Lobel proposal for 1 mw crystalline pv solar power plant

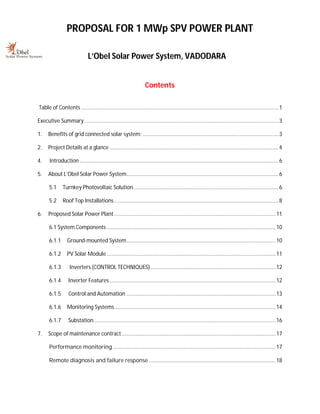

- 1. PROPOSAL FOR 1 MWp SPV POWER PLANT L’Obel Solar Power System, VADODARA Contents Table of Contents ................................................................................................................................... 1 Executive Summary ................................................................................................................................. 3 1. Benefits of grid connected solar system: .......................................................................................... 3 2. Project Details at a glance ................................................................................................................ 4 4. Introduction .................................................................................................................................... 6 5. About L’Obel Solar Power System ..................................................................................................... 6 5.1 Turnkey Photovoltaic Solution ................................................................................................ 6 5.2 Roof Top Installations ............................................................................................................. 8 6. Proposed Solar Power Plant ........................................................................................................... 11 6.1 System Components ................................................................................................................ 10 6.1.1 Ground-mounted System ................................................................................................... 10 6.1.2 PV Solar Module ................................................................................................................ 11 6.1.3 Inverters (CONTROL TECHNIQUES) ................................................................................... 12 6.1.4 Inverter Features .............................................................................................................. 12 6.1.5 Control and Automation ................................................................................................... 13 6.1.6 Monitoring Systems ........................................................................................................... 14 6.1.7 Substation......................................................................................................................... 16 7. Scope of maintenance contract ...................................................................................................... 17 Performance monitoring ............................................................................................................ 17 Remote diagnosis and failure response .................................................................................... 18

- 2. Preventive maintenance ............................................................................................................. 18 Corrective maintenance .............................................................................................................. 18 Facility management .................................................................................................................. 18 Module cleaning ......................................................................................................................... 18 Security management ................................................................................................................. 19 8. Project Implementation and Schedule ............................................................................................ 19 9.1 Project Implementation Strategy ............................................................................................. 20 9. Project Management and Engineering .......................................................................................... 21 9.1 Procurement of the System ...................................................................................................... 22 9.2 Typical System Integration ....................................................................................................... 22 10. Bill of Material .............................................................................................................................. 23 11. Typical Execution of installation under accomplishment of all national regulation & norms: .......... 25 12. Budgetary Cost for 1 MWp Power Plant …………………………………………………………………………………….. 29 13. Retention clause ........................................................................................................................... 29 14. Transportation ............................................................................................................................. 29 15. Insurance ..................................................................................................................................... 29 16. Currency and taxes ....................................................................................................................... 29 17. General terms of payment ............................................................................................................ 29 18. Contractual conditions ................................................................................................................. 29 19. Transparency and compliance ...................................................................................................... 29 20. Bid validity.................................................................................................................................... 29 21. Warranties and Securities ………………………………………………………………………………………………………. 28 22. Project Plan / Time of Erection .................................................................................................... 30 23. General Reservation ..................................................................................................................... 30 2

- 3. 3 Executive Summary Energy is a necessary driver of growth and its per capita consumption is growing all across the world. This is primarily associated with the growth and development. Any developmental activity in a nation fuels the energy demand. The world already realise the need to switch over Renewable Energy (RE) source to augment the energy needs. Clean sources of energy not only help our environment to recover from the mindless exploitation it has been subjected to in the last 150 years, but also provides power to millions of people especially in the developing nations. The renewable energy sector has emerged as the fastest growing industry in recent times and there are hopes of it getting only bigger in the coming years. Most nations have put plans in motion to promote this sector in a big way. Green growth is the way to future for the developed nations and a huge opportunity of energy security for the developing nations. There is one more advantage which is slowly being recognized as the most important aspect of this change- it’s potential to create employment for millions in the coming decade. In India, there is still a huge gap between the demand and supply of electricity. Its power sector is consistently plagued by shortages. India currently ranks fourth in the world for green house gas emissions. There is a need to balance the two- the growing huge energy needs with climate change issues. That is where the renewable energy sources come into play. The Indian government, Ministry of New & Renewable Energy (MNRE) has various policies and plans to advance solar and other renewable energy in the country. The support from Government is a prerequisite to push forth the emerging concept of generation-based incentive of solar power. The incentives announced by MNRE are a well timed policy measure, which is oriented towards a bigger role for solar power and is based on some gainful insights into the actual operation of megawatt sizes solar power plants. 1. Benefits of grid connected Solar Photovoltaic (SPV) System: Power from the sun is clean, silent, limitless and free Power production from Solar Photovoltaic process does not releases gases like CO, CO2, SO2, NO2, which are normally associated with burning finite fossil fuel reserves and don’t contribute to global warming.

