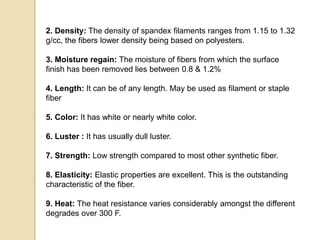

Spandex is a synthetic fiber known for its elasticity, produced through a process of reacting monomers to form a prepolymer solution, which is then spun through spinnerets into fibers. It is stronger and more durable than natural rubber. The solution dry spinning method produces over 94.5% of the world's spandex fibers through a five step process involving chain extension reactions and curing the polymer solution into fibers. Spandex fibers have excellent elastic properties, low strength, good resistance to acids and solvents but vulnerability to chlorine bleach. Its main uses are in clothing where stretch is desired for comfort and fit, such as athletic wear, swimsuits, and hosiery.