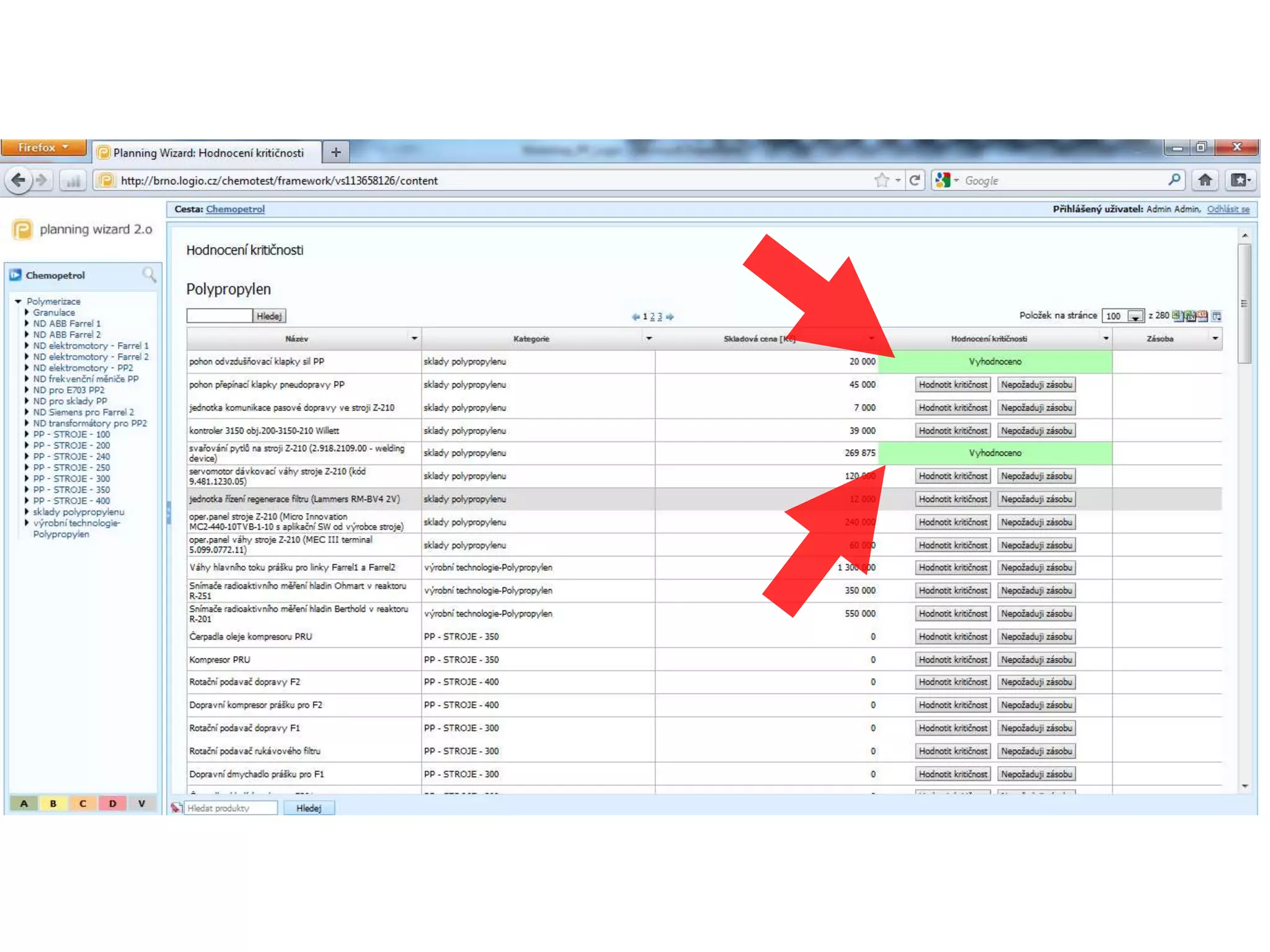

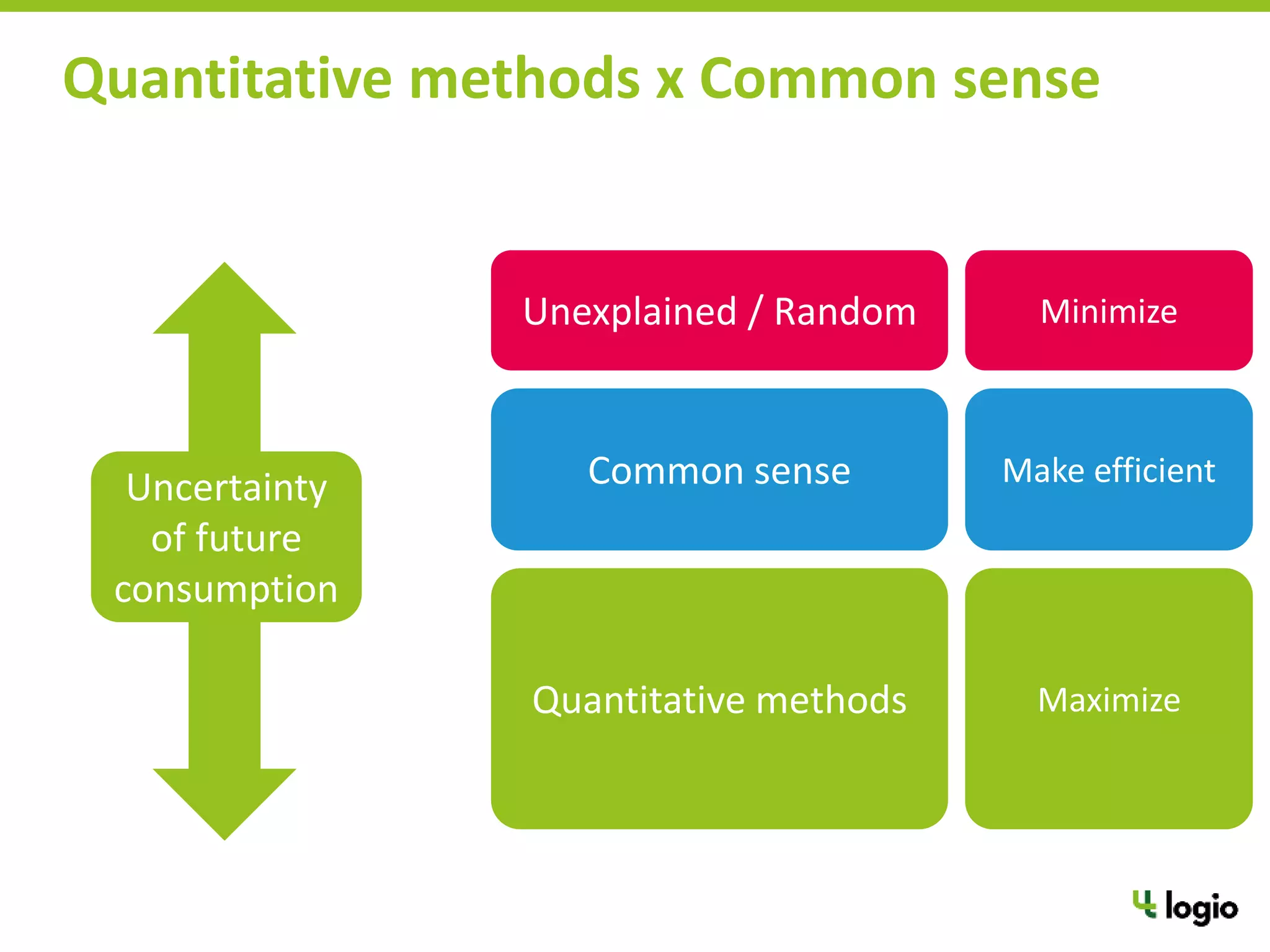

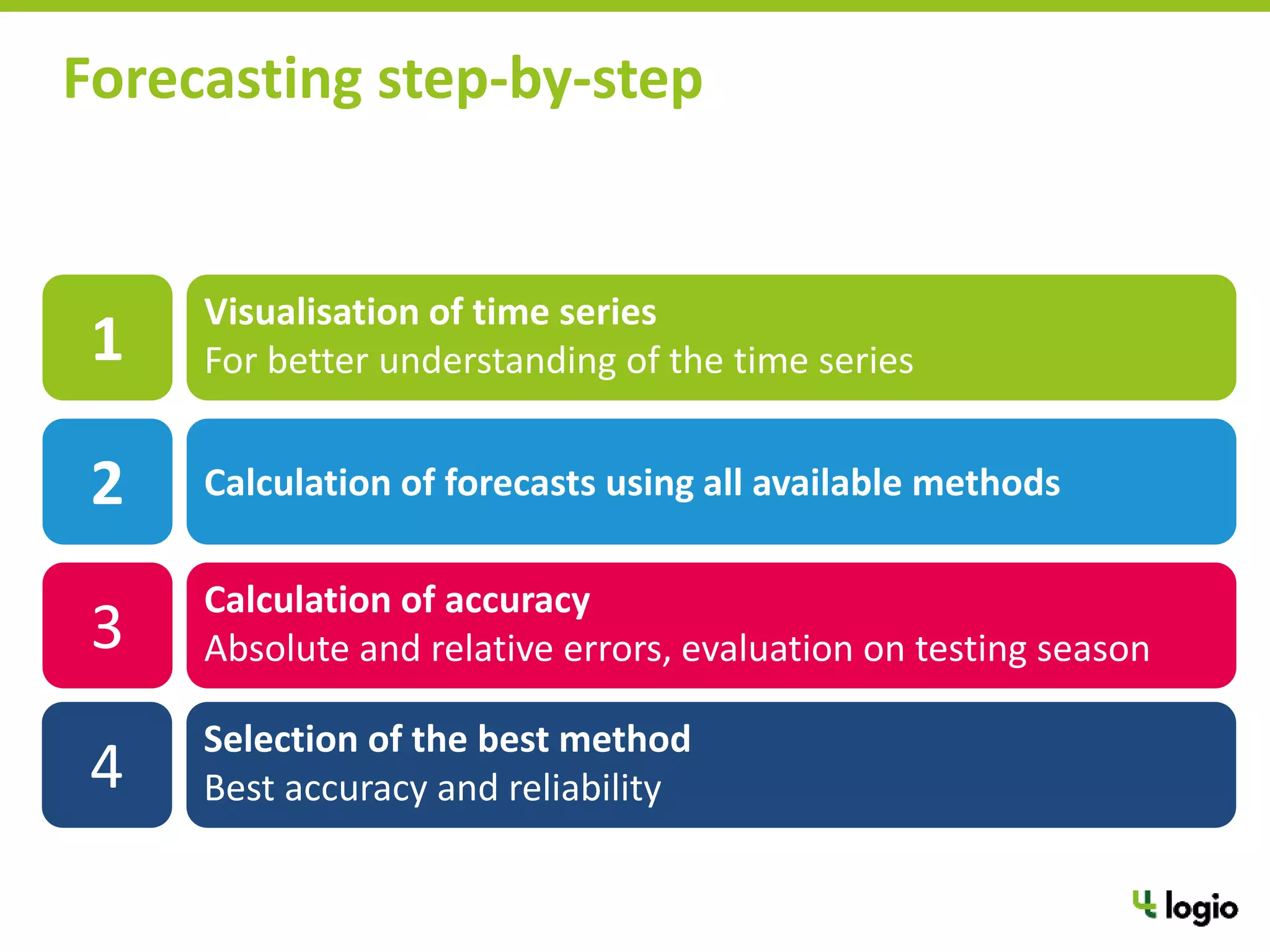

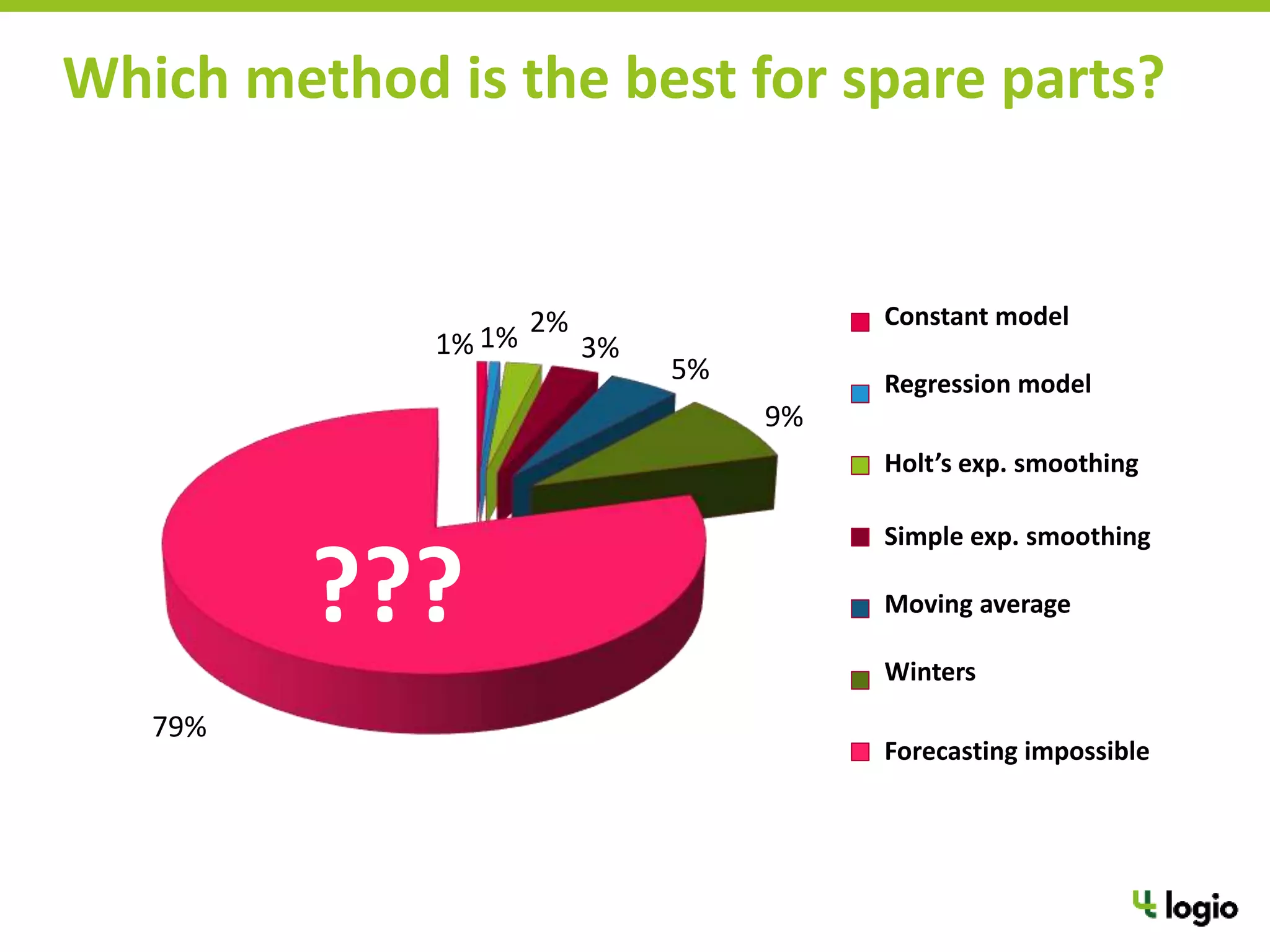

