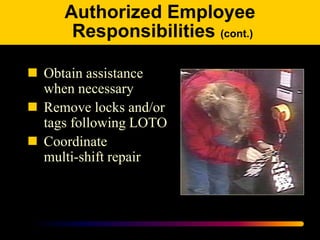

Lockout/tagout (LOTO) procedures are used to isolate hazardous energy sources during equipment service and maintenance to prevent injury. LOTO involves shutting off power at the source, applying locks and tags to energy-isolating devices to warn others not to reenergize equipment, and dissipating any stored energy. The Occupational Safety and Health Administration's Control of Hazardous Energy standard requires training and procedures for affected and authorized employees to safely isolate energy sources before performing service or maintenance on machines and equipment.