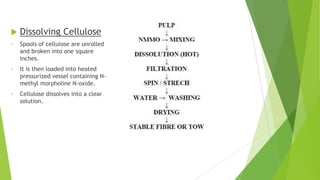

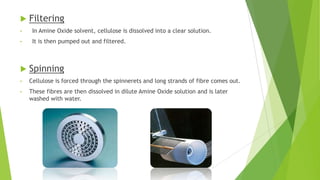

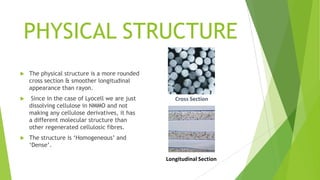

Lyocell, also known by the brand name Tencel, is a man-made cellulosic fiber produced by dissolving cellulose in an organic solvent without derivatization. It is produced from wood pulp through a solvent-spinning process using N-methylmorpholine N-oxide (NMMO) as the solvent. The manufacturing process involves dissolving cellulose pulp in NMMO, filtering the solution, extruding it through spinnerets into fibers, and removing the solvent to produce a strong yet soft fiber. Lyocell fibers have properties similar to cotton such as high strength, absorbency and softness but are more durable and easier to care for.