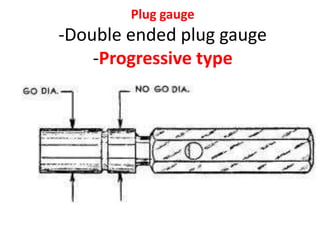

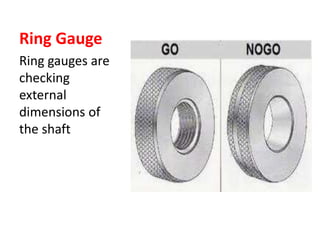

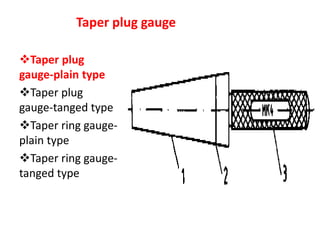

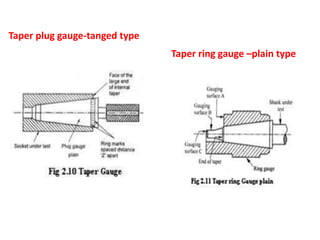

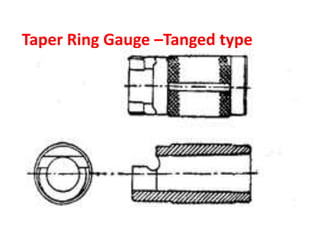

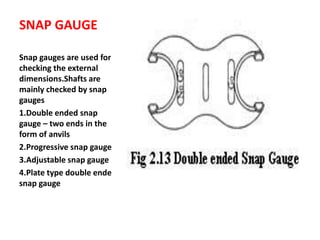

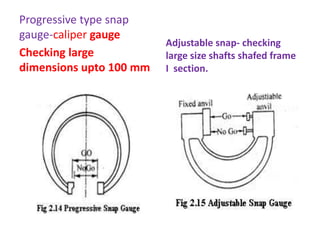

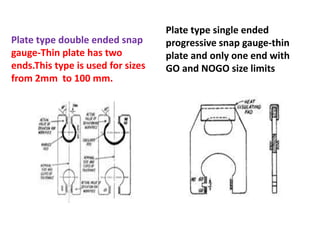

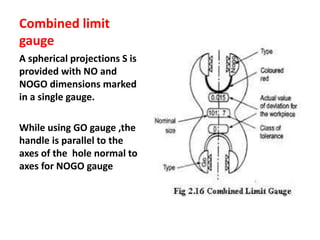

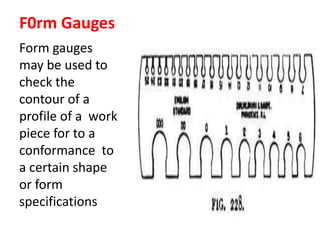

Limit gauges are inspection gauges used to check if a component's dimensions fall within specified upper and lower tolerance limits. They include NO-GO and GO gauges. Common types are plug, ring, snap, taper, thread, and form gauges. Plug gauges come in double-ended or progressive styles. Ring gauges check shaft diameters. Snap gauges check external dimensions and come in double-ended, progressive, or adjustable styles. Taper gauges check tapers in plain or tanged styles. Thread gauges check pitch diameters. Form gauges check profile contours. Limit gauges help speed up inspection processes and ensure component quality.