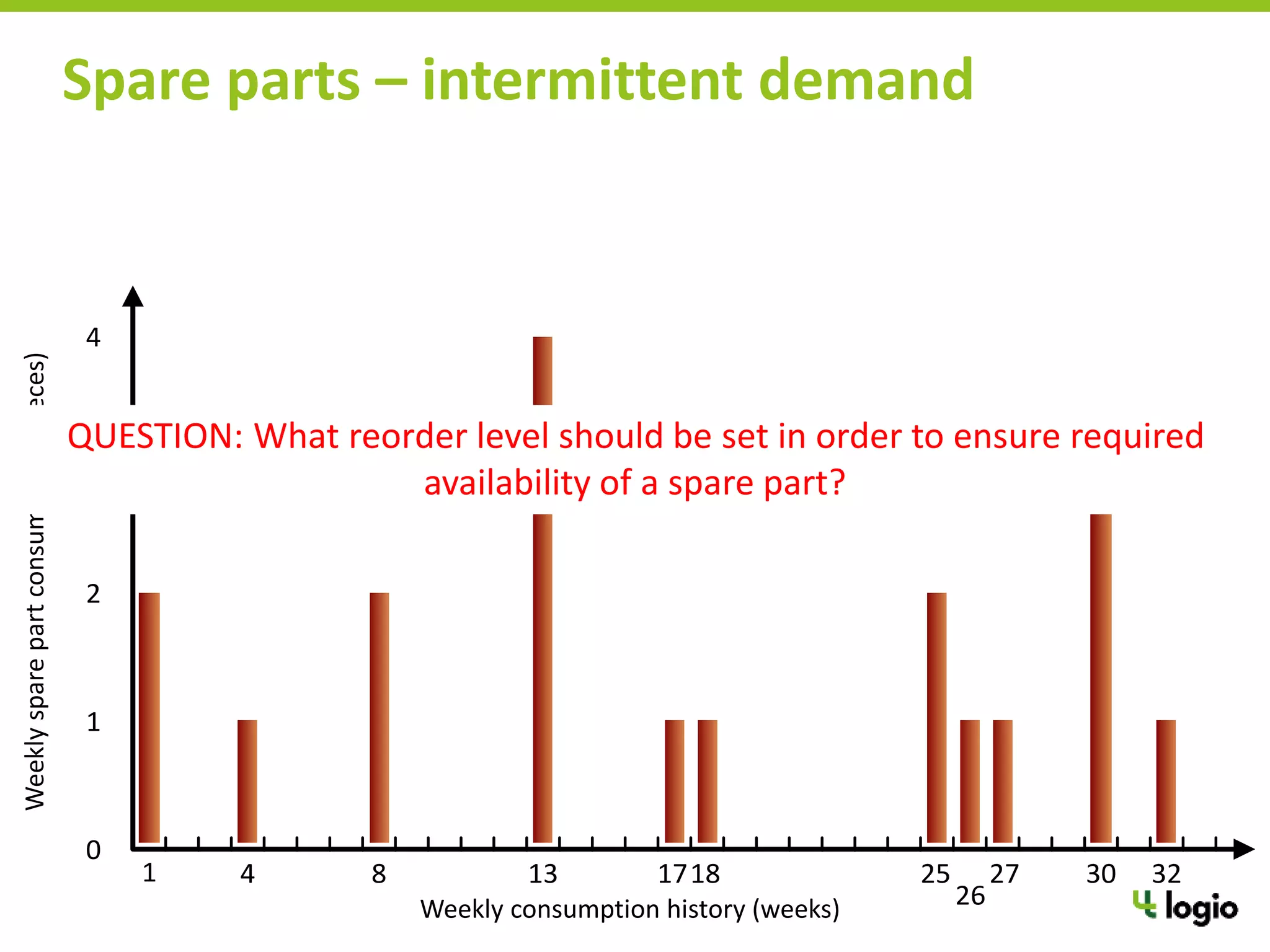

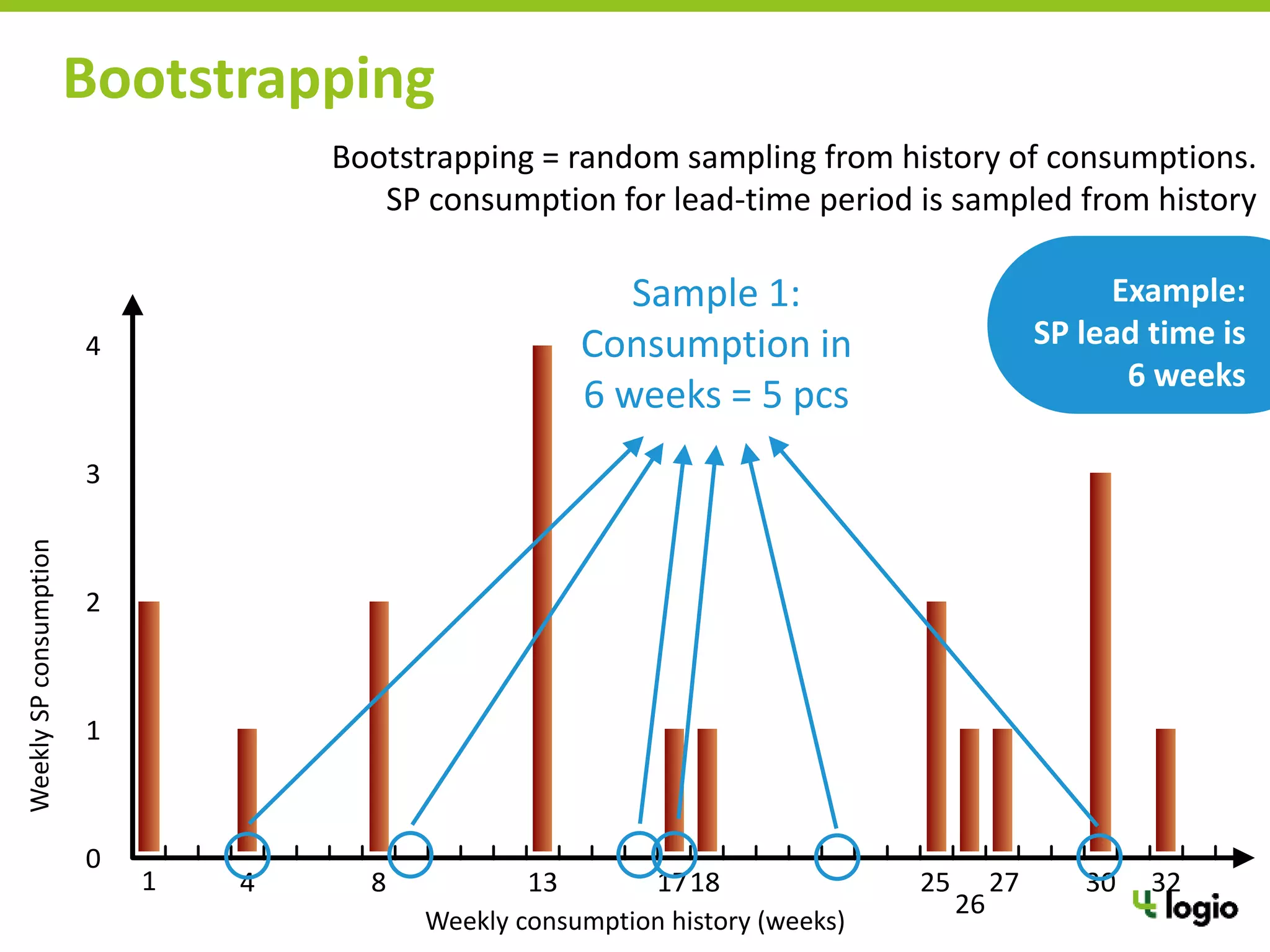

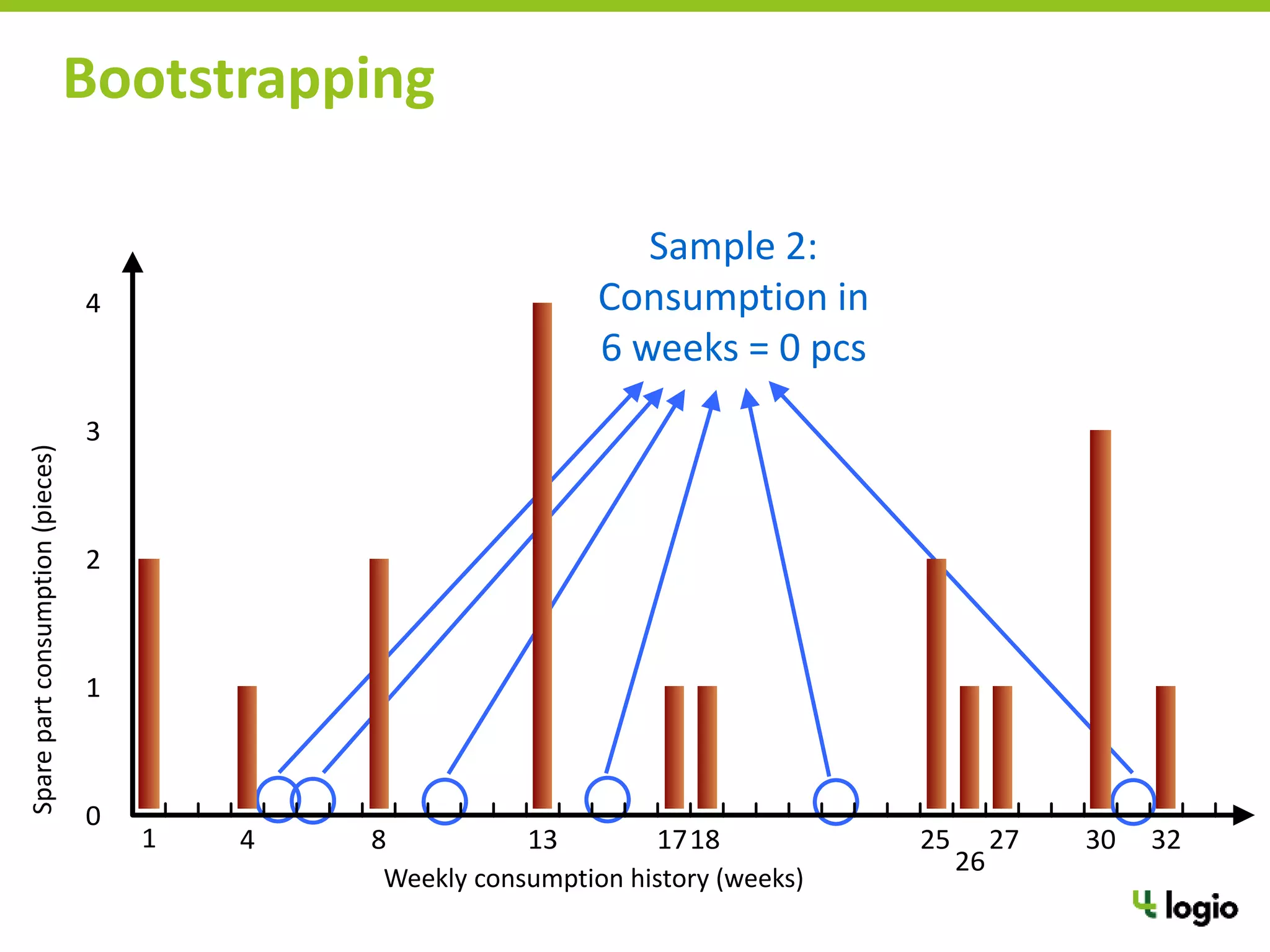

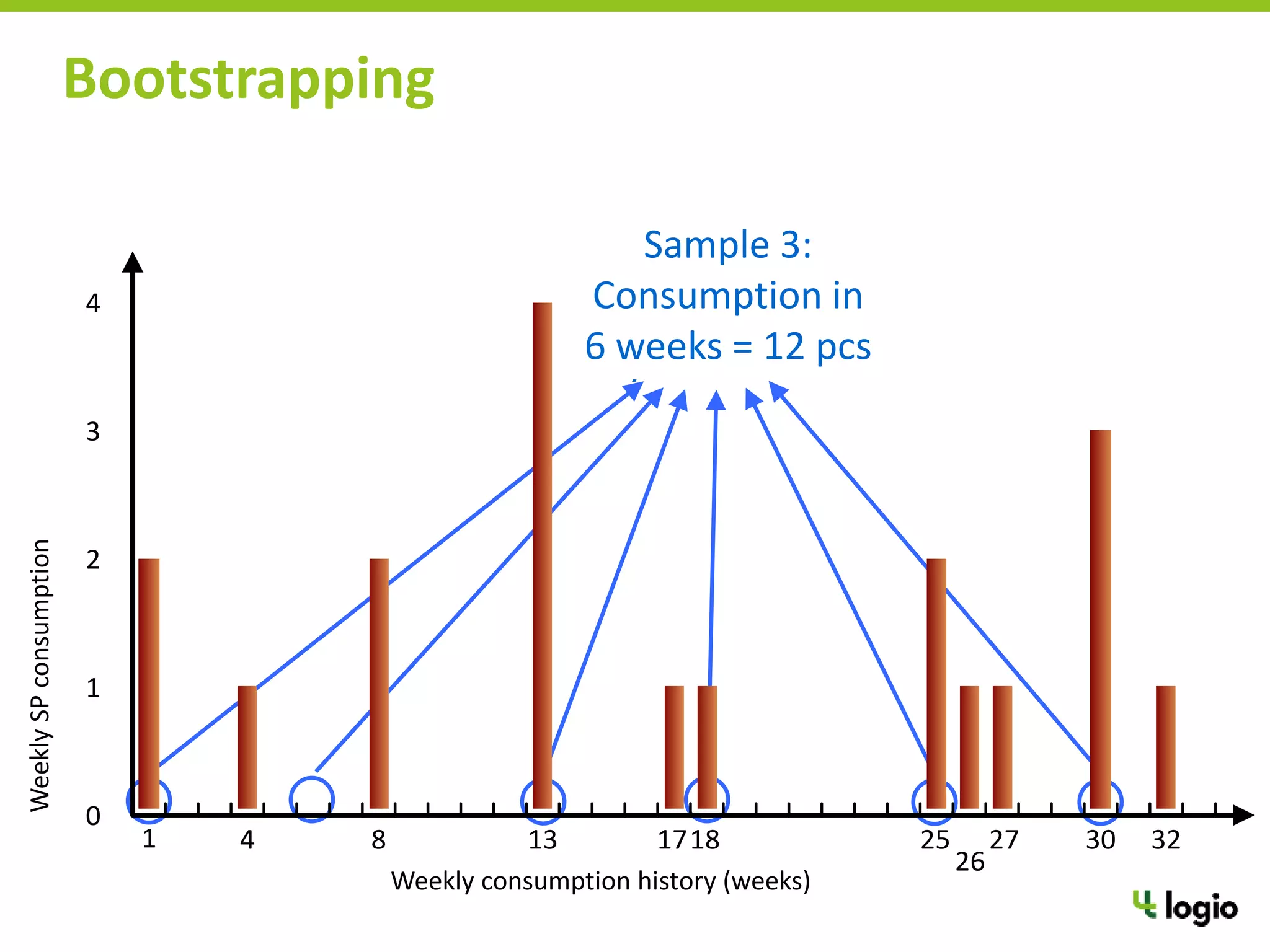

