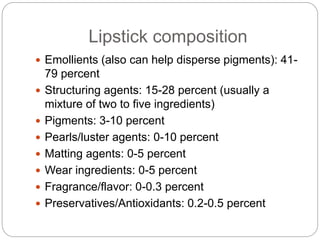

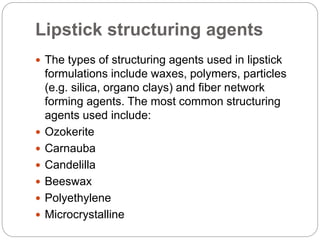

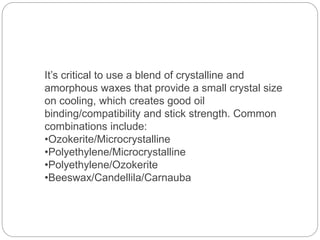

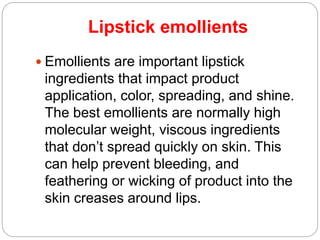

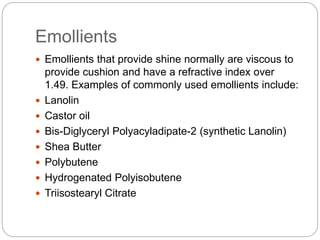

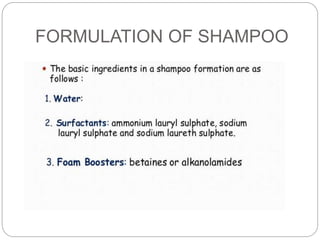

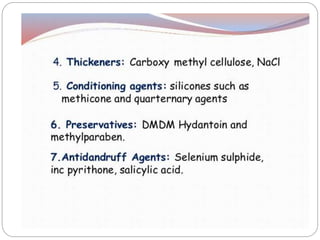

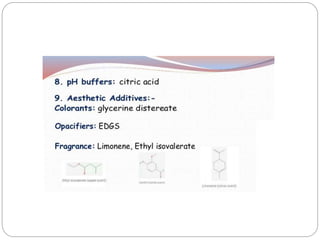

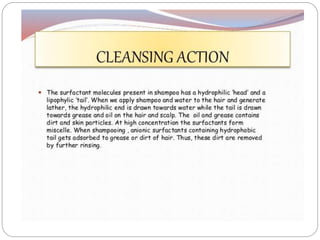

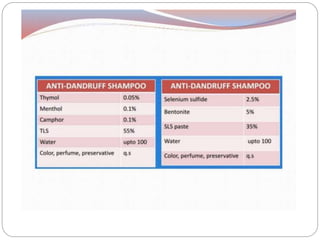

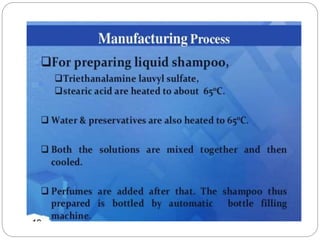

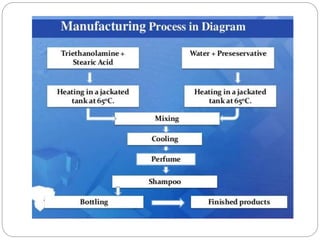

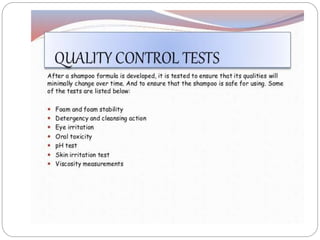

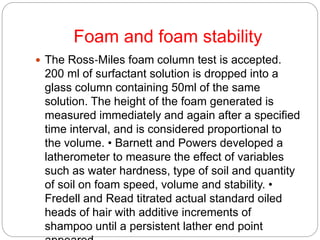

This document discusses the composition and formulation of lipsticks and shampoos. It provides details on the typical ingredients in lipsticks, which include emollients, structuring agents, pigments, and other components. It also discusses considerations for formulating lipsticks such as using a pigment grind, wax base, and dilution oil blend. For shampoos, it outlines common formulation tests including those measuring foam, detergency, wetting action, and conditioning action. It also describes methods for evaluating a shampoo's microbiological properties, eye irritancy, and viscosity.