This document discusses operations and maintenance (O&M) of facilities and equipment. It covers:

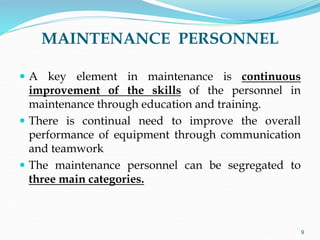

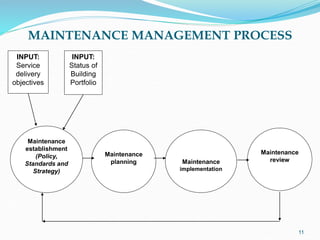

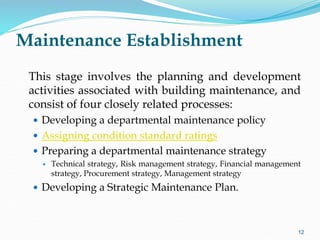

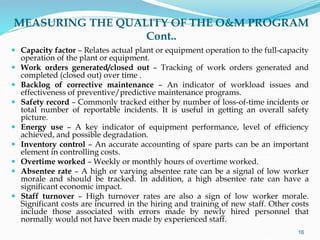

1) The importance of effective O&M for reliability, safety, and efficiency through technical systems, competent personnel, and continuous improvement.

2) Definitions of key terms including maintenance, operations and maintenance, and operational efficiency.

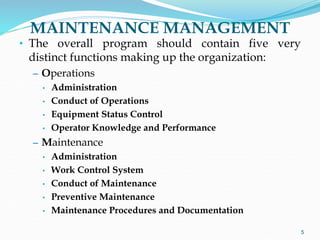

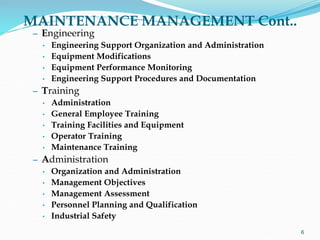

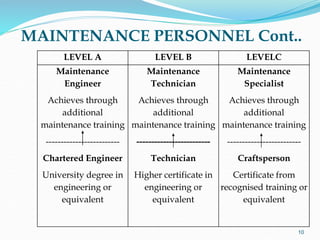

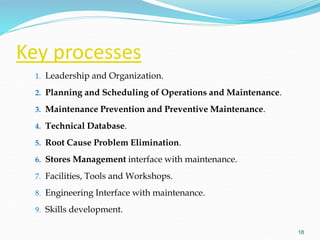

3) The five distinct functions that should make up an O&M organization: operations, maintenance, engineering, training, and administration.

4) Potential benefits of O&M including energy savings, hazard mitigation, improved indoor air quality, and achieving design life of equipment.