- 4. Solar Photovoltaic are now a proven technology which is inherently safe as opposed to other fossil fuel based electricity generating technologies. Reduces or avoids the necessity to build new transmission/distribution lines or upgrade existing ones. Solar power shall augment the needs of peak power needs. Increases the grid reliability i.e., voltage and frequency. Reduce the transmission line losses. Provides a potential revenue source in a diverse energy portfolio Assists in meeting renewable portfolio standard goals. 4 2. Project Details at a glance This proposal highlights the implementation of 1 MWp power generation project. As an initiative towards green energy generation, L’Obel Solar Power System is interested in setting up a 1 MWp Grid Connected project. The system configuration of the Power plant will be as follows: a) Proposed Solar PV Power Plant Capacity of 1 MWp. b) The generated power is going to be fed to state Electricity Grid. This report highlights the details of the proposed power generation scheme, site facilities, features of the main plant and equipment including the Solar PV array, electrical systems, evacuation of generated power, environmental and safety aspects, distribution mechanism and the financial analysis. Sr. No Components Details 1 Location Kutch, Gujarat 2 Proposed capacity 1 MWp 3 Type of system Grid Connected 4 Type of Module Poly- Crystalline 5 Proposed module area 5.5-6 Vigha = 1.25 lac sq feet 6 Capacity range of each module proposed 240 Wp 7 Inverter capacity 1060 KW 8 Expected life of power plant years 9 Project Developer L’Obel Solar Power System

- 5. 5 4. Introduction Climate change and fossil fuel depletion are threatening our very existence on this planet. This is primarily due to our dependence on fossil fuels for an upkeep of modern day life styles. Nearly 75% of energy usage takes place in urban and semi-urban areas accommodating large chunks of population. The rapid urbanization with an accompanying economic development is responsible for a sudden rise in energy demand. Essential public services like electricity services for homes, transport, industry, commerce, and other infrastructure run by virtue of fossil fuels. To secure the energy supply for all this and to mitigate the risks of climate change, RE source of energy form the most obvious solution. With its abundant solar energy, India can exploit this resource easily. Most of today’s electrical energy is generated by fossil fuel based plant with a low production cost and high reliability. However, concerns about the longer term sustainability of fossil fuel-based generation, are driving the energy industry toward sustainable, low carbon emitting, renewable energy sources. Indian government - MNRE has demonstrated its commitment to the cause of promoting RE power generation and solar in specific by its current policies. India is a tropical country, where sunshine is available for longer hours per day and in great intensity. It is home to one of the most abundant solar resources in the world, with 2.97 million square kilometres of tropical and subtropical land and an average of 300 clear sunny days a year. As such, solar power offers significant potential to meet a large share of the country's energy needs. Solar energy, therefore, has a tremendous potential as a future energy source. It has the advantage of permitting decentralized distribution of energy, large, centralized power generation plants, smaller distributed heat and power plants; or scaled down, at the individual consumer level. Thus it has the leverage of empowering people at grass root level. It is not only technically and economically feasible for India to make the shift to renewable energy sources (if this rollout is combined with energy-efficiency measures), but also prudent to begin this transition now. The Government has recently approved an ambitious new plan to increase solar power capacity to 20 Giga watts by 2020, under the National Solar Mission. The Mission is to provide lighting for 20 million homes and eliminate 42 million tons of carbon dioxide emissions annually. There are several reasons for this urgency. First, India's power-generation infrastructure is undergoing rapid expansion to meet national development objectives, with the country still facing unmet power demands that equate to as much as 80 percent of current installed capacity. Second, they point to rising energy security concerns as

- 6. energy prices go up and supplies shrink, making it a ripe time to shift to a new model of energy production. As on March, 2009, India’s power system had an installed generating capacity around 1,48,700.00 MW and thermal power plants powered by coal, gas, naphtha or oil accounted for approximately 64.70 % of total power generation capacity. Hydropower picks up a share of 24.80%. Renewable sources of energy account for around 8% of the power generated, with wind power having a share of around 5.5%. In the same year a capacity addition of nearly 51,300 MW has been planned by the ministry of power during the eleventh five year plan period (2009-2012).Thus there is a need for large scale power generation from both Non-renewable and renewable sources of energy to sustain a targeted GDP growth of 8%to 10% per year. Of late, solar power investments in the country are registering a fast increase. In fact, India is a home to many national and international PV manufacturers setting up large scale PV manufacturing facilities. There is a growing optimism on the fact that solar power may well attain the much needed grid parity within the next few years. India is a developing nation and cannot halt its developmental goals. While we have a need to cut down the GHG emissions, it also has to ensure that its infrastructural growth is not hindered in any way. Solar energy in India is a potential huge source of energy. If we are able to harness the high amount of sunlight received by India, then we can meet its energy demand like no other fuel. 5. About L’OBEL SOLAR POWER SYSTEM L’Obel Solar Power System is a vertically integrated, end-to-end renewable energy services provider. Our goal is to provide clean, renewable solar energy at affordable prices. As a solar energy services company, we: Manufacture high quality solar devices Provide turnkey solar energy solutions Provide solar energy consulting and service. 6 5.1 Turnkey Photovoltaic Solution L’Obel Solar Power System’s engineers help design solar power for commercial, industrial and residential clients in the India and have 20 years experience of manufacturing and executing Solar Projects. Our 20 years relationships in renewable energy field enable us to source top-quality components at competitive prices from around the world. As a system integrator, we provide complete PV services including:

