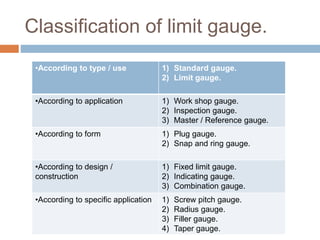

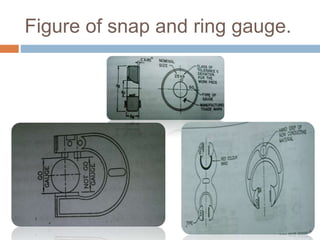

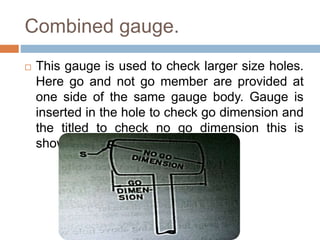

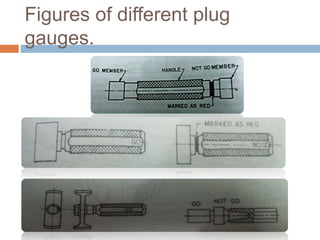

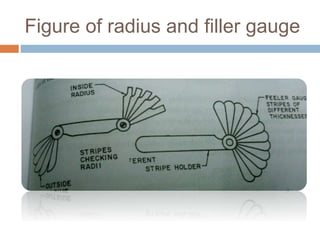

Gauge is an inspection tool used to check product dimensions against maximum and minimum acceptable limits without knowing the exact value. There are different types of gauges classified by type, application, form, design, and specific application. Gauges provide advantages like faster checking, less operator dependence, and checking multiple dimensions simultaneously. However, gauges cannot provide exact values and lose accuracy over time. Common gauges include snap and ring, plug, radius, filler, and taper gauges. Snap and ring gauges check diameters while plug gauges check holes. Radius and filler gauges measure radii and gaps.