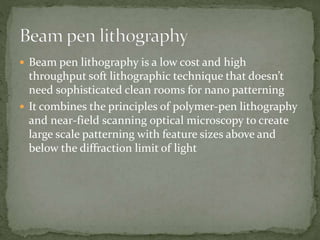

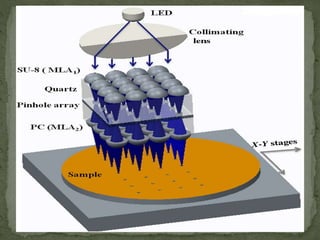

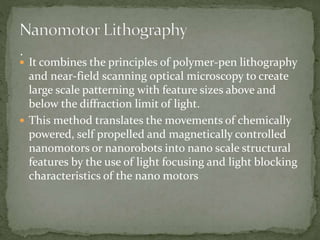

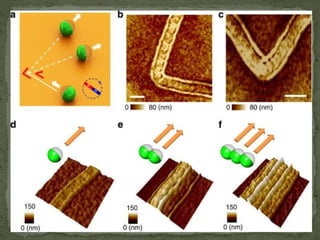

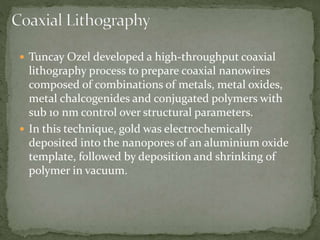

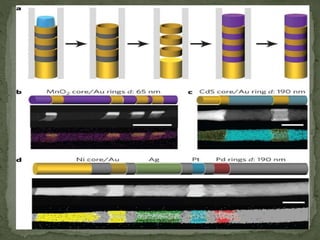

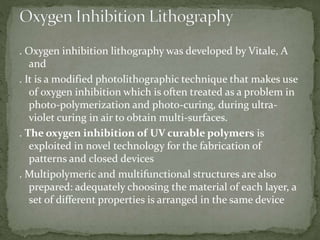

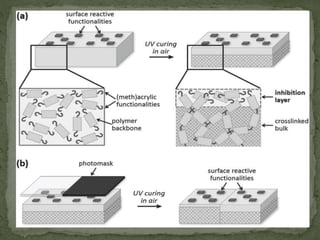

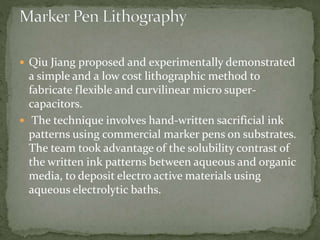

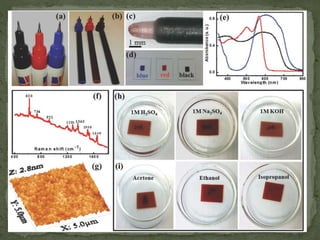

The document discusses various lithography techniques. It begins with an introduction and overview of lithography and its history. It then describes several types of lithography techniques such as electron beam lithography, ion beam lithography, x-ray lithography, and nanoimprint lithography. The document also outlines the typical steps used in lithography processes. Finally, it provides more details on several emerging lithography techniques such as beam pen lithography, nanomotor lithography, coaxial lithography, and oxygen inhibition lithography.