- 7. 7 Consultation Site assessment and solar analysis System design and installation Integration (EPC) services Service and maintenance L’Obel Solar Power System has manufacturing facility located in Vadodara, Gujarat. L’Obel Solar Power System is geared up to provide environment friendly solar energy on a large scale. Our projects office is also located in Vadodara where we have one of the finest engineering and execution teams. L’Obel Solar Power System has an unmatched ability to provide a comprehensive, integrated, state-of-the-art, turnkey solution through a well-structured consortium. The company is experienced in working, in diverse climates and ground conditions. L’Obel Solar Power System utilize local contractor base for maximum efficiency and economy, hence provides with seamless project execution from project development to plant commissioning. L’Obel Solar Power System capitalizes on its broad experience in significant solar projects and thereby relies on its professional and technically sound project management team. This results in professional installations on given schedules. Such high standards make L’Obel Solar Power System to be your preferred partner for PV large – scale projects. L’Obel Solar Power System is committed for providing the most efficient solar power plants with special regard to the long life efficiency. Therefore L’Obel Solar Power System works in a vertically integrated end-to-end engineering process which results in plant layouts with their possible yield / investment ratio. As L’Obel Solar Power System also provides with the modules, the plant reaches highest efficiency in a very cost effective way. L’Obel Solar Power System believes in procurement of the most efficient components from different vendor companies to provide our customers with most advanced and reliable systems. Our technological alliances allow us to guarantee a comprehensive performance ratio (PR) to secure your investment and your cash-flow. As a turnkey provider L’Obel Solar Power System is a right partner to handle whatever is necessary for the efficient erection and operation of solar power PV- plants. Experience shows that the profitability of a PV plant relies on both the performance of its single parts but also proper matching and compatibility between the

- 8. components. Being a well recognized player in the international market, L’Obel Solar Power System enjoys well proven relations with its suppliers. Our partners and suppliers have been assessed not only for fulfilling the L’Obel Solar Power System quality standards but also for their capability to professionally realize large – scale projects on time. 8 5.2 Roof Top Installations 1. Solar PV Power Plants 2. Industrial roof top PV Power Plants 3. Solar PV Powered Railway Signals (LED) At Rajkot & Bhavnagar Division of Western Railways

- 9. 4. Solar PV 4. Powered Street Lights & Home Lights 9 6. Proposed Solar Power Plant L’Obel Solar Power System will install a grid-tied solar power generation system using state-of-the art ground-mounted structure. Figure shows the schematic diagram of a typical grid-tied solar system.

- 10. UTILITY PV ARRAY MAIN SERVICE PANEL DC FUSED SWITCH DC/AC INVERTER AC FUSED SWITCH UTILITY SWITCH PV ARRAY CIRCUIT COMBINER GROUND FAULT PROTECTOR Sunlight captured by solar panels is converted into DC electricity. This DC electricity is collected from all the solar panels and is passed through an inverter, which converts it into usable AC electricity. This AC electricity is fed into the electricity grid. 6.1 System Components 6.1.1 Ground-mounted System L’Obel Solar Power System will install a fixed mounting structure made up of high strength high performance galvanized steel. Panels are pushed in for faster assembly no nuts and bolts are required. The structure is designed for 200 Km/hr wind load. The installation and anchorage technology is drawn from experienced highway crash barrier technology. It can be installed solid ground conditions including solid rock. This mounting system comes with a 25-year warranty. 10 L’Obel Solar Power System is looking forward to a new technology which is Innovative and can be installed without any concrete. This technology is known as screw-pile technology. This technology allows erecting the mounting structure in a very less span of time and has a superior holding capacity with distinct advantage in unstable soils. As with this technology the foundation can be erected in few hrs as there is very less concrete work and the mounting is done by the machines, implementation is swift with several hundred foundation points being completed in a day.

- 11. A PV Array is made up of PV modules, which are environmentally sealed collections PV cells-the devices that convert sunlight to electricity. This allows some assembly and wirings functions to be done on the ground if called for by the installation instructions. The panels will be mounted in rows and electrically connected with cables. The cable will need to be made safe and tamper proof. The electrical output from the PV panels will be fed via cables to a bank of inverters. 6.1.2 PV Solar Module Top quality, high efficiency, and high wattage (240 Wp) solar panels will be used 11 in the system. PV panels use high efficiency polycrystalline cells and are assembled with top-quality raw materials sourced globally Panels are tested in accordance with IEC 61215, IEC 61730, TUV and UL 1703 certified. Approx. size: 1644mm X982 mm Best-in-class performance ratings proven by field installations 25 year power warranty Higher strength with wind and snow loads guaranteed up to 80 lbs/ft2 Mechanical Data of 240 Wp Solar PV Module Sr. No. Parameter Value 1 Cell 156mm2 high power Polycrystalline solar cells 2 Connection 60 cells in series 3 Dimensions 1644.6 x 982.2 x 40 mm (1.62 sqm) 4 Weight 18.60 Kg 5 Connection type Cable with plug connector (compatible with MC-4 connectors) 6 Bypass Diode 3 (Three) 15A bypass diodes Electrical Data of 240 Wp Solar PV Module