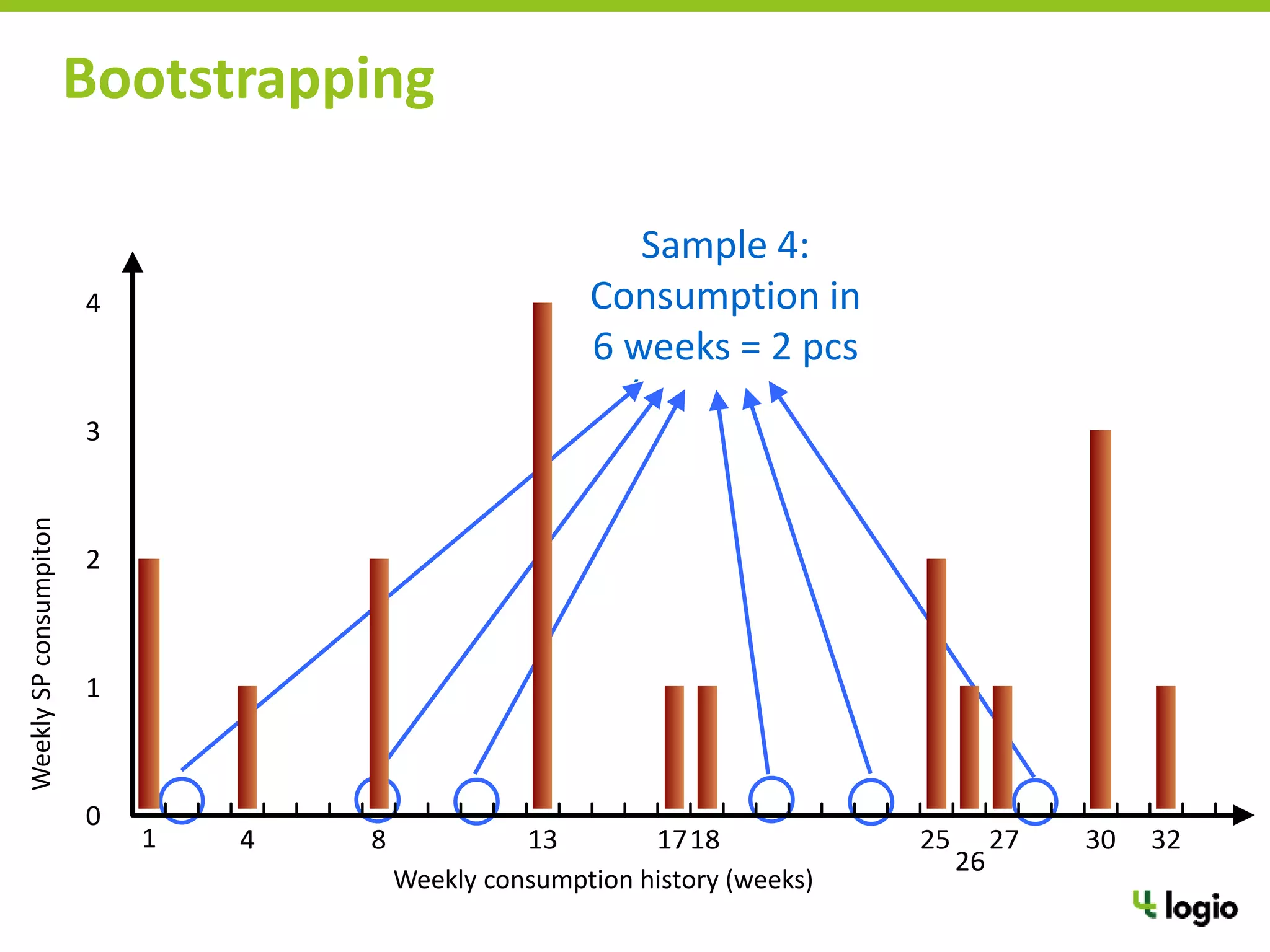

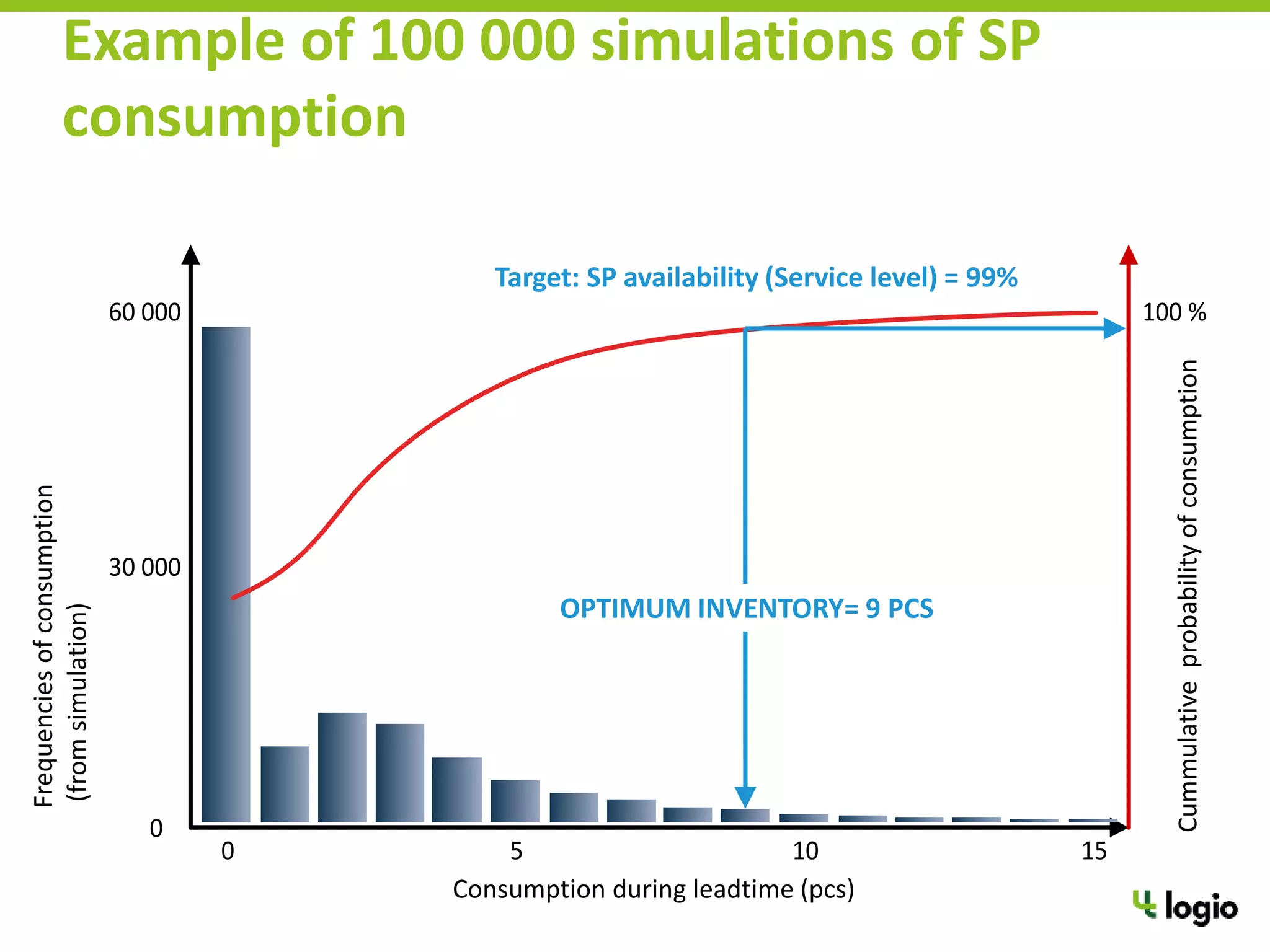

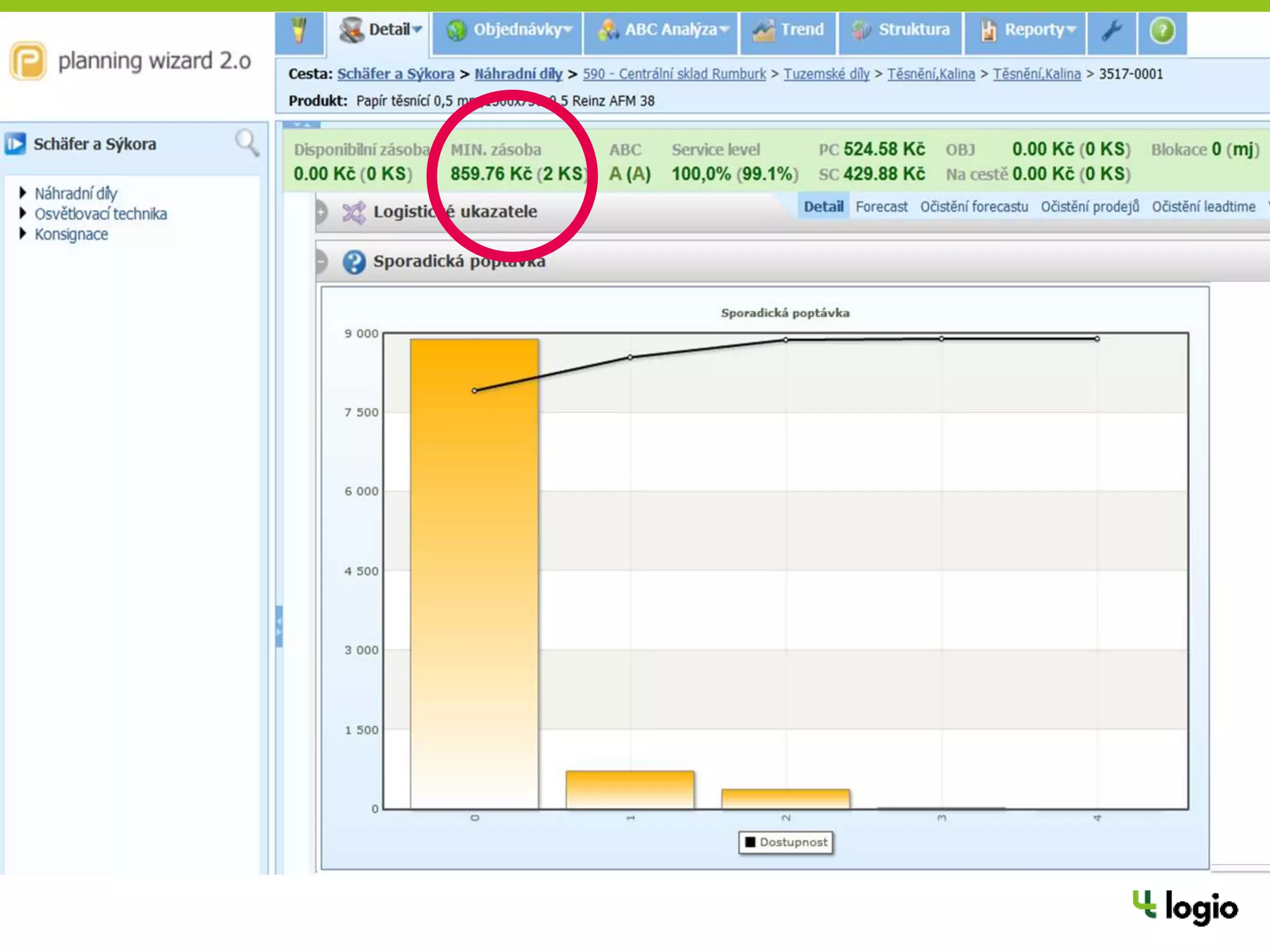

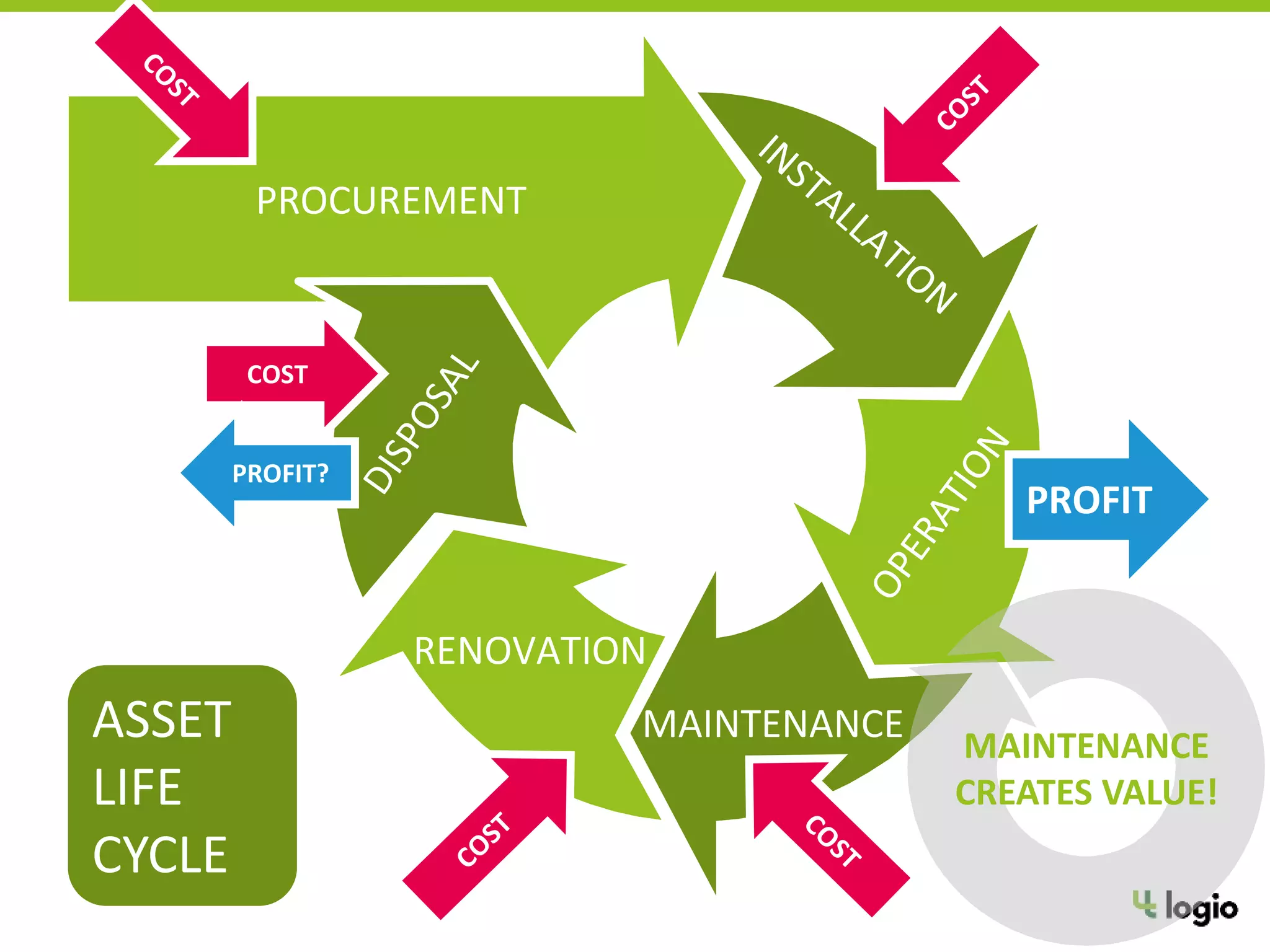

