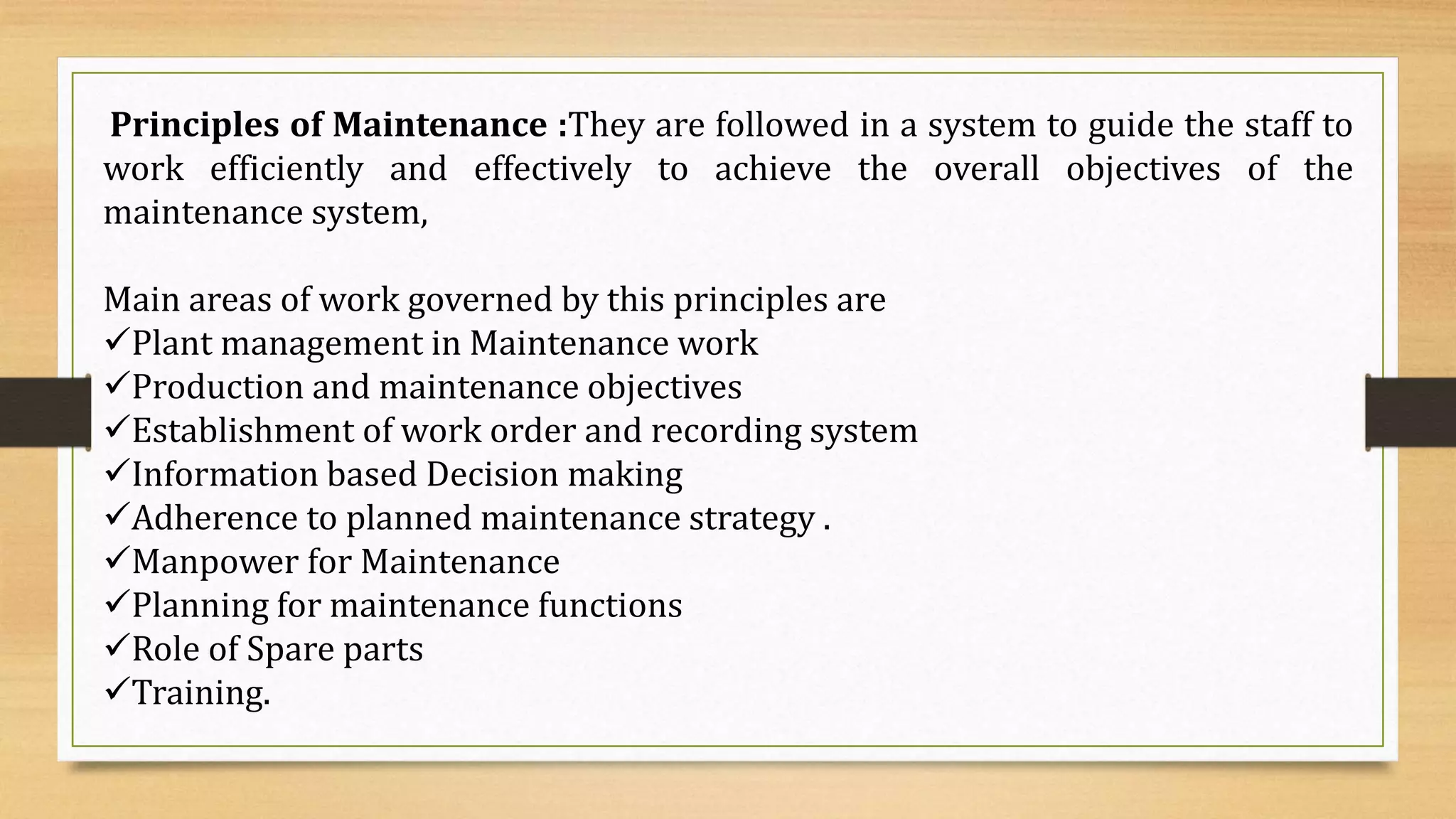

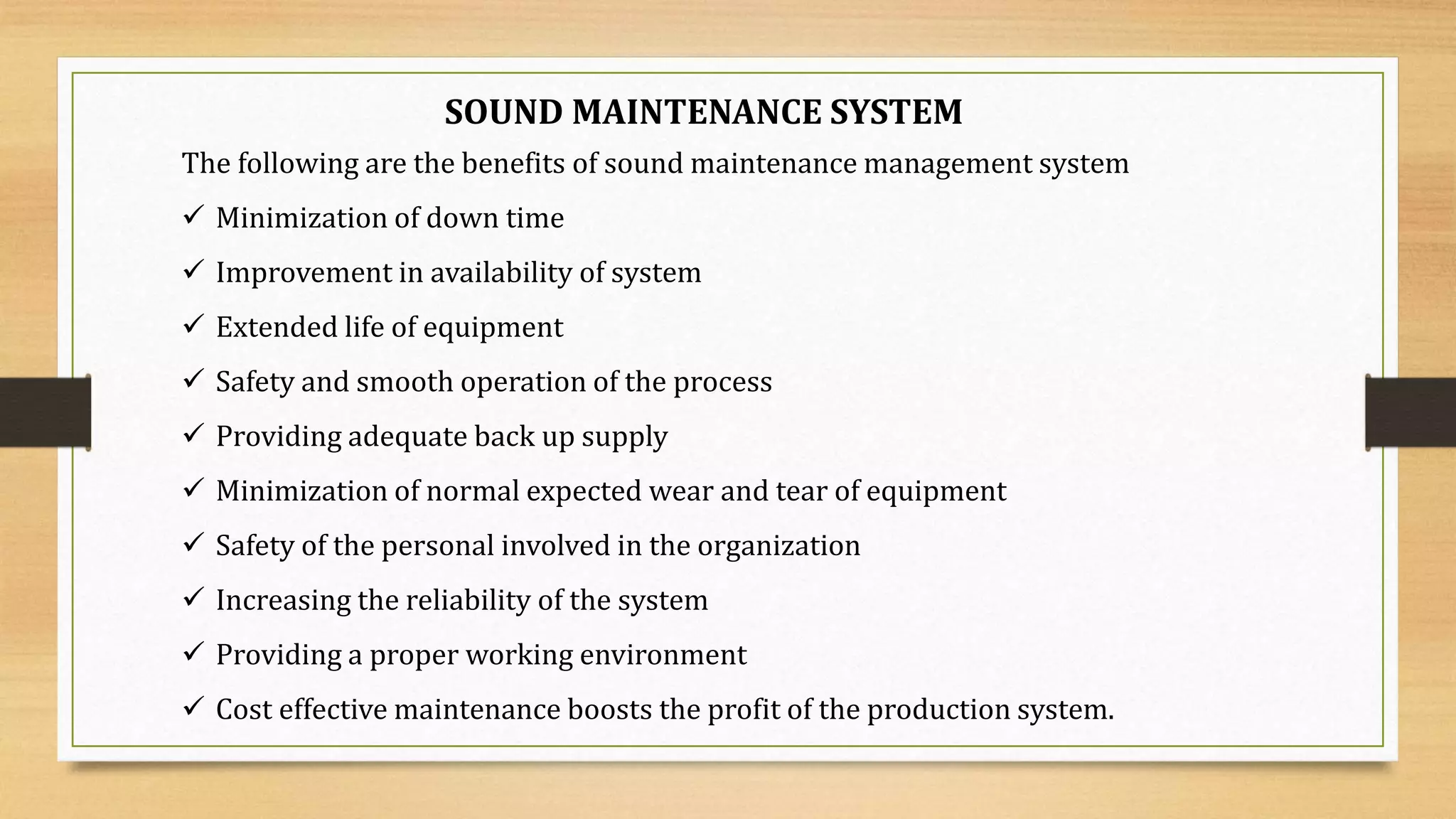

The document discusses principles and practices of maintenance planning in engineering systems. It describes key concepts like maintenance engineering, types of planning, objectives of planned maintenance, principles of maintenance systems, reliability measures like MTBF and MTTR, maintenance organization structures, and maintenance economics and costs. The overall goal of maintenance planning is to optimize equipment availability and performance at lowest cost through reliable maintenance strategies.