- 12. Sr. No. Parameter Value 1 Maximum Power 240 Wp 2 Open Circuit Voltage 37.26 V 3 Short Circuit Current 8.39 A 4 Voltage at point of maximum power 30.85 V 5 Current at point of maximum power 7.80 A 6 Max System Voltage 600/1000 V (UL/IEC) 7 Tolerance at Pmax 0% to 3% 8 Temperature Coefficient - Power -0.45%/°C 12 6.1.3 Inverters (CONTROL TECHNIQUES) The grid tie inverter in a solar PV power plant converts the DC power generated by the PV module in to suitable AC power for feeding to the grid. This inverter automates the start up and shut down functions. By incorporating advanced maximum power point tracking technology, it maximizes the energy harvested for PV modules. To minimize the power losses during the conversion process, the inverter switching technology uses insulated gate bipolar transistors. Multiple inverters are paralleled for large power installations. High efficiency of conversion under partial load conditions is essential for economic viability of the entire solar power station the inverters with their own weatherproof enclosure installed in close proximity to PV modules are considered for this project. 6.1.4 Inverter Features Enhanced conversion efficiency 98% peak Enhanced availability Greater Yield at low irradiance High accuracy MPPT algorithm over a wide voltage range Compact and easy to maintain Anti Islanding and supply dlp ride-through Communications and PC tools for local or remote configuration and monitoring.

- 13. Electrical Data of Inverter Sr. No. Parameter Value 1 AC Current 1800 A 2 DC Current 2100 A 3 Inverter Power @ 50°C 1060KWp 4 Max. THD 2.28% 5 Euro. efficiency 98% 6 MPPT voltage Range 400V – 800V 7 Maximum no. Of internal DC landings points 18 13 6.1.5 Control and Automation In order to have a smooth functioning of inverter, control and automation forms an integral part of PV system. Different types of controllers are available. A typical controller will have following control and automated functions. Inverter start up, shut off and disconnection sequence Over/under voltage & frequency protection Anti islanding protection Power tracking to match inverter to the arrays Adjustment of delay periods to customize system shutdown sequence Graphical user interface for real time communications, monitoring and control Optional remote monitoring via internet modem Faults notification via modem Data acquisition and logging DC monitoring

- 14. The system is an innovative monitoring and analysis system for large PV plants. It is upgradeable with CAN bus compatible components. The system also enables diagnostic and monitoring functions for these components. Monitoring of central inverters and junction boxes to string level. Transmits the data required for monitoring, such as yields and the system efficiency to the Internet portal. Here the data is converted into straight forward diagrams and stored. A constant target/actual analysis enable malfunctions to be detected in their initial stages. In such cases, a definable group of persons is notified immediately Remote-controlled connection/disconnection reduces service outlay on site. The long-life electronic safety feature; Real protect optimizes system availability. Data modem (analogue/Ethernet) can open interface for connecting the connecting the system components, RS232. 14 6.1.6 Monitoring Systems System: Monitoring central system: String monitoring junction boxes: Communication: Electrical protection equipment will be required to be specified in conjunction with PEA, for the connection of the PV plant to the electrical network. Highlights: Remotely monitor, diagnose, manage and control systems, without costly "truck rolls" Receive alerts that serve as early warnings to equipment and system issues Perform remote diagnostics, updates and resets to optimize performance Weid Muller monitoring or equivalent will be used to monitor the performance of the solar power plant. Features and Benefits: Control system based on modular concept easy to adapt to any solar application. Integrated strings fuse protection. No need of local key-pad programming since all parameters can be set in an easier and quicker manner using Eos-Array Soft software, Eos software. Simplified installation since there is no need of auxiliary bus wiring.

- 15. RS485 for easy and quick data transmission to remote acquisition system. Local RGB LED on board of the VMU units for easy colour code diagnostics. Antitheft control, fuse blow detection, wrong PV panel connection for plant 15 control and maintenance. Protection trip and breaker status detection by means of two digital inputs. Alarm notification and automatic PV panel cleaning by means of two relay outputs. String control for immediate string failure detection and localisation. String for energy production and pay-back efficiency pay control. DC/AC efficiency calculation for inverter working control. Data and event logging for plant control. 6.1.7 Substation Building for housing the electronic (sub-station) The substation building will house all the electronic equipments like MCB (main DC combiner boxes), central inverters, low voltage panels, transformer, high voltage panels, etc. below shown are the few reference snapshots of the same. Description of power evacuation system and interfacing with grid It is important that the power plant is designed to operate satisfactorily in parallel with grid, under the voltage and frequency fluctuation condition, so as to export the maximum possible unit to the grid. It is also extremely important to safeguard the system during major disturbances like tripping, pulling and sudden over loading during the fluctuation of the grid loads on the generating unit in the island mode, under fault/feeder tripping conditions. Grid Synchronization Scheme Utilities/license owns and operates a high voltage transmission and distribution network in the project area. It is envisaged that the solar generation plant will be connected to the high voltage network. It will be necessary to negotiate a network connection and access agreement and undertake further activities, such as: a) System studies. b) Investigation of connection issues including assessment of the need to upgrade or modify equipment due to an increase in fault levels. c) Protection modifications as compatible for system frequency and grid stability.

