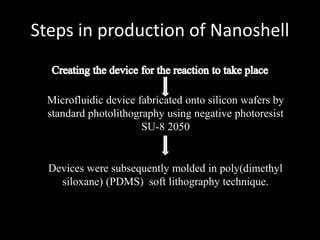

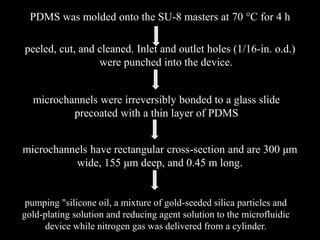

A nanoshell is a spherical nanoparticle with a dielectric core covered by a thin metallic shell, usually gold. It was discovered in 2003 by Professor Naomi Halas at Rice University. The nanoshell involves plasmons, which are collective electron oscillations that can be used for cancer therapy applications. Nanoshells are now produced using a microfluidic method involving pumping solutions through microchannels to plate gold onto gold-seeded silica particles, aging the solution, and centrifuging to separate the nanoshells.