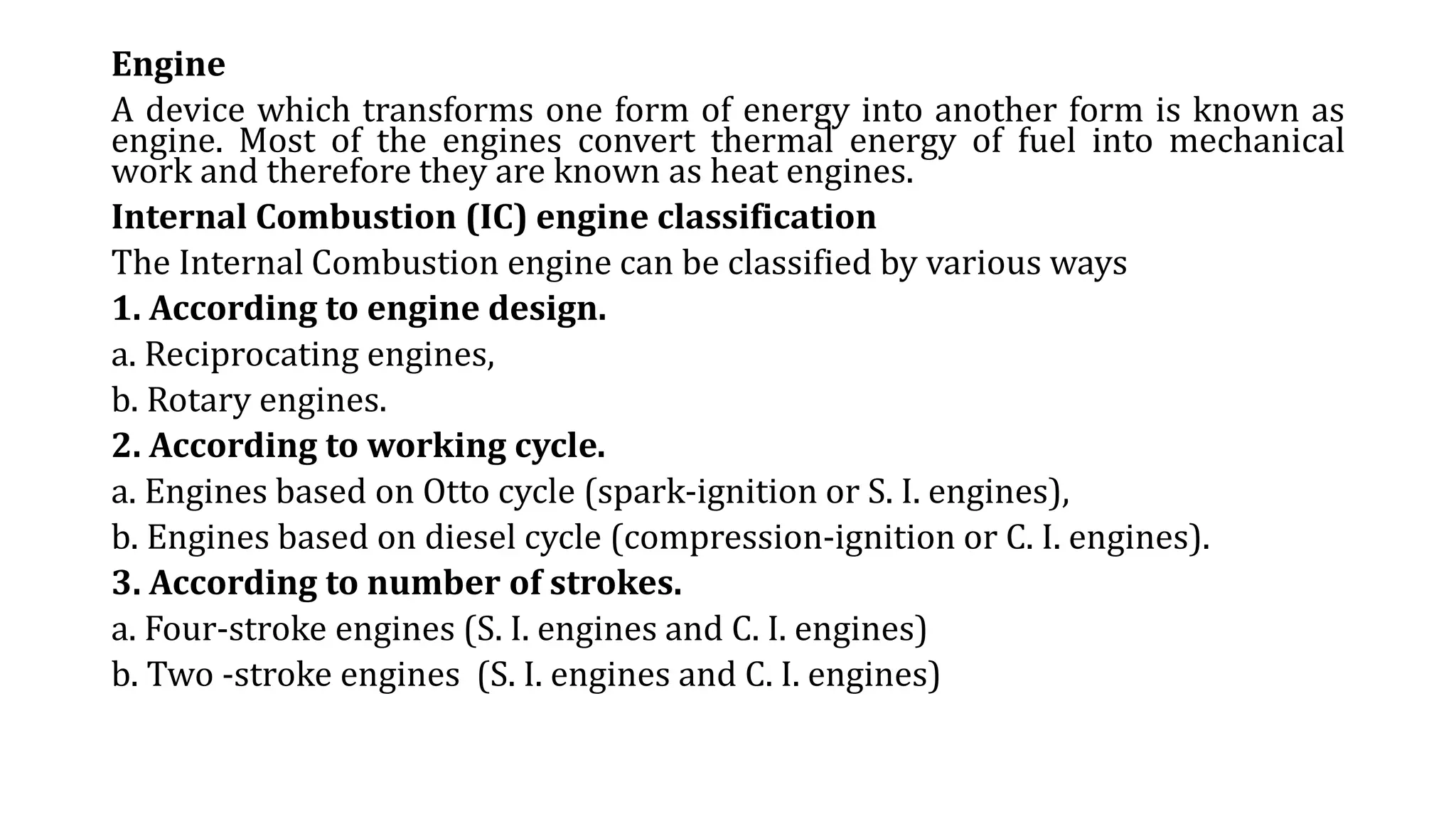

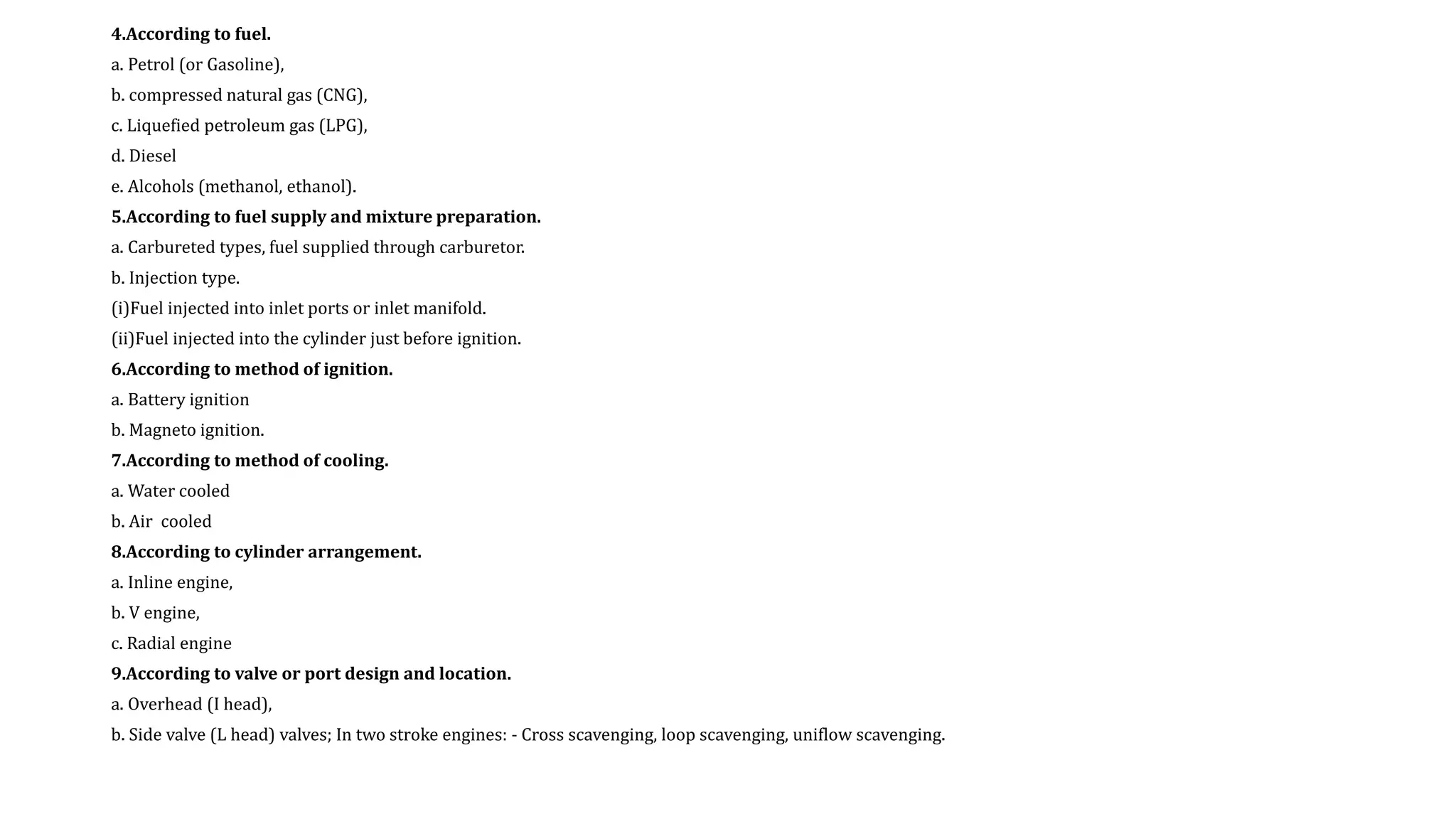

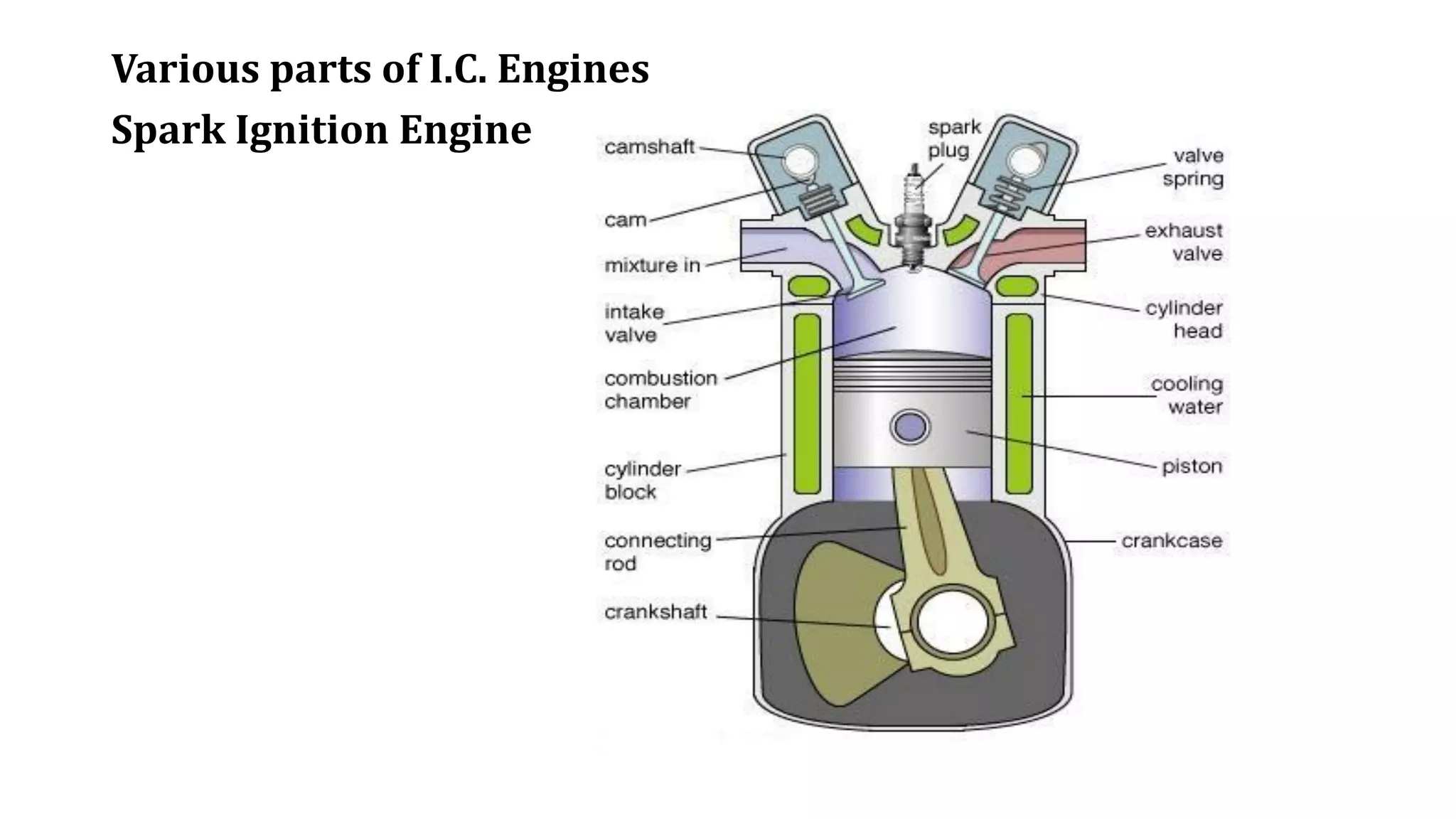