- 16. 16 Network Connection The solar PV project size is proposed to be 1 MWp. The higher rating is used for grid connection designs. The proposed plant will be connected to the high voltage transmission system through a 0.415/11/33KV substation. This involves an appropriate power transformer, underground cables and overhead lines at appropriate voltage level. The network connection is designed to carry rated power on a 24-hour basis. For connection to the state transmission grid, it is necessary to adhere to grid code. This requires a series of studies and designs, including: Load flow studies. Fault level analysis. Dynamic stability assessment. Connection substation concept design. Protection measures for connection substation and power transmission line. 7 Scope of maintenance contract L’Obel Solar Power System offers an initial 5 year full service maintenance contract which enables the operator to implement a reliable and effective operation making use of the well established L’Obel Solar Power System service competence. The Operations and Maintenance package offered by L’Obel Solar Power System include the following services a) Performance monitoring b) Remote diagnosis and failure response c) Preventive maintenance d) Corrective maintenance (The prices are subjected to escalation starting from two years) Performance monitoring A plant monitoring system is installed which enables permanent system monitoring and performance evaluation. We collect the data on site via our PV monitoring system. This data are available for remote diagnosis and a useful subset of the gathered performance data is made available online to the customer so that he can track and control the system performance himself.

- 17. 17 Remote diagnosis and failure response Automatic alarm functions issue messages in case of unexpected system behavior that will trigger the first level support to log onto the system and investigate and initiate remedial action if required. Second and third level expert support will be involved as required. Field service engineer are dispatched as needed in order to clarify the fault situation. Preventive maintenance Preventive maintenance is carried out by qualified technical personnel on a regular inspection and maintenance cycle basis, typically once or twice per year, depending on local site conditions. The various systems are subjected to visual checks, cleaning, measurement and replacement as the case may be the findings and the overall state of the plant is documented. Corrective maintenance Corrective maintenance is performed in order to restore the desired state of repair. To keep the restore time as short as possible spare part availability is a crucial element. L’Obel Solar Power System always aims to increase the plant performance in order to achieve the contractually agreed performance ratio. Analysis and failure repair will be realized on various levels. Data input from the electronic operation log in combination with the local inspection and measurements are used to drive the effective measures. Failure repair due to system failures will be under the service contract and no further cost for the service and the spare part will be charged to the customer. Facility management (by Customer) This service compromises the care taking of the facility. Like visual inspection of all outdoor plant installations from inside the plant fences as well as cleaning and minor maintenance of building and fixed installations, e.g. maintenance of signage, oiling of locks, exchange of light bulbs. As well the green management is contained like grass and plant cutting to minimize shadows. Module cleaning (by Customer) Modules are exposed to the environment and depending on the local conditions a dirt layer settles on the modules, which reduces the plant yield. Cleaning is executed by a qualified service provider with a suitable cleaning method including man hours, material and cleaning tools.

- 18. 18 Security management (by Customer) The substantial investment shall be safeguarded by e.g. 24/7 hrs monitoring of motion – activated CCTV cameras and / of daily patrols as well as security field forces in case of theft alarms or suspicious observations via CCTV. Based on the information available to L’Obel Solar Power System and what we understood from our conversation and analyses, we offer only those services and supplies that match all your needs and still maintain a low investment. Should you be interested in additional service and supplies, please approach us and we will be happy to present you an updated proposal. 8 Project Implementation and Schedule For a 1 MWp power plant, approximately 5 acres of area is required. This will include installation of all the panels, equipment, and construction of supporting and auxiliary buildings, access network. Various activities under the project development and implementation are listed below (in no particular order): Site survey Detailed engineering design Civil works and preliminary engineering construction (clearing, fencing, soil exploration, ground improvement, foundations, surfacing, grading, etc.) Ground-mounted PV support structure design, drawings, documentation Safety signage Installation, interconnection and commissioning of solar photovoltaic panels Connection of PV array junction (combiner) box & main junction boxes Installation and commissioning of grid-connected inverter All DC cabling (conduits, fasteners etc.) up to inverters AC cabling, switchgear, fuse boxes etc from inverters to local PCC Installation and commissioning of power evacuation system including transmission of power from generation side to the point of connection Installation of proper metering equipment in conformance with local electricity codes Remote Monitoring (installation of modem, PC and data cable for real-time monitoring)

- 19. Installation of data display system (kWh, CO2 cumulative and kW 19 instantaneous) AC switchboard/interface and protection All regulatory approvals for project and to connect to AC mains grid Staff and client training Operational & maintenance services 8.1 Project Implementation Strategy Overall project implementation will have the following stages of activities. These stages are not mutually exclusive; to implement the project on fast track basis, some degree of overlapping is anticipated. Stage I - Project Development Stage II - Finalization of the Equipment and Contracts Stage III - Procurement and Construction (phased approach) Stage IV - Plant Commission (phased approach) Stage 1 – Project Development Project development will begin with one or more visits to the region with the objective of understanding regional ground conditions including socio-economic conditions, transportation and infrastructure facilities available in the region. The key step in this stage will be the negotiation and establishment of a power purchase agreement (PPA) with the utility company. Following specific activities/tasks will be completed during this stage: Land acquisition Preparation and submission of Detailed Project Report (DPR) Power purchase agreement (PPA) Expedite Central Regulatory Authority clearance During this phase, a project team consisting of engineers, logistics experts and project managers will be formed for the execution of the project. This project team will work together from the earliest stages of the project, according to member’s specific expertise, and will be responsible for: Planning project execution including development of GANTT charts Inspection of fabrication items and other equipment Supervise construction and commissioning of the plant