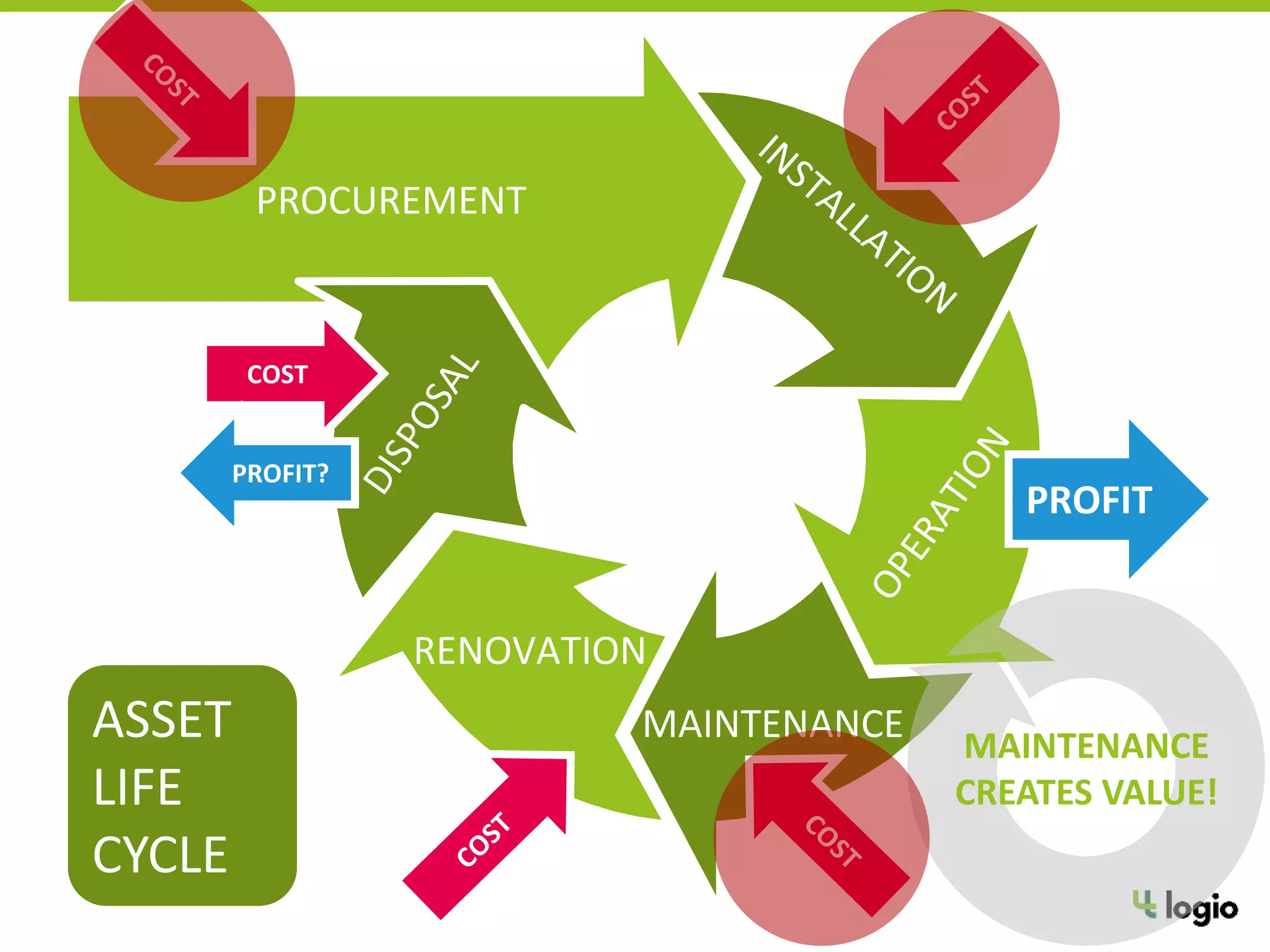

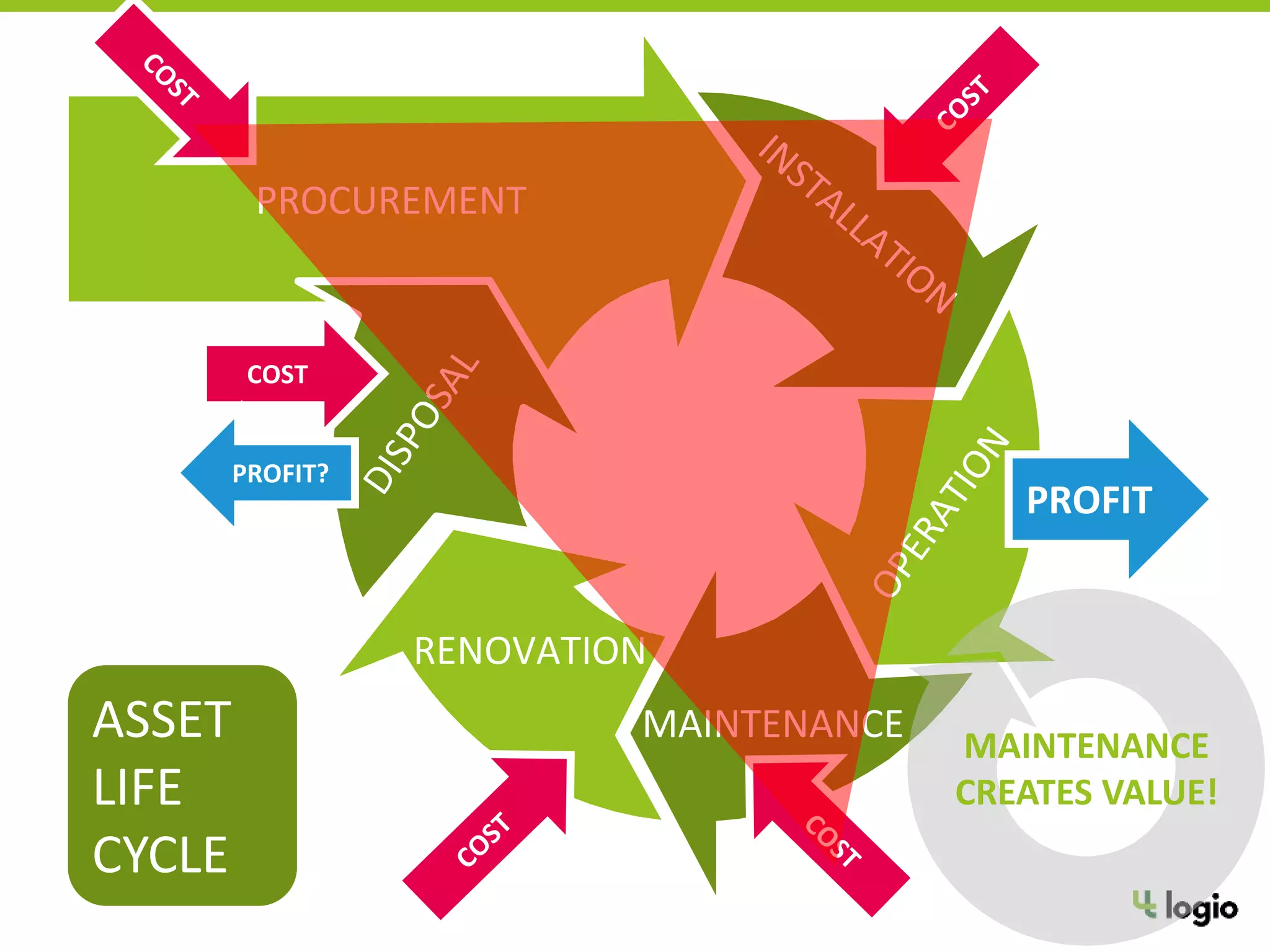

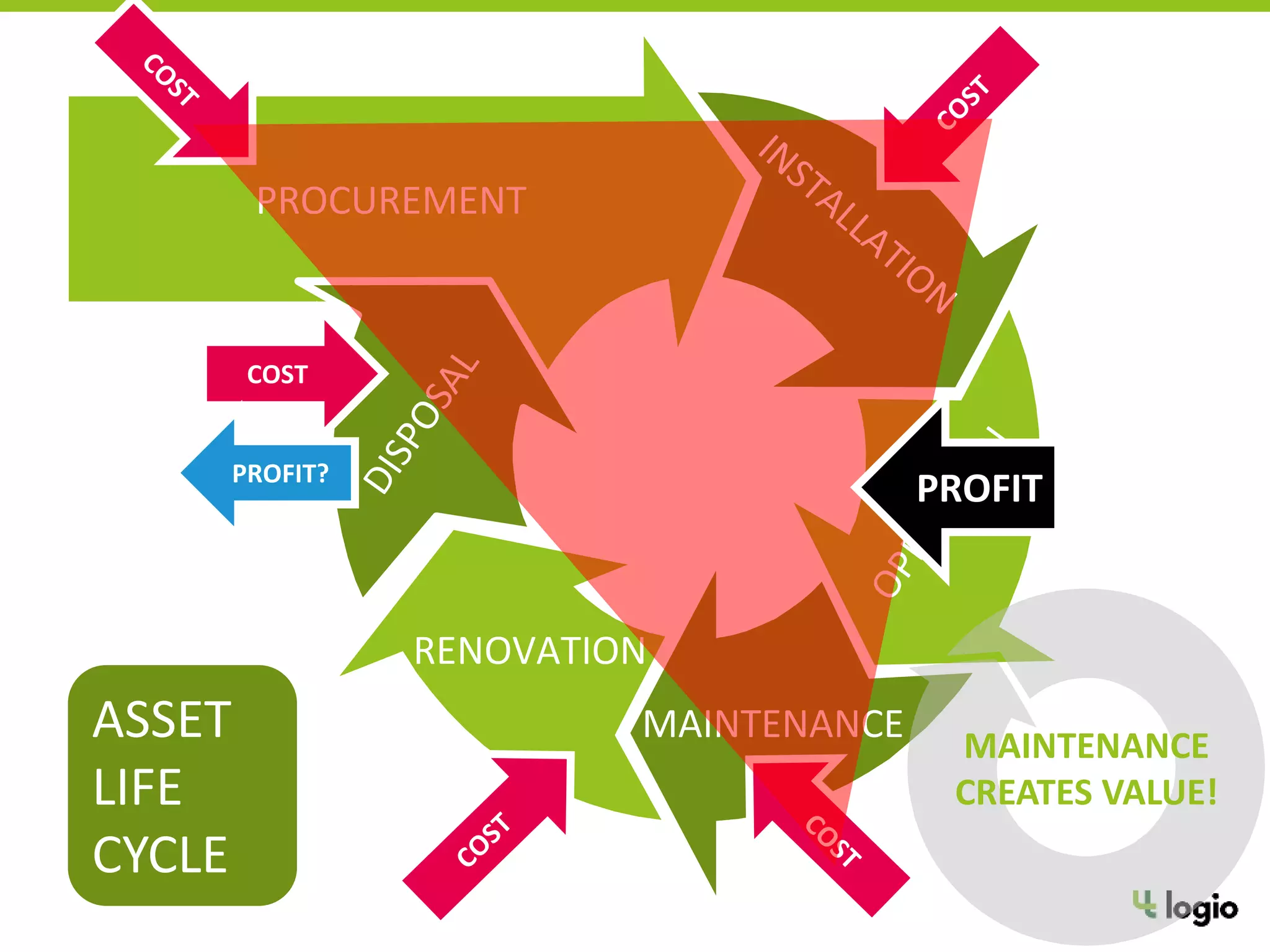

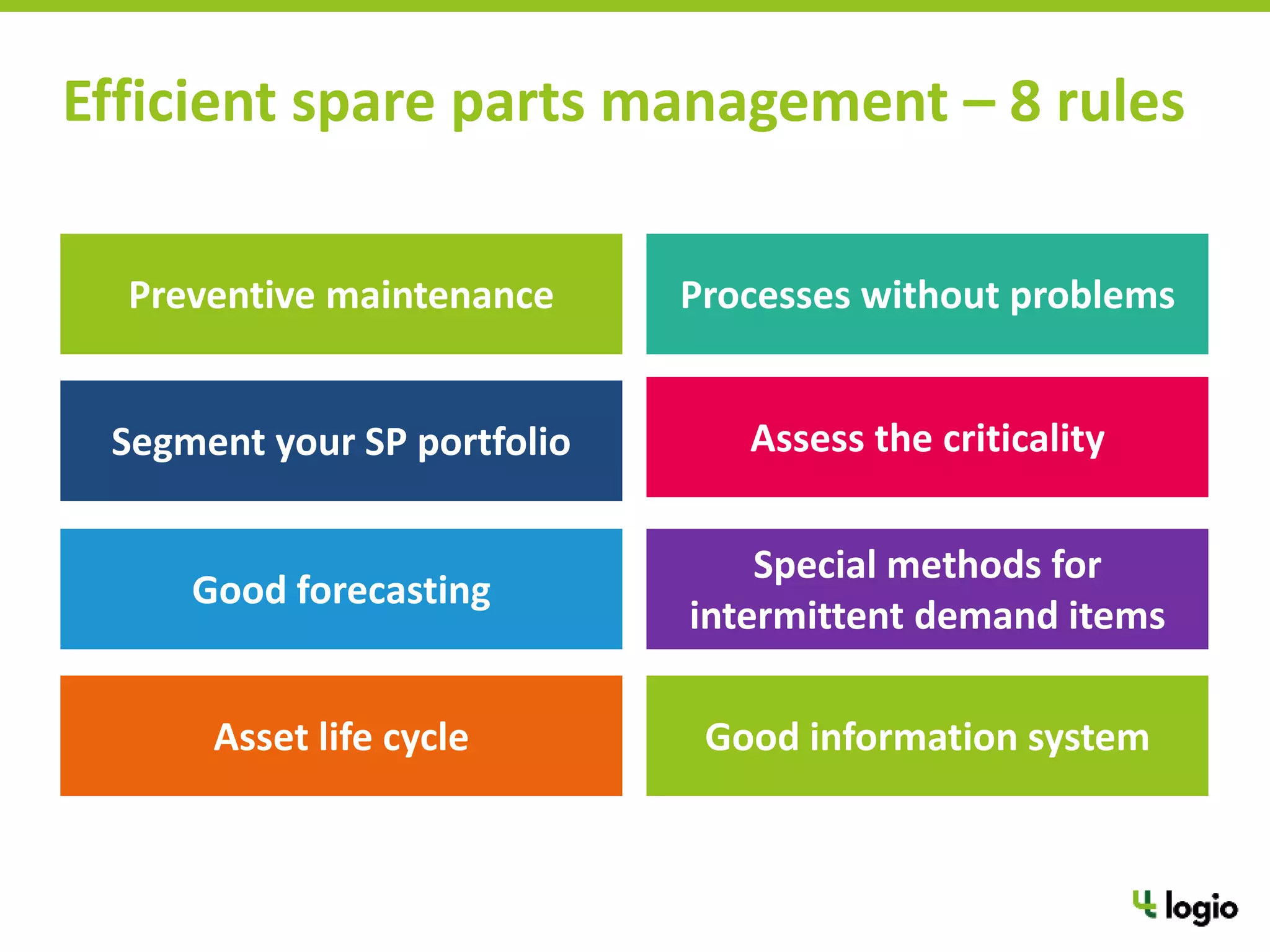