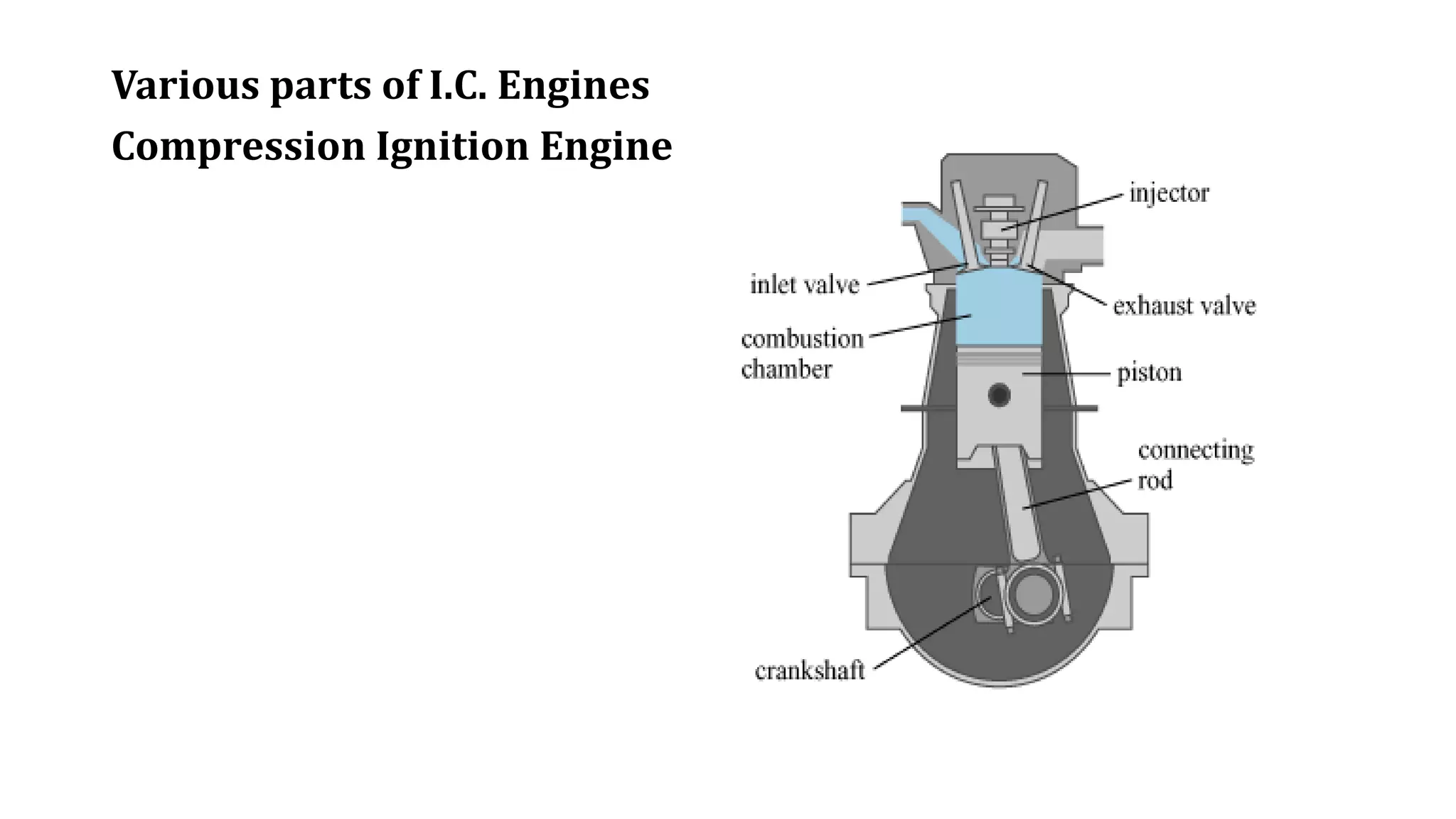

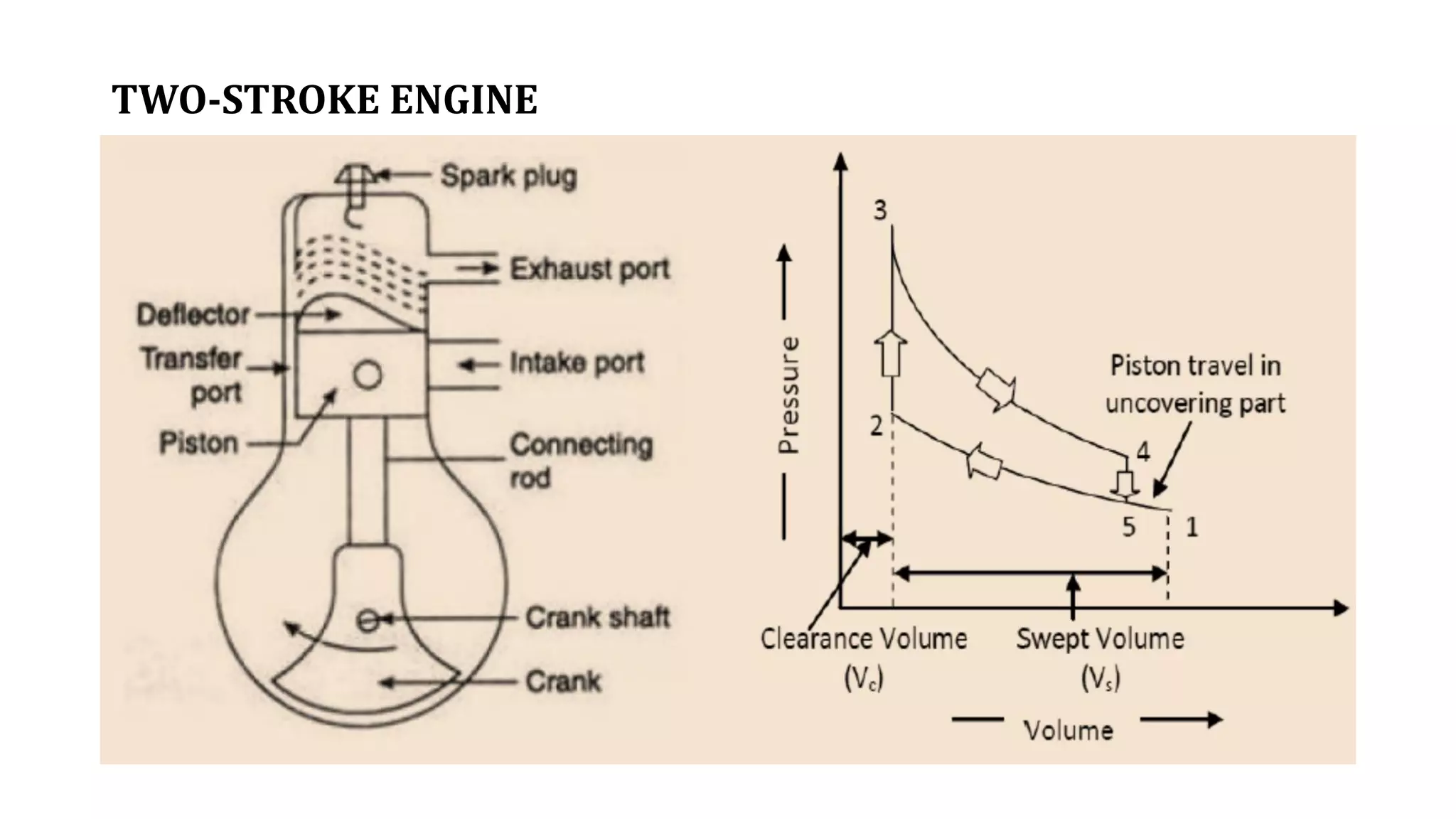

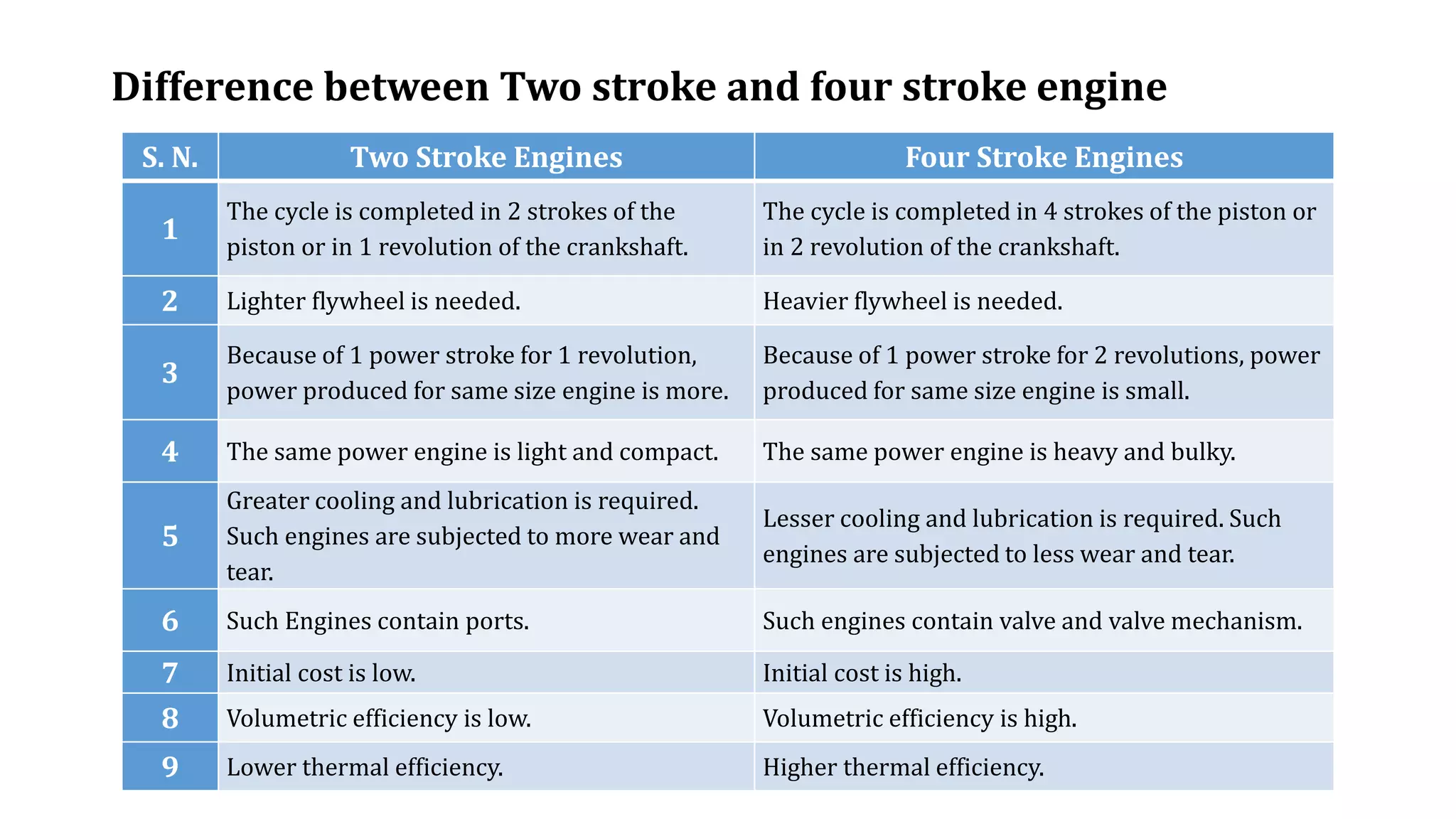

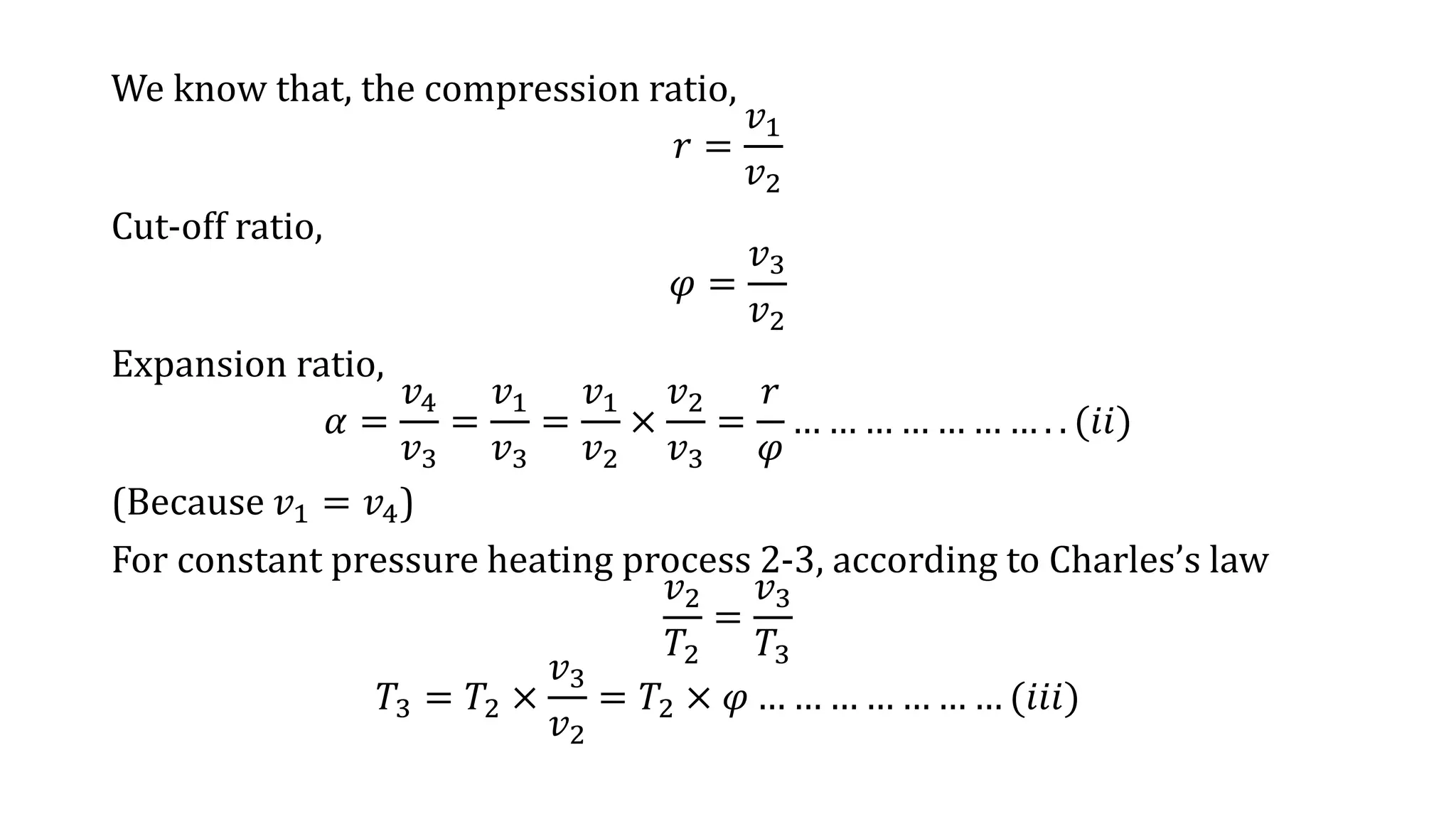