- 20. Controlling and managing contractor payments Monitoring and managing project progress Maintaining project budget and schedule Stage II – Finalization of Equipment and Contracts In this stage, procurement packages are developed to send to suppliers for detailed and final costs for all services and products. It is expected that detailed engineering design will overlap with this stage and specifications for major equipment will be developed in parallel with information from vendor catalogs and specification sheets. For a solar installation, typically, solar panels and combiner boxes are the longest lead items and project planning must provide adequate time period for the acquisition and installation of these equipment. This stage calls for close and constant communication between the project engineers, equipment suppliers and vendors, and procurement specialists to ensure that all documentation is made in strict accordance with project specifications and schedule. Stage III – Procurement and Construction Following contract award and issuance of purchase order, the project team will follow up regularly to ensure smooth and timely execution of the contract. The procurement activity includes review of drawings, stage and final pre delivery inspection, and supervision of installation and construction. During construction, the erection and commissioning phase of multiple contracts will proceed simultaneously. Stage IV – Erection and Commissioning Phase It is the commissioning phase where design, manufacturing, erection and quality assurance expertise are put to test. The commissioning team will consist of key equipment manufacturers of the equipment, L’Obel Solar Power System engineers, and other specialized experts, where necessary. First step during commissioning is to use a designed check list to ensure that the plant has been properly installed with appropriate safety measures. The commissioning team will follow the internal operating instructions. The plant shall be subjected to a performance test before synchronizations. The plant shall be subjected to a performance test before synchronization under the supervision of professional engineers/consultants. 20

- 21. The design of the centralised configuration will start with the DC side of the power plant and then based on the DC section the AC section of the power plant is designed. 9 Project Management and Engineering The project is being planned, implemented, monitored and controlled through the L’Obel Solar Power System. Project planning and monitoring is done on the following activities of engineering, contracts, manufacturing, erection and commissioning. Engineering and Design Contract and Procurement of Project Components Erection and Commissioning Operation and Maintenance of the project L’Obel Solar Power System will provide a global expertise in designing, setting up and maintaining large scale grid connected solar farms. L’Obel Solar Power System shall provide the Engineering service including undertaking a engineering study to review the basic design and where possible to suggest optimized design solutions, detailed designs, preparation of tender documents and detailed specifications of the components and preparation of documentations in this regard. L’Obel Solar Power System will also look after civil & mechanical works, equipment supply and other contracts. Construction design and construction supervision will be done by L’Obel Solar Power System during the execution of the project including supervising the construction, equipment installation and commissioning, undertaking quality assurance at site and oversee the contractors` quality systems. 21

- 22. There are two types of power generation schemes. The project engineering changes according to this generation scheme. A brief introduction on the different power generation scheme is given below. 9.1 Procurement of the System Being a well recognized player in the international market, L’Obel Solar Power System enjoys well proven relations with its suppliers. Our partners and suppliers have been assessed not only for fulfilling the L’Obel Solar Power System quality standards but also for their capability to professionally realize large – scale projects on time. Hence L’Obel Solar Power System will procure project components directly from its vendors. Procurement process includes the following broad activities: Procurement of modules Procurement of balance of system (BOS) Procurement of transmission system accessories and Procurement of other project components L’Obel Solar Power System will procure the project components from various sources under the onshore contracts and offshore contracts. This will be done with the suitable entities at the time of procurement of the project components. Some of the general information about the equipments that will be utilized in the power plant is given below for the reference of the customer. 9.2 Typical System Integration The panels will be ground mounted. The ground mounting will require a flat level surface and will be set into concrete. The panels will require an area which is not shaded. Any vegetation underneath the panels will need to be kept to a level below that of the panels in order to avoid shading. All the panels will be at least 0.8 m from the ground. It is assumed that this is adequate to keep the panels above the flood height of the site. The panels will be mounted in rows and electrically connected with cables. The cable will need to be made safe and tamper proof. The electrical output from the PV panels will be fed via cables to a bank of inverters. The inverters will be housed in a structure to protect them from the weather and from tampering. A design decision based on cost will need to be made whether the inverters are all located in one area or are interspersed around the site. 22

- 23. The power plant will have a SCADA system to monitor the output of the rows of panels. In this way, any system faults can be detected to a particular array and rectified. Electrical protection equipment with be required, to be specified in conjunction with PEA, for the connection of the PV plant to the electrical network. 10 Bill of Material Sr. No Items Scope of Work 1 Solar Panel Supply, Transportation, Insurance and 23 Installation 2 Solar Mounting Structure Design, Supply, Transportation, Panel Mounting. 3 Power Conditioning Unit Supply, Transportation, Insurance, Testing, Installation Weather station. 4 Wire & Cable Design, Supply, Transportation, Cable tray, Cable tie, Conduit, Ferrules, Electrical Lugs, Communication Cable and HT cable 5 Junction Box with Monitoring system &Central Scada System Supply, Transportation, Insurance, Monitoring system, Central Scada System, Auxiliary Supply for communication port. 6 Civil Work Control Room, Metering room, Land levelling, Land clearing, Pathways, Drainage, Water system for module cleaning. 7 Lights, Lightning Arrester and Earthing Street Lights, Lightning Arrester, Earthing pits, Transformer soak pit, Earthing for DC side and AC side. 8 Power Evacuation Isolation T/F, LT panel, Step up transformer with OLTC, HT panel, Metering cubical 9 Project Management Design & Engineering, Project monitoring, Time management, Site Survey, Construction Management.