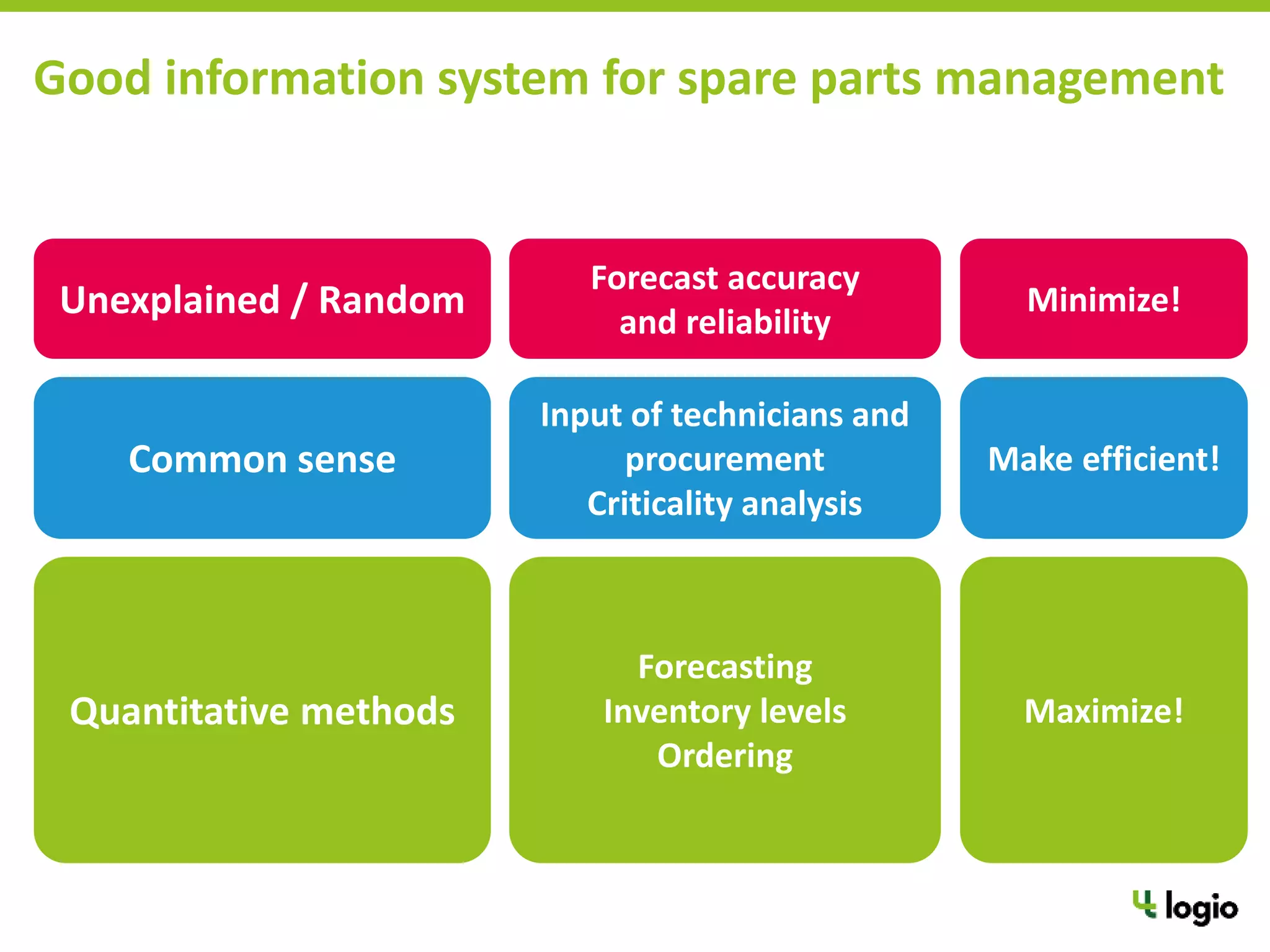

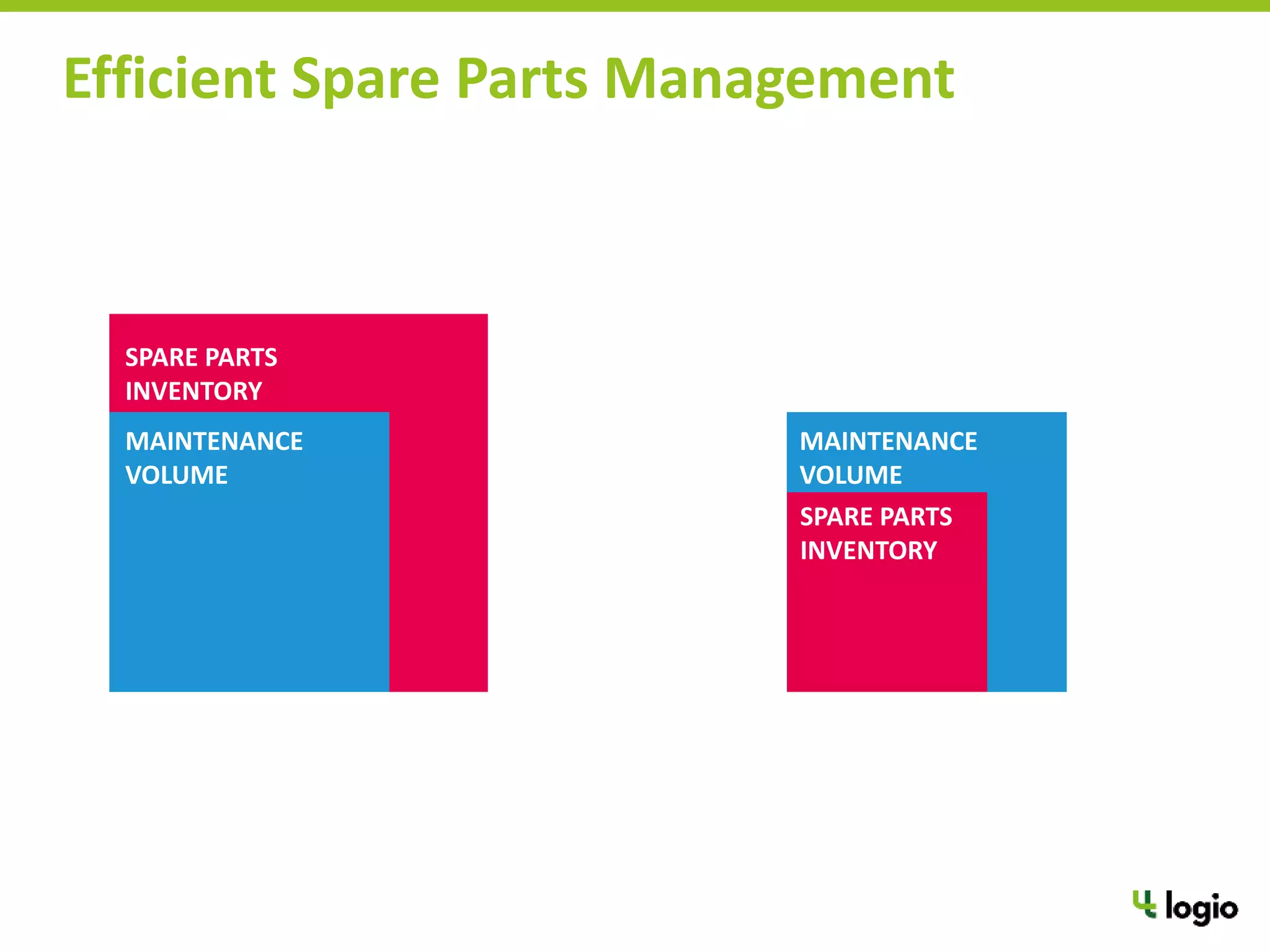

The document outlines eight essential rules for effective spare parts management, emphasizing preventive maintenance, process improvement, portfolio segmentation, criticality evaluation, accurate forecasting, handling intermittent demand, lifecycle consideration, and establishing a robust information system. It details common problems in procurement, inventory management, and consumption processes, providing examples and methods to evaluate spare parts criticality and optimize inventory levels. The conclusions underscore the importance of efficient practices to enhance maintenance operations and reduce costs.