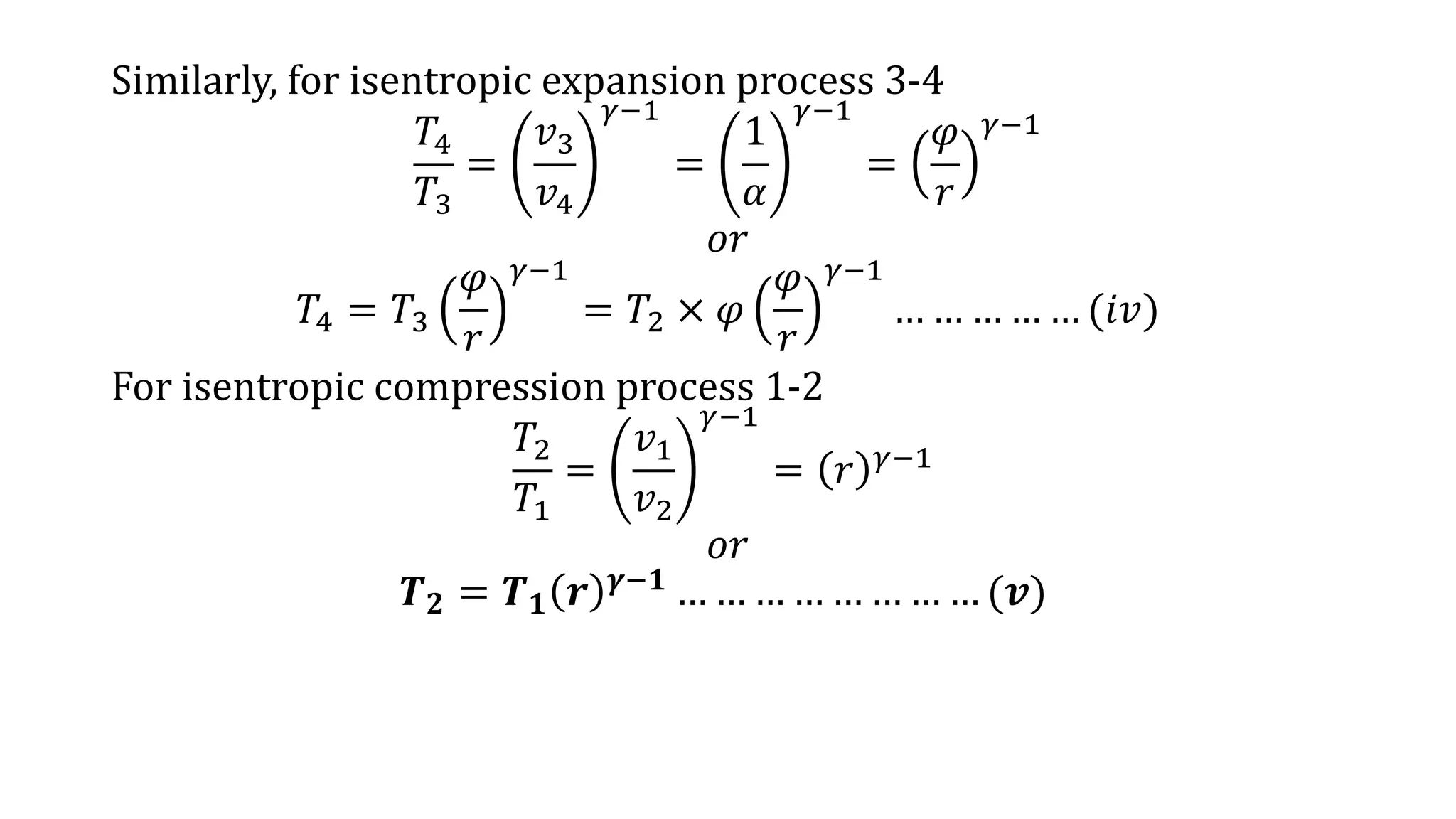

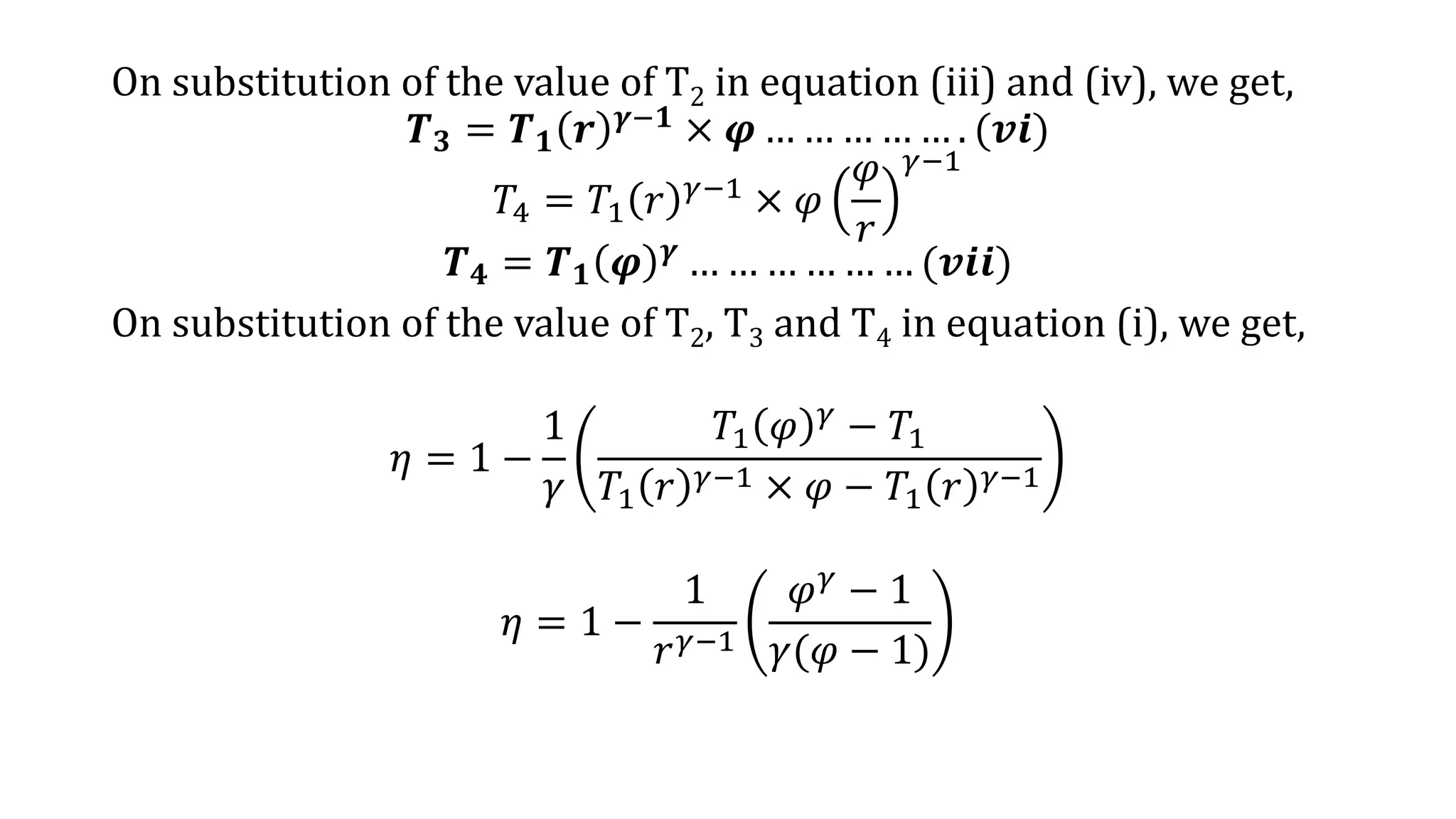

The document discusses internal combustion engines. It defines an internal combustion engine as a heat engine that converts thermal energy from fuel into mechanical work. It then classifies internal combustion engines in several ways such as by design, working cycle, number of strokes, fuel used, and other factors. The key parts of internal combustion engines like the cylinder, piston, valves are also defined. Important terminology used in internal combustion engines such as cylinder bore, stroke, swept volume, compression ratio are explained. The workings of different types of internal combustion engines such as spark ignition engines, compression ignition engines, and 2-stroke engines are outlined. Their differences and various engine efficiencies are also compared.