- 24. 11 Typical Execution of installation under accomplishment of all 24 national regulation & norms: POSITION DESCRIPTION 1 Construction Management 1.1 Construction management and planning for all materials and works delivered or executed by Subcontractor 1.2 Provide project management and supervision. 2 Modules 2.1 Receiving and unloading of Modules (delivered by customer) with appropriate vehicle (e.g. forklift truck, 4x4 forklift, etc.) 2.2 Check and comparison of modules delivered with delivery note and visual inspection of delivered modules 2.3 Storage of modules (temporary) with appropriate protection against weather impacts, damage and theft (e.g. lockable containers or lockable tents). In customer’s scope; not in GB scope. 2.4 Transport from (temporary) storage to site/point of installation with appropriate vehicles (e.g. fork lift truck) 2.5 Passing of risk (from Customer to GB) starts with delivery of modules to site/temporary storage and from the time the modules are taken by GB from the storage till the point they are installed and commissioned. However, after the commissioning, the risk of the performance of the modules will be entirely and severally of the customer. 3 Structures for modules with the general conditions: 3.1 Evaluation of soil/ground: The ground/soil must be prepared to endure transport of all components (modules, structure, connection boxes, etc.) to the installation point on site. The ground/soil must withstand the loads of wind and the weight of structures (incl. modules and other components). 3.2 Preparation of the soil/ground on site with all necessary works like earthmoving, digging holes for the foundations/pilings and levelling. 3.3 Surveying of structures for the modules and calibration and pitching for the foundations/pilings of the structures. 3.4 Delivery and/or manufacturing of foundations/pilings for the structures on site including all necessary material and works. The foundations/pilings must full fill all necessary regulations and norms and be according to calculations by static expert.

- 25. 25 3.5 Manufacturing, delivery, installation and calibration of structures including all necessary material and works. The structures must full fill all necessary regulations and norms and calculations of static expert as well as requirements of manufacturer. Installation on prepared foundations/pilings . Minimum quality of structure: hot galvanized steel 3.6 Installation of modules on prepared structures including all necessary material and works especially the system for clamping/fixing the modules on the structures. In case the materials of module frames and structures are different (e.g. aluminium and galvanized steel) there must be installed an intermediate layer (e.g. EPDM-rubber) which will come at extra cost. 3.7 Reconstruction/Regeneration of site. Dispose or recycle surplus soil material and dispose waste material including all necessary material and works. 3.8 Provide and deliver a certified/approved statistics for the structure including all fixings and fundaments according regulations and norms of the Country. 4 Service Station for inverters, transformers and metering/safety system 4.1 Planning, delivery and installation of the service stations for inverters, transformers and switchboards including all installation for appropriate ventilation and electrification with lights, plugs, auxiliary supply, etc. of the stations. Including all necessary material and works. The station will full fill all necessary regulations, norms and special specifications of the utility company. (The Details have to be defined by the Customer and the utility company). 5 Security and protection system 5.1 Delivery and installation of a fence around the site of the power plant including all necessary material and works. The fence will be as per the customer’s specifications. 5.2 Delivery and installation of security system for the power plant including all necessary material and works. The security system must full fill all necessary regulations, norms and as well specifications due to insurance necessities. 6 Earth moving works 6.1a Installation and laying of DC-Main-Cables from connection boxes to main junction boxes and to inverters, including earth moving work due to national regulations and norms. Including all necessary material and works. 6.1b (alternatively to 6.1a) Installation and laying of DC-Main-Cables in cable channels from connection boxes to main junction boxes and to inverters, due to national regulations and norms. Including all necessary material and works. 7 Electrical Installation of solar generator 7.1 Connection of modules to strings. Including all necessary material and works. 7.2 Installation of connection boxes at the metal structure including all necessary material of works.

- 26. 7.3 Installation of main junction boxes in the service station including all necessary material 26 and works. 7.4 Delivery, installation and connection in the connection boxes of Cables (or similar) for the module strings. Including all necessary material and works. 7.5 Delivery, installation and connection in between the connection boxes with Cables NYY (or similar) including all necessary material and works. (The specification of the cables will be defined Green Brilliance Energy Pvt Ltd) 7.6 Delivery, installation and connection between the connection boxes and main junction boxes and the inverters of Cables NYY (or similar) including all necessary material and works. (The specification of the cables have to be defined by Subcontractor and Green Brilliance Energy Pvt Ltd) 7.7 Delivery and installation of Cable Conduits/Cable Channel with cover at metal structure including all necessary material and works. 8 Earthing/Grounding of solar generator 8.1 Delivery, installation and connection for the earthing/grounding of solar inverter (modules, structures, cable channels and connection boxes) including all necessary material and works. 9 Installation of inverters and AC-cables from inverters to transformer 9.1 Receiving and unloading of inverters (delivered by GB) with appropriate vehicle (e.g. fork lift truck) 9.2 Check of inverters delivered with delivery note and visual inspection of delivered inverters 9.3 Transport to service station with appropriate vehicles (e.g. fork lift truck) and installation in service station. 9.4 Delivery, installation and connection between the inverters and transformers of Cables NYY (or similar) including all necessary material and works. 9.5 Delivery, installation and connection of remote monitoring system including all necessary material and works. 10 Transformers, metering and safety system and switch board medium Voltage 10.1 Delivery, installation and connection of transformers for medium voltage, metering and safety system as well as switch board for medium voltage level including all necessary material and works. The components have to accomplish all national regulations and norms.

- 27. 27 10.2 Delivery, installation and connection of a low voltage connection point, metering and safety system for auxiliary power (e.g. for the inverters, lights, sockets, etc.) including all necessary material and works. The components have to accomplish all national regulations and norms. 11 Lightning protection for service station 11.1 Delivery, installation and connection of lightning arresters for the service stations. 12 Site facilities 12.1 Delivery, installation and operation of office for project management/site management with all installation like electricity, light, telephone/fax, etc. including all necessary material and works 12.2 Delivery, installation and operation of containers for the construction team including all necessary material and works 12.3 Delivery, installation and operation of storage facilities for all components, material and tools, etc. including all necessary material and works 12.4 Delivery, installation and operation of containers with bathroom/lavatory facilities including all necessary material and works 12.5 Delivery, installation and operation of temporary power generator for electricity on site. including all necessary material and works 12.6 Delivery, installation and operation of containers for the collection of waste. including all necessary material and works 13 Documentation 13.1 Provide and deliver a complete documentation with all drawings ,plans, datasheets, statics, calculations, measurements etc.

- 28. 12 Budgetary cost for 1 MWp power plant Turnkey Supply of PV plant including Modules (Full EPC) Price for1MWp INR 7.5 Cr (Approx) Price in words Rs Seven Cr & fifty lac 28 13 Retention clause L’Obel Solar Power System obligation to fulfill this agreement is subject to the provision that the fulfillment is not prevented by any impediments arising out of national and international foreign trade and customs requirements or any embargos or other sanctions. 14 Transportation We have included estimation of transportation prices for all components. Our prices include delivery to suitable nearby port and consecutive trucking to the site, assuming that the roads allow for unhindered traffic of heavy loaded vehicles. 15 Insurance Following insurances are included in our scope of supplies Transportation insurance Construction all risk insurance 16 Currency and taxes The prices are stated in rupees. Tolerance accepted will be ± 2% of the Exchange rate taken into consideration. The price is exclusive of all applicable taxes and duties. 17 Contractual conditions The budgetary offer is based on: The terms and conditions as stated in this budgetary offer L’Obel Solar Power System EPC contract for 1 MWp Photovoltaic (PV) power plant

- 29. 29 18 Transparency and compliance L’Obel Solar Power System has set itself the target of being one of the world’s best companies in terms of transparency and compliance. By strengthening our compliance program and internal controls we have taken an important step towards this target. However, we also need your assistance. We have a zero tolerance policy for any illegal or unethical behavior and our appeal to you is: should you detect any misconduct on the part of our employees, please inform us to this effect immediately. 19 Bid validity This offer is valid until 10.6.2012. 21. Warranties and Securities Our PV power plant with central inverter systems are designed for a technical life of more than 25 years with highest efficiency and availability. The parts of the offered plant and the used materials for installations are selected for their durability: Support structures from durable aluminum and galvanized steel with stainless steel fixing materials, with special attention to the design process for the fixing method of the modules. Engineering and installation of cabling, connections and coupling cabinets suitable for long life operation by applying amongst other things; multi-contact connectors, special cables, etc. All warranties have to reflect site and project specific terms and conditions The warranty period will be 5 years. The warranties are conditioned by L’Obel Solar Power System carrying out service and maintenance under a service and maintenance contract for the duration of warranty period. 22. Project Plan / Time of Erection The delivery time of the plant is dependent on several factors still to be clarified Grid access to the public high voltage net Presentation of all approvals (e.g. operation and net connecting approvals) Delivery times of the components Exact topographical details on the finalization of the PV field layouts

- 30. Condition of thee ground: effort for possible excavation/screwing foundation Utility demands and grid access conditions Module availability 30 23. General Reservation L’Obel Solar Power System the right to modify, at any time and at our discretion, technical terms and conditions stated in the offer. We hope our offer has sparked your interest, and look forward to hearing from you at your earliest convenience. Note: The above pricing is based on standard ideal site condition. Any further need at site or any change order will be changed extra. For Lobel Solar Power System Er. Chintan Gandhi 093-270-07854 Gujarat, India-09327007852 ISO 9001:2008 Certified Company Promise for continuous power URL: www.lobelpower.com | www.lobelpower.in M ID: lobelpower@gmail.com | info@lobelpower.com Contact me: lobelpower